ASTM G137-97

(Test Method)Standard Test Method for Ranking Resistance of Plastic Materials to Sliding Wear Using a Block-On-Ring Configuration

Standard Test Method for Ranking Resistance of Plastic Materials to Sliding Wear Using a Block-On-Ring Configuration

SCOPE

1.1 This test method covers a laboratory procedure to measure the resistance of plastic materials under dry sliding conditions. The test utilizes a block-on-ring geometry to rank materials according to their sliding wear characteristics under various conditions.

1.2 The test specimens are small so that they can be molded or cut from fabricated plastic parts. The test may be run at the load, velocity, and temperature which simulate the service condition.

1.3 Wear test results are reported as specific wear rates calculated from volume loss, sliding distance, and load. Materials with superior wear resistance have lower specific wear rates.

1.4 This test method allows the use of both single- and multi-station apparatus to determine the specific wear rates.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: G 137 – 97

Standard Test Method for

Ranking Resistance of Plastic Materials to Sliding Wear

Using a Block-On-Ring Configuration

This standard is issued under the fixed designation G 137; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope G 77 Test Method for Ranking Resistance of Materials to

Sliding Wear Using Block-on-Ring Wear Test

1.1 This test method covers a laboratory procedure to

G 117 Guide for Calculating and Reporting Measures of

measure the resistance of plastic materials under dry sliding

Precision Using Data from Interlaboratory Wear or Ero-

conditions. The test utilizes a block-on-ring geometry to rank

sion Tests

materials according to their sliding wear characteristics under

various conditions.

3. Terminology

1.2 The test specimens are small so that they can be molded

3.1 Definitions:

or cut from fabricated plastic parts. The test may be run at the

3.1.1 wear—damage to a solid surface, generally involving

load, velocity, and temperature which simulate the service

progressive loss of material, due to relative motion between

condition.

that surface and a contacting substance or substances.

1.3 Wear test results are reported as specific wear rates

3.1.2 Additional definitions relating to wear are found in

calculated from volume loss, sliding distance, and load. Mate-

Terminology G 40.

rials with superior wear resistance have lower specific wear

3.2 Definitions of Terms Specific to This Standard:

rates.

3.2.1 specific wear rate—the volume loss per unit sliding

1.4 This test method allows the use of both single- and

distance, divided by the load. It can be calculated as the volume

multi-station apparatus to determine the specific wear rates.

loss per unit time, divided by the load and the sliding velocity.

1.5 This standard does not purport to address all of the

3.2.2 steady state specific wear rate—the specific wear rate

safety concerns, if any, associated with its use. It is the

that is established during that part of the test when the specific

responsibility of the user of this standard to establish appro-

wear rate remains substantially constant (the specific wear rate

priate safety and health practices and determine the applica-

versus sliding distance curve flattens out considerably with less

bility of regulatory limitations prior to use.

than 30 % difference between the specific wear rates) during a

2. Referenced Documents minimum of three time intervals spanning a total time duration

of at least 18 h, with ideally no single interval exceeding 8 h.

2.1 ASTM Standards:

However, one time interval during the steady state can be as

D 618 Practice for Conditioning Plastics for Testing

long as 16 h.

D 3702 Test Method for Wear Rate of Materials in Self-

Lubricated Rubbing Contact Using a Thrust Washer Test-

4. Summary of Test Method

ing Machine

4.1 A plastic block of known dimensions is brought into

E 122 Practice for Choice of Sample Size to Estimate a

4 contact with a counterface ring (usually metal) under con-

Measure of Quality for a Lot or Process

trolled conditions of contact pressure and relative velocity. This

E 177 Practice for Use of the Terms Precision and Bias in

4 is achieved using a block-on-ring configuration as illustrated in

ASTM Test Methods

5 Fig. 1. Periodic weighing of the polymer block results in a

G 40 Terminology Relating to Wear and Erosion

number of mass-time data points where the time relates to the

time of sliding. The test is continued until the steady state wear

This test method is under the jurisdiction of ASTM Committee G-2 on Wear rate is established. Mass loss measurements made after the

and Erosion and is the direct responsibility of Subcommittee G02.40 on Non-

steady state is established are used to determine the steady state

Abrasive Wear.

specific wear rate, which is the volume loss per unit sliding

Current edition approved Apr. 10, 1997. Published November 1997. Originally

distance per unit load. The frictional torque may also be

published as G 137 – 95. Last previous edition G 137 – 95.

Annual Book of ASTM Standards, Vol 08.01.

measured during the steady state using a load cell. These data

Annual Book of ASTM Standards, Vol 05.02.

can be used to evaluate the coefficiency of friction for the test

Annual Book of ASTM Standards, Vol 14.02.

5 combination.

Annual Book of ASTM Standards, Vol 03.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

G137–97

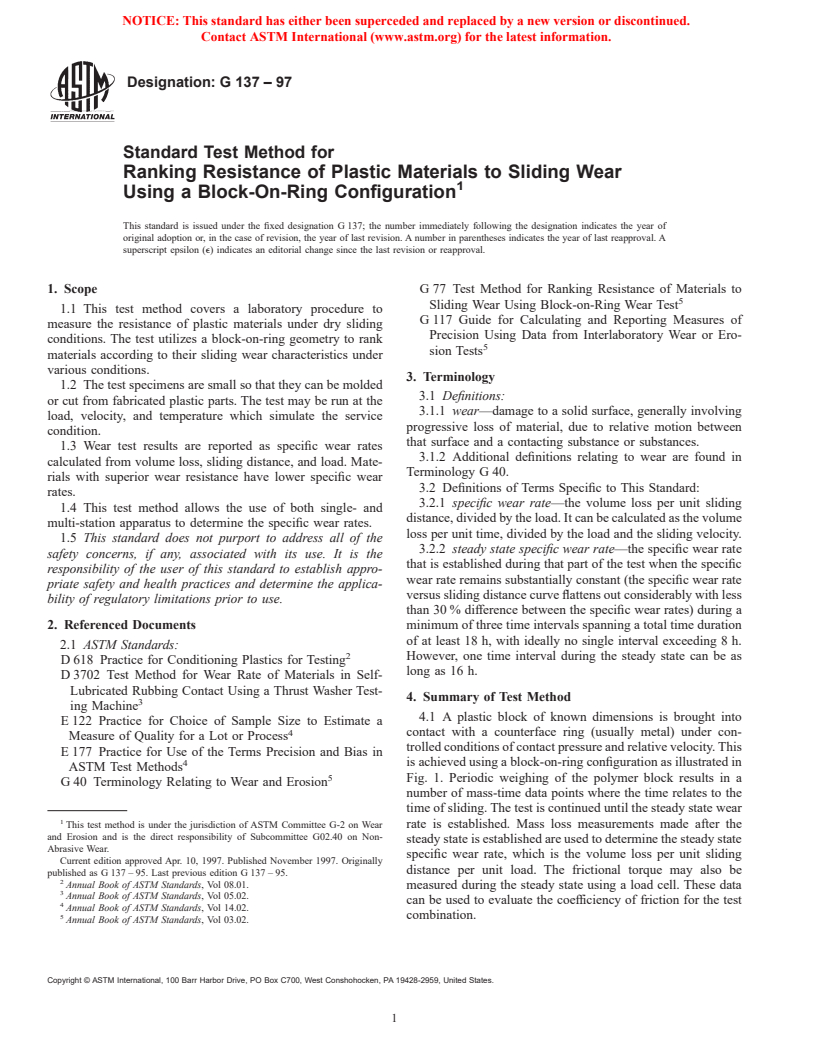

FIG. 1 Single Station Block-on-Ring Arrangement

NOTE 1—Another test method that utilizes a block-on-ring test configu-

reposition the specimen after weighing as before, and a

ration for the evaluation of plastics is Test Method G 77.

counterface ring with acceptable eccentricity. All other design

elements can be varied according to the user preference.

5. Significance and Use

6.1.1 Bearings recommended for counterface drive shafts

5.1 The specific wear rates determined by this test method

are industrial-grade tapered roller bearings.

can be used as a guide in ranking the wear resistance of plastic

6.1.2 Required centerline alignment limits of the counter-

materials. The specific wear rate is not a material property and

face drive shafts are 60.41 mm (60.016 in.) from the center of

will therefore differ with test conditions and test geometries.

a counterface ring. Allowable eccentricity of the counterface

The significance of this test will depend on the relative

ring is no greater than 60.06 mm (60.002 in.).

similarity to the actual service conditions.

6.1.3 Bearings recommended for the linear ball grooved

5.2 This test method seeks only to describe the general test

bushing bearing are industrial-grade linear bearings.

procedure and the procedure for calculating and reporting data.

6.2 Counterface Ring—The recommended dimensions for

NOTE 2—This test configuration allows steady state specific wear rates the counterface ring are 100 + 0.05, − 0.00-mm diameter and

to be achieved very quickly through the use of high loads and speeds. The

15.88 + 0.30, − 0.13-mm width. Often a hardened tool steel

thrust washer configuration described in Test Method D 3702 does not

ring with a hardness of 50 to 60 HRC and a surface roughness

allow the use of such high speeds and loads because of possible

of 0.102 to 0.203 μm (4 to 8 μin.) R in the direction of sliding

a

overheating (which may cause degradation or melting, or both) of the

is used for the general evaluation of plastics. The requirement

specimen. Despite the differences in testing configurations, a good

for the ring material is that it should not wear appreciably or

correlation in the ranking of wear resistance is achieved between the two

change dimensions during the course of the test. Therefore,

tests (Table X2.1).

other materials and surface conditions may also be used. It

6. Apparatus and Materials

should be noted that test results will be influenced by the

6.1 Test Setup—An example of the basic test configuration choice of ring material and surface roughness.

and part names are shown in Fig. 1. The recommended 6.3 Test Block—The recommended dimensions of the test

dimensions of the test apparatus are shown in Fig. 2. The block are 6.35 + 0.00, − 0.03-mm (0.250 + 0.000, − 0.001-in.)

figures shown in this test method represent one example of a width, 6.00 + 0.00, − 0.03-mm (0.236 + 0.000, − 0.001-in.)

block-on-ring test apparatus. The mandatory elements are: the depth, and 12.70 6 0.2-mm height. For materials where

capability to change load and sliding speed, the ability to surface condition is not a parameter under study, a ground

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

G137–97

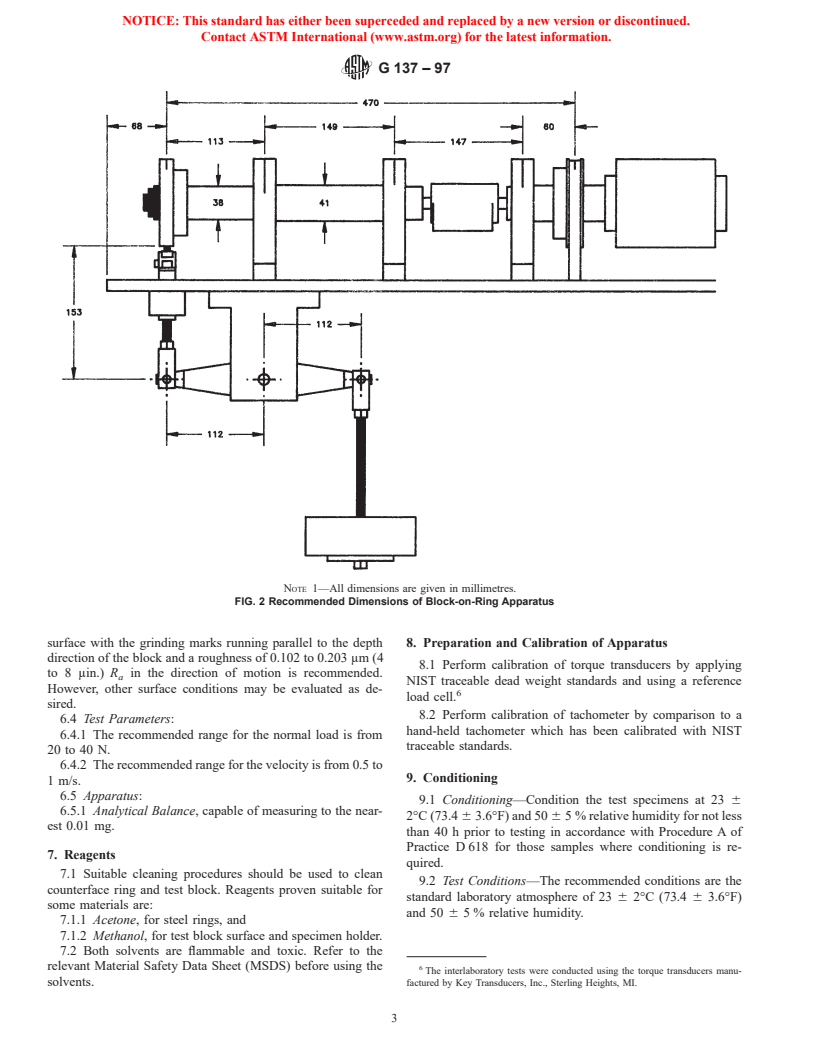

NOTE 1—All dimensions are given in millimetres.

FIG. 2 Recommended Dimensions of Block-on-Ring Apparatus

surface with the grinding marks running parallel to the depth 8. Preparation and Calibration of Apparatus

direction of the block and a roughness of 0.102 to 0.203 μm (4

8.1 Perform calibration of torque transducers by applying

to 8 μin.) R in the direction of motion is recommended.

a

NIST traceable dead weight standards and using a reference

However, other surface conditions may be evaluated as de-

load cell.

sired.

8.2 Perform calibration of tachometer by comparison to a

6.4 Test Parameters:

hand-held tachometer which has been calibrated with NIST

6.4.1 The recommended range for the normal load is from

traceable standards.

20 to 40 N.

6.4.2 The recommended range for the velocity is from 0.5 to

9. Conditioning

1 m/s.

6.5 Apparatus:

9.1 Conditioning—Condition the test specimens at 23 6

6.5.1 Analytical Balance, capable of measuring to the near-

2°C (73.4 6 3.6°F) and 50 6 5 % relative humidity for not less

est 0.01 mg.

than 40 h prior to testing in accordance with Procedure A of

Practice D 618 for those samples where conditioning is re-

7. Reagents

quired.

7.1 Suitable cleaning procedures should be used to clean

9.2 Test Conditions—The recommended conditions are the

counterface ring and test block. Reagents proven suitable for

standard laboratory atmosphere of 23 6 2°C (73.4 6 3.6°F)

some materials are:

and 50 6 5 % relative humidity.

7.1.1 Acetone, for steel rings, and

7.1.2 Methanol, for test block surface and specimen holder.

7.2 Both solvents are flammable and toxic. Refer to the

relevant Material Safety Data Sheet (MSDS) before using the 6

The interlaboratory tests were conducted using the torque transducers manu-

solvents. factured by Key Transducers, Inc., Sterling Heights, MI.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

G137–97

10. Procedure 10.9 Frictional torque values produced by the machine itself

(should not be more than 60.05 Nm) should be zeroed as

10.1 Clean the counterface ring using mild soap and water

follows:

so as to remove bulk dirt and corrosion-inhibiting oil. After-

10.9.1 The block-on-ring tester is turned on without any

wards, clean the counterface ring in an ultrasonic acetone bath

load being applied to the specimen. This gives a stable torque

for 2 h (43 kHz 95 W) to remove the remaining contaminants.

reading which should be zeroed. After zero marker is obtained,

Allow the ring to dry completely. Handle the ring from this

load may be applied to run the test.

point on with lint-free cotton gloves.

10.10 Bring the lever arm angle adjusting rod gently into

10.2 Mount the counterface ring on the drive shaft and

contact with the specimen load shaft to apply the load.

secure with a counterface retaining nut (Fig. 1).

10.11 Start the motor and adjust to a desired speed. The

10.3 Clean the test block and specimen holder with metha-

speed should preferably not exceed 1 m/s.

nol. Handle the test block and the specimen holder with

10.11.1 Frictional torque values may be recorded so that an

lint-free cotton gloves from this point.

average value for the test period may be obtained. Values for

10.4 Measure the width and the depth of the test block to

the frictional force can be obtained from these measurements

ensure that the surface dimensions fall within the specifica-

by dividing the frictional torque by an appropriate moment

tions.

arm.

10.5 Mount the test block into the specimen holder and

10.12 The test should be interrupted a minimum of six times

tighten so that the test block does not move within the

to determine mass loss as a function of time, though more may

specimen holder (Fig. 3).

be required to ensure that steady state is established. The

10.6 Weigh the test block and specimen holder to the

intervals need not be uniform. Shorter intervals should be used

nearest 0.01 mg.

during the initial portion of the test and longer intervals during

10.7 Position the specimen holder with the test block under

the latter portion of the test. The test should be continued until

the counterface ring. Repositioning is possible with the use of

three or more of the intervals occur in the steady state range.

a guide that the specimen load shaft slides on and an alignment

10.12.1 Halt the speed controlling motor for weight mea-

screw which secures the specimen holder to the specimen load

surements.

shaft. The linear ball grooved bushing bearing prevents the

10.12.2 Remove the load from the test block by removing

specimen load shaft from rotating.

the lever arm angle adjusting rod from the specimen load shaft.

10.8 Apply the required load. Yokes 1 and 2, and Nuts 1 and

10.12.3 Remove the specimen holder with the test block

2 in Fig. 1 are of equal weight and will not figure into

from the specimen load shaft.

calculations. The weight of the weight hanger will be included

10.12.4 Use compressed air to blow off the worn particles

in the total weight needed. The weight of specimen, specimen

from the test block and from within the specimen holder.

holder, specimen load shaft, and lever arm angle adjusting rod

10.12.5 Weigh the specimen holder with the test block on a

will have to be countered to equal the desired force. To ensure

balance to the nearest 0.01 mg.

that the proper load has been applied, a small load cell can be

10.12.6 Reload the specimen holder with the test block

mounted between the specimen and the counterface ring with

following the procedure in 10.7-10.11.

the load being applied. The lever arm should be maintained

horizontally by adjusting the height of the lever arm angle

11. Calculation

adjusting rod. The required load can be applied by other

11.1 Calculation of Specific Wear Rate:

mechanisms.

11.1.1 Periodic weighing of the specimen holder and the test

block results in a number of mass-time data points where the

time relates to the time of sliding.

11.1.2 The specific wear rate for each interval can be

calculated from (Eq 1):

1 Dm

W 5 · (1)

s

F vr Dt

N

where:

3 2

W = specific wear rate, mm /N·m, dimensions, (L /F),

s

F = applied normal force, N,

N

v = velocity, m/s,

r = density, kg/mm ,

Dm = mass loss, kg, and

Dt = time interval, s.

11.1.3 The specific wear rate reported is the average value

within the steady state region.

11.2 Calculation of Coeffıcient of Friction:

11.2.1 The dynamic coefficient of f

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.