ASTM D6447-99

(Test Method)Standard Test Method for Hydroperoxide Number of Aviation Turbine Fuels by Voltammetric Analysis

Standard Test Method for Hydroperoxide Number of Aviation Turbine Fuels by Voltammetric Analysis

SCOPE

1.1 The test method covers the determination of the hydroperoxide content of aviation turbine fuels. The test method may also be applicable to the determination of the hydroperoxide content of any water-insoluble, organic fluid, particularly diesel fuela, gasolines, and kerosenes. The precision of the test method has not yet been determined.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use. For specific precautionary statements, see 6.3, 6.4, 6.5, and Annex A1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 6447 – 99

Standard Test Method for

Hydroperoxide Number of Aviation Turbine Fuels by

Voltammetric Analysis

This standard is issued under the fixed designation D 6447; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope depleting substance precludes U. S. military bases from utiliz-

ing Test Method D 3703. This test method and Test Method

1.1 The test method covers the determination of the hydro-

D 3703 measure the same peroxide species (primarily hydro-

peroxide content of aviation turbine fuels. The test method may

peroxides) in aviation fuels.

also be applicable to the determination of the hydroperoxide

4.2 The magnitude of the hydroperoxide number is an

content of any water-insoluble, organic fluid, particularly

indication of the quantity of oxidizing constituents present.

diesel fuels, gasolines, and kerosenes. The precision of the test

Deterioration of fuel results in the formation of hydroperoxides

method has not yet been determined.

and other oxygen-carrying compounds. The hydroperoxide

1.2 The values stated in SI units are to be regarded as the

number measures those compounds that will oxidize potassium

standard.

iodide.

1.3 This standard does not purport to address all the safety

4.3 The determination of the hydroperoxide number of fuels

concerns, if any, associated with its use. It is the responsibility

is significant because of the adverse effect of hydroperoxides

of the user of this standard to consult and establish appropriate

upon certain elastomers in the fuel systems.

safety and health practices and determine the applicability of

regulatory limitations prior to use. For specific precautionary

5. Apparatus

statements, see 6.3, 6.4, 6.5, and Annex A1.

5.1 Voltammetric Analyzer —The instrument used to quan-

2. Referenced Documents tify the liberated iodine is a voltammetric analyzer equipped

with a three electrode system and a digital or analog output.

2.1 ASTM Standards:

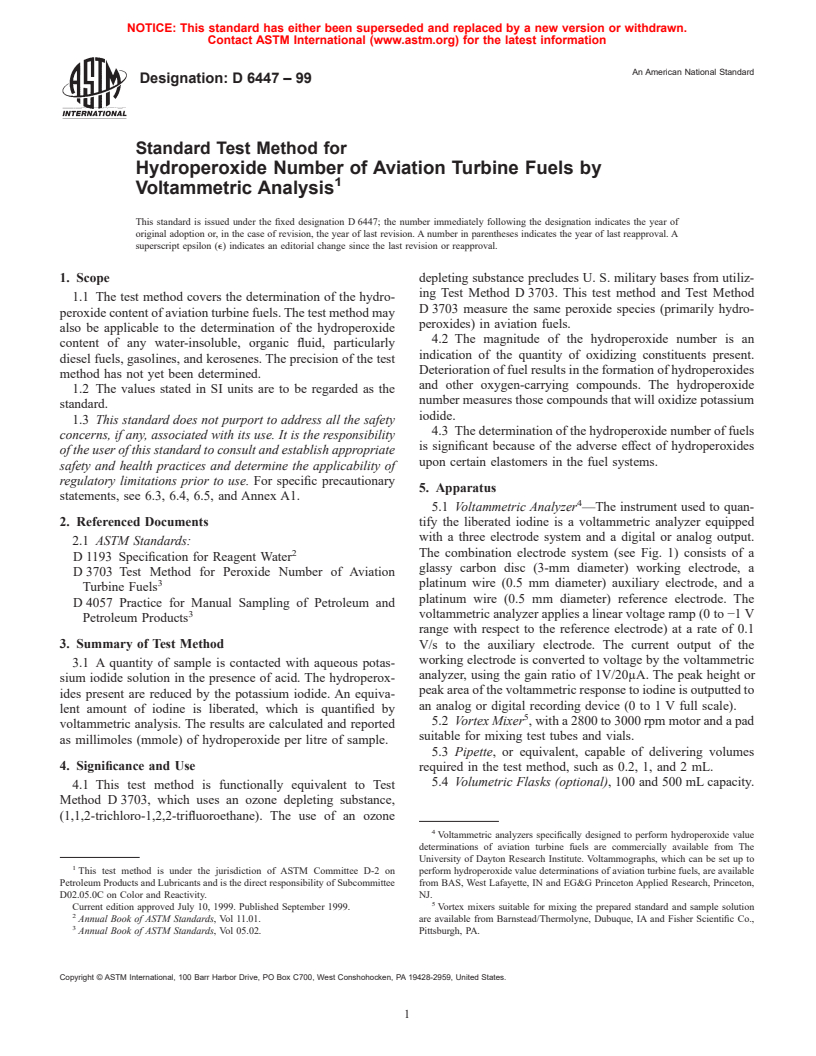

The combination electrode system (see Fig. 1) consists of a

D 1193 Specification for Reagent Water

glassy carbon disc (3-mm diameter) working electrode, a

D 3703 Test Method for Peroxide Number of Aviation

platinum wire (0.5 mm diameter) auxiliary electrode, and a

Turbine Fuels

platinum wire (0.5 mm diameter) reference electrode. The

D 4057 Practice for Manual Sampling of Petroleum and

voltammetric analyzer applies a linear voltage ramp (0 to −1 V

Petroleum Products

range with respect to the reference electrode) at a rate of 0.1

3. Summary of Test Method

V/s to the auxiliary electrode. The current output of the

working electrode is converted to voltage by the voltammetric

3.1 A quantity of sample is contacted with aqueous potas-

analyzer, using the gain ratio of 1V/20μA. The peak height or

sium iodide solution in the presence of acid. The hydroperox-

peak area of the voltammetric response to iodine is outputted to

ides present are reduced by the potassium iodide. An equiva-

an analog or digital recording device (0 to 1 V full scale).

lent amount of iodine is liberated, which is quantified by

5.2 Vortex Mixer , with a 2800 to 3000 rpm motor and a pad

voltammetric analysis. The results are calculated and reported

suitable for mixing test tubes and vials.

as millimoles (mmole) of hydroperoxide per litre of sample.

5.3 Pipette, or equivalent, capable of delivering volumes

4. Significance and Use

required in the test method, such as 0.2, 1, and 2 mL.

5.4 Volumetric Flasks (optional), 100 and 500 mL capacity.

4.1 This test method is functionally equivalent to Test

Method D 3703, which uses an ozone depleting substance,

(1,1,2-trichloro-1,2,2-trifluoroethane). The use of an ozone

Voltammetric analyzers specifically designed to perform hydroperoxide value

determinations of aviation turbine fuels are commercially available from The

University of Dayton Research Institute. Voltammographs, which can be set up to

This test method is under the jurisdiction of ASTM Committee D-2 on perform hydroperoxide value determinations of aviation turbine fuels, are available

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee from BAS, West Lafayette, IN and EG&G Princeton Applied Research, Princeton,

D02.05.0C on Color and Reactivity. NJ.

Current edition approved July 10, 1999. Published September 1999. Vortex mixers suitable for mixing the prepared standard and sample solution

Annual Book of ASTM Standards, Vol 11.01. are available from Barnstead/Thermolyne, Dubuque, IA and Fisher Scientific Co.,

Annual Book of ASTM Standards, Vol 05.02. Pittsburgh, PA.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 6447

FIG. 1 Combination Electrode

5.5 Glass Vials, 5 or 10 mL capacity. of 0.1 N K Cr O solution with water to 100 mL in a

2 2 7

volumetric flask. Store in a closed container.

6. Reagents and Materials

6.6 Potassium Iodide Solution—Dissolve6gof potassium

iodide (KI) in5gof water. Store in a closed container. Do not

6.1 Purity of Reagents—Reagent grade chemicals shall be

used in all tests. Unless otherwise indicated, it is intended that use if the solution shows any color or is cloudy.

6.7 Potassium Chloride Solution—Dissolve4gof potas-

all reagents shall conform to the specifications of the Commit-

tee on Analytical Reagents of the American Chemical Society, sium chloride (KCl) in 20 g of water. Store in a closed

container.

where such specifications are available. Other grades may be

used, provided it is first ascertained that the reagent’s purity

7. Sampling

suffices to permit its use without lessening the accuracy of the

7.1 Samples shall be taken in accordance with the proce-

determination.

dures described in Practice D 4057.

6.2 Purity of Water—Unless otherwise indicated, references

to water shall be understood to mean reagent water as defined

8. Procedure

by Type II of Specification D 1193.

8.1 Electrode Cleaning Solution Preparation—Transfer

6.3 Acetic Acid Solution—Mix 0.5 g of concentrated hydro-

equal amounts of the acetic acid solution and distilled water

chloric acid (HCl), (Warning: Poison. Corrosive. Can be fatal

intoa5mL glass vial. One way to do this is to use separate

if swallowed. Causes severe burns. Harmful if inhaled. See

pipettes for each material that can delivera2mL volume.

Annex A1.1), 0.5 g of water, and 24 g of glacial acetic acid

8.2 Blank Preparation (0 mmole)—Intoa5mL glass vial, in

(CH COOH) (Warning: Poison. Corrosive. Combustible. Can

succession, pipette 1 mL of KCl solution, 1 mL of acetic acid

be fatal if swallowed. Causes severe burns. Harmful if inhaled.

solution, and 0.2 mL of KI solution. Reversal of mixing order

See Annex A1.2) in a suitable container. Store in a closed

container. The acetic acid solution shall be prepared bi-weekly. will result in high blank readings of the voltammetric analyzer

calibration. Cap the vial and shake for 5 s using a vortex mixer

6.4 Potassium Dichromate Solution, Standard (0.1 N)—

Recrystallize twice from an aqueous solution of potassium (see 5.2).

8.3 Standard Preparation (1 mmole)—Intoa5mL glass

dichromate (K Cr O)(Warning: Poison. Can be fatal if

2 2 7

vial, in succession, pipette 1 mL of 0.002 N K Cr O solution,

swallowed. Avoid contact with eyes and skin, and avoid

2 2 7

1 mL of acetic solution, and 0.2 mL of KI solution. Cap the vial

breathing of dust, possible cancer hazard, strong oxidizer. See

and shake for 5 s using a vortex mixer (see 5.2).

Annex A1.2) Dry at 120°C to constant mass. Dissolve 2.452 g

8.4 Calibration:

of the purified K Cr O in water and dilute to 500 mL in a

2 2 7

8.4.1 The voltammetric analyzer used in this test method

volumetric flask. This solution is 0.1 N. Commercially avail-

gives linear results between 0.2 and 2 mmole. Below 0.1

able solutions certified to this standard ca

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.