ASTM D6604-00(2009)e1

(Practice)Standard Practice for Glass Transition Temperatures of Hydrocarbon Resins by Differential Scanning Calorimetry

Standard Practice for Glass Transition Temperatures of Hydrocarbon Resins by Differential Scanning Calorimetry

SIGNIFICANCE AND USE

Thermal analysis provides a rapid method for determining transition temperatures in HC resins that possess them.

This practice is useful for both quality assurance and research.

SCOPE

1.1 This practice covers determination of glass transition temperatures of hydrocarbon (HC) resins by differential scanning calorimetry (DSC).

1.2 This practice is applicable to HC resins as defined in Terminology D 6440. The normal operating temperature range is from the cryogenic region to approximately 180°C. The temperature range can be extended.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 Further discussion of glass transition can be found in Test Method D 3418, and Test Method E 1356.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D6604 − 00 (Reapproved 2009)

StandardPractice for

Glass Transition Temperatures of Hydrocarbon Resins by

Differential Scanning Calorimetry

This standard is issued under the fixed designation D6604; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Note 5 was added editorially in January 2009.

1. Scope E1356 Test Method for Assignment of the Glass Transition

Temperatures by Differential Scanning Calorimetry

1.1 This practice covers determination of glass transition

temperatures of hydrocarbon (HC) resins by differential scan-

3. Terminology

ning calorimetry (DSC).

3.1 Definitions:

1.2 This practice is applicable to HC resins as defined in

3.1.1 differential scanning calorimetry (DSC), n—A tech-

Terminology D6640. The normal operating temperature range

nique in which the difference in energy inputs into a substance

is from the cryogenic region to approximately 180°C. The

and a reference material is measured as a function of

temperature range can be extended.

temperature, while the substance and reference material are

1.3 The values stated in SI units are to be regarded as

subjected to a controlled temperature program.

standard. No other units of measurement are included in this

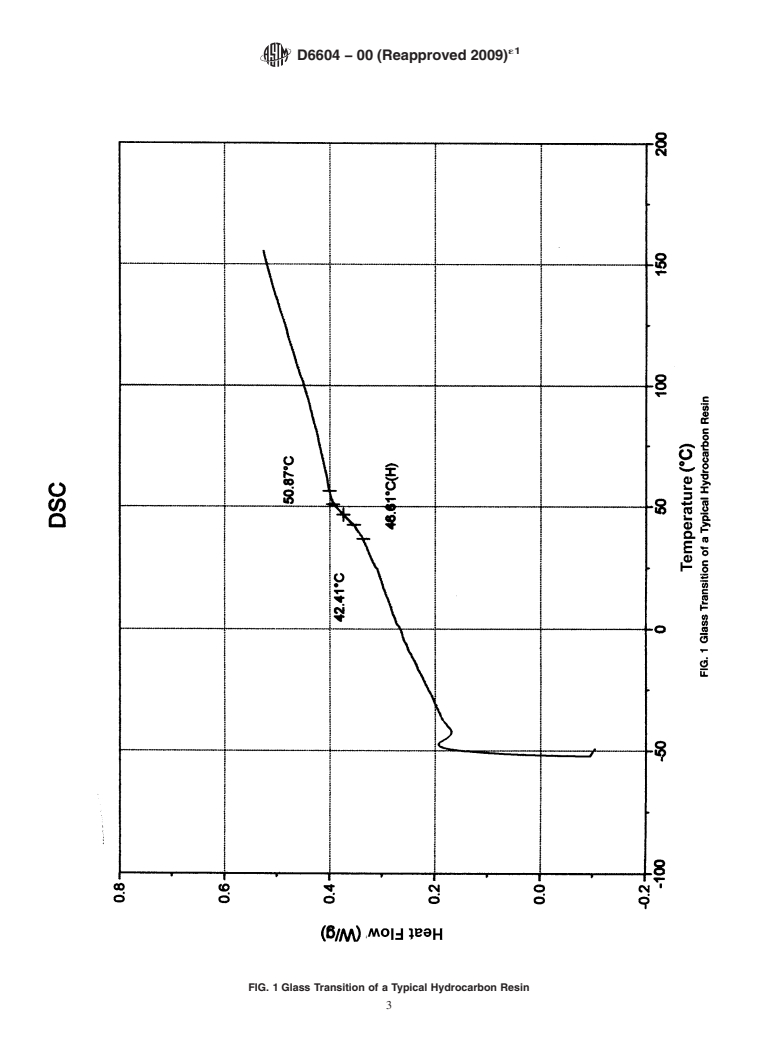

3.1.1.1 Discussion—The record is the DSC curve. Two

standard.

modes, power-compensation DSC and heat-flux DSC, can be

1.4 Further discussion of glass transition can be found in

distinguished, depending on the method of measurement used.

Test Method D3418, and Test Method E1356.

3.2 For other definitions of terms relating to thermal

1.5 This standard does not purport to address all of the

analysis, see Terminology E473.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4. Summary of Practice

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. 4.1 This practice consists of heating or cooling the test

material at a controlled rate, in a controlled atmosphere, and

2. Referenced Documents continuously monitoring with a suitable sensing device, the

2 difference in heat input between a reference material and a test

2.1 ASTM Standards:

material due to energy changes in the material. Absorption or

D3418 Test Method for Transition Temperatures and En-

release of energy marks a transition in the specimen resulting

thalpies of Fusion and Crystallization of Polymers by

in a corresponding baseline shift in the heating or cooling

Differential Scanning Calorimetry

curve.

D6640 Practice for Collection and Handling of Soils Ob-

tained in Core Barrel Samplers for Environmental Inves-

5. Significance and Use

tigations

E473 Terminology Relating to Thermal Analysis and Rhe-

5.1 Thermal analysis provides a rapid method for determin-

ology

ing transition temperatures in HC resins that possess them.

5.2 This practice is useful for both quality assurance and

research.

This practice is under the jurisdiction of ASTM Committee D01 on Paint and

Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.34 on Pine Chemicals and Hydrocarbon Resins. 6. Apparatus

Current edition approved Nov. 10, 2000. Published January 2009. Originally

6.1 Differential Scanning Calorimeter—An instrument ca-

approved in 2000. Last previous edition approved in 2000 as D6604 - 00. DOI:

10.1520/D6604-00R09E01.

pable of heating or cooling at rates up to 20 6 1°C/minute and

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

automatically recording the difference in input between the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

sample and a reference material to the required sensitivity and

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. precision.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D6604 − 00 (Reapproved 2009)

size has an effect on the detected transition temperatures. Therefore

6.2 Sample Tubes or Pans—Borosilicate glass tubes are

particle size should be fairly consistent from sample to sample.

used for certain applications and aluminum or other metal pans

of high thermal conductivity for other applications. 10.2 Perform and record a preliminary thermal cycle up to a

temperature high enough to erase previous therm

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation:D6604–00 Designation:D6604–00(Reapproved2009)

Standard Practice for

Glass Transition Temperatures of Hydrocarbon Resins by

Differential Scanning Calorimetry

This standard is issued under the fixed designation D 6604; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Note 5 was added editorially in January 2009.

1. Scope

1.1 This practice covers determination of glass transition temperatures of hydrocarbon (HC) resins by differential scanning

calorimetry (DSC).

1.2 This practice is applicable to HC resins as defined in Terminology D 6440. The normal operating temperature range is from

the cryogenic region to approximately 180°C. The temperature range can be extended.

1.3The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 Further discussion of glass transition can be found in Test Method D 3418, and Test Method E 1356.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D 3418 Test Method for Transition Temperatures of Polymers by Differential Scanning Calorimetry Test Method for Transition

Temperatures and Enthalpies of Fusion and Crystallization of Polymers by Differential Scanning Calorimetry

D6440Terminology Relating to Hydrocarbon Resins 6640 Practice for Collection and Handling of Soils Obtained in Core

Barrel Samplers for Environmental Investigations

E 473 Terminology Relating to Thermal Analysis and Rheology

E 1356 Test Method forAssignment of the Glass Transition Temperatures by Differential Scanning Calorimetry or Differential

Thermal Analysis

3. Terminology

3.1 Definitions:

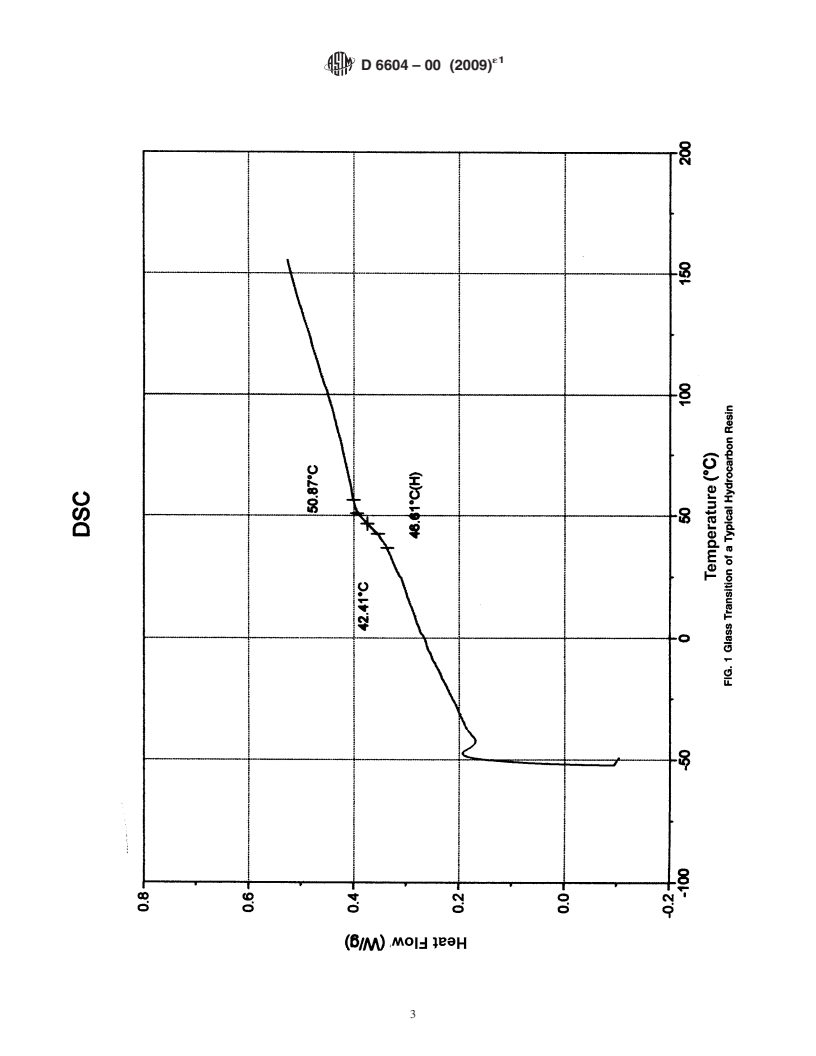

3.1.1 differential scanning calorimetry (DSC)differential scanning calorimetry (DSC), n—Atechnique in which the difference

in energy inputs into a substance and a reference material is measured as a function of temperature, while the substance and

reference material are subjected to a controlled temperature program.

3.1.1.1 Discussion—The record is the DSC curve. Two modes, power-compensation DSC and heat-flux DSC, can be

distinguished, depending on the method of measurement used.

3.2 For other definitions of terms relating to thermal analysis, see Terminology E 473.

4. Summary of Practice

4.1 Thispracticeconsistsofheatingorcoolingthetestmaterialatacontrolledrate,inacontrolledatmosphere,andcontinuously

monitoring with a suitable sensing device, the difference in heat input between a reference material and a test material due to

energy changes in the material. Absorption or release of energy marks a transition in the specimen resulting in a corresponding

baseline shift in the heating or cooling curve.

This practice is under the jurisdiction of ASTM Committee D01 on Paint and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.38 on Hydrocarbon Resins.

Current edition approved Nov. 10, 2000. Published January 2001.

Current edition approved January 15, 2009. Published January 2009. Originally approved in 2000. Last previous edition approved in 2000 as D 6604 - 00.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 08.02.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

D6604–00 (2009)

5. Significance and Use

5.1 Thermal analysis provides a rapid method for determining transition temperatures in HC resins that possess them.

5.2 This practice is useful for both quality assurance and research.

6. Apparatus

6.1 Differential Scanning Calorimeter —An instrument capable of heating or cooling at rates up to 20 6 1°C/minute and

automatically recording the difference in input between the sample and a reference material to the required sensitivity and

precision.

6.2 Sample Tubes or Pans—Borosilicate glass tubes are used for certain applica

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.