ASTM B30-00

(Specification)Standard Specification for Copper Alloys in Ingot Form

Standard Specification for Copper Alloys in Ingot Form

SCOPE

1.1 This specification establishes the requirements for copper alloys in ingot form for remelting for the manufacturing of castings having the Copper Alloy UNS No. designation, commercial designations and nominal composition shown in Table 1 and Table 2.

1.2 A cross reference of Copper Alloy UNS Nos. and copper alloy casting specifications is given in Table 3.

1.3 Inch-pound units are the standard. SI values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: B 30 – 00

Standard Specification for

Copper Alloys in Ingot Form

This standard is issued under the fixed designation B 30; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope * B 584 Specification for Copper Alloy Sand Castings for

General Applications

1.1 This specification establishes the requirements for cop-

B 763 Specification for Copper Alloy Sand Castings for

per alloys in ingot form for remelting for the manufacturing of

Valve Application

castings having the Copper Alloy UNS No. designation,

B 770 Specification for Copper-Beryllium Alloy Sand Cast-

commercial designations and nominal composition shown in

ings for General Applications

Table 1 and Table 2.

B 806 Specification for Copper Alloy Permanent Mold

1.2 A cross reference of Copper Alloy UNS Nos. and copper

Castings for General Applications

alloy casting specifications is given in Table 3.

E 8 Test Methods for Tension Testing of Metallic Materials

1.3 Inch-pound units are the standard. SI values given in

E 29 Practice for Using Significant Digits in Test Data to

parentheses are for information only.

Determine Conformance with Specifications

2. Referenced Documents E 54 Test Methods for Chemical Analysis of Special

Brasses and Bronzes

2.1 The following documents of the issue in effect on date

E 62 Test Methods for Chemical Analysis of Copper and

of material purchase form a part of this specification to the

Copper Alloys (Photometric Methods)

extent referenced herein:

E 76 Test Methods for Chemical Analysis of Nickel-Copper

2.2 ASTM Standards:

Alloys

B 22 Specification for Bronze Castings for Bridges and

E 255 Practice for Sampling Copper and Copper Alloys for

Turntables

Determination of Chemical Composition

B 61 Specification for Steam or Valve Bronze Castings

E 478 Test Methods for Chemical Analysis of Copper

B 62 Specification for Composition Bronze or Ounce Metal

Alloys

Castings

E 581 Test Methods for Chemical Analysis of Manganese-

B 66 Specification for Bronze Castings for Steam Locomo-

Copper Alloys

tive Wearing Parts

B 67 Specification for Car and Tender Journal Bearings,

3. Ordering Information

Lined

3.1 Orders for ingot should include the following informa-

B 148 Specification for Aluminum-Bronze Sand Castings

tion:

B 176 Specification for Copper-Alloy Die Castings

3.1.1 ASTM designation and year of issue (for example,

B 194 Specification for Copper-Beryllium Alloy Plate,

B 30 – 00),

Sheet, Strip, and Rolled Bar

3.1.2 Copper Alloy UNS No. (for example, C83450 and

B 208 Practice for Preparing Tension Test Specimens for

Table 1, Table 2, Table 4, and Table 5),

Copper Alloy Sand, Permanent Mold, Centrifugal, and

2 3.1.3 Quantity; total weight, and

Continuous Castings

3.1.4 When purchase is for agencies of U.S. Government.

B 271 Specification for Copper-Base Alloy Centrifugal

2 3.2 The following options are available under this specifi-

Castings

cation and shall be specified in the contract or purchase order

B 369 Specification for Copper-Nickel Alloy Castings

2 when required:

B 427 Specification for Gear Bronze Alloy Castings

3.2.1 Mechanical requirements, when specified in the pur-

B 505 Specification for Copper-Base Alloy Continuous

2 chase order (Section 7).

Castings

3.2.2 Nickel content in Copper Alloys UNS Nos. C90300,

C90500, C92200, and C92300 (Table 4).

This specification is under the jurisdiction of ASTM Committee B05 on Copper

and Copper Alloys and is the direct responsibility of Subcommittee B05.05 on

Castings and Ingots for Remelting.

Current edition approved March 10, 2000. Published April 2000. Originally Annual Book of ASTM Standards, Vol 03.01.

published as B 30 – 19T. Last previous edition B 30 – 98a. Annual Book of ASTM Standards, Vol 14.02.

2 5

Annual Book of ASTM Standards, Vol 02.01. Annual Book of ASTM Standards, Vol 03.05.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

B30

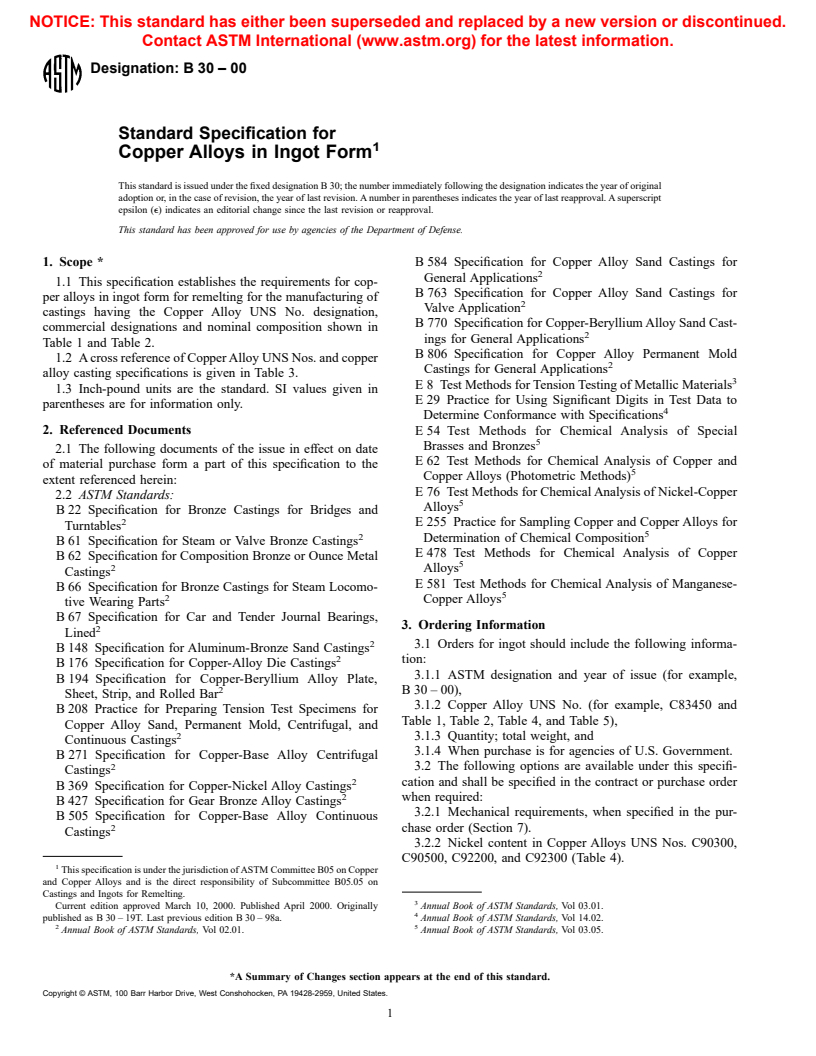

TABLE 1 Nominal Compositions

Copper

Nominal Composition, %

Previously

Alloy

Alloy Name Used Commercial Designation

Alumi- Man- Sili- Nio- Bis-

UNS

Copper Tin Lead Zinc Nickel Iron

Designation

num ganese con bium muth

No.

Leaded red brass C83450 . . . 88 2.5 2 6.5 1 . . . . . . . . . . . . . . . . . .

C83600 4A 85-5-5-5 or No. 1 composition 85 5 5 5 . . . . . . . . . . . . . . . . . .

C83800 4B commercial red brass, 83-4-6-7 83 4 6 7 . . . . . . . . . . . . . . . . . . . . .

Leaded semi-red brass C84200 . . . semi-red brass, 80-5-2-13 80 5 2 13 . . . . . . . . . . . . . . . . . . . . .

C84400 5A valve composition 81-3-7-9 81 3 7 9 . . . . . . . . . . . . . . . . . . . . .

1 1

C84800 5B semi-red brass, 76-2 ⁄2-6 ⁄2-15 76 2.5 6.5 15 . . . . . . .

Leaded yellow brass C85200 6A high-copper yellow brass 72 1 3 24 . . . . . . . . . . . . . . . . . . . . .

C85400 6B commercial No. 1 yellow brass 67 1 3 29 . . . . . . . . . . . . . . . . . . . . .

C85700 6C 60–40 leaded yellow (naval) 61 1 1 37 . . . . . . .

brass

C85800 . . . die-cast yellow brass 62 1 1 36 . . . . . . . . . . . . . . . . . . . . .

C86100 . . . high-strength manganese 67 . . 21 . 3 5 4 . . .

bronze

Leaded high-strength C86200 8B high-strength manganese 63 . . 27 . 3 4 3 . . .

yellow brass and bronze

high-strength

yellow brass

C86300 8C high-strength manganese 61 . . 27 . 3 6 3 . . .

bronze

C86400 7A leaded manganese bronze 58 1 1 38 . . . 1 0.5 0.5 . . . . . . . . .

C86500 8A No. 1 manganese bronze 58 . . . . . . 39 . . . 1 1 1 . . .

C86700 . . . leaded manganese bronze 58 1 1 34 . . . 2 2 2 . . .

Silicon bronze C87300 . . . silicon bronze 95 . . . . . . . . . . . . . . . . . . 1 4 . . . . . .

Silicon brass C87400 13A silicon brass 82 . . . 0.5 14 . . . . . . . . . . . . 3.5 . . . . . .

C87500 13B 82 . . . . . . 14 . . . . . . . . . . . . 4 . . . . . .

Silicon bronze C87600 . . . silicon bronze 91 . . . . . . 5 . . . . . . . . . . . . 4 . . . . . .

C87610 . . . silicon bronze 92 . . . . . . 4 . . . . . . . . . . . . 4 . . . . . .

Silicon brass C87800 . . . die-cast silicon brass 82 . . . . . . 14 . . . . . . . . . . . . 4 . . . . . .

A

Bismuth tin bronze C89320 lead-free bronze 89 6 . . . . . . . . . . . . . . . . . . . . . . . . . . .

B

Bismuth selenium brass C89510 lead-free bronze 87 5.0 . . . 5.0 . . . . . . . . . . . . . . . . . . 1.0

C

C89520 . . . lead-free brass 86 5.5 . . . 5 . . . . . . . . . . . . . . . . . . 1.9

Bismuth semi-red brass C89844 . . . cast bismuth brass 84.5 4 . . . 8 . . . . . . . . . . . . . . . . . . 3

Tin bronze and leaded C90300 1B 88-8-0-4 or modified “G” 88 8 . 4 . . . . . . .

tin bronze bronze

C90500 1A 88-10-0-2 or “G” bronze 88 10 . . . 2 . . . . . . . . . . . . . . . . . . . . .

C90700 . . . 89-11 gear bronze 89 11 . . . . . . . . . . . . . . . . . . . . . . . . . . .

C90800 . . . 88-12 gear bronze 88 12 . . . . . . . . . . . . . . . . . . . . . . . . . . .

C91000 . . . 85-15 tin bronze 85 15 . . . . . . . . . . . . . . . . . . . . . . . . . . .

C91100 . . . 84-16 tin bronze 84 16 . . . . . . . . . . . . . . . . . . . . . . . . . . .

C91300 . . . 81-19 tin bronze or bell metal 81 19 . . . . . . . . . . . . . . . . . . . . . . . . . . .

C91600 . . . nickel gear bronze 88 10.5 . . . . . . 1.5 . . . . . . . . . . . . . . . . . .

C91700 . . . nickel gear bronze 86.5 12 . . . . . . 1.5 . . . . . . . . . . . . . . . . . .

C92200 2A steam or valve bronze-Navy 88 6 1.5 4.5 . . . . . . .

“M”

C92210 . . . . . . 88 5 2 4 1 . . . . . .

C92300 2B 87-8-1-4 Navy P-C 87 8 1 4 . . . . . . . . . . . . . . . . . . . . .

C92500 87-11-1-0-1 leaded gear 87 11 1 . 1 . . . . . .

bronze

C92600 87-10-1-2 leaded tin bronze 87 10 1 2 . . . . . . . . . . . . . . . . . . . . .

C92700 88-10-2-0 leaded tin bronze 88 10 2 . . . . . . . . . . . . . . . . . . . . . . . .

C92800 79-16-5 leaded tin bronze 79 16 5 . . . . . . . . . . . . . . . . . . . . . . . .

C92900 leaded gear bronze 84 10 2.5 . . . 3.5 . . . . . . . . . . . . . . . . . .

High-leaded tin bronze C93200 3B 83-7-7-3 83 7 7 3 . . . . . . . . . . . . . . . . . . . . .

C93400 84-8-8 84 8 8 . . . . . . . . . . . . . . . . . . . . . . . .

C93500 3C 85-5-9-1 85 5 9 1 . . . . . . . . . . . . . . . . . . . . .

C93600 81-7-12 81 7 12 . . . . . . . . . . . . . . . . . . . . . . . .

C93700 3A 80-10-10 80 10 10 . . . . . . . . . . . . . . . . . . . . . . . .

C93800 3D 78-7-15 78 7 15 . . . . . . . . . . . . . . . . . . . . . . . .

C93900 77-6-16-1 high-lead-tin bronze 77 6 16 1 . . . . . . . . . . . . . . . . . . . . .

C94000 72-13-15 72 13 15 . . . . . . . . . . . . . . . . . . . . . . . .

C94100 journal bronze 75 5 18 2 . . . . . . . . . . . . . . . . . . . . .

C94300 71-5-24 71 5 24 . . . . . . . . . . . . . . . . . . . . . . . .

C94400 81-8-11 81 8 11 . . . . . . . . . . . . . . . . . . . . . . . .

C94500 73-7-20 73 7 20 . . . . . . . . . . . . . . . . . . . . . . . .

Nickel-tin bronze and C94700 nickel-tin bronze Grade “A” 88 5 . . . 2 5 . . . . . . . . . . . . . . . . . .

leaded nickel tin

bronze

C94800 leaded nickel-tin bronze Grade 87 5 1 2 5 . . . . . .

“B”

C94900 leaded nickel-tin bronze Grade 80 5 5 5 5 . . . . . .

“C”

B30

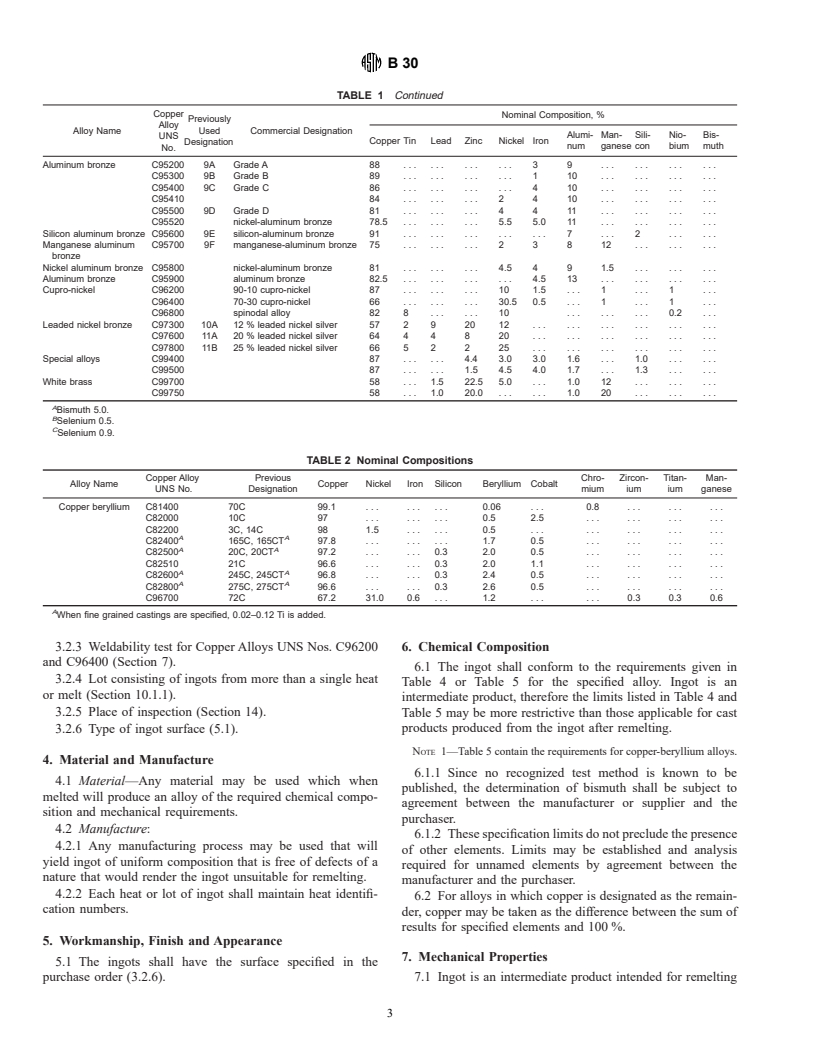

TABLE 1 Continued

Copper

Nominal Composition, %

Previously

Alloy

Alloy Name Used Commercial Designation

Alumi- Man- Sili- Nio- Bis-

UNS

Copper Tin Lead Zinc Nickel Iron

Designation

num ganese con bium muth

No.

Aluminum bronze C95200 9A Grade A 88 . . . . . . . . . . . . 3 9 . . . . . . . . . . . .

C95300 9B Grade B 89 . . . . . . . . . . . . 1 10 . . . . . . . . . . . .

C95400 9C Grade C 86 . . . . . . . . . . . . 4 10 . . . . . . . . . . . .

C95410 84 . . . . . . . . . 2 4 10 . . . . . . . . . . . .

C95500 9D Grade D 81 . . . . . . . . . 4 4 11 . . . . . . . . . . . .

C95520 nickel-aluminum bronze 78.5 . . . . . . . . . 5.5 5.0 11 . . . . . . . . . . . .

Silicon aluminum bronze C95600 9E silicon-aluminum bronze 91 . . . . . . . . . . . . . . . 7 . . . 2 . . . . . .

Manganese aluminum C95700 9F manganese-aluminum bronze 75 . . . . . . . . . 23812 . . .

bronze

Nickel aluminum bronze C95800 nickel-aluminum bronze 81 . . . . . . . . . 4.5 4 9 1.5 . . . . . . . . .

Aluminum bronze C95900 aluminum bronze 82.5 . . . . . . . . . . . . 4.5 13 . . . . . . . . . . . .

Cupro-nickel C96200 90-10 cupro-nickel 87 . . . . . . . . . 10 1.5 . . . 1 . . . 1 . . .

C96400 70-30 cupro-nickel 66 . . . . . . . . . 30.5 0.5 . . . 1 . . . 1 . . .

C96800 spinodal alloy 82 8 . . . . . . 10 . . . . . . . . . 0.2 . . .

Leaded nickel bronze C97300 10A 12 % leaded nickel silver 57 2 9 20 12 . . . . . . . . . . . . . . . . . .

C97600 11A 20 % leaded nickel silver 64 4 4 8 20 . . . . . . . . . . . . . . . . . .

C97800 11B 25 % leaded nickel silver 66 5 2 2 25 . . . . . . . . . . . . . . . . . .

Special alloys C99400 87 . . . . . . 4.4 3.0 3.0 1.6 . . . 1.0 . . . . . .

C99500 87 . . . . . . 1.5 4.5 4.0 1.7 . . . 1.3 . . . . . .

White brass C99700 58 . . . 1.5 22.5 5.0 . . . 1.0 12 . . . . . . . . .

C99750 58 . . . 1.0 20.0 . . . . . . 1.0 20 . . . . . . . . .

A

Bismuth 5.0.

B

Selenium 0.5.

C

Selenium 0.9.

TABLE 2 Nominal Compositions

Copper Alloy Previous Chro- Zircon- Titan- Man-

Alloy Name

Copper Nickel Iron Silicon Beryllium Cobalt

UNS No. Designation mium ium ium ganese

Copper beryllium C81400 70C 99.1 . . . . . . . . . 0.06 . . . 0.8 . . . . . . . . .

C82000 10C 97 . . . . . . . . . 0.5 2.5 . . . . . . . . . . . .

C82200 3C, 14C 98 1.5 . . . . . . 0.5 . . . . . . . . . . . . . . .

A A

C82400 165C, 165CT 97.8 . . . . . . . . . 1.7 0.5 . . . . . . . . . . . .

A A

C82500 20C, 20CT 97.2 . . . . . . 0.3 2.0 0.5 . . . . . . . . . . . .

C82510 21C 96.6 . . . . . . 0.3 2.0 1.1 . . . . . . . . . . . .

A A

C82600 245C, 245CT 96.8 . . . . . . 0.3 2.4 0.5 . . . . . . . . . . . .

A A

C82800 275C, 275CT 96.6 . . . . . . 0.3 2.6 0.5 . . . . . . . . . . . .

C96700 72C 67.2 31.0 0.6 . . . 1.2 . . . . . . 0.3 0.3 0.6

A

When fine grained castings are specified, 0.02–0.12 Ti is added.

3.2.3 Weldability test for Copper Alloys UNS Nos. C96200 6. Chemical Composition

and C96400 (Section 7).

6.1 The ingot shall conform to the requirements given in

3.2.4 Lot consisting of ingots from more than a single heat

Table 4 or Table 5 for the specified alloy. Ingot is an

or melt (Section 10.1.1).

intermediate product, therefore the limits listed in Table 4 and

3.2.5 Place of inspection (Section 14).

Table 5 may be more restrictive than those applicable for cast

3.2.6 Type of ingot surface (5.1). products produced from the ingot after remelting.

NOTE 1—Table 5 contain the requirements for copper-beryllium alloys.

4. Material and Manufacture

6.1.1 Since no recognized test method is known to be

4.1 Material—Any material may be used which when

published, the determination of bismuth shall be subject to

melted will produce an alloy of the required chemical compo-

agreement between the manufacturer or supplier and the

sition and mechanical requirements.

purchaser.

4.2 Manufacture:

6.1.2 These specification limits do not preclude the presence

4.2.1 Any manufacturing process may be used that will

of other elements. Limits may be established and analysis

yield ingot of uniform composition that is free of defects of a

required for unnamed elements by agreement between the

nature that would render the ingot unsuitable for remelting.

manufacturer and the purchaser.

4.2.2 Each heat or lot of ingot shall maintain heat identifi-

6.2 For alloys in which copper is designated as the remain-

cation numbers.

der, copper may be taken as the difference between the sum of

results for specified elements and 100 %.

5. Workmanship, Finish and Appearance

7. Mechanical Properties

5.1 The ingots shall have the surface specified in the

purchase order (3.2.6). 7.1 Ingot is an intermediate product intended for remelting

B30

Numbers for which no mechanical requirements are given in the appli-

by the purchaser, therefore, mechanical properties are not

cable casting specification shall be by agreement between the purchaser

applicable.

and the manufacturer.

NOTE 2—However, when specified in the purchase order, ingot when

remelted and cast into tension test coupons shall meet the mechanical 7.2 Table 3 provides a cross reference between the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.