ASTM D2321-00

(Practice)Standard Practice for Underground Installation of Thermoplastic Pipe for Sewers and Other Gravity-Flow Applications

Standard Practice for Underground Installation of Thermoplastic Pipe for Sewers and Other Gravity-Flow Applications

SCOPE

1.1 This practice provides recommendations for the installation of buried thermoplastic pipe used in sewers and other gravity-flow applications. These recommendations are intended to ensure a stable underground environment for thermoplastic pipe under a wide range of service conditions. However, because of the numerous flexible plastic pipe products available and the inherent variability of natural ground conditions, achieving satisfactory performance of any one product may require modification to provisions contained herein to meet specific project requirements.

1.2 The scope of this practice necessarily excludes product performance criteria such as minimum pipe stiffness, maximum service deflection, or long term strength. Thus, it is incumbent upon the product manufacturer, specifier, or project engineer to verify and assure that the pipe specified for an intended application, when installed according to procedures outlined in this practice, will provide a long term, satisfactory performance according to criteria established for that application. A commentary on factors important in achieving a satisfactory installation is included in Appendix X1. Note 1-Specific paragraphs in the appendix are referenced in the body of this practice for informational purposes. Note 2-The following ASTM standards may be found useful in connection with this practice: Practice D420, Test Method D1556, Method D2216, Specification D2235, Test Method D2412, Specification D2564, Practice D2657, Practice D2855, Test Methods D2922, Test Method D3017, Practice F402, Specification F477, Specification F545, and Specification F913.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.>

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 2321 – 00

Standard Practice for

Underground Installation of Thermoplastic Pipe for Sewers

1

and Other Gravity-Flow Applications

This standard is issued under the fixed designation D 2321; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2. Referenced Documents

1.1 This practice provides recommendations for the instal- 2.1 ASTM Standards:

lation of buried thermoplastic pipe used in sewers and other D 8 Terminology Relating to Materials for Roads and Pave-

2

gravity-flow applications. These recommendations are in- ments

tended to ensure a stable underground environment for ther- D 653 Terminology Relating to Soil, Rock, and Contained

3

moplastic pipe under a wide range of service conditions. Fluids

However, because of the numerous flexible plastic pipe prod- D 698 Test Methods for Laboratory Compaction Character-

3

ucts available and the inherent variability of natural ground istics of Soil Using Standard Effort (12,400 ft-lbf/ft (600

3

conditions, achieving satisfactory performance of any one kN-m/m ))

product may require modification to provisions contained D 2487 Test Method for Classification of Soils for Engi-

3,

4

herein to meet specific project requirements. neering Purposes

1.2 The scope of this practice necessarily excludes product D 2488 Practice for Description and Identification of Soils

,

3 4

performance criteria such as minimum pipe stiffness, maxi- (Visual-Manual Procedure)

mum service deflection, or long term strength. Thus, it is D 3839 Practice for Underground Installation of “Fiber-

incumbent upon the product manufacturer, specifier, or project glass’’ (Glass-Fiber Reinforced Thermosetting Resin)

4

engineer to verify and assure that the pipe specified for an Pipe

intended application, when installed according to procedures D 4318 Test Method for Liquid Limit, Plastic Limit, and

3

outlined in this practice, will provide a long term, satisfactory Plasticity Index of Soils

4

performance according to criteria established for that applica- F 412 Terminology Relating to Plastic Piping Systems

tion. A commentary on factors important in achieving a

3. Terminology

satisfactory installation is included in Appendix X1.

3.1 General—Definitions used in this practice are in accor-

NOTE 1—Specific paragraphs in the appendix are referenced in the

dance with Terminologies F 412 and D 8 and Terminology

body of this practice for informational purposes.

D 653 unless otherwise indicated.

NOTE 2—The following ASTM standards may be found useful in

3.2 Definitions of Terms Specific to This Standard:

connection with this practice: Practice D 420, Test Method D 1556,

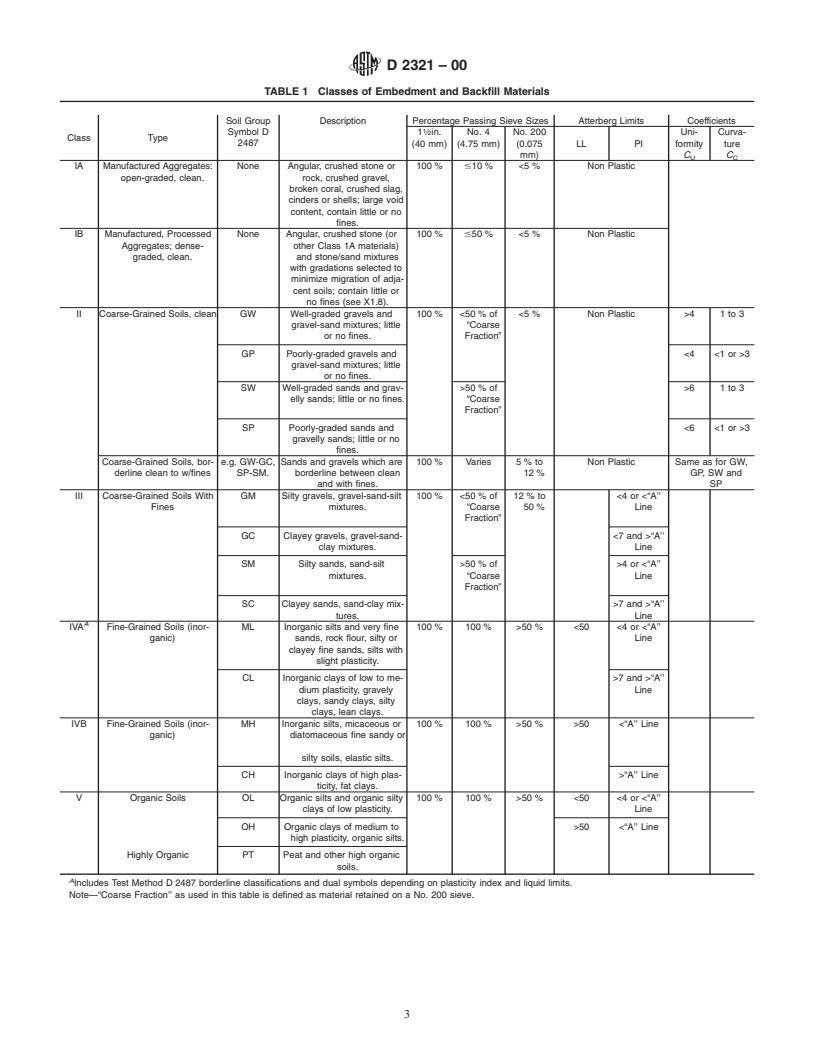

Method D 2216, Specification D 2235,Test Method D 2412, Specification 3.2.1 foundation, bedding, haunching, initial backfill, final

D 2564, Practice D 2657, Practice D 2855, Test Methods D 2922, Test

backfill, pipe zone, excavated trench width—See Fig. 1 for

Method D 3017, Practice F 402, Specification F 477, Specification F 545,

meaning and limits, and trench terminology.

and Specification F 913.

3.2.2 aggregate—a granular material of mineral composi-

NOTE 3—Most Plumbing Codes and some Building Codes have provi-

tion such as sand, gravel, shell, slag or crushed stone (see

sions for the installation of underground “building drains and building

Terminology D 8).

sewers.” See them for plumbing piping applications.

3.2.3 deflection—any change in the inside diameter of the

1.3 This standard does not purport to address all of the

pipe resulting from installation and imposed loads. Deflection

safety problems, if any, associated with its use. It is the

may be either vertical or horizontal and is usually reported as

responsibility of the user of this standard to establish appro-

a percentage of the base (undeflected) inside pipe diameter.

priate safety and health practices and determine the applica-

3.2.4 dense-graded aggregate—an aggregate that has a

bility of regulatory limitations prior to use.

particle size distribution such that, when it is compacted, the

1

This practice is under the jurisdiction of ASTM Committee F-17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.62 on Sewer

2

Pipe. Annual Book of ASTM Standards, Vol 04.03.

3

Current edition approved May 10, 2000. Published August 2000. Annual Book of ASTM Standards, Vol 04.08.

4

Originally published as D2321–89. Last previous edition D2321– 89 (95). Annual Book of ASTM Standards, Vol 08.04.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.