ASTM E208-06

(Test Method)Standard Test Method for Conducting Drop-Weight Test to Determine Nil-Ductility Transition Temperature of Ferritic Steels

Standard Test Method for Conducting Drop-Weight Test to Determine Nil-Ductility Transition Temperature of Ferritic Steels

SIGNIFICANCE AND USE

The fracture-strength transitions of ferritic steels used in the notched condition are markedly affected by temperature. For a given “low” temperature, the size and acuity of the flaw (notch) determines the stress level required for initiation of brittle fracture. The significance of this test method is related to establishing that temperature, defined herein as the NDT temperature, at which the “small flaw” initiation curve, Fig. 1, falls to nominal yield strength stress levels with decreasing temperature, that is, the point marked NDT in Fig. 1.

Interpretations to other conditions required for fracture initiation may be made by the use of the generalized flaw-size, stress-temperature diagram shown in Fig. 1. The diagram was derived from a wide variety of tests, both fracture-initiation and fracture-arrest tests, as correlated with the NDT temperature established by the drop-weight test. Validation of the NDT concept has been documented by correlations with numerous service failures encountered in ship, pressure vessel, machinery component, forged, and cast steel applications.

FIG. 1 Generalized Fracture Analysis Diagram Indicating the Approximate Range of Flaw Sizes Required for Fracture Initiation at Various Levels of Nominal Stress, as Referenced by the NDT Temperature4 , 5

SCOPE

1.1 This test method covers the determination of the nil-ductility transition (NDT) temperature of ferritic steels, 5/8 in. (15.9 mm) and thicker.

1.2 This test method may be used whenever the inquiry, contract, order, or specification states that the steels are subject to fracture toughness requirements as determined by the drop-weight test.

1.3 The values stated in inch-pound units are to be regarded as the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E208 − 06

StandardTest Method for

Conducting Drop-Weight Test to Determine Nil-Ductility

1

Transition Temperature of Ferritic Steels

This standard is issued under the fixed designation E208; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

INTRODUCTION

This drop-weight test was developed at the Naval Research Laboratory in 1952 and has been used

extensively to investigate the conditions required for initiation of brittle fractures in structural steels.

Drop-weight test facilities have been established at several Naval activities, research institutions, and

industrial organizations in this country and abroad. The method is used for specification purposes by

industrial organizations and is referenced in several ASTM specifications and the ASME Boiler and

Pressure Vessel Code. This procedure was prepared to ensure that tests conducted at all locations

wouldhaveacommonmeaning.ThistestmethodwasoriginallypublishedasDepartmentoftheNavy

document NAVSHIPS-250-634-3.

1. Scope* 3.1.1 ferritic—thewordferriticasusedhereafterreferstoall

α-Fe steels. This includes martensitic, pearlitic, and all other

1.1 This test method covers the determination of the nil-

nonaustenitic steels.

5

ductility transition (NDT) temperature of ferritic steels, ⁄8 in.

(15.9 mm) and thicker.

3.1.2 nil-ductility transition (NDT) temperature—themaxi-

mum temperature where a standard drop-weight specimen

1.2 This test method may be used whenever the inquiry,

breaks when tested according to the provisions of this method.

contract,order,orspecificationstatesthatthesteelsaresubject

to fracture toughness requirements as determined by the

4. Summary of Test Method

drop-weight test.

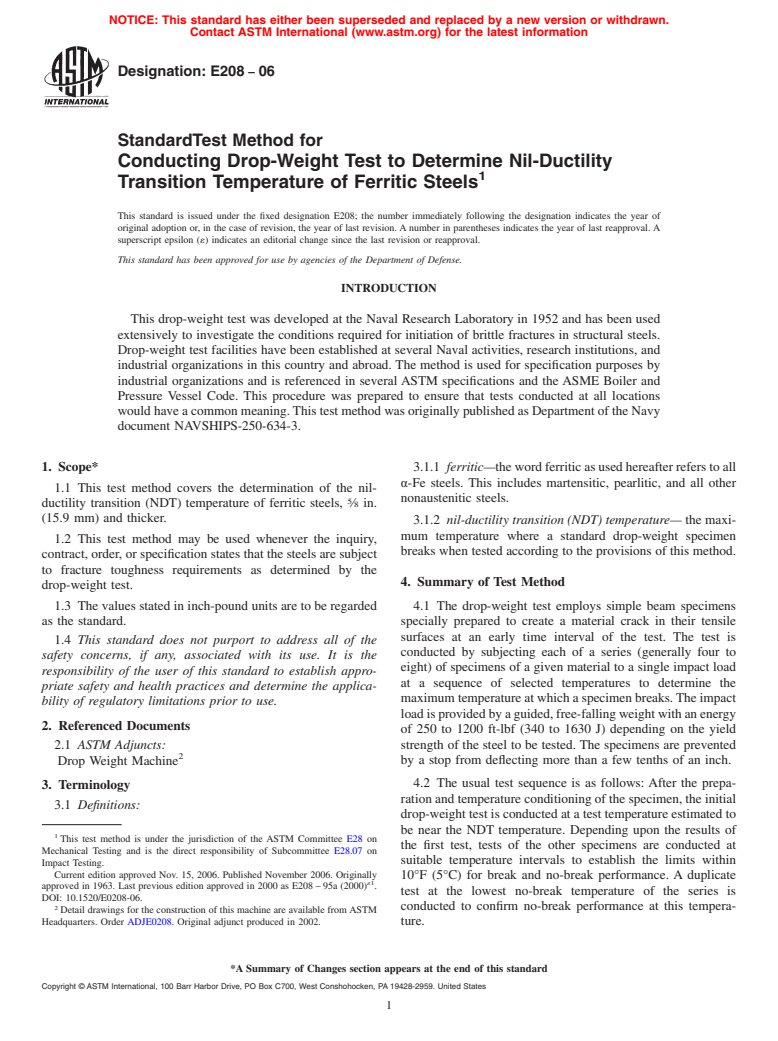

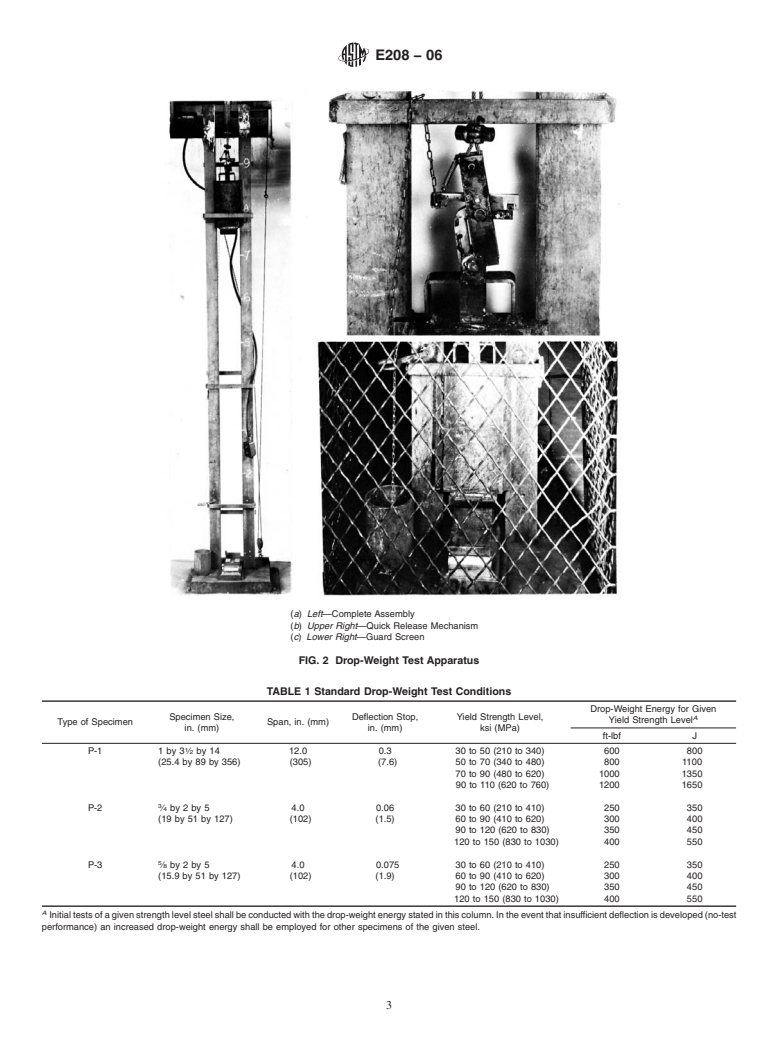

1.3 The values stated in inch-pound units are to be regarded 4.1 The drop-weight test employs simple beam specimens

as the standard. specially prepared to create a material crack in their tensile

surfaces at an early time interval of the test. The test is

1.4 This standard does not purport to address all of the

conducted by subjecting each of a series (generally four to

safety concerns, if any, associated with its use. It is the

eight) of specimens of a given material to a single impact load

responsibility of the user of this standard to establish appro-

at a sequence of selected temperatures to determine the

priate safety and health practices and determine the applica-

maximumtemperatureatwhichaspecimenbreaks.Theimpact

bility of regulatory limitations prior to use.

loadisprovidedbyaguided,free-fallingweightwithanenergy

2. Referenced Documents

of 250 to 1200 ft-lbf (340 to 1630 J) depending on the yield

2.1 ASTM Adjuncts: strength of the steel to be tested. The specimens are prevented

2

by a stop from deflecting more than a few tenths of an inch.

Drop Weight Machine

4.2 The usual test sequence is as follows: After the prepa-

3. Terminology

rationandtemperatureconditioningofthespecimen,theinitial

3.1 Definitions:

drop-weighttestisconductedatatesttemperatureestimatedto

be near the NDT temperature. Depending upon the results of

1

This test method is under the jurisdiction of the ASTM Committee E28 on

the first test, tests of the other specimens are conducted at

Mechanical Testing and is the direct responsibility of Subcommittee E28.07 on

suitable temperature intervals to establish the limits within

Impact Testing.

Current edition approved Nov. 15, 2006. Published November 2006. Originally

10°F (5°C) for break and no-break performance. A duplicate

´1

approved in 1963. Last previous edition approved in 2000 as E208–95a (2000) .

test at the lowest no-break temperature of the series is

DOI: 10.1520/E0208-06.

2 conducted to confirm no-break performance at this tempera-

Detail drawings for the construction of this machine are available fromASTM

Headquarters. Order ADJE0208. Original adjunct produced in 2002. ture.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E208 − 06

4.3 In 1984, the method of applying the crack-starter weld 6. Apparatus

bead was changed from a two-pass technique to the current

6.1 The drop-weight machine is of simple design based on

single-passprocedure,andthepracticeofrepair-weldingofthe

2

the use of readily available structural steel products. The

crack-starter weld bead was prohibited. For steels whose

principalcomponentsofadrop-weightmachineareavertically

properties are influen

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.