ASTM D4051-99

(Practice)Standard Practice for Preparation of Low-Pressure Gas Blends

Standard Practice for Preparation of Low-Pressure Gas Blends

SCOPE

1.1 This practice describes a laboratory procedure for the preparation of low-pressure multicomponent gas blends. The technique is applicable to the blending of components at percent levels and can be extended to lower concentrations by performing dilutions of a previously prepared base blend. The maximum blend pressure obtainable is dependent upon the range of the manometer used, but ordinarily is about 101 kPa (760 mm Hg). Components must not be condensable at the maximum blend pressure.

1.2 The possible presence of small leaks in the manifold blending system will preclude applicability of the method to blends containing part per million concentrations of oxygen or nitrogen.

1.3 This practice is restricted to those compounds that do not react with each other, the manifold, or the blend cylinder.

1.4 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statement, see Note 3.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: D 4051 – 99

Standard Practice for

Preparation of Low-Pressure Gas Blends

This standard is issued under the fixed designation D 4051; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Significance and Use

1.1 This practice describes a laboratory procedure for the 3.1 The laboratory preparation of gas blends of known

preparation of low-pressure multicomponent gas blends. The composition is required to provide primary standards for the

technique is applicable to the blending of components at calibration of chromatographic and other types of analytical

percent levels and can be extended to lower concentrations by instrumentation.

performing dilutions of a previously prepared base blend. The

4. Apparatus

maximum blend pressure obtainable is dependent upon the

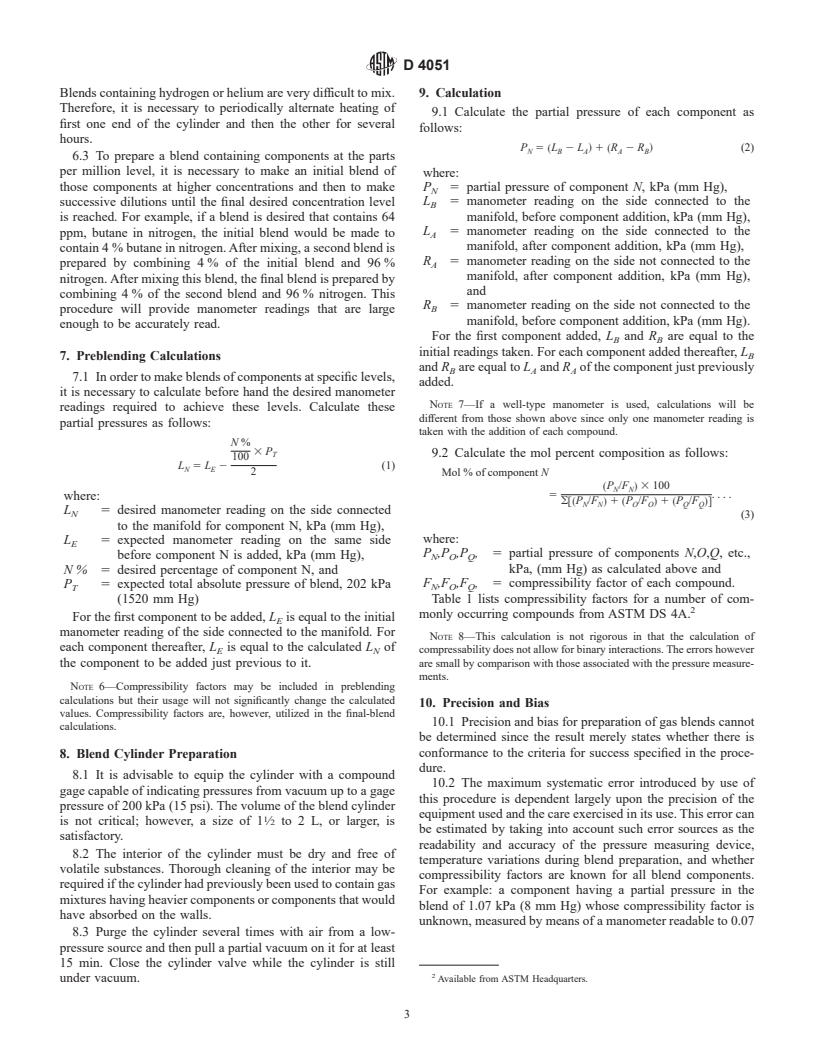

range of the manometer used, but ordinarily is about 101 kPa 4.1 Blending Manifold—Construct manifold as shown in

Fig. 1. Details of construction are not critical; that is, glass,

(760 mm Hg). Components must not be condensable at the

maximum blend pressure. pipe, or tubing with welded or compression fittings may be

used. The manifold must be leak free and arranged for

1.2 The possible presence of small leaks in the manifold

blending system will preclude applicability of the method to convenience of operation. More than one feedstock connection

point may be included if desired. Connections to the pump and

blends containing part per million concentrations of oxygen or

nitrogen. manometer shall follow accepted vacuum practice. Valves shall

have large enough apertures to permit adequate pumping in a

1.3 This practice is restricted to those compounds that do

not react with each other, the manifold, or the blend cylinder. reasonable length of time.

4.1.1 The finished manifold shall have a leak rate no greater

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the than 1 mm Hg/h (0.133 kPa/h).

4.2 Gage, open manometer, vacuum, or pressure, consisting

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica- of a full-length U-tube mounted on a vertically adjustable

meter scale.

bility of regulatory limitations prior to use.For specific hazard

statement, see Note 3.

NOTE 1—A well-type manometer such as the Miriam Model 30EB25

may be used in place of the U-tube manometer.

2. Summary of Practice

NOTE 2—A high-vacuum gage of the McLeod Manostat type pressure

2.1 Through the use of a blending manifold, the blend transducer ora0to2bar (absolute) may be included in the manifold

system to determine how well the system has been evacuated.

components are combined based upon partial pressure. Com-

ponents are added in order of ascending vapor pressure; that is,

4.2.1 Alternatively, an electronic pressure gage may be used

components of lowest vapor pressure are added first, with the

in place of a mercury manometer.

exception that components at concentrations of 5 % or less

4.3 Pump, high-vacuum, two-stage, capable of pumping

–4

would usually be added first. Compressibility factors are

down to a pressure of 1.33 3 10 kPa (0.1 μm).

applied to the component partial pressures to convert them

5. Reagents and Materials

from ideal to real gas. The real partial pressures, which are

proportional to gas volumes, are normalized to give mol

5.1 Blend Components high-purity, as required depending

percent composition of the blend.

on the composition of the proposed blend.

5.2 Mercury reagent grade, triple distilled.

NOTE 3—Warning: Mercury may be harmful if inhaled or swallowed.

This practice is under the jurisdiction of ASTM Committee D-2 on Petroleum

Products and Lubricantsand is the direct responsibility of Subcommittee D02.04 on

5.3 Nitrogen, high purity, as required, for purging and for

Hydrocarbon Analyses.

balance gas, where applicable.

Current edition approved Apr. 10, 1999. Published June 1999. Originally

e1

published as D 4051 – 81. Last previous edition D 4051 – 89 (1993) .

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 4051

FIG. 1 Manifold System

6. Procedure back to the feedstock cylinder valve. Assume this to be the

case; value 4 will, therefore, always be used as the feedstock

6.1 Connect the blend cylinder to the manifold at position A

control valve.

(see Fig. 1 for valve and position designations). Open valves 1,

6.1.4 When manifold evacuation is complete, close valve 1

2, 3, and 6 and evacuate the manifold system thoroughly.

and 4. Open the feedstock cylinder valve and then slowly open

Valves 4 and 5 are closed.

valve 4, allowing the second blend gas to flow into the

NOTE 4—A McLeod gage may be used at various times during the

manifold. Carefully watch the mercury level of the manometer.

procedure to determine how well the system has been evacuated and to

indicate if there are leaks present. Otherwise, a steady state condition of

NOTE 5—All additions should be made slowly to avoid temperature

the mercury in the manometer can be taken as an indication that an

changes.

acceptable vacuum has been attained.

6.1.5 When the pressure in the manifold is several pascals

6.1.1 When a good vacuum less than 0.01 kPa (0.1 mm Hg)

(or millimetres of mercury) higher than the previous reading

is reached, connect one or more blend component cylinders to

and is still slowly rising, slowly begin to open valve 3 so as to

the manifold at positions B or C, or both. Close valve 2 and

admit the component to the sample cylinder. Valve 4 will

open valves 4 and 5, thereby evacuating the connecting lines

remain partially open. Continue to open valve 3 while control-

up to the blend component cylinder valves. When a good

ling the flow through valve 4 until the next desired pressure

vacuum is again reached, close valves 4 and 5 and open the

level is reached, always maintaining a higher pressure in the

blend component cylinder valves. Ensure that the presure of

manifold than that in the cylinder. Close valve 4, allow the

any blend component delivered to valves 4 and 5 does not

pressure to equilibrate, and record the manometer reading from

exceed 200 kPa (1500 mm Hg). Record the initial pressure

both sides. Close valve 3. When additional components are to

readings from both sides of the manometer.

be included in the blend, repeat the procedures outlined above

6.1.2 The first component to be added will either have the

for each component.

lowest vapor pressure or will be present in the final blend at a

6.1.6 When all components have been added, and valve 3 is

concentration of 5 % or less. Assume that the first component

closed, evacuate the manifold, close valve 2 and disconnect the

feedstock is connected to manifold valve 4. Close valve 1 and

blend cylinder from the manifold at position A. To shut down

open valve 2. While carefully watching the mercury level in the

the apparatus, close the feedstock cylinder valve and open

manometer, slowly open valve 4. Allow the blend gas compo-

valve 4 to evacuate the connection. Close valve 4, remove the

nent to flow into the blend manifold until the desired precal-

feedstock cylinder, close valve 1 and by using valve 2 or 4

culated manometer reading is reached (see 7.1). Close valve 4

slowly admit air into the system until it is at atmospheric

and be sure that the pressure remains constant. Tap the

pressure.

manometer lightly to be certain the correct reading is obtained.

Record the reading of both sides of the manometer and then 6.2 The blend must be mixed before it is used. This can be

close valve 3. Open valve 1 and wait until the manifold is accomplished in several ways, one of which is to cause

thoroughly evacuated. convection currents to occur within the cylinder. This may

6.1.3 If the manifold includes o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.