ASTM E243-97(2004)e1

(Practice)Standard Practice for Electromagnetic (Eddy-Current) Examination of Copper and Copper-Alloy Tubes

Standard Practice for Electromagnetic (Eddy-Current) Examination of Copper and Copper-Alloy Tubes

SIGNIFICANCE AND USE

Eddy-current examination is a nondestructive method of locating discontinuities in a product. Signals can be produced by discontinuities located either on the external or internal surface of the tube or by discontinuities totally contained within the walls. Since the density of eddy currents decreases nearly exponentially as the distance from the external surface increases, the response to deep-seated defects decreases.

Some indications obtained by this method may not be relevant to product quality; for example, a reject signal may be caused by minute dents or tool chatter marks that are not detrimental to the end use of the product. Irrelevant indications can mask unacceptable discontinuities. Relevant indications are those which result from nonacceptable discontinuities. Any indication above the reject level that is believed to be irrelevant shall be regarded as unacceptable until it is demonstrated by re-examination or other means to be irrelevant (see 10.3.2).

Eddy-current examination systems are generally not sensitive to discontinuities adjacent to the ends of the tube (end effect). On-line eddy-current examining would not be subject to end effect.

Discontinuities such as scratches or seams that are continuous and uniform for the full length of the tube may not always be detected.

SCOPE

1.1 This practice covers the procedures that shall be followed in eddy-current examination of copper and copper-alloy tubes for detecting discontinuities of a severity likely to cause failure of the tube. These procedures are applicable for tubes with outside diameters to 31/8 in. (79.4 mm), inclusive, and wall thicknesses from 0.017 in. (0.432 mm) to 0.120 in. (3.04 mm), inclusive, or as otherwise stated in ASTM product specifications; or by other users of this practice. These procedures may be used for tubes beyond the size range recommended, upon contractual agreement between the purchaser and the manufacturer.

1.2 The procedures described in this practice are based on methods making use of encircling annular test coil systems.

1.3 The values stated in inch-pound units are to be regarded as the standard. Note 1-This practice may be used as a guideline for the examination, by means of internal probe test coil systems, of installations using tubular products where the outer surface of the tube is not accessible. For such applications, the technical differences associated with the use of internal probe coils should be recognized and accommodated. The effect of foreign materials on the tube surface and signals due to tube supports are typical of the factors that must be considered.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation:E243–97 (Reapproved 2004)

Standard Practice for

Electromagnetic (Eddy-Current) Examination of Copper and

Copper-Alloy Tubes

This standard is issued under the fixed designation E243; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

e NOTE—Editorial changes were made throughout the standard in January 2004.

1. Scope 2. Referenced Documents

2 3

1.1 This practice covers the procedures that shall be 2.1 ASTM Standards:

followed in eddy-current examination of copper and copper- B111 Specification for Copper and Copper-Alloy Seamless

alloy tubes for detecting discontinuities of a severity likely to Condenser Tubes and Ferrule Stock

cause failure of the tube. These procedures are applicable for B395 Specification for U-Bend Seamless Copper and Cop-

tubes with outside diameters to 3 ⁄8 in. [79.4 mm], inclusive, per Alloy Heat Exchanger and Condenser Tubes

and wall thicknesses from 0.017 in. [0.432 mm] to 0.120 in. B543 Specification for Welded Copper and Copper-Alloy

[3.04 mm], inclusive, or as otherwise stated inASTM product Heat Exchanger Tube

specifications; or by other users of this practice. These proce- E543 Practice for Evaluating Agencies that Perform Non-

dures may be used for tubes beyond the size range recom- destructive Testing

mended, upon contractual agreement between the purchaser E1316 Terminology for Nondestructive Examinations

and the manufacturer. 2.2 Other Documents:

1.2 The procedures described in this practice are based on SNT-TC-1A Recommended Practice for Nondestructive

methods making use of encircling annular examination coil Testing Personnel Qualification and Certification

systems. ANSI/ASNTCP-189 ASNT Standard for Qualification and

1.3 The values stated in inch-pound units are to be regarded Certification of Nondestructive Testing Personnel

as the standard. NAS-410 NAS Certification and Qualification of Nonde-

structive Personnel (Quality Assurance Committee)

NOTE 1—This practice may be used as a guideline for the examination,

bymeansofinternalprobeexaminationcoilsystems,ofinstallationsusing

3. Terminology

tubular products where the outer surface of the tube is not accessible. For

3.1 Definitions of Terms Specific to this Standard

such applications, the technical differences associated with the use of

internal probe coils should be recognized and accommodated. The effect 3.1.1 The following terms are defined in relation to this

of foreign materials on the tube surface and signals due to tube supports

standard.

are typical of the factors that must be considered.

3.1.1.1 artificial discontinuity reference standard—a stan-

1.4 This standard does not purport to address all of the dard consisting of a selected tube with defined artificial

safety concerns, if any, associated with its use. It is the discontinuities, used when adjusting the system controls to

responsibility of the user of this standard to establish appro- obtain some predetermined system output signal level. This

priate safety and health practices and determine the applica- standard may be used for periodic checking of the instrument

bility of regulatory limitations prior to use. during an examination.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

This practice is under the jurisdiction of ASTM Committee E07 on Nonde- contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

structive Testing and is the direct responsibility of Subcommittee E07.07 on Standards volume information, refer to the standard’s Document Summary page on

Electromagnetic Methods. the ASTM website.

Current edition approved January 1, 2004. Published February 2004. Originally AvailablefromTheAmericanSocietyforNondestructiveTesting(ASNT),P.O.

approved in 1967. Last previous edition approved in 1997 as E243-97. Box 28518, 1711 Arlingate Ln., Columbus, OH 43228-0518.

2 5

For ASME Boiler and Pressure Vessel Code applications see related Practice Available from Aerospace Industries Association of America, Inc., 1250 Eye

SE-243 in the Code. St., NW, Washington, DC 20005.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

E243–97 (2004)

3.1.1.2 percent maximum unbalance standardization indicationabovetherejectlevelthatisbelievedtobeirrelevant

standard—a method of standardization that can be used with shall be regarded as unacceptable until it is demonstrated by

speed-insensitive instruments (see 3.1.1.4). The acceptance re-examination or other means to be irrelevant (see 10.3.2).

level of the examination is established at the operating exami- 5.3 Eddy-current examination systems are generally not

nation frequency as an accurate fraction of the maximum sensitivetodiscontinuitiesadjacenttotheendsofthetube(end

unbalance signal resulting from the end effect of a tube. Any effect). On-line eddy-current examining would not be subject

low-noise tube from the production run having a squared end to end effect.

may be used as this standard. This standard may be used for 5.4 Discontinuities such as scratches or seams that are

periodic checking of the instrument during an examination. continuous and uniform for the full length of the tube may not

3.1.1.3 electrical center—thecenterestablishedbytheelec- always be detected.

tromagnetic field distribution within the examination coil. A

6. Basis of Application

constant-intensity signal, irrespective of the circumferential

position of a discontinuity, is indicative of electrical centering. 6.1 Personnel Qualification—Nondestructivetesting(NDT)

The electrical center may be different from the physical center personnel shall be qualified in accordance with a nationally

of the examination coil. recognized NDT personnel qualification practice or standard

3.1.1.4 speed-sensitive equipment—examination equipment

such as ANSI/ASNT CP-189, SNT-TC-1A, MIL-STD-410,

that produces a variation in signal response with variations in NAS-410,orasimilardocument.Thepracticeorstandardused

theexaminationspeed.Speed-insensitiveequipmentprovidesa

and its applicable revision shall be specified in the purchase

constant signal response with changing examination speeds. specification or contractual agreement between the using

3.1.1.5 off-line examining—eddy-current examinations con- parties.

ducted on equipment that includes the examination coil and

NOTE 2—MIL-STD-410 is canceled and has been replaced with NAS-

means to propel individual tubes under examination through

410,however,itmaybeusedwithagreementbetweencontractingparties.

the coil at appropriate speeds and conditions.

6.2 Qualification of Nondestructive Testing Agencies—If

3.1.1.6 on-line examining—eddy-current examinations con-

specified in the purchase specification or contractual agree-

ducted on equipment that includes the examination coil and

ment, NDT agencies shall be evaluated and qualified as

means to propel tubes under examination through the coil at

described in Practice E543. The applicable edition of Practice

appropriate speeds and conditions as an integral part of a

E543 shall be identified in the purchase specification or

continuous tube manufacturing sequence.

contractual agreement between the using parties.

3.2 Definitions of Terms—Refer to Terminology E1316 for

definitions of terms that are applicable to nondestructive

7. Apparatus

examinations in general.

7.1 Electronic Apparatus—The electronic apparatus shall

be capable of energizing the examination coil with alternating

4. Summary of Practice

currents of suitable frequencies (for example, 1 kHz to 125

4.1 Examining is usually performed by passing the tube

kHz), and shall be capable of sensing the changes in the

lengthwise through a coil energized with alternating current at

electromagnetic response of the coils. Electrical signals pro-

one or more frequencies. The electrical impedance of the coil

duced in this manner are processed so as to actuate an audio or

is modified by the proximity of the tube, the tube dimensions,

visual signaling device or mechanical marker which produces

electrical conductivity and magnetic permeability of the tube

a record.

material,andmetallurgicalormechanicaldiscontinuitiesinthe

7.2 Examination Coils—Examination coils shall be capable

tube. During passage of the tube, the changes in electromag-

of inducing current in the tube and sensing changes in the

netic response caused by these variables in the tube produce

electrical characteristics of the tube. The examination coil

electrical signals which are processed so as to actuate an audio

diameter should be selected to yield the largest practical

or visual signaling device or mechanical marker which pro-

fill-factor.

duces a record.

7.3 Driving Mechanism—A mechanical means of passing

5. Significance and Use the tube through the examination coil with minimum vibration

of the examination coil or the tube. The device shall maintain

5.1 Eddy-currentexaminationisanondestructivemethodof

the tube substantially concentric with the electrical center of

locating discontinuities in a product. Signals can be produced

theexaminationcoil.Auniformspeed(65.0%speedvariation

by discontinuities located either on the external or internal

maximum) shall be maintained.

surface of the tube or by discontinuities totally contained

7.4 End Effect Suppression Device—A means capable of

within the walls. Since the density of eddy currents decreases

suppressing the signals produced at the ends of the tube.

nearly exponentially as the distance from the external surface

IndividualASTM product specifications shall specify when an

increases, the response to deep-seated defects decreases.

end effect suppression device is mandatory.

5.2 Some indications obtained by this method may not be

relevanttoproductquality;forexample,arejectsignalmaybe

NOTE 3—Signals close to the ends of the tube may carry on beyond the

caused by minute dents or tool chatter marks that are not

limits of end suppression. Refer to 9.5.

detrimentaltotheenduseoftheproduct.Irrelevantindications

8. Reference Standards

can mask unacceptable discontinuities. Relevant indications

arethosewhichresultfromnonacceptablediscontinuities.Any 8.1 Artificial Discontinuity Reference Standard:

e1

E243–97 (2004)

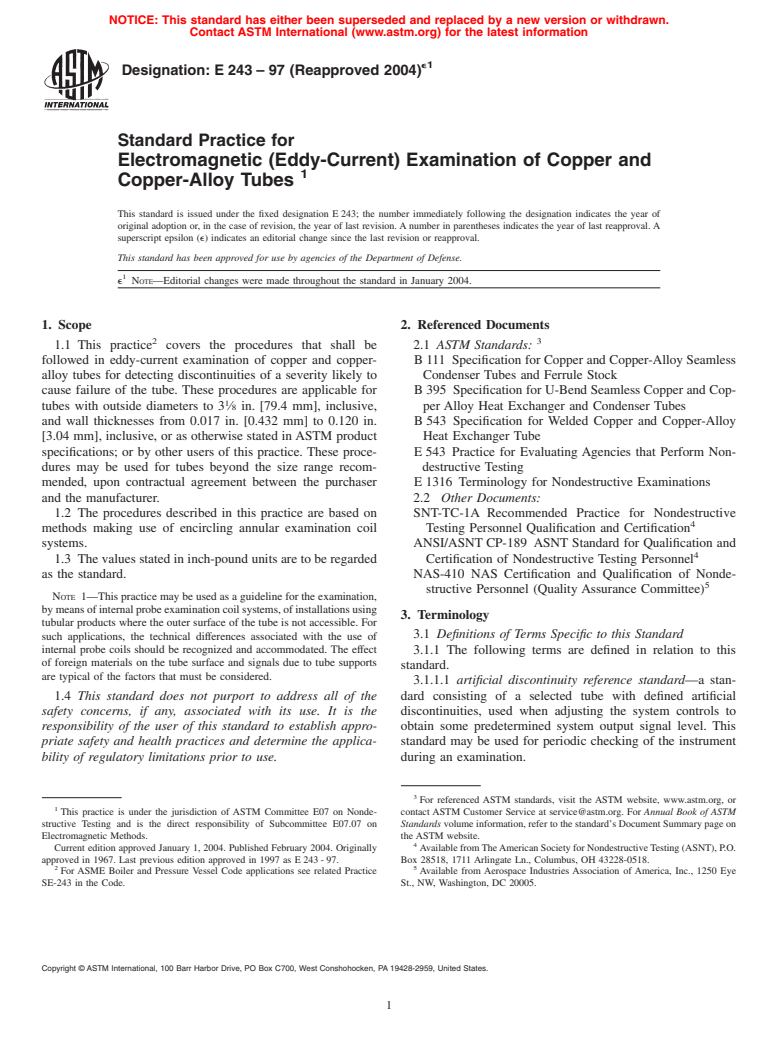

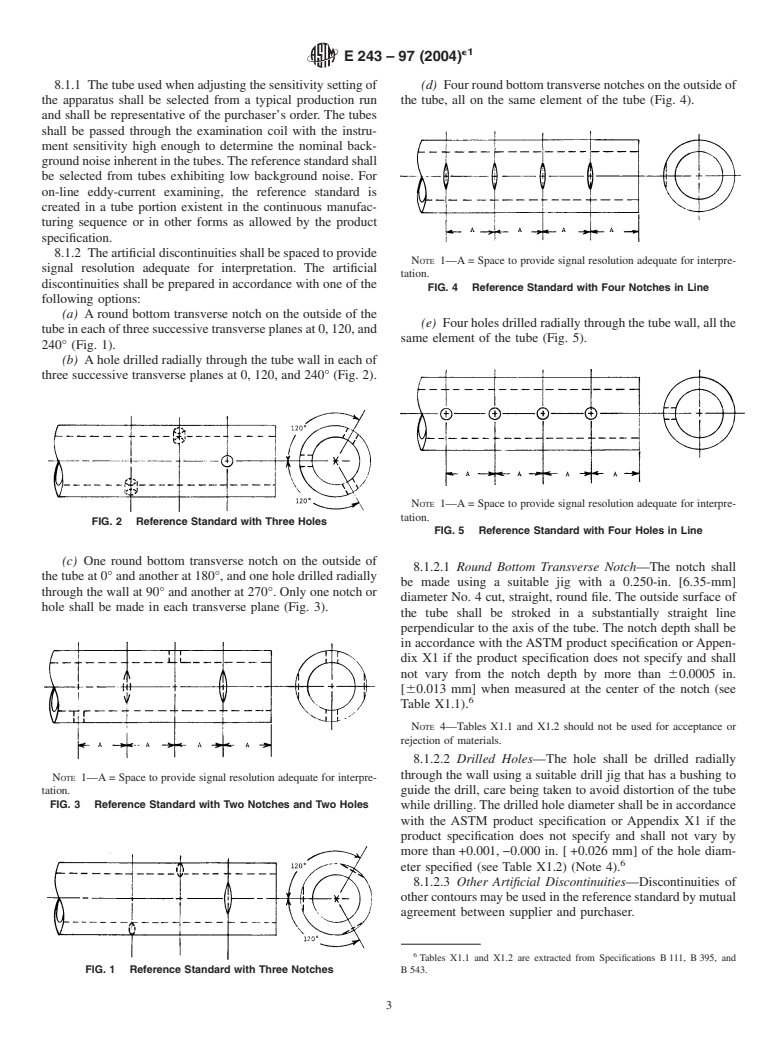

8.1.1 Thetubeusedwhenadjustingthesensitivitysettingof (d) Fourroundbottomtransversenotchesontheoutsideof

the apparatus shall be selected from a typical production run the tube, all on the same element of the tube (Fig. 4).

and shall be representative of the purchaser’s order. The tubes

shall be passed through the examination coil with the instru-

ment sensitivity high enough to determine the nominal back-

groundnoiseinherentinthetubes.Thereferencestandardshall

be selected from tubes exhibiting low background noise. For

on-line eddy-current examining, the reference standard is

created in a tube portion existent in the continuous manufac-

turing sequence or in other forms as allowed by the product

specification.

8.1.2 Theartificialdiscontinuitiesshallbespacedtoprovide

NOTE 1—A= Space to provide signal resolution adequate for interpre-

signal resolution adequate for interpretation. The artificial

tation.

discontinuities shall be prepared in accordance with one of the

FIG. 4 Reference Standard with Four Notches in Line

following options:

(a) Around bottom transverse notch on the outside of the

(e) Fourholesdrilledradiallythroughthetubewall,allthe

tubeineachofthreesuccessivetransverseplanesat0,120,and

same element of the tube (Fig. 5).

240° (Fig. 1).

(b) Ahole drilled radially through the tube wall in each of

three successive transverse planes at 0, 120, and 240° (Fig. 2).

NOTE 1—A= Space to provide signal resolution adequate for interpre-

tation.

FIG. 2 Reference Standard with Three Holes

FIG. 5 Reference Standard with Four Holes in Line

(c) One round bottom transverse notch on the outside of

8.1.2.1 Round Bottom Transverse Notch—The notch shall

thetubeat0°andanotherat180°,andoneholedrilledradially

be made using a suitable jig with a 0.250-in. [6.35-mm]

through the wall at 90° and another at 270°. Only one notch or

diameter No. 4 cut, straight, round file. The outside surface of

hole shall be made in each transverse plane (Fig. 3).

the tube shall be stroked in a substantially straight line

perpendicular to the axis of the tube. The notch depth shall be

in accordance with theASTM product specification orAppen-

dix X1 if the product specification does not specify and shall

not vary from the notch depth by more than 60.0005 in.

[60.013 mm] when measured at the center of the notch (see

Table X1.1).

NOTE 4—Tables X1.1 and X1.2 should not be used for acceptance or

rejection of materials.

8.1.2.2 Drilled Holes—The hole shall be drilled radially

through the wall using a suitable drill jig that has a bushing to

NOTE 1—A= Space to provide signal resolution adequate for interpre-

tation. guide the drill, care being taken to avoid distortion of the tube

FIG. 3 Reference Standard with Two Notches and Two Holes

whiledrilling.Thedrilledholediametershallbeinaccordance

with the ASTM product specification or Appendix X1 if the

product specification does not specify and shall not vary by

more than+0.001,−0.000 in. [+0.026 mm] of the hole diam-

eter specified (see Table X1.2) (Note 4).

8.1.2.3 Other Artificial Discontinuities—Discontinuities of

othercontoursmaybeusedinthereferencestandardbymutual

agreement between supplier and purchaser.

Tables X1.1 and X1.2 are extracted from Specifications B111, B395, and

FIG. 1 Reference Standard with Three Notches B543.

e1

E243–97 (2004)

8.2 Percent Maximum Unbalance Reference Standard— 9.5 Determine the length of tubing requiring suppression of

This method of standardization shall be used only with end effect signals by selecting a tube of low background noise

speed-insensitive equipment, and equipment specifically de- and making a series of reference holes or notches at 0.5-in.

signed or adapted to accommodate the use of this calibration [12.7-mm] intervals near the end of this special tube. Pass the

method. Maximum unbalance of differential coils is obtained tube through the examination coil at the production examina-

by placing the squared end of a tube in only one of the tion speed with the artificial discontinuities end first, and then

differential coils and using an accurately calibrated attenuator with the artificial discontinuities end last. Determine

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.