ASTM F660-83(2002)e1

(Practice)Standard Practice for Comparing Particle Size in the Use of Alternative Types of Particle Counters

Standard Practice for Comparing Particle Size in the Use of Alternative Types of Particle Counters

SCOPE

1.1 This practice provides a procedure for comparing the sizes of nonspherical particles in a test sample determined with different types of automatic particle counters, which operate on different measuring principles.

1.2 A scale factor is obtained by which, in the examination of a given powder, the size scale of one instrument may be multiplied to agree with the size scale of another.

1.3 The practice considers rigid particles, free of fibers, of the kind used in studies of filtration, such as: commercially available test standards of quartz or alumina, or fly ash, or some powdered chemical reagent, such as iron oxide or calcium sulfate.

1.4 Three kinds of automatic particle counters are considered:

1.4.1 Image analyzers, which view stationary particles under the microscope and, in this practice, measure the longest end-to-end distance of an individual particle.

1.4.2 Optical counters, which measure the area of a shadow cast by a particle as it passes by a window; and

1.4.3 Electrical resistance counters, which measure the volume of a particle as it passes through an orifice in an electrically conductive liquid.

1.5 This practice also considers the use of instruments that provide sedimentation analyses, which is to say provide measures of the particle mass distribution as a function of Stokes diameter. The practice provides a way to convert mass distribution into number distribution so that the meaning of Stokes diameter can be related to the diameter measured by the instruments in 1.4.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation:F660–83(Reapproved2002)

Standard Practice for

Comparing Particle Size in the Use of Alternative Types of

Particle Counters

This standard is issued under the fixed designation F 660; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Keywords were added editorially in January 2002.

1. Scope 2. Referenced Documents

1.1 This practice provides a procedure for comparing the 2.1 ASTM Standards:

sizes of nonspherical particles in a test sample determined with F 661 Practice for Particle Count and Size Distribution

different types of automatic particle counters, which operate on MeasurementinBatchSamplesforFilterEvaluationUsing

different measuring principles. an Optical Particle Counter

1.2 A scale factor is obtained by which, in the examination F 662 Method for Measurement of Particle Count and Size

of a given powder, the size scale of one instrument may be Distribution in Batch Samples for Filter Evaluation Using

multiplied to agree with the size scale of another. an Electrical Resistance Particle Counter

1.3 The practice considers rigid particles, free of fibers, of F 796 Practice for Determining the Performance of a Filter

the kind used in studies of filtration, such as: commercially Medium Employing a Single-Pass, Constant-Rate, Liquid

available test standards of quartz or alumina, or fly ash, or Test

some powdered chemical reagent, such as iron oxide or

3. Summary of Practice

calcium sulfate.

1.4 Three kinds of automatic particle counters are consid- 3.1 After calibrating an automatic particle counter with

standard spherical particles, such as latex beads, the instrument

ered:

1.4.1 Image analyzers, which view stationary particles un- is presented with a known weight of filtration-test particles

from which is obtained the data: cumulative number of

der the microscope and, in this practice, measure the longest

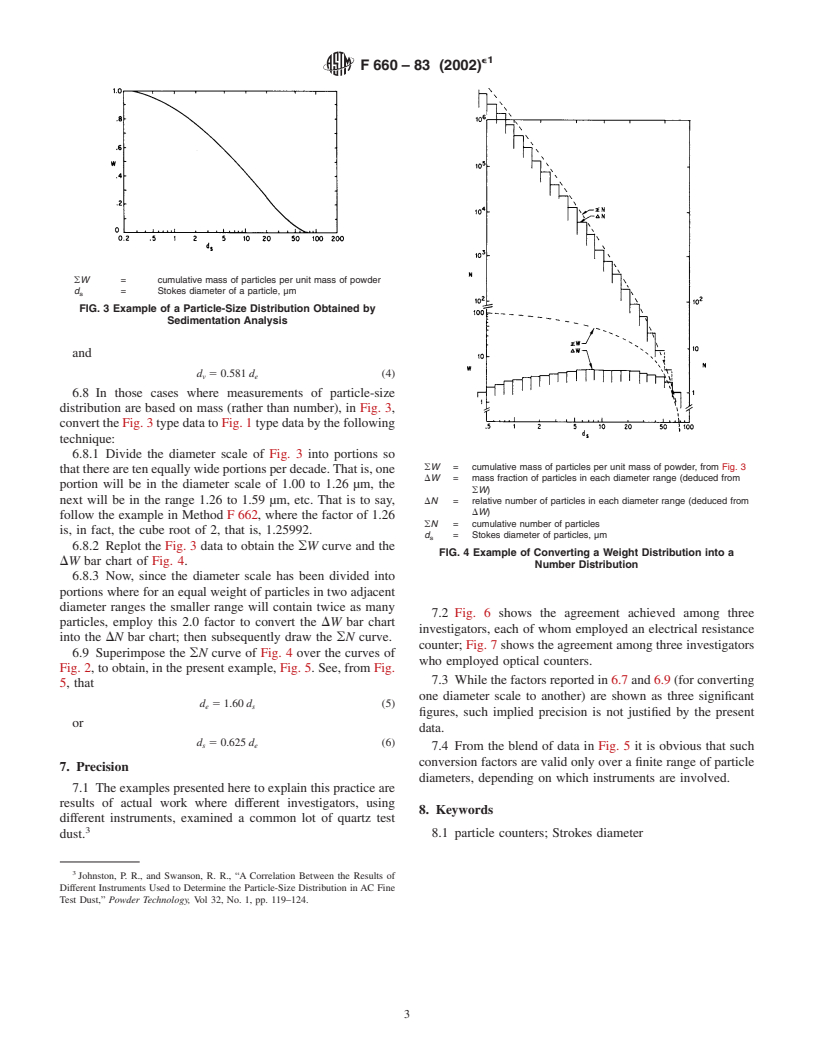

end-to-end distance of an individual particle. particles, (N, as a function of particle diameter, d; and a plot

1.4.2 Optical counters, which measure the area of a shadow of these data is made on log-log paper.

3.2 The plot from the results of one kind of instrument is

cast by a particle as it passes by a window; and

1.4.3 Electrical resistance counters, which measure the vol- placed over the plot from another and one plot is moved along

the particle-diameter axis until the two separate curves coin-

ume of a particle as it passes through an orifice in an

electrically conductive liquid. cide. (If the two separate curves cannot be made to coincide,

then this practice cannot be used.)

1.5 This practice also considers the use of instruments that

provide sedimentation analyses, which is to say provide 3.3 The magnitude of the shift from one diameter scale to

the other provides the scale-conversion factor.

measures of the particle mass distribution as a function of

Stokes diameter. The practice provides a way to convert mass 3.4 Any of the three particle counters in 1.4 can provide the

frame-of-reference measurement of particle diameter.

distribution into number distribution so that the meaning of

Stokes diameter can be related to the diameter measured by the 3.5 An alternative reference is the Stokes diameter, as

mentioned in 1.5.

instruments in 1.4.

1.6 This standard does not purport to address all of the

4. Significance and Use

safety concerns, if any, associated with its use. It is the

4.1 This practice supports test methods designed to evaluate

responsibility of the user of this standard to establish appro-

the performance of fluid-filter media, for example, Practice

priate safety and health practices and determine the applica-

F 796 wherein particle size distributions are addressed and at

bility of regulatory limitations prior to use.

the same time this practice provides a means to compare size

measurements obtained from several different types of instru-

ments.

This practice is under the jurisdiction of ASTM Committee D19 on Water and

is the direct responsibility of Subcommittee D19.07 on Sediments, Geomorphology,

and Open-Channel Flow.

Current edition approved Jan. 10, 2002. Published March 1983. Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

F660–83 (2002)

4.2 The factor for converting one kind of diameter scale to

another is only valid for the specific test particles studied.

5. Apparatus

5.1 Automatic Particle Counters:

5.1.1 Any, or all, of the three types are employed:

5.1.1.1 The Image Analyzer—This instrument counts par-

ticlesbysizeasthoseparticleslieonamicroscopeslide.Inthis

practice, size means the longest end-to-end distance. This

diameter, in the examples to follow, is designated d .

e

5.1.1.2 TheOpticalCounter—This instrument measures the

area of a shadow cast by a particle as it passes a window. From

thatareatheinstrumentreportsthediameterofacircleofequal

area. This diameter is designated d . See Practice F 661.

o

5.1.1.3 The Electrical Resistance Counter— This instru-

ment measures the volume of an individual particle. From that

volumetheinstrumentreportsthediameterofasphereofequal

volume. This diameter is designated d . See Method F 662.

v

5.2 Sedimentation Instruments—These instruments provide

a measure of the mass distribution of particles (as opposed to

the number distributions determined in 5.1). This diameter, the

Stokes diameter, is designated d .

s

6. Procedure

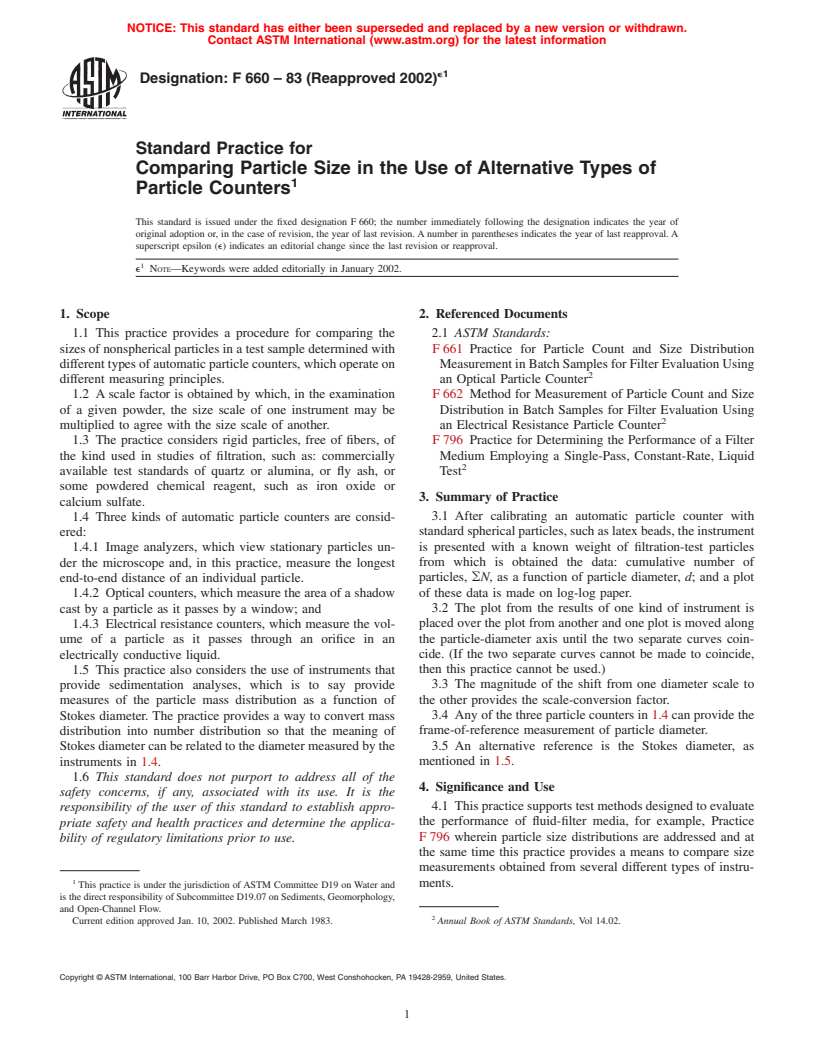

(N = cumulative number of particles per unit mass of powder

6.1 Calibrate each particle counter with standard, spherical

d = particle diameter (see 5.1)

particles, following the instructions of the manufacturer of the

The solid line represents the “real” count.The broken lines represent failures

counter.

to obtain correct counts because of either presenting too many particles to the

6.2 Presentaknownmassofparticlestothecounter.Thatis,

counter, a, or of presenting too few, b.

with the image analyzer present a known mass of particles to

FIG. 1 Example of Particle Counts

a field of view; and, with the other counters present a liquid

suspension with a known mass concentration of particles.

6.3 In counting particles at the small-diameter end of the

spectrum, present at least three different, relatively small,

masses of particles. In counting particles at the large-diameter

end, present at least three different, relatively large, masses.

6.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.