ASTM B3-01(2007)

(Specification)Standard Specification for Soft or Annealed Copper Wire

Standard Specification for Soft or Annealed Copper Wire

ABSTRACT

This specification covers drawn and annealed or soft round bare copper wire for electrical purposes. The matterial shall be copper of such quality and purity that the finished product shall have the properties and characteristics prescribed. Tensile strength, elongation, and resistivity of the wires shall be determined. A micrometer caliper equipped with a vernier shall be used to measure the material dimensions. The wires shall be subjected to surface finish and shall conform to the particularized requirements.

SCOPE

1.1 This specification covers drawn and annealed or soft round bare copper wire for electrical purposes (see Explanatory Note 1).

1.2 The values stated in inch-pound or SI units are to be regarded separately as standard. Each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the specification. For conductor sizes designated by AWG or kcmil sizes, the requirements in SI units are numerically converted from the corresponding requirements in inch-pound units. For conductor sizes designation by AWG or kcmil, the requirements in SI units have been numerically converted from corresponding values stated or derived in inch-pound units. For conductor sizes designated by SI units only, the requirements are stated or derived in SI units.

1.2.1 For density, resistivity and temperature, the values stated in SI units are to be regarded as standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B3 −01(Reapproved 2007)

Standard Specification for

1

Soft or Annealed Copper Wire

This standard is issued under the fixed designation B3; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2.3 National Institute of Standards and Technology:

3

NBS Handbook 100—Copper Wire Tables

1.1 This specification covers drawn and annealed or soft

roundbarecopperwireforelectricalpurposes(seeExplanatory

3. Ordering Information

Note 1).

3.1 Orders for material under this specification shall include

1.2 The values stated in inch-pound or SI units are to be

the following information:

regarded separately as standard. Each system shall be used

3.1.1 Quantity of each size,

independently of the other. Combining values from the two

3.1.2 Wire size: diameter in inches (see 5.4 and Table 1),

systems may result in non-conformance with the specification.

3.1.3 Type of copper, if special (Section 4),

For conductor sizes designated by AWG or kcmil sizes, the

3.1.4 Package size (see 10.1),

requirements in SI units are numerically converted from the

3.1.5 Special package marking, if required, and

correspondingrequirementsininch-poundunits.Forconductor

3.1.6 Place of inspection (see 9.1).

sizes designation by AWG or kcmil, the requirements in SI

units have been numerically converted from corresponding

4. Materials and Manufacture

values stated or derived in inch-pound units. For conductor

4.1 The material shall be copper of such quality and purity

sizesdesignatedbySIunitsonly,therequirementsarestatedor

that the finished product shall have the properties and charac-

derived in SI units.

teristics prescribed in this specification.

1.2.1 For density, resistivity and temperature, the values

stated in SI units are to be regarded as standard.

NOTE 1—The following standards define the materials suitable for use:

Specification B49.

2. Referenced Documents

4.2 Copper bars of special qualities, forms, or types, as may

be agreed upon between the manufacturer and the purchaser,

2.1 The following documents of the issue in effect at the

and which will conform to the requirements prescribed in this

time of reference form a part of this specification to the extent

specification may also be used.

referenced herein:

2

2.2 ASTM Standards:

5. General Requirements (see Section 7)

B49 Specification for Copper Rod Drawing Stock for Elec-

5.1 Tensile Strength and Elongation—The wire shall con-

trical Purposes

form to the requirements for elongation prescribed in Table 1

B193 Test Method for Resistivity of Electrical Conductor

(see Explanatory Note 2). No requirements for tensile strength

Materials

are specified. For wire whose nominal diameter is more than

B258 Specification for Nominal Diameters and Cross-

0.001 in. (0.025 mm) greater than a size listed in Table 1, but

SectionalAreasofAWGSizesofSolidRoundWiresUsed

less than that of the next larger size, the requirements of the

as Electrical Conductors

next larger size shall apply.

5.2 Joints—Necessary joints in the completed wire and in

1 the wire and rods prior to final drawing shall be made in

This specification is under the jurisdiction of ASTM Committee B01 on

Electrical Conductorsand is the direct responsibility of Subcommittee B01.04 on accordance with the best commercial practice.

Conductors of Copper and Copper Alloys.

5.3 Resistivity—The electrical resistivity 20°C shall not

Current edition approved March 15, 2007. Published April 2007. Originally

2 2

approved in 1912. Last previous edition approved in 2001 as B3 – 01. DOI: exceed 875.20Ω·lb/mile (0.15328Ω·g/m ).

10.1520/B0003-01R07.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from the National Technical Information Service, 5285 Port Royal

the ASTM website. Rd, Springfield, VA 22161.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B3−01 (2007)

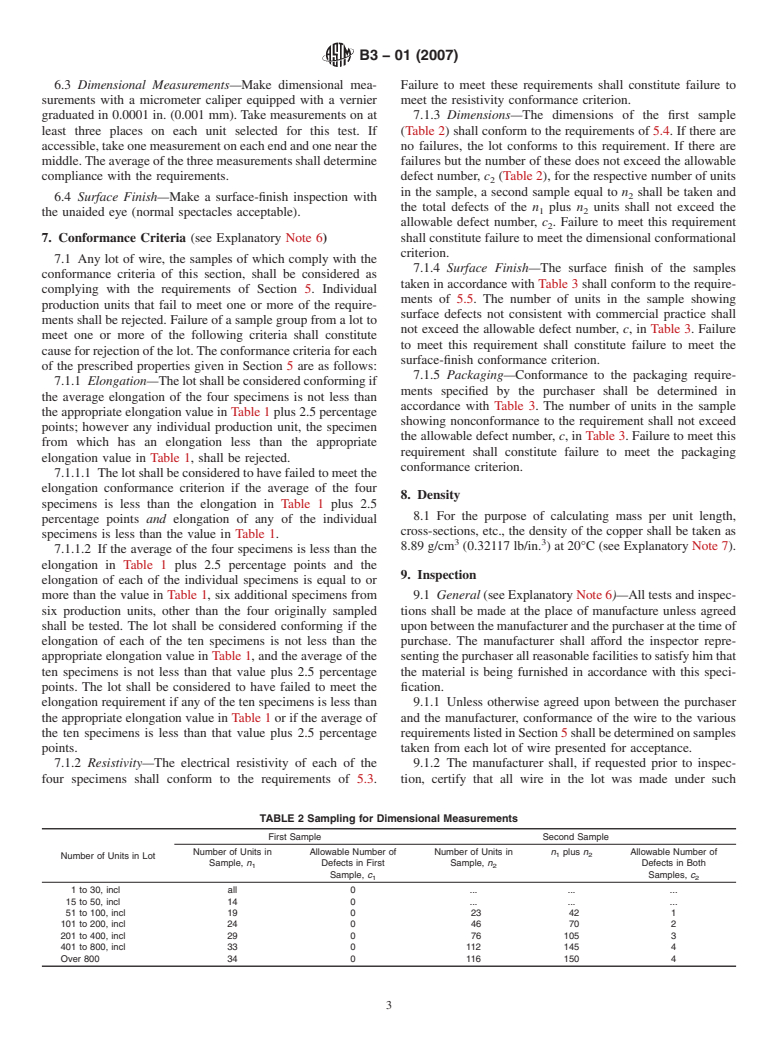

TABLE 1 Tensile Requirements

Diameter Area at 20°C Elongation in

2 2

in. mm cmils in. mm 10 in.

(254 mm),

%min

0.4600 11.684 211 600 0.1662 107.0 35

0.4096 10.404 167 800 0.1318 85.0 35

0.3648 9.266 133 100 0.1045 67.4 35

0.3249 8.252 105 600 0.08291 53.5 35

0.2893 7.348 83 690 0.06573 42.4 30

0.2576 6.543 66 360 0.05212 33.6 30

0.2294 5.827 52 620 0.04133 26.7 30

0.2043 5.189 41 740 0.03278 21.2 30

0.1819

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.