ASTM D6395-11

(Test Method)Standard Test Method for Flatwise Flexural Impact Resistance of Rigid Plastics (Withdrawn 2019)

Standard Test Method for Flatwise Flexural Impact Resistance of Rigid Plastics (Withdrawn 2019)

SIGNIFICANCE AND USE

The flatwise flexural impact test is a test in which the kinetic energy lost by a moving pendulum during impact is used to determine the energy to break or deform a test specimen.

The standard Izod test apparatus as described in Test Method D256 is retrofitted with clamping jaws, which hold the test specimen such that the flat face of the specimen is struck by the pendulum during a test.

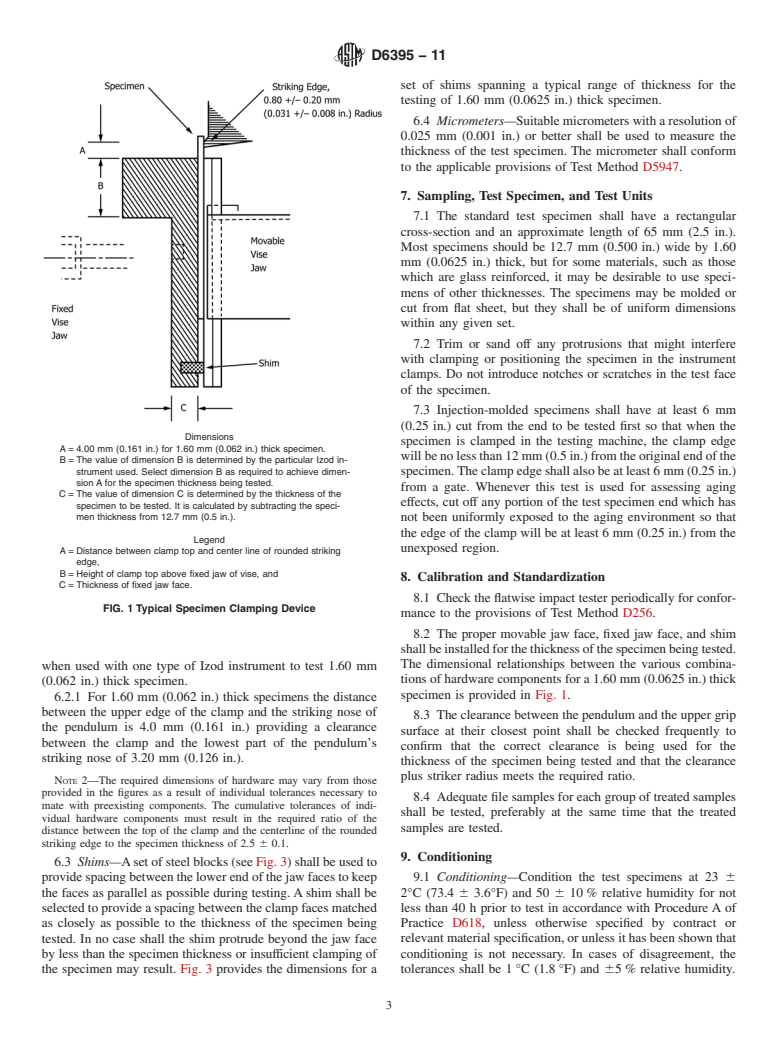

The pendulum shall be a standard Izod pendulum as described in Test Method D256. It shall be capable of delivering an energy of 2.71 ± 0.14 J (2.00 ± 0.10 ft.-lbf). Except as detailed in 10.5, this basic pendulum shall be used with all specimens that extract less than 85 % of the available energy. Higher energy pendulums or a basic pendulum to which weights are added to increase its available energy shall be used with specimens that require more energy to break. A series of energy levels such that each has twice the energy of the next lighter one will be found convenient. The striking nose of the pendulum shall contact one of the flat faces of the specimen at a specified distance above the clamp edge. The ratio of the distance between the top of the clamp and the centerline of the rounded striking edge to the specimen thickness shall be 2.5 ± 0.1.

The type of failure of each specimen tested shall be assigned one of the following categories:

Complete Break (C) A break in which the specimen is separated into two or more pieces.

Hinge Break (H)A nearly complete break in which there is little or no spring back when the free end is bent or displaced.

Partial Break (P)An incomplete break in which fracture extends through at least 50 % of the specimen thickness, and such that the free end can be bent with relatively little effort yet has considerable spring back.

Nonbreak (N)A result where there is no fracture or the fracture extends less than 50 % of the specimen thickness.

The value of this impact test is to determine the change in impact properties that may result from a mat...

SCOPE

1.1 The resistance of plastics to breakage by flexural shock may be determined by test methods such as those contained in Test Method D256. Specimens used in those test methods feature a milled notch to promote brittle fracture. The test specimens are struck by a pendulum with the depth dimension parallel to the direction of pendulum swing. This test method is differentiated from the others by its application to the assessment of the affect on impact resistance of changes in the surface of specimens resulting from weathering or other exposure. In this test method, specimens are struck by a pendulum with the depth dimension perpendicular to the direction of pendulum swing. Test Method D5420 may also be used to conduct testing of weathered or exposed specimens. This test method is differentiated from Gardner Impact by the smaller size of the specimens, which may result in substantially higher productivity of accelerated weathering instruments. Additionally, this test method provides multiple data from a single specimen for characterization of within specimen variability.

1.2 This test method describes the determination of the resistance of rigid plastic strip specimens to breakage or permanent deformation when one end of the specimen is subjected to an impact upon its wide face while the other end of the specimen is firmly clamped.

1.3 This test method is applicable to specimens of 1.60 mm (0.0625 in.) thickness. However, the limits of applicability of the test are not sharply defined, and specimens having other dimensions may frequently be used. For specimens of thicknesses other than 1.60 mm (0.0625 in.) the ratio of the distance between the top of the clamp and the centerline of the rounded striking edge to the specimen thickness must be 2.5 ± 0.1.

1.4 This test method measures the relative impact resistance of samples having approximately the same thickness. Normalization of the impact resistance to unit cross-se...

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6395 − 11

Standard Test Method for

1

Flatwise Flexural Impact Resistance of Rigid Plastics

This standard is issued under the fixed designation D6395; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* shear stress to tensile stress in bending increases with

thickness, and the importance of these effects in contributing to

1.1 The resistance of plastics to breakage by flexural shock

theenergyabsorbedisgreaterforductilethanforbrittlefailure.

may be determined by test methods such as those contained in

Test Method D256. Specimens used in those test methods 1.5 This test method is used primarily as a means of

feature a milled notch to promote brittle fracture. The test assessing, for a series of samples, changes relative to a control

specimens are struck by a pendulum with the depth dimension due to some treatment such as weathering or exposure to active

parallel to the direction of pendulum swing.This test method is environments. It has been particularly useful as a sensitive

differentiated from the others by its application to the assess- indicator of the development of surface cracks or a brittle

ment of the affect on impact resistance of changes in the surface. The existence or formation of cracks in an inherently

surface of specimens resulting from weathering or other brittle surface produces marked lowering of impact strength

exposure. In this test method, specimens are struck by a when that surface is the one subjected to tension in the test.

pendulum with the depth dimension perpendicular to the

1.6 This test method is not generally applicable to materials

direction of pendulum swing. Test Method D5420 may also be

such as elastomers or nonrigid plastics in which there is no

used to conduct testing of weathered or exposed specimens.

fracture, permanent deformation, or other change due to

This test method is differentiated from Gardner Impact by the

yielding in flexure. However, it may be desirable to test such

smallersizeofthespecimens,whichmayresultinsubstantially

materials as file samples to establish reference points when the

higher productivity of accelerated weathering instruments.

test is applied as described in 1.5.

Additionally, this test method provides multiple data from a

1.7 The values stated in SI units are to be regarded as the

single specimen for characterization of within specimen vari-

standard. The values given in parentheses are for information

ability.

only.

1.2 This test method describes the determination of the

1.8 This standard does not purport to address all of the

resistance of rigid plastic strip specimens to breakage or

safety concerns, if any, associated with its use. It is the

permanent deformation when one end of the specimen is

responsibility of the user of this standard to establish appro-

subjected to an impact upon its wide face while the other end

priate safety and health practices and determine the applica-

of the specimen is firmly clamped.

bility of regulatory limitations prior to use.

1.3 This test method is applicable to specimens of 1.60 mm

NOTE 1—There is no known ISO equivalent to this standard.

(0.0625 in.) thickness. However, the limits of applicability of

the test are not sharply defined, and specimens having other

2. Referenced Documents

dimensions may frequently be used. For specimens of thick-

2

2.1 ASTM Standards:

nesses other than 1.60 mm (0.0625 in.) the ratio of the distance

D256 Test Methods for Determining the Izod Pendulum

between the top of the clamp and the centerline of the rounded

Impact Resistance of Plastics

striking edge to the specimen thickness must be 2.5 6 0.1.

D618 Practice for Conditioning Plastics for Testing

1.4 This test method measures the relative impact resistance

D883 Terminology Relating to Plastics

of samples having approximately the same thickness. Normal-

D5420 Test Method for Impact Resistance of Flat, Rigid

izationoftheimpactresistancetounitcross-sectionalareaonly

Plastic Specimen by Means of a Striker Impacted by a

partly compensates for the effects of specimen thickness

Falling Weight (Gardner Impact)

variation because, at the fixed cantilever length, the ratio of

D5947 Test Methods for Physical Dimensions of Solid

Plastics Specimens

1

This test method is under the jurisdiction ofASTM Committee D20 on Plastics

2

and is the direct responsibility of Subcommittee D20.10 on Mechanical Properties. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved April 1, 2011. Published April 2011. Originally contact ASTM Customer Service at service@astm.org. For Annual Bo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.