ASTM A479/A479M-12

(Specification)Standard Specification for Stainless Steel Bars and Shapes for Use in Boilers and Other Pressure Vessels

Standard Specification for Stainless Steel Bars and Shapes for Use in Boilers and Other Pressure Vessels

ABSTRACT

This specification covers hot- and cold-finished bars of stainless steel, including rounds, squares, and hexagons, and hot-rolled or extruded shapes such as angles, tees, and channels for use in boiler and pressure vessel construction. Four grades of the stainless steel are available which includes austenitic, austenitic-ferritic, ferritic, and martensitic grades. Mechanical properties such as tensile strength, yield strength, elongation, and hardness shall be determined for the specimens subjected to normalized, tempered, annealed, and quenched conditions. The austenitic stainless steels shall be subjected to heat treatment and shall undergo corrosion test.

SCOPE

1.1 This specification2 covers hot- and cold-finished bars of stainless steel, including rounds, squares, and hexagons, and hot-rolled or extruded shapes such as angles, tees, and channels for use in boiler and pressure vessel construction.2Note 1—There are standards covering high nickel, chromium, austenitic corrosion, and heat-resisting alloy materials. These standards are under the jurisdiction of ASTM Subcommittee B02.07 and may be found in Annual Book of ASTM Standards, Vol 02.04.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 Unless the order specifies the applicable “M” specification designation, the material shall be furnished to the inch-pound units.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A479/A479M −12 Usedin USDOE-NE Standards

Standard Specification for

Stainless Steel Bars and Shapes for Use in Boilers and

1

Other Pressure Vessels

This standard is issued under the fixed designationA479/A479M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* E112 Test Methods for Determining Average Grain Size

2 E527 Practice for Numbering Metals and Alloys in the

1.1 This specification covers hot- and cold-finished bars of

Unified Numbering System (UNS)

stainless steel, including rounds, squares, and hexagons, and

4

hot-rolledorextrudedshapessuchasangles,tees,andchannels 2.2 SAE Document:

2

for use in boiler and pressure vessel construction. SAE J 1086 Recommended Practice for Numbering Metals

and Alloys

NOTE 1—There are standards covering high nickel, chromium, auste-

nitic corrosion, and heat-resisting alloy materials. These standards are

under the jurisdiction ofASTM Subcommittee B02.07 and may be found 3. General Requirements

in Annual Book of ASTM Standards, Vol 02.04.

3.1 The following requirements for orders for material

1.2 The values stated in either SI units or inch-pound units

furnished under this specification shall conform to the appli-

are to be regarded separately as standard. The values stated in

cable requirements of the current edition of Specification

each system may not be exact equivalents; therefore, each

A484/A484M.

system shall be used independently of the other. Combining

3.1.1 Definitions,

values from the two systems may result in non-conformance

3.1.2 General requirements for delivery,

with the standard.

3.1.3 Ordering information,

1.3 Unless the order specifies the applicable “M” specifica-

3.1.4 Process,

tion designation, the material shall be furnished to the inch-

3.1.5 Special tests,

pound units.

3.1.6 Heat treatment,

3.1.7 Dimensions and permissible variations,

2. Referenced Documents

3.1.8 Workmanship, finish, and appearance,

3

2.1 ASTM Standards:

3.1.9 Number of tests/test methods,

A262 Practices for Detecting Susceptibility to Intergranular

3.1.10 Specimen preparation,

Attack in Austenitic Stainless Steels

3.1.11 Retreatment,

A370 Test Methods and Definitions for Mechanical Testing

3.1.12 Inspection,

of Steel Products

3.1.13 Rejection and rehearing,

A484/A484M Specification for General Requirements for

3.1.14 Material test report,

Stainless Steel Bars, Billets, and Forgings

3.1.15 Certification, and

A751 Test Methods, Practices, and Terminology for Chemi-

cal Analysis of Steel Products 3.1.16 Packaging, marking, and loading.

4. Other Requirements

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

4.1 In addition to the requirements of this specification, all

Stainless Steel and Related Alloysand is the direct responsibility of Subcommittee

requirements of the current editions of Specification A484/

A01.17 on Flat-Rolled and Wrought Stainless Steel.

Current edition approved Nov. 1, 2012. Published November 2012. Originally

A484M shall apply. Failure to comply with the general

approved in 1962. Last previous edition approved in 2011 as A479/A479M – 11.

requirements of Specification A484/A484M constitutes non-

DOI: 10.1520/A0479_A0479M-12.

conformance with this specification.

2

For ASME Boiler and Pressure Vessel Code applications see related Specifi-

cation SA-479/SA-479M in Section II of that Code.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4

Standards volume information, refer to the standard’s Document Summary page on Available from Society of Automotive Engineers (SAE), 400 Commonwealth

the ASTM website. Dr., Warrendale, PA 15096-0001, http://www.sae.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A479/A479M−12

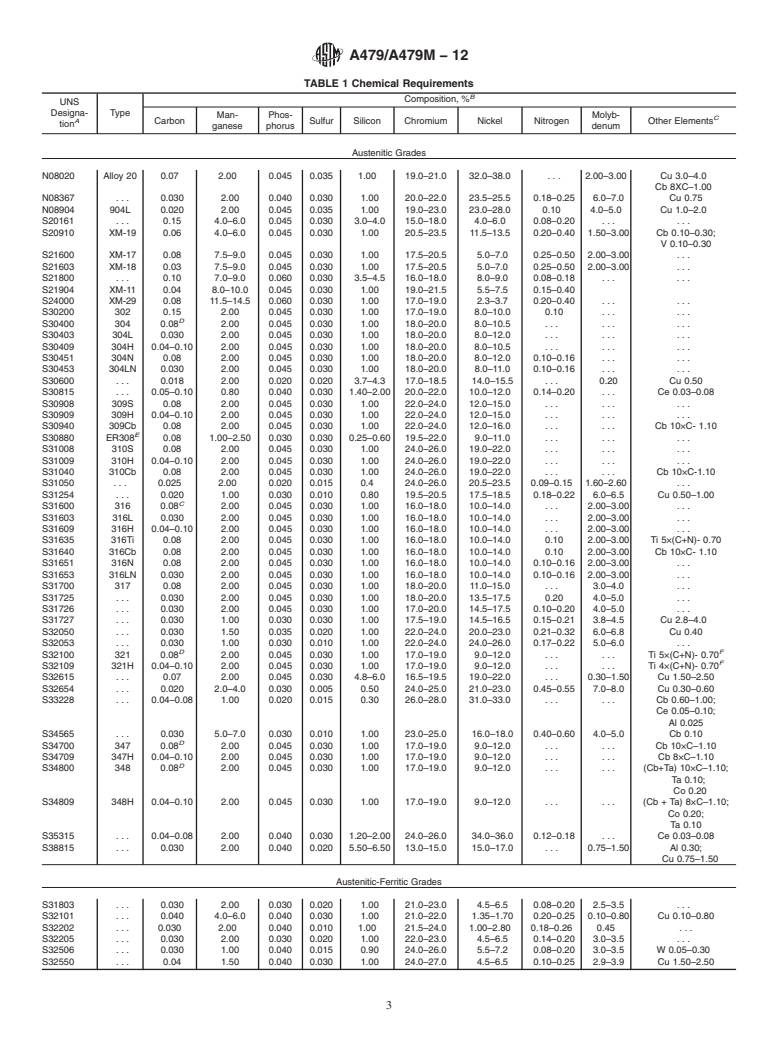

5. Chemical Composition 9. Testing for Intermetallic Compounds

9.1 When specified by the purchaser in the purchase order,

5.1 Chemical composition shall be reported to the

the manufacturer shall test the austenitic or austenitic-ferritic

purchaser, or his representative, and shall conform to the

(duplex) stainless steel material in its final condition in

requirements specified in Table 1.

accordance with supplementary test requirements S6.

5.2 When a product analysis is performed or requested by

NOTE 2—Many, if not all, duplex stainless steels an

...

Designation: A479/A479M − 11 A479/A479M − 12 Used in USDOE-NE Standards

Standard Specification for

Stainless Steel Bars and Shapes for Use in Boilers and

1

Other Pressure Vessels

This standard is issued under the fixed designation A479/A479M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope*

2

1.1 This specification covers hot- and cold-finished bars of stainless steel, including rounds, squares, and hexagons, and

2

hot-rolled or extruded shapes such as angles, tees, and channels for use in boiler and pressure vessel construction.

NOTE 1—There are standards covering high nickel, chromium, austenitic corrosion, and heat-resisting alloy materials. These standards are under the

jurisdiction of ASTM Subcommittee B02.07 and may be found in Annual Book of ASTM Standards, Vol 02.04.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the

two systems may result in non-conformance with the standard.

1.3 Unless the order specifies the applicable “M” specification designation, the material shall be furnished to the inch-pound

units.

2. Referenced Documents

3

2.1 ASTM Standards:

A262 Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A484/A484M Specification for General Requirements for Stainless Steel Bars, Billets, and Forgings

A751 Test Methods, Practices, and Terminology for Chemical Analysis of Steel Products

E112 Test Methods for Determining Average Grain Size

E527 Practice for Numbering Metals and Alloys in the Unified Numbering System (UNS)

4

2.2 SAE Document:

SAE J 1086 Recommended Practice for Numbering Metals and Alloys

3. General Requirements

3.1 The following requirements for orders for material furnished under this specification shall conform to the applicable

requirements of the current edition of Specification A484/A484M.

3.1.1 Definitions,

3.1.2 General requirements for delivery,

3.1.3 Ordering information,

3.1.4 Process,

3.1.5 Special tests,

3.1.6 Heat treatment,

3.1.7 Dimensions and permissible variations,

3.1.8 Workmanship, finish, and appearance,

3.1.9 Number of tests/test methods,

3.1.10 Specimen preparation,

3.1.11 Retreatment,

3.1.12 Inspection,

3.1.13 Rejection and rehearing,

3.1.14 Material test report,

3.1.15 Certification, and

3.1.16 Packaging, marking, and loading.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A479/A479M − 12

4. Other Requirements

4.1 In addition to the requirements of this specification, all requirements of the current editions of Specification A484/A484M

shall apply. Failure to comply with the general requirements of Specification A484/A484M constitutes nonconformance with this

specification.

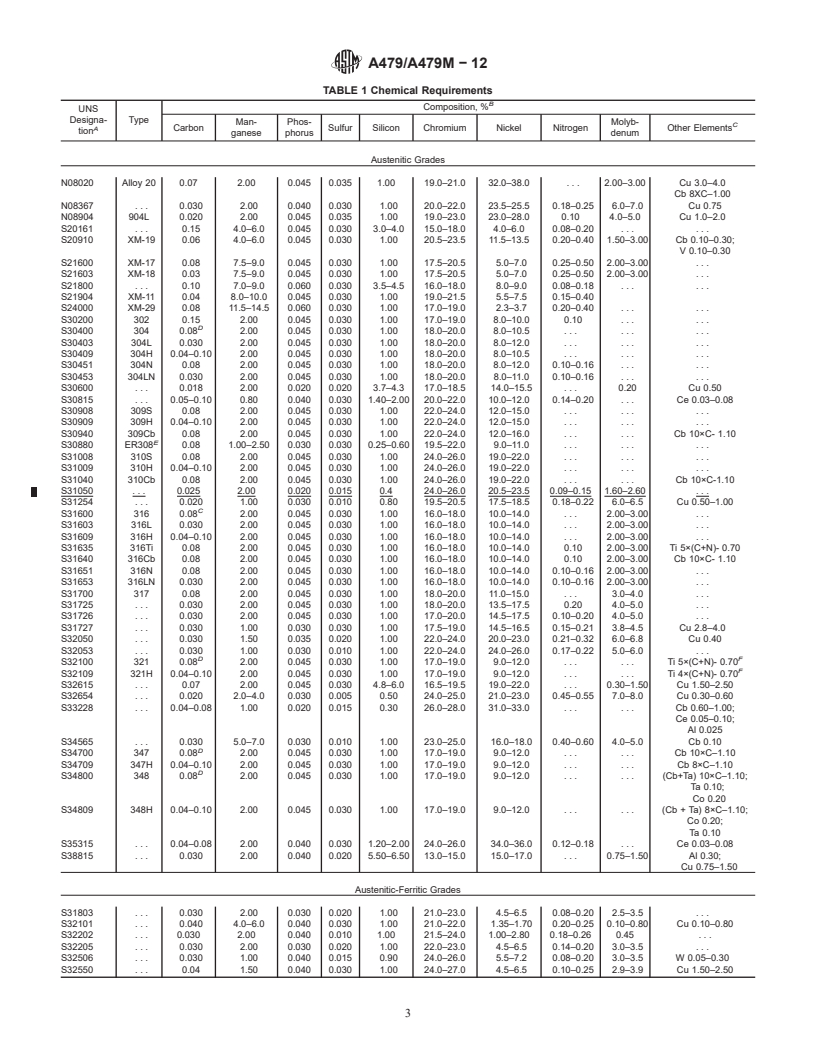

5. Chemical Composition

5.1 Chemical composition shall be reported to the purchaser, or his representative, and shall conform to the requirements

specified in Table 1.

5.2 When a product analysis is performed or requested by the purchaser, the tolerance limits as described in Specification

A484/A484M apply unless Supplementary Requirement S3 is invoked.

5.3 Methods and practices relating to chemical analysis required by this specification shall be in accordance with Test Methods,

Practices, and Terminology A751.

6. Grain Size for Austenitic Grades

6.1 All austenitic grades shall be tested for average grain size by Test Methods E112.

6.2 The H grades shall conform to an average grain size as follows:

6.2.1 ASTM No. 6 or coarser for Types 304H, 309H, 310H, and 316H,

6.2.2 ASTM No. 7 or coarser for Types 321H, 347H, and 348H.

6.3 For S32615, the grain size as determined in accordance with Test Methods E112, comparison method, Plate 11, shall be No.

3 or finer.

6.4 Supplementary Requirement S1 shall be invoked when non–H grade austenitic stainless steels are ordered for ASME Code

applications for service above 1000°F [540°C].

7. Mechanical Properties Requirements

7.1 The material shall conform to the mechanical property requirements specified in Table 2 for the grade ordered. At least one

room-temperature test shall be performed by the manufacturer on a sample from at least one bar or shape from each lot of material.

7.2 The yield strength shall be determined by the offset (0.2 %) method as prescribed in Test Methods and Definitions A370.

7.3 Martensitic material su

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.