ASTM F1376-92(2020)

(Guide)Standard Guide for Metallurgical Analysis for Gas Distribution System Components (Withdrawn 2023)

Standard Guide for Metallurgical Analysis for Gas Distribution System Components (Withdrawn 2023)

SIGNIFICANCE AND USE

4.1 This guide defines a procedure for testing components being considered for installation into a high-purity gas distribution system. Application of this guide is expected to yield comparable data among components tested for purposes of qualification for this installation.

4.2 This guide establishes a procedure for determining the elemental composition and metallurgical characteristics of metal used to fabricate components for high purity gas distribution systems in the semiconductor industry. The composition and metallurgy of stainless steel may be expected to affect properties of importance to this application, including surface roughness, incidence of surface defects, passivation, corrosion resistance, and welding.

SCOPE

1.1 This guide covers corrosion resistant metallic alloys of the general class stainless steel, containing chromium, nickel, manganese, and silicon as major alloying additions and possibly molybdenum, that are qualified or specified for the materials of components used in high-purity gas supply systems for the semiconductor industry. This guide is primarily intended for testing to determine conformance to applicable composition and metallurgical specifications as stated in supplier product specifications or customer purchase specifications, or both.

1.2 Elements analyzed and reported in this guide are as follows:

1.2.1 The alloying additions chromium, nickel, and molybdenum (if specified in alloy, as in type 316L),

1.2.2 The minor elements and residuals manganese, silicon, copper, cobalt, and stabilizers such as titanium and columbium (niobium), if present,

1.2.3 Carbon, sulfur and phosphorus,

1.2.4 Nitrogen and oxygen gases,

1.2.5 Any additional minor element additions that may be made as part of the melting and casting practice, such as aluminum and calcium,

1.2.6 Available standard analytical and reporting techniques are described for these elements.

1.3 Metallurgical characteristics to be analyzed and reported are inclusion contents, grain structure, mechanical properties, and intergranular corrosion susceptibility.

1.4 Limitations:

1.4.1 This guide is limited to corrosion resistant metal alloys of the general class stated in the Scope.

1.4.2 The test methods cited in this guide are not intended to preclude the use of other generally accepted techniques of demonstrated equivalent or superior precision and bias.

1.4.3 Inclusion of testing and analysis procedures for any given element or metallurgical characteristic in this guide is not to be construed as being a requirement for incorporation of that element or metallurgical characteristic into any specifications.

1.5 The values stated in SI units are to be regarded as the standard. The inch-pound units given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

WITHDRAWN RATIONALE

This guide covers corrosion resistant metallic alloys of the general class stainless steel, containing chromium, nickel, manganese, and silicon as major alloying additions and possibly molybdenum, that are qualified or specified for the materials of components used in high-purity gas supply systems for the semiconductor industry. This guide is primarily intended for testing to determine conformance to applicable composition and metallurgical specifications as stated in supplier product sp...

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F1376 − 92 (Reapproved 2020)

Standard Guide for

Metallurgical Analysis for Gas Distribution System

Components

This standard is issued under the fixed designation F1376; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Semiconductor clean rooms are serviced by high-purity gas distribution systems. This guide

presents a procedure that may be applied for the evaluation of one or more components considered for

use in such systems.

1. Scope 1.4.2 Thetestmethodscitedinthisguidearenotintendedto

preclude the use of other generally accepted techniques of

1.1 This guide covers corrosion resistant metallic alloys of

demonstrated equivalent or superior precision and bias.

the general class stainless steel, containing chromium, nickel,

1.4.3 Inclusion of testing and analysis procedures for any

manganese, and silicon as major alloying additions and possi-

givenelementormetallurgicalcharacteristicinthisguideisnot

bly molybdenum, that are qualified or specified for the mate-

to be construed as being a requirement for incorporation of that

rials of components used in high-purity gas supply systems for

element or metallurgical characteristic into any specifications.

the semiconductor industry. This guide is primarily intended

fortestingtodetermineconformancetoapplicablecomposition 1.5 The values stated in SI units are to be regarded as the

and metallurgical specifications as stated in supplier product standard. The inch-pound units given in parentheses are for

specifications or customer purchase specifications, or both. information only.

1.6 This standard does not purport to address all of the

1.2 Elements analyzed and reported in this guide are as

safety concerns, if any, associated with its use. It is the

follows:

responsibility of the user of this standard to establish appro-

1.2.1 The alloying additions chromium, nickel, and molyb-

priate safety, health, and environmental practices and deter-

denum (if specified in alloy, as in type 316L),

mine the applicability of regulatory limitations prior to use.

1.2.2 The minor elements and residuals manganese, silicon,

1.7 This international standard was developed in accor-

copper, cobalt, and stabilizers such as titanium and columbium

dance with internationally recognized principles on standard-

(niobium), if present,

ization established in the Decision on Principles for the

1.2.3 Carbon, sulfur and phosphorus,

Development of International Standards, Guides and Recom-

1.2.4 Nitrogen and oxygen gases,

mendations issued by the World Trade Organization Technical

1.2.5 Any additional minor element additions that may be

Barriers to Trade (TBT) Committee.

made as part of the melting and casting practice, such as

aluminum and calcium,

2. Referenced Documents

1.2.6 Available standard analytical and reporting techniques

are described for these elements.

2.1 ASTM Standards:

A262 Practices for Detecting Susceptibility to Intergranular

1.3 Metallurgicalcharacteristicstobeanalyzedandreported

Attack in Austenitic Stainless Steels

are inclusion contents, grain structure, mechanical properties,

A370 Test Methods and Definitions for Mechanical Testing

and intergranular corrosion susceptibility.

of Steel Products

1.4 Limitations:

A479/A479M Specification for Stainless Steel Bars and

1.4.1 This guide is limited to corrosion resistant metal

Shapes for Use in Boilers and Other Pressure Vessels

alloys of the general class stated in the Scope.

A484/A484M Specification for General Requirements for

This guide is under the jurisdiction of ASTM Committee F01 on Electronics

and is the direct responsibility of Subcommittee F01.10 on Contamination Control. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition published April 15, 2020. Published May 2020. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approvedin1992.Lastpreviouseditionapprovedin2012asF1376–92(2012).DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/F1376-92R20. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1376 − 92 (2020)

Stainless Steel Bars, Billets, and Forgings and metallurgy of stainless steel may be expected to affect

A751 Test Methods, Practices, and Terminology for Chemi- properties of importance to this application, including surface

cal Analysis of Steel Products roughness, incidence of surface defects, passivation, corrosion

E8 Test Methods for Tension Testing of Metallic Materials resistance, and welding.

[Metric] E0008_E0008M

5. Materials and Manufacture

E45 Test Methods for Determining the Inclusion Content of

Steel

5.1 Materials and instrumentation are specified in the

E112 Test Methods for Determining Average Grain Size

ASTM test methods utilized in this guide.

E353 Test Methods for Chemical Analysis of Stainless,

Heat-Resisting, Maraging, and Other Similar Chromium-

6. Procedure

Nickel-Iron Alloys

6.1 ThegeneralrequirementsofSpecificationA484/A484M

E572 Test Method forAnalysis of Stainless andAlloy Steels

prevail for verification analysis, sampling, and test methods.

byWavelength Dispersive X-Ray Fluorescence Spectrom-

6.2 Specification A479/A479M prevails for the determina-

etry

tion of conformance of test results to ASTM standard require-

E1019 Test Methods for Determination of Carbon, Sulfur,

ments.

Nitrogen, and Oxygen in Steel, Iron, Nickel, and Cobalt

Alloys by Various Combustion and Inert Gas Fusion

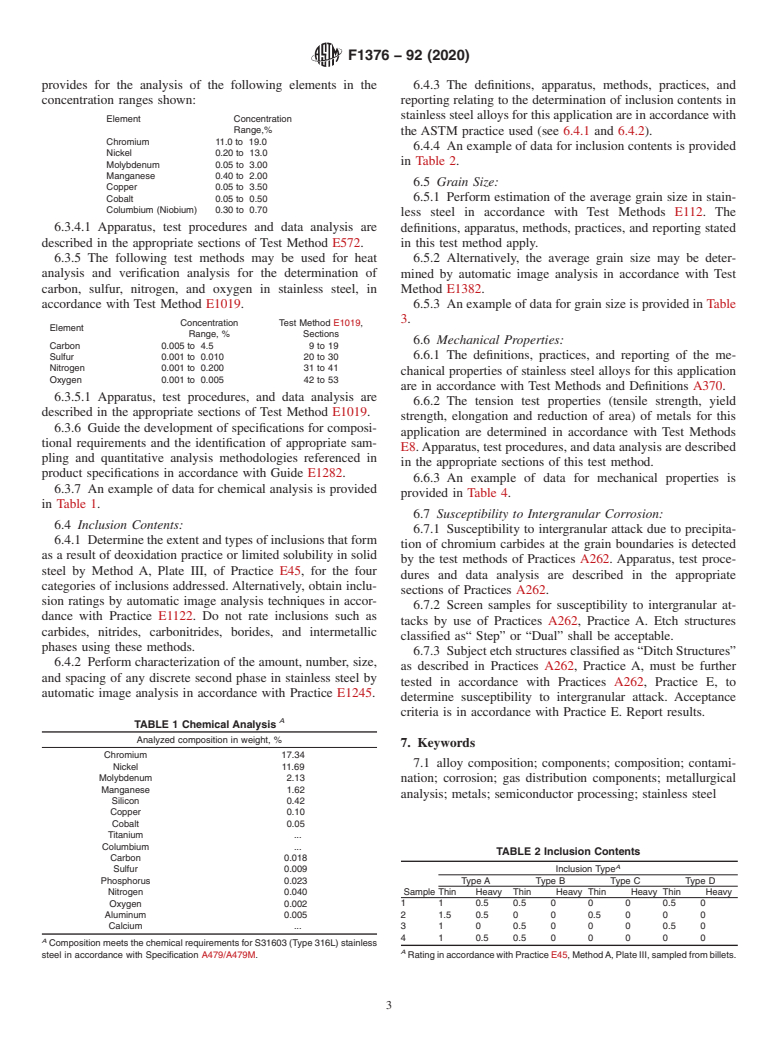

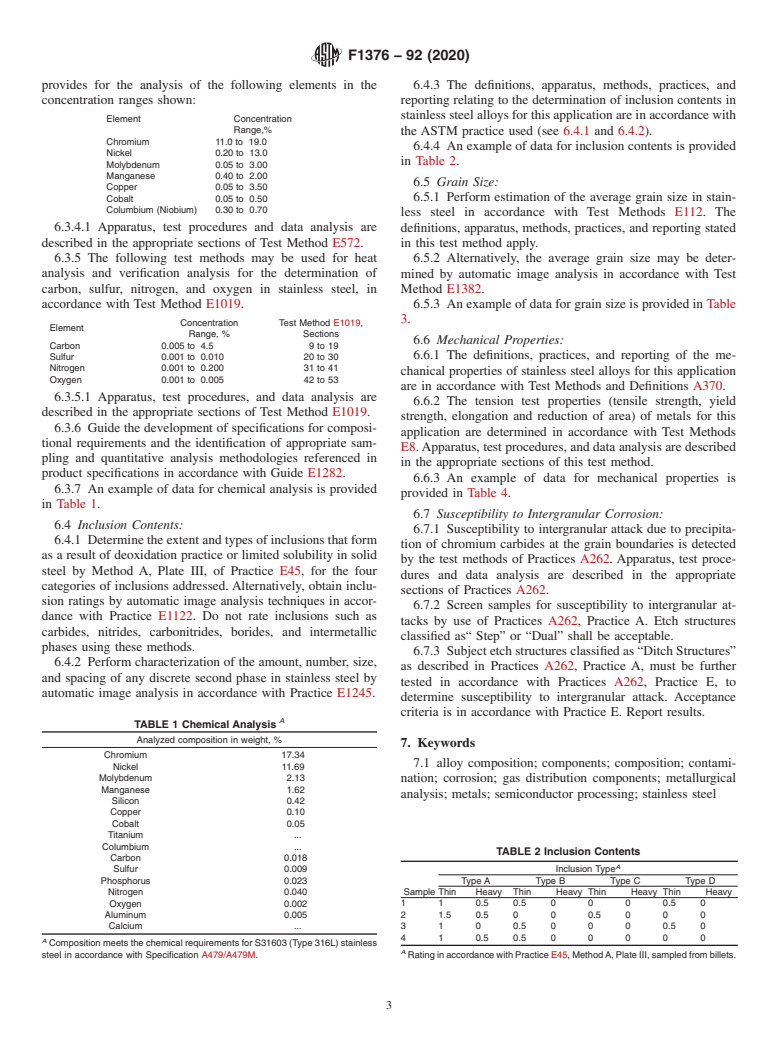

6.3 Chemical Analysis:

Techniques

6.3.1 The definitions, reference methods, practices, and

E1086 TestMethodforAnalysisofAusteniticStainlessSteel

reporting related to the chemical analysis of stainless steel

by Spark Atomic Emission Spectrometry

alloys for this application shall be in accordance with Test

E1122 Practice for Obtaining JK Inclusion Ratings Using

Methods A751.

Automatic Image Analysis (Withdrawn 2006)

6.3.2 Use the following wet chemical test methods as

E1245 Practice for Determining the Inclusion or Second-

control test methods and as the basis for standardizing instru-

Phase Constituent Content of Metals byAutomatic Image

mental analysis techniques, in accordance with Test Method

Analysis

E353:

E1282 GuideforSpecifyingtheChemicalCompositionsand

Concentration Test Method E353,

Element

Selecting Sampling Practices and Quantitative Analysis

Range, % Sections

Chromium 0.10 to 35.00 212 to 220

Methods for Metals, Ores, and Related Materials

Nickel 10.1 to 48.00 172 to 179

E1382 Test Methods for Determining Average Grain Size

Molybdenum 1.5 to 7.0 242 to 249

Using Semiautomatic and Automatic Image Analysis

Manganese 0.01 to 5.00 8 to 17

Silicon 0.05 to 4.00 46 to 52

Copper 0.01 to 5.00 82 to 89

3. Terminology

Copper 0.01 to 5.00 109 to 118

Cobalt 0.01 to 5.00 61 to 70

3.1 Definitions:

Titanium 0.01 to 0.35 231 to 241

3.1.1 heat analysis—chemical analysis of the heat of stain-

Sulfur 0.005 to 0.50 37 to 45

less steel determined by analyzing a sample obtained during

Phosphorus 0.002 to 0.35 18 to 29

Phosphorus 0.02 to 0.35 164 to 171

the pouring of the heat for the elements designated in a

Aluminum 0.003 to 0.20 71 to 81

specification.

6.3.2.1 Apparatus, test procedures and data analysis are

3.1.2 inclusion—discrete second phases (oxides, sulfides,

described in the appropriate sections of the Test Method E353.

carbides, inter-metallic compounds) that are distributed in the

6.3.3 Use the method of optical emission vacuum spectro-

metal matrix.

metric analysis in accordance with Method E1086 for heat

3.1.3 verification analysis—chemical analysis of a semifin-

analysis or v

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F1376 − 92 (Reapproved 2020)

Standard Guide for

Metallurgical Analysis for Gas Distribution System

Components

This standard is issued under the fixed designation F1376; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Semiconductor clean rooms are serviced by high-purity gas distribution systems. This guide

presents a procedure that may be applied for the evaluation of one or more components considered for

use in such systems.

1. Scope 1.4.2 The test methods cited in this guide are not intended to

preclude the use of other generally accepted techniques of

1.1 This guide covers corrosion resistant metallic alloys of

demonstrated equivalent or superior precision and bias.

the general class stainless steel, containing chromium, nickel,

1.4.3 Inclusion of testing and analysis procedures for any

manganese, and silicon as major alloying additions and possi-

given element or metallurgical characteristic in this guide is not

bly molybdenum, that are qualified or specified for the mate-

to be construed as being a requirement for incorporation of that

rials of components used in high-purity gas supply systems for

element or metallurgical characteristic into any specifications.

the semiconductor industry. This guide is primarily intended

for testing to determine conformance to applicable composition 1.5 The values stated in SI units are to be regarded as the

and metallurgical specifications as stated in supplier product standard. The inch-pound units given in parentheses are for

specifications or customer purchase specifications, or both. information only.

1.6 This standard does not purport to address all of the

1.2 Elements analyzed and reported in this guide are as

safety concerns, if any, associated with its use. It is the

follows:

responsibility of the user of this standard to establish appro-

1.2.1 The alloying additions chromium, nickel, and molyb-

priate safety, health, and environmental practices and deter-

denum (if specified in alloy, as in type 316L),

mine the applicability of regulatory limitations prior to use.

1.2.2 The minor elements and residuals manganese, silicon,

1.7 This international standard was developed in accor-

copper, cobalt, and stabilizers such as titanium and columbium

dance with internationally recognized principles on standard-

(niobium), if present,

ization established in the Decision on Principles for the

1.2.3 Carbon, sulfur and phosphorus,

Development of International Standards, Guides and Recom-

1.2.4 Nitrogen and oxygen gases,

mendations issued by the World Trade Organization Technical

1.2.5 Any additional minor element additions that may be

Barriers to Trade (TBT) Committee.

made as part of the melting and casting practice, such as

aluminum and calcium,

2. Referenced Documents

1.2.6 Available standard analytical and reporting techniques

are described for these elements.

2.1 ASTM Standards:

A262 Practices for Detecting Susceptibility to Intergranular

1.3 Metallurgical characteristics to be analyzed and reported

Attack in Austenitic Stainless Steels

are inclusion contents, grain structure, mechanical properties,

A370 Test Methods and Definitions for Mechanical Testing

and intergranular corrosion susceptibility.

of Steel Products

1.4 Limitations:

A479/A479M Specification for Stainless Steel Bars and

1.4.1 This guide is limited to corrosion resistant metal

Shapes for Use in Boilers and Other Pressure Vessels

alloys of the general class stated in the Scope.

A484/A484M Specification for General Requirements for

This guide is under the jurisdiction of ASTM Committee F01 on Electronics

and is the direct responsibility of Subcommittee F01.10 on Contamination Control. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition published April 15, 2020. Published May 2020. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1992. Last previous edition approved in 2012 as F1376–92(2012). DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/F1376-92R20. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1376 − 92 (2020)

Stainless Steel Bars, Billets, and Forgings and metallurgy of stainless steel may be expected to affect

A751 Test Methods, Practices, and Terminology for Chemi- properties of importance to this application, including surface

cal Analysis of Steel Products roughness, incidence of surface defects, passivation, corrosion

E8 Test Methods for Tension Testing of Metallic Materials resistance, and welding.

[Metric] E0008_E0008M

5. Materials and Manufacture

E45 Test Methods for Determining the Inclusion Content of

Steel

5.1 Materials and instrumentation are specified in the

E112 Test Methods for Determining Average Grain Size

ASTM test methods utilized in this guide.

E353 Test Methods for Chemical Analysis of Stainless,

Heat-Resisting, Maraging, and Other Similar Chromium-

6. Procedure

Nickel-Iron Alloys

6.1 The general requirements of Specification A484/A484M

E572 Test Method for Analysis of Stainless and Alloy Steels

prevail for verification analysis, sampling, and test methods.

by Wavelength Dispersive X-Ray Fluorescence Spectrom-

6.2 Specification A479/A479M prevails for the determina-

etry

tion of conformance of test results to ASTM standard require-

E1019 Test Methods for Determination of Carbon, Sulfur,

ments.

Nitrogen, and Oxygen in Steel, Iron, Nickel, and Cobalt

Alloys by Various Combustion and Inert Gas Fusion

6.3 Chemical Analysis:

Techniques

6.3.1 The definitions, reference methods, practices, and

E1086 Test Method for Analysis of Austenitic Stainless Steel

reporting related to the chemical analysis of stainless steel

by Spark Atomic Emission Spectrometry

alloys for this application shall be in accordance with Test

E1122 Practice for Obtaining JK Inclusion Ratings Using

Methods A751.

Automatic Image Analysis (Withdrawn 2006)

6.3.2 Use the following wet chemical test methods as

E1245 Practice for Determining the Inclusion or Second-

control test methods and as the basis for standardizing instru-

Phase Constituent Content of Metals by Automatic Image

mental analysis techniques, in accordance with Test Method

Analysis

E353:

E1282 Guide for Specifying the Chemical Compositions and

Concentration Test Method E353,

Element

Selecting Sampling Practices and Quantitative Analysis

Range, % Sections

Chromium 0.10 to 35.00 212 to 220

Methods for Metals, Ores, and Related Materials

Nickel 10.1 to 48.00 172 to 179

E1382 Test Methods for Determining Average Grain Size

Molybdenum 1.5 to 7.0 242 to 249

Using Semiautomatic and Automatic Image Analysis

Manganese 0.01 to 5.00 8 to 17

Silicon 0.05 to 4.00 46 to 52

Copper 0.01 to 5.00 82 to 89

3. Terminology

Copper 0.01 to 5.00 109 to 118

Cobalt 0.01 to 5.00 61 to 70

3.1 Definitions:

Titanium 0.01 to 0.35 231 to 241

3.1.1 heat analysis—chemical analysis of the heat of stain-

Sulfur 0.005 to 0.50 37 to 45

less steel determined by analyzing a sample obtained during

Phosphorus 0.002 to 0.35 18 to 29

Phosphorus 0.02 to 0.35 164 to 171

the pouring of the heat for the elements designated in a

Aluminum 0.003 to 0.20 71 to 81

specification.

6.3.2.1 Apparatus, test procedures and data analysis are

3.1.2 inclusion—discrete second phases (oxides, sulfides,

described in the appropriate sections of the Test Method E353.

carbides, inter-metallic compounds) that are distributed in the

6.3.3 Use the method of optical emission vacuum spectro-

metal matrix.

metric analysis in accordance with Method E1086 for heat

3.1.3 verification analysis—chemical analysis of a semifin-

analysis or verification analysis of stainless steel samples that

ished or finished product for th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.