ASTM E1827-96

(Test Method)Standard Test Methods for Determining Airtightness of Buildings Using an Orifice Blower Door

Standard Test Methods for Determining Airtightness of Buildings Using an Orifice Blower Door

SCOPE

1.1 These test methods describe two techniques for measuring air leakage rates through a building envelope in buildings that may be configured to a single zone. Both techniques use an orifice blower door to induce pressure differences across the building envelope and to measure those pressure differences and the resulting airflows. The measurements of pressure differences and airflows are used to determine airtightness and other leakage characteristics of the envelope.

1.2 These test methods allow testing under depressurization and pressurization.

1.3 These test methods are applicable to small indoor-outdoor temperature differentials and low wind pressure conditions; the uncertainty in the measured results increases with increasing wind speeds and temperature differentials.

1.4 These test methods do not measure air change rate under normal conditions of weather and building operation. To measure air change rate directly, use Test Methods E 741.

1.5 The text of these methods reference notes and footnotes that provide explanatory material. These notes and footnotes, excluding those in tables and figures, shall not be considered as requirements of the standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements see Section 7.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: E 1827 – 96

Standard Test Methods for

Determining Airtightness of Buildings Using an Orifice

Blower Door

This standard is issued under the fixed designation E 1827; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 1186 Practice for Air Leakage Site Detection in Building

Envelopes

1.1 These test methods describe two techniques for measur-

E 1258 Test Method for Airflow Calibration of Fan Pressur-

ing air leakage rates through a building envelope in buildings

ization Devices

that may be configured to a single zone. Both techniques use an

2.2 ISO International Standard:

orifice blower door to induce pressure differences across the

ISO 9972 Thermal Insulation—Determination of Building

building envelope and to measure those pressure differences

Airtightness—Fan Pressurization Method

and the resulting airflows. The measurements of pressure

2.3 Other Standard:

differences and airflows are used to determine airtightness and

ANSI/ASME PTC 19.1—Part 1, Measurement Uncertainty,

other leakage characteristics of the envelope.

Instruments, and Apparatus

1.2 These test methods allow testing under depressurization

and pressurization.

3. Terminology

1.3 These test methods are applicable to small indoor-

3.1 Definitions—Refer to Terminology E 456 for definitions

outdoor temperature differentials and low wind pressure con-

of accuracy, bias, precision, and uncertainty.

ditions; the uncertainty in the measured results increases with

3.1.1 ACH , n—the ratio of the air leakage rate at 50 Pa

increasing wind speeds and temperature differentials.

(0.2 in. H O), corrected for a standard air density, to the

1.4 These test methods do not measure air change rate under

volume of the test zone (1/h).

normal conditions of weather and building operation. To

3.1.2 air leakage rate, Q , n—the total volume of air

env

measure air change rate directly, use Test Methods E 741.

passing through the test zone envelope per unit of time (m /s,

1.5 The text of these test methods reference notes and

ft /min).

footnotes that provide explanatory material. These notes and

3.1.3 airtightness, n—the degree to which a test zone

footnotes, excluding those in tables and figures, shall not be

envelope resists the flow of air.

considered as requirements of the standard.

1.6 This standard does not purport to address all of the

NOTE 1—ACH , air leakage rate, and effective leakage area are

safety concerns, if any, associated with its use. It is the examples of measures of building airtightness.

responsibility of the user of this standard to establish appro-

3.1.4 blower door, n—a fan pressurization device incorpo-

priate safety and health practices and determine the applica-

rating a controllable fan and instruments for airflow measure-

bility of regulatory limitations prior to use. For specific hazard

ment and building pressure difference measurement that

statements see Section 7.

mounts securely in a door or other opening.

3.1.5 building pressure difference, P, n—the pressure differ-

2. Referenced Documents

ence across the test zone envelope (Pa, in. H O).

2.1 ASTM Standards:

3.1.6 fan airflow rate, Q , n—the volume of airflow

fan

E 456 Terminology Relating to Quality and Statistics 3 3

through the blower door per unit of time (m /s, ft /min).

E 631 Terminology of Building Constructions

3.1.7 nominal airflow rate, Q , n—the flow rate indicated

nom

E 741 Test Methods for Determining Air Change in a Single

by the blower door using the manufacturer’s calibration

Zone by Means of Tracer Gas Dilution 3 3

coefficients (m /s, ft /min).

E 779 Test Method for Determining Air Leakage Rate by

3.1.8 orifice blower door, n—a blower door in which

Fan Pressurization

airflow rate is determined by means of the pressure drop across

an orifice or nozzle.

These test methods are under the jurisdiction of ASTM Committee E06 on

Performance of Buildings and are the direct responsibility of Subcommittee E06.41

on Air Leakage and Ventilation.

Current edition approved Sept. 10, 1996. Published January 1997.

2 4

Annual Book of ASTM Standards, Vol 14.02. Available from American National Standards Institute, 11 W. 42nd St., 13th

Annual Book of ASTM Standards, Vol 04.11. Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E1827–96

3.1.9 precision index of the average, n—the sample stan-

T = temperature,° C (°F),

dard deviation divided by the square root of the number of

t = value from a two-tailed student t table for

samples.

the 95 % confidence level,

3.1.10 pressure station, n—a specified induced change in dn = measurement uncertainty of the envelope

the building pressure difference from the initial zero-flow flow exponent (dimensionless),

3 3

V = volume of the test zone, m (ft ),

building pressure difference (Pa, in. H O).

zone

dQ = measurement uncertainty of the average air

3.1.11 single zone, n—a space in which the pressure differ-

env

3 3

leakage rate, m /s (ft /min),

ences between any two places, as indicated on a manometer,

dQ = the measurement uncertainty of Q ,m /s

differ by no more than 2.5 Pa (0.01 in. H O) during fan 50 50

(ft /min),

pressurization at a building pressure difference of 50 Pa (0.2 in.

3 3

dQ = estimated bias of the flow rate, m /s (ft /

bias

H O) and by no more than 5 % of the highest building pressure

min),

difference achieved.

dQ = estimated bias of the flow rate at the primary

bias1

3 3

NOTE 2—A multiroom space that is interconnected within itself with

pressure station, m /s (ft /min),

door-sized openings through any partitions or floors is likely to satisfy this

dQ = estimated bias of the flow rate at the second-

bias2

3 3 3

criterion if the fan airflow rate is less than 3 m /s (6 3 10 ft /min) and the

3 3

ary pressure station, m /s (ft /min),

test zone envelope is not extremely leaky.

dQ = precision index of the average measured

precision

3 3

3.1.12 test zone, n—a building or a portion of a building that flow rate, m /s (ft /min),

is configured as a single zone for the purpose of this standard. dQ = precision index of the average measured

prec1

flow rate at the primary pressure station,

NOTE 3—For detached dwellings, the test zone envelope normally

3 3

m /s (ft /min),

comprises the thermal envelope.

dQ = precision index of the average measured

prec2

3.1.13 test zone envelope, n—the barrier or series of barriers

flow rate at the secondary pressure station,

3 3

between a test zone and the outdoors.

m /s (ft /min),

dP = measurement uncertainty of the average

NOTE 4—The user establishes the test zone envelope at such places as

measured pressure differential across the

basements or neighboring rooms by choosing the level of resistance to

building envelope, Pa (in. H O),

airflow between the test zone and outdoors with such measures as opening

or closing windows and doors to, from, and within the adjacent spaces. dP = estimated bias of the pressure differential

bias

across the building envelope, Pa (in. H O),

3.1.14 zero-flow building pressure difference, n—the natural

dP = estimated bias of the pressure differential

bias1

building pressure difference measured when there is no flow

across the building envelope at the primary

through the blower door.

pressure station, Pa (in. H O),

3.2 Symbols—The following is a summary of the principal

dP = estimated bias of the pressure differential

bias2

symbols used in these test methods:

across the building envelope at the second-

ary pressure station, Pa (in. H O),

dP = precision index of the average measured

precision

Alt = altitude at site, m (ft),

pressure differential across the building en-

C = flow coefficient at standard conditions, m /s

n 3 n 5

velope, Pa (in. H O),

(Pa )ft /min (in. H O ),

dP = precision index of the average measured

L = effective leakage area at standard conditions, prec1

2 2

pressure differential across the building en-

m (in. ),

velope at the primary pressure station, Pa

n = envelope flow exponent (dimensionless),

(in. H O),

P = building pressure difference (see 3.1.5),

¯ dP = precision index of the average measured

P = average pressure, P , at the primary pres-

prec2

1 sta

pressure differential across the building en-

sure station, Pa (in. H O),

¯

velope at the secondary pressure station, Pa

P = average pressure, P , at the secondary pres-

2 sta

(in. H O),

sure station, Pa (in. H O),

P = the reference pressure differential across the dV = measurement uncertainty of the zone vol-

zone

ref

3 3

ume, m (ft ),

building envelope, Pa (in. H O),

P = station pressure, Pa (in. H O), μ = dynamic viscosity, kg/m·s (lbm/ft·hr),

sta 2

3 3

P = test pressure, Pa (in. H O), r = air density, kg/m (lbm/ft ), and

test 2

r = air density at which the calibration values

P = zero-airflow pressure before test, Pa (in.

cal

zero1

3 3

H O), are valid, kg/m (lbm/ft ).

P = zero-airflow pressure after test, Pa (in. H O),

zero2 2

3 3

4. Summary of Test Methods

Q = the air leakage rate, m /s (ft /min),

env

¯

Q = average air leakage rate, Q , at the primary

env1 env 4.1 Pressure versus Flow—These test methods consist of

3 3

pressure station, m /s (ft /min),

mechanical depressurization or pressurization of a building

¯

Q = average air leakage rate, Q , at the second-

env2 env

zone during which measurements of fan airflow rates are made

3 3

ary pressure station, m /s (ft /min),

Q = fan airflow rate (see 3.1.6),

fan

Q = nominal airflow rate (see 3.1.7),

nom 5

Historically, a variety of other units have been used.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

E1827–96

at one or more pressure stations. The air leakage characteristics used or suggested for characterizing building airtightness.

of a building envelope are evaluated from the relationship These pressures include 4 Pa (0.016 in. H O), 10 Pa (0.04 in.

between the building pressure differences and the resulting H O), 30 Pa (0.12 in. H O), and 50 Pa (0.2 in. H O). The

2 2 2

airflow rates. Two alternative measurement and analysis pro- ASHRAE Handbook of Fundamentals uses 4 Pa.

cedures are specified in this standard, the single-point method 5.4 Depressurization versus Pressurization—Depending on

and the two-point method. the goals of the test method, the user may choose depressur-

4.1.1 Single-Point Method—This method provides air leak- ization or pressurization or both. This standard permits both

age estimates by making multiple flow measurements near depressurization and pressurization measurements to compen-

P = 50 Pa (0.2 in. H O) and assuming a building flow sate for asymmetric flow in the two directions. Depressuriza-

1 2

exponent of n = 0.65. tion is appropriate for testing the building envelope tightness to

4.1.2 Two-Point Method—This method provides air leakage include the tightness of such items as backdraft dampers that

estimates by making multiple flow measurements near P =50 inhibit infiltration but open during a pressurization test. Com-

Pa (0.2 in. H O) and near P = 12.5 Pa (0.05 in. H O) that bining the results of depressurization and pressurization mea-

2 2 2

permit estimates of the building flow coefficient and flow surements can minimize wind and stack-pressure effects on

exponent. calculating airtightness but may overestimate air leakage due to

backdraft dampers that open only under pressurization.

5. Significance and Use

5.5 Effects of Wind and Temperature Differences—Calm

5.1 Airtightness—Building airtightness is one factor that

winds and moderate temperatures during the test improve

affects building air change rates under normal conditions of

precision and bias. Pressure gradients over the envelope caused

weather and building operation. These air change rates account

by inside-outside temperature differences and wind cause bias

for a significant portion of the space-conditioning load and

in the measurement by changing the building pressure differ-

affect occupant comfort, indoor air quality, and building

ences over the test envelope from what would occur in the

durability. These test methods produce results that characterize

absence of these factors. Wind also causes pressure fluctuations

the airtightness of the building envelope. These results can be

that affect measurement precision and cause the data to be

used to compare the relative airtightness of similar buildings,

autocorrelated.

determine airtightness improvements from retrofit measures

6. Apparatus

applied to an existing building, and predict air leakage. Use of

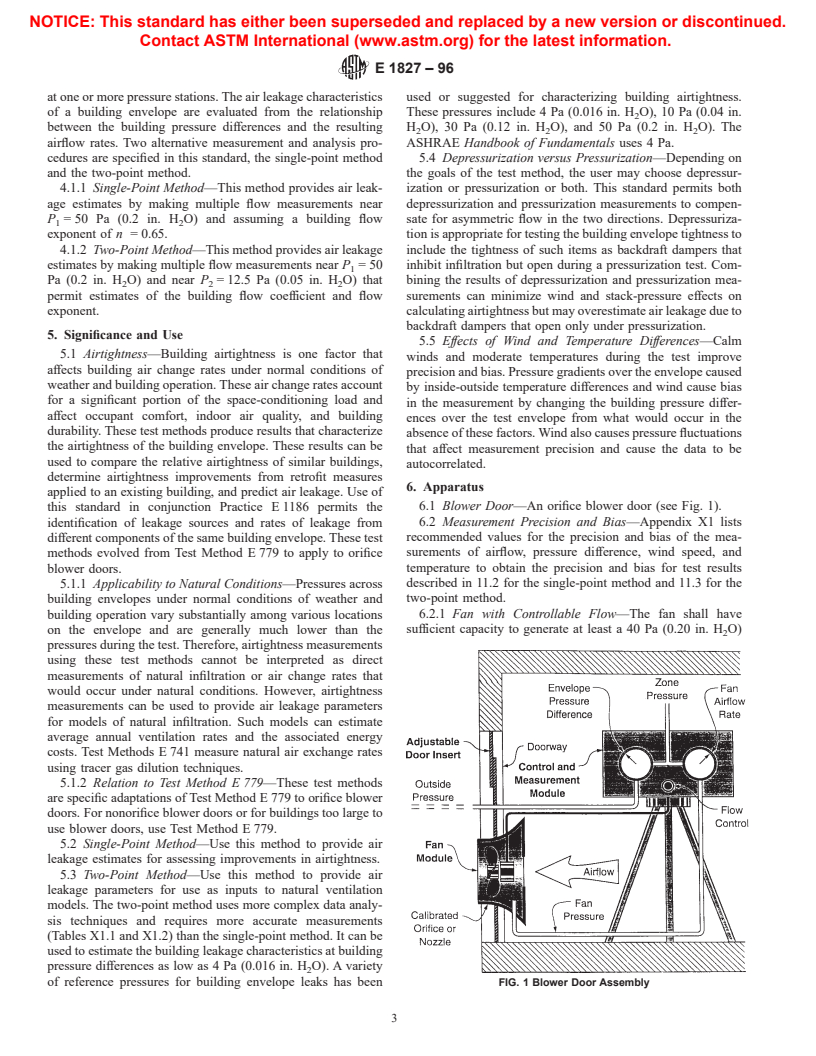

6.1 Blower Door—An orifice blower door (see Fig. 1).

this standard in conjunction Practice E 1186 permits the

6.2 Measurement Precision and Bias—Appendix X1 lists

identification of leakage sources and rates of leakage from

recommended values for the precision and bias of the mea-

different components of the same building envelope. These test

surements of airflow, pressure difference, wind speed, and

methods evolved from Test Method E 779 to apply to orifice

temperature to obtain the precision and bias for test results

blower doors.

5.1.1 Applicability to Natural Conditions—Pressures across described in 11.2 for the single-point method and 11.3 for the

two-point method.

building envelopes under normal conditions of weather and

building operation vary substantially among various locations 6.2.1 Fan with Controllable Flow—The fan shall have

sufficient capacity to generate at least a 40 Pa (0.20 in. H O)

on the envelope and are generally much lower than the

pressures during the test. Therefore, airtightness measurements

using these test methods cannot be interpreted as direct

measurements of natural infiltration or air change rates that

would occur under natural conditions. However, airtightness

measurements can be used to provide air leakage parameters

for models of natural infiltration. Such models can estimate

average annual ventilation rates and the associated energy

costs. Test Methods E 741 measure natural air exchange rates

using tracer gas dilution techniques.

5.1.2 Relation to Test Method E 779—These test methods

are specific adaptations of Test Method E 779 to orifice blower

doors. For nonorifice blower doors or for buildings too large to

use blower doors, use Test Met

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.