ASTM D6188-97(2003)

(Test Method)Standard Test Method for Viscosity of Cellulose by Cuprammonium Ball Fall

Standard Test Method for Viscosity of Cellulose by Cuprammonium Ball Fall

SIGNIFICANCE AND USE

This test method is suitable for use as a rapid control test for pulp manufacture or for careful determination of the viscometric molecular weight of purified cotton or wood derived pulps.

This test method is applicable over a very large range of cellulose molecular weights because seven sample sizes are defined. (Sample weights are reduced as cellulose molecular weight increases.)

Cotton and high molecular weight pulps may be difficult to dissolve. (Warning—This test method is only valid if the sample dissolves completely without gels.)

SCOPE

1.1 This test method describes the procedure for estimating the molecular weight of cellulose by determining the viscosity of cuprammonium (CuAm) solutions of cellulosic materials, such as wood pulp, cotton, and cotton linters. This test method is suitable for rapid, routine testing of large numbers of samples with high accuracy and precision. This test method updates and extends the procedure reported by the American Chemical Society (ACS).

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6188–97(Reapproved2003)

Standard Test Method for

1

Viscosity of Cellulose by Cuprammonium Ball Fall

This standard is issued under the fixed designation D 6188; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope ized water. Samples are either squeezed or pressed to 20 to

40 % consistency as necessary, then passed through a picker.

1.1 This test method describes the procedure for estimating

4.2 The wet pulp sample is dried with air whose maximum

the molecular weight of cellulose by determining the viscosity

temperature is 120°C and weighed under conditions that cause

of cuprammonium (CuAm) solutions of cellulosic materials,

the specified quantity of sample to be obtained. The weighed

such as wood pulp, cotton, and cotton linters. This test method

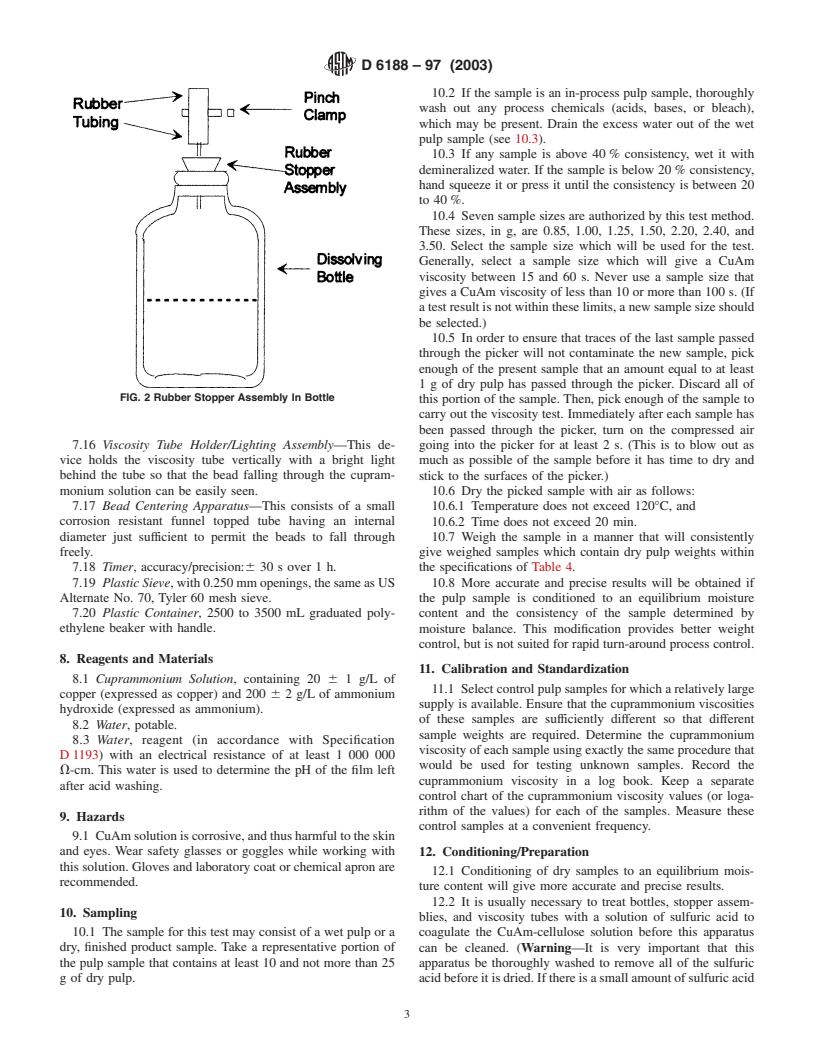

sample is placed in a glass 120-mL (4-oz) bottle, steel shot are

is suitable for rapid, routine testing of large numbers of

added, a vacuum is pulled on the bottle, and 97 mL of

samples with high accuracy and precision. This test method

cuprammonium solution are added to the bottle. The bottle is

updates and extends the procedure reported by the American

2

placed on a shaker to mix and dissolve the pulp sample in the

Chemical Society (ACS) .

CuAm solution.

1.2 The values stated in SI units are to be regarded as the

4.3 The dissolved sample is transferred to a glass viscosity

standard. The values given in parentheses are for information

tube. The tube is mounted vertically with a bright light behind

only.

the tube. A special glass bead (see 7.13) is dropped into the

1.3 This standard does not purport to address all of the

center of the solution in the tube. The time is measured in

safety concerns, if any, associated with its use. It is the

seconds(s)fortheglassbeadtopassbetweentwomarksonthe

responsibility of the user of this standard to establish appro-

tube which are 20 cm apart.This time (s) is the uncorrected “as

priate safety and health practices and determine the applica-

is” cuprammonium ball fall viscosity. The temperature of the

bility of regulatory limitations prior to use.

solution is determined, and the correction factor for this

2. Referenced Documents

temperature is multiplied by the uncorrected viscosity of the

sample. This gives the “as is” cuprammonium ball fall viscos-

2.1 ASTM Standards:

3

ity value.

D 1193 Specification for Reagent Water

4.4 The “as is” viscosity value for the sample size used is

D 1695 Terminology of Cellulose and Cellulose Deriva-

4

converted to the 2.50-g ACS viscosity by the equations

tives

5

provided in 14.4. The viscosity is reported in “ACS seconds”.

E 438 Specification for Glasses in Laboratory Apparatus

5. Significance and Use

3. Terminology

5.1 Thistestmethodissuitableforuseasarapidcontroltest

3.1 This standard terminology of cellulose and cellulose

for pulp manufacture or for careful determination of the

derivatives, see Terminology D 1695.

viscometric molecular weight of purified cotton or wood

4. Summary of Test Method

derived pulps.

5.2 This test method is applicable over a very large range of

4.1 An in-process or finished product sample is taken. All

cellulose molecular weights because seven sample sizes are

cooking and bleaching chemicals must be washed out of

defined. (Sample weights are reduced as cellulose molecular

in-process samples. Dry samples are wetted with demineral-

weight increases.)

5.3 Cotton and high molecular weight pulps may be difficult

1

This test method is under the jurisdiction of ASTM Committee D01 on Paint

to dissolve. (Warning—This test method is only valid if the

and Related Coatings, Materials, andApplications and is the direct responsibility of

sample dissolves completely without gels.)

Subcommittee D01.36 on Cellulose and Cellulose Derivatives.

Current edition approved May 10, 2003. Published June 2003. Originally

6. Interferences

approved in 1997. Last previous edition approved in 1997 as D 6188 - 97.

2

Carver et al., “A Standard Method for Determining the Viscosity of Cellulose

6.1 High temperature drying of pulp causes a reduction in

in Cuprammonium Hydroxide,” Industrial and Engineering Chemistry, Analytical

viscosity. Therefore, limit the maximum temperature of the air

Edition, Vol 1, No 1, 1929, pp. 49-51.

3 used to dry the sample to 120°C and the maximum drying time

Annual Book of ASTM Standards, Vol 11.01.

4

Annual Book of ASTM Standards, Vol 6.03. to 20 min to keep viscosity loss to a minimum. All in-process

5

Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United S

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.