ASTM D4385-08

(Practice)Standard Practice for Classifying Visual Defects in Thermosetting Reinforced Plastic Pultruded Products

Standard Practice for Classifying Visual Defects in Thermosetting Reinforced Plastic Pultruded Products

ABSTRACT

This practice focuses on the establishment of acceptance levels and criteria upon inspection of visual defects in thermosetting reinforced plastic pultruded rods, bars, shapes, and sheets. Presented here is the definition of possible defects to serve as a guide for contracts, drawings, product specifications, and final inspection. This practice also categorizes different inspection requirements for three grades of product quality.

SCOPE

1.1 This practice covers acceptance criteria for visual acceptance of thermosetting reinforced plastic pultruded rods, bars, shapes, and sheets.

1.2 This practice presents definitions of possible defects to serve as a guide for contracts, drawings, product specifications, and final inspection.

1.3 This practice also categorizes different inspection requirements for three grades of product quality.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—There is no similar or equivalent ISO standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:D4385–08

Standard Practice for

Classifying Visual Defects in Thermosetting Reinforced

1

Plastic Pultruded Products

This standard is issued under the fixed designation D4385; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 3.3 Punchability—Products not exceeding 5 mm (0.197 in.)

thickness, having Reinforcement Material G and Reinforce-

1.1 This practice covers acceptance criteria for visual ac-

ment Type M in accordance with Practice D3647, shall be

ceptance of thermosetting reinforced plastic pultruded rods,

capable of being punched, drilled, and riveted without causing

bars, shapes, and sheets.

splitting or delamination when good commercial practices are

1.2 This practice presents definitions of possible defects to

employed (for example, proper backup, adequate hole spacing,

serve as a guide for contracts, drawings, product specifications,

etc.).

and final inspection.

3.4 Critical Areas—Areas in which the presence of imper-

1.3 This practice also categorizes different inspection re-

fections is considered to be detrimental to the proper function

quirements for three grades of product quality.

of the part shall be designated as critical areas. The areas of a

1.4 This standard does not purport to address all of the

product that are critical structurally, aerodynamically, electri-

safety concerns, if any, associated with its use. It is the

cally, or for some other purpose shall be uniform and in

responsibility of the user of this standard to establish appro-

accordance with the quality levels of Table 1 as stated on the

priate safety and health practices and determine the applica-

product drawing. Critical areas may be designated on the

bility of regulatory limitations prior to use.

product drawing by one of the following methods:

NOTE 1—There is no similar or equivalent ISO standard.

3.4.1 Encircle critical areas,

3.4.2 Cross-hatch areas to designate areas of various levels,

2. Referenced Documents

or

2

2.1 ASTM Standards:

3.4.3 Word description.

D3647 Practice for Classifying Reinforced Plastic Pul-

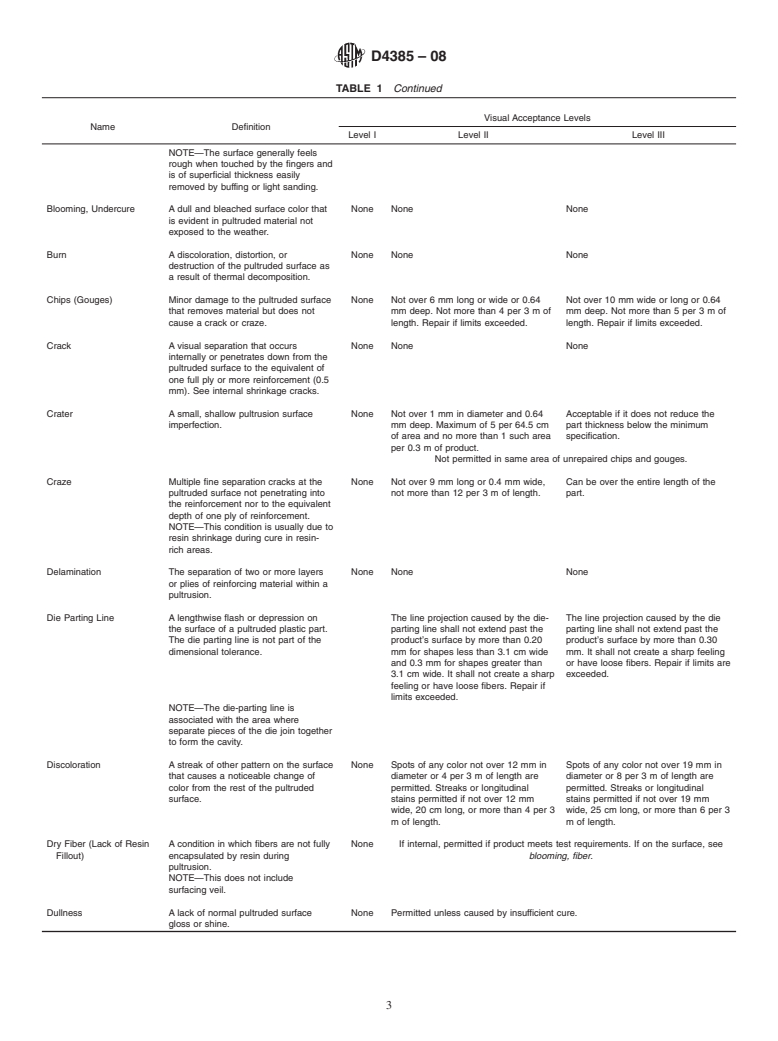

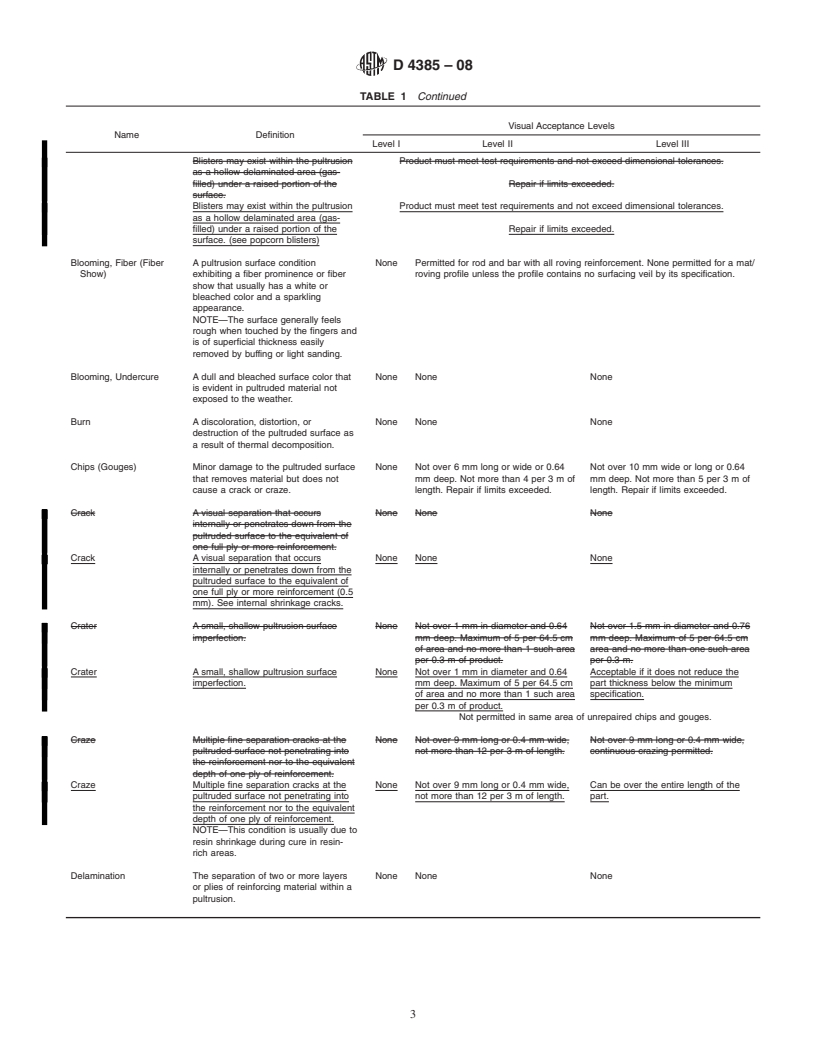

3.5 Allowable Defects—Defects that by nature, number, or

truded Shapes According to Composition

frequency of occurrence do not affect the serviceability of the

D3917 Specification for DimensionalTolerance ofThermo-

product. These allowable defects shall be fully described as to

setting Glass-Reinforced Plastic Pultruded Shapes

type, size, number, extent allowed, and spacing. The appropri-

ate acceptance level (see Table 1) for defects in these areas

3. Acceptance Criteria

mustbespecified.Defectsinexcessofthoselistedasallowable

3.1 The method and frequency of sampling and the quality

in the product specifications, drawings, or contracts for the

levelshallbeagreeduponbetweenthepurchaserandtheseller.

product shall be cause for rejection.

3.2 Dimensions and Tolerances—Pultruded shapes shall be

3.6 Acceptable Defects—Unless otherwise specified, the

inspected for conformance with dimensions and tolerances

following defects shall be acceptable in all instances:

specified on the product drawing. Products with any dimen-

3.6.1 Shrink-Mark—A dimple-like depression on the sur-

sions exceeding the specified limits shall be rejected.

face of a pultruded shape where it has retracted from the

pultrusion die, and which has well-rounded edges. A shrink-

mark generally occurs on one surface of a part where there is

1

ThispracticeisunderthejurisdictionofASTMCommitteeD20onPlasticsand

a boss, flange, rib, or other heavy section on the opposite

is the direct responsibility of Subcommittee D20.18 on Reinforced Thermosetting

surface. The shrink-mark may be caused by the difference in

Plastics.

total shrinkage when there is a sudden change in section along

Current edition approved March 1, 2008. Published March 2008. Originally

the surface of the part.

approved in 1984. Last previous edition approved in 2002 as D4385 - 02. DOI:

10.1520/D4385-08.

3.6.2 Resin Voids—Applicable to a number of mat- and

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

fabric-type reinforcement systems, particularly continuous

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

strand mat used without a surfacing material or woven fabrics.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. The resin voids appear as multiple surface interruptions that

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

-----------

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D4385–02 Designation:D4385–08

Standard Practice for

Classifying Visual Defects in Thermosetting Reinforced

1

Plastic Pultruded Products

This standard is issued under the fixed designation D 4385; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This practice covers acceptance criteria for visual acceptance of thermosetting reinforced plastic pultruded rods, bars,

shapes, and sheets.

1.2 This practice presents definitions of possible defects to serve as a guide for contracts, drawings, product specifications, and

final inspection.

1.3 This practice also categorizes different inspection requirements for three grades of product quality.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

NOTE 1—There is no similar or equivalent ISO standard.

2. Referenced Documents

2

2.1 ASTM Standards:

D 3647 Practice for Classifying Reinforced Plastic Pultruded Shapes According to Composition

D 3917 Specification for Dimensional Tolerance of Thermosetting Glass-Reinforced Plastic Pultruded Shapes

3. Acceptance Criteria

3.1 The method and frequency of sampling and the quality level shall be agreed upon between the purchaser and the seller.

3.2 DimensionsandTolerances—Pultrudedshapesshallbeinspectedforconformancewithdimensionsandtolerancesspecified

on the product drawing. Products with any dimensions exceeding the specified limits shall be rejected.

3.3 Punchability—Products not exceeding 5 mm thick or thinner,(0.197 in.) thickness, having Reinforcement Material G and

ReinforcementTypeMinaccordancewithPracticeD 3647,shallbecapableofbeingpunched,drilled,andrivetedwithoutcausing

splittingordelaminationwhengoodcommercialpracticesareemployed(forexample,properbackup,adequateholespacing,etc.).

3.4 Critical Areas—Areas in which the presence of imperfections is considered to be detrimental to the proper function of the

part shall be designated as critical areas. The areas of a product that are critical structurally, aerodynamically, electrically, or for

some other purpose shall be uniform and in accordance with the quality levels ofTable 1 as stated on the product drawing. Critical

areas may be designated on the product drawing by one of the following methods:

3.4.1 Encircle critical areas,

3.4.2 Cross-hatch areas to designate areas of various levels, or

3.4.3 Word description.

3.5 Allowable Defects—Defects that by nature, number, or frequency of occurrence do not affect the serviceability of the

product. These allowable defects shall be fully described as to type, size, number, extent allowed, and spacing. The appropriate

acceptance level (see Table 1) for defects in these areas must be specified. Defects in excess of those listed as allowable in the

product specifications, drawings, or contracts for the product shall be cause for rejection.

3.6 Acceptable Defects—Unless otherwise specified, the following defects shall be acceptable in all instances:

3.6.1 Shrink-Mark—Adimple-like depression on the surface of a pultruded shape where it has retracted from the pultrusion die,

and which has well-rounded edges. A shrink-mark generally occurs on one surface of a part where there is a boss, flange, rib, or

other heavy section on the opposite surface. The shrink-mark may be caused by the difference in total shrinkage when there is a

sudden change in section along the surface of the part.

1

ThispracticeisunderthejurisdictionofASTMCommitteeD20onPlasticsandisthedirectresponsibilityofSubcommitteeD20.18onReinforcedThermosettingPlastics.

Current edition approved March 10, 2002. Published May 2002. Originally published as D4385–84. Last previous edition D4385–95.

Current edition approved March 1, 2008. Published March 2008. Originally approved in 1984. Last previous edition approved in 2002 as D4385 - 02.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book ofASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*ASummary of Changes section appears at the end of this standard.

Copyright © AST

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.