ASTM D1955-85(1995)

(Test Method)Standard Test Method for Gel Time of Drying Oils (Withdrawn 2003)

Standard Test Method for Gel Time of Drying Oils (Withdrawn 2003)

SCOPE

1.1 This test method covers the determination of the gel time of tung oil, oiticica oil, and, with modification of temperature, other oils having gelling characteristics.

1.2 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.>

WITHDRAWN RATIONALE

This test method covers the determination of the gel time of tung oil, oiticica oil, and, with modification of temperature, other oils having gelling characteristics.

Formerly under the jurisdiction of Committee D01 on Paint and Related Coatings, Materials, and Applications, this test method was withdrawn in December 2003 in accordance with section 10.6.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 1955 – 85 (Reapproved 1995)

Standard Test Method for

Gel Time of Drying Oils

This standard is issued under the fixed designation D 1955; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This test method covers the determination of the gel

time of tung oil, oiticica oil, and, with modification of

temperature, other oils having gelling characteristics.

1.2 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

E 1 Specification for ASTM Thermometers

3. Terminology

3.1 Definition:

3.1.1 gel time, of a drying oil—the time required for the oil

to form a solid gel under specified conditions of temperature.

4. Significance and Use

4.1 The gel time of an oil at elevated temperature is an

indication of its drying characteristics. Oils that have a high

degree of unsaturation are classed as drying oils. Oils in which

a high percentage of this unsaturation is conjugated dry the

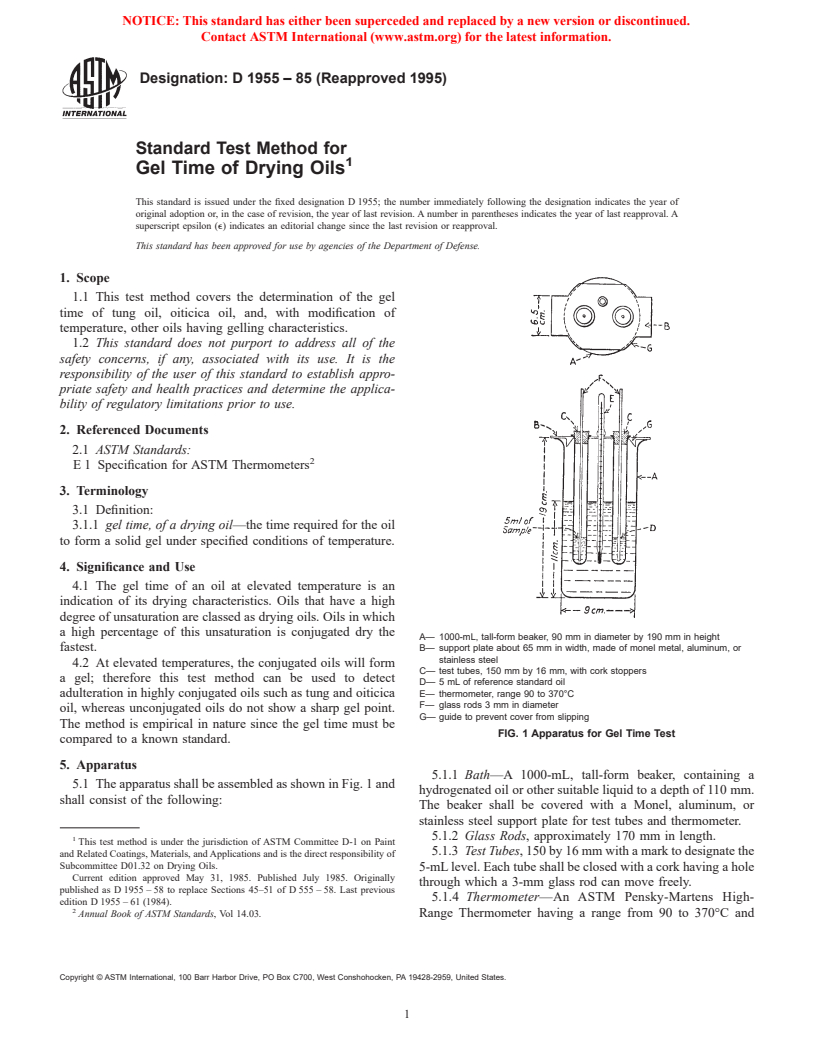

A— 1000-mL, tall-form beaker, 90 mm in diameter by 190 mm in height

fastest. B— support plate about 65 mm in width, made of monel metal, aluminum, or

stainless steel

4.2 At elevated temperatures, the conjugated oils will form

C— test tubes, 150 mm by 16 mm, with cork stoppers

a gel; therefore this test method can be used to detect

D— 5 mL of reference standard oil

adulteration in highly conjugated oils such as tung and oiticica E— thermometer, range 90 to 370°C

F— glass rods 3 mm in diameter

oil, whereas unconjugated oils do not show a sharp gel point.

G— guide to prevent cover from slipping

The method is empirical in nature since the gel time must be

FIG. 1 Apparatus for Gel Time Test

compared to a known standard.

5. Apparatus

5.1.1 Bath—A 1000-mL, tall-form beaker, containing a

5.1 The apparatus shall be assembled as shown in Fig. 1 and

hydrogenated oil or other suitable liquid to a depth of 110 mm.

shall consist of the following:

The beaker shall be covered with a Monel, aluminum, or

stainless steel support plate for test tubes and thermometer.

1 5.1.2 Glass Rods, approximately 170 mm in length.

This test method is under the jurisdiction of ASTM Committee D-1 on Paint

5.1.3 Test Tubes, 150 by 16 mm with a mark to designate the

and Related Coatings, Materials, and Applications and is the direct responsibility of

Subcommittee D01.32 on Drying Oils.

5-mL level. Each tube shall be closed with a cork having a hole

Current edition approved May 31, 1985. Published July 1985. Originally

through which a 3-mm glass rod can move freely.

published as D 1955 – 58 to replace Sections 45–51 of D 555 – 58. Last previous

5.1.4 Thermometer—An ASTM Pensky-Martens High-

edition D 1955 – 61 (1984).

Annual Book of ASTM

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.