ASTM D2915-98e1

(Practice)Standard Practice for Evaluating Allowable Properties for Grades of Structural Lumber

Standard Practice for Evaluating Allowable Properties for Grades of Structural Lumber

SCOPE

1.1 This practice covers sampling and analysis procedures for the investigation of specified populations of stress-graded structural lumber. Depending on the interest of the user, the population from which samples are taken may range from the lumber from a specific mill to all the lumber produced in a particular grade from a particular geographic area, during some specified interval of time. This practice generally assumes that the population is sufficiently large so that, for sampling purposes, it may be considered infinite. Where this assumption is inadequate, that is, the population is assumed finite, many of the provisions of this practice may be employed but the sampling and analysis procedure must be designed to reflect a finite population. The statistical techniques embodied in this practice provide procedures to summarize data so that logical judgments can be made. This practice does not specify the action to be taken after the results have been analyzed. The action to be taken depends on the particular requirements of the user of the product.

1.2 The values stated in inch-pound units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: D 2915 – 98

Standard Practice for

Evaluating Allowable Properties for Grades of Structural

Lumber

This standard is issued under the fixed designation D 2915; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Equation 5 was corrected in October 2000.

INTRODUCTION

The mechanical properties of structural lumber depend upon natural growth characteristics and

manufacturing practices. Several procedures can be used to sort lumber into property classes or stress

grades, the most widely used being the visual methods outlined in Practice D 245. With each, a

modulus of elasticity and a set of from one to five allowable stresses may be associated with each

stress grade. The allowable stresses are extreme fiber stress in bending, tension parallel to the grain,

compression parallel to the grain, shear, and compression perpendicular to the grain. This test method

for evaluation of the properties of structural lumber defines an allowable property as the value of the

property that would normally be published with the grade description.

This practice is useful in assessing the appropriateness of the assigned properties and for checking

the effectiveness of grading procedures.

For situations where a manufactured product is sampled repeatedly or lot sizes are small, alternative

test methods as described in Ref (1) may be more applicable.

1. Scope 1.2 The values stated in inch-pound units are to be regarded

as the standard.

1.1 This practice covers sampling and analysis procedures

1.3 This standard does not purport to address all of the

for the investigation of specified populations of stress-graded

safety concerns, if any, associated with its use. It is the

structural lumber. Depending on the interest of the user, the

responsibility of the user of this standard to establish appro-

population from which samples are taken may range from the

priate safety and health practices and determine the applica-

lumber from a specific mill to all the lumber produced in a

bility of regulatory limitations prior to use.

particular grade from a particular geographic area, during some

specified interval of time. This practice generally assumes that

2. Referenced Documents

the population is sufficiently large so that, for sampling

2.1 ASTM Standards:

purposes, it may be considered infinite. Where this assumption

D 198 Methods of Static Tests of Timber in Structural

is inadequate, that is, the population is assumed finite, many of

Sizes

the provisions of this practice may be employed but the

D 245 Practice for Establishing Structural Grades and Re-

sampling and analysis procedure must be designed to reflect a

lated Allowable Properties for Visually Graded Lumber

finite population. The statistical techniques embodied in this

E 105 Practice for Probability Sampling of Materials

practice provide procedures to summarize data so that logical

judgments can be made. This practice does not specify the

3. Statistical Methodology

action to be taken after the results have been analyzed. The

3.1 Two general analysis procedures are described under

action to be taken depends on the particular requirements of the

this practice, parametric and nonparametric. The parametric

user of the product.

approach assumes a known distribution of the underlying

population, an assumption which, if incorrect, may lead to

inaccurate results. Therefore, if a parametric approach is used,

This practice is under the jurisdiction of ASTM Committee D-7 on Wood and

appropriate statistical tests shall be employed to substantiate

is the direct responsibility of Subcommittee D07.02 on Lumber and Engineered

this choice along with measures of test adequacy (2, 3, 4, 5, 6,

Wood Products.

Current edition approved Oct. 10, 1998. Published March 1999. Originally

published as D 2915 – 70 T. Last previous edition D 2915 – 94.

2 3

The boldface numbers in parentheses refer to the list of references at the end of Annual Book of ASTM Standards, Vol 04.10.

this practice. Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 2915

7). Alternatively a nonparametric approach requires fewer allowable stresses, a near-minimum property is generally the

assumptions, and is generally more conservative than a para- objective.

metric procedure. 3.4.2 Determine sample size sufficient for estimating the

mean by a two-stage method, with the use of the following

3.2 Population:

equation. This equation assumes the data is normally distrib-

3.2.1 It is imperative that the population to be evaluated be

uted and the mean is to be estimated to within 5 % with

clearly defined, as inferences made pertain only to that popu-

specified confidence:

lation. In order to define the population, it may be necessary to

t

specify ( 1) grade name and description, (2) geographical area

¯

n 5 ~ts/0.05 X! 5 CV (1)

S D

0.05

over which sampling will take place (nation, state, mill, etc.),

(3) species or species group, (4) time span for sampling (a

where:

day’s production, a month, a year, etc.), (5) lumber size, and

n = sample size,

(6) moisture content.

s = standard deviation of specimen values,

¯

3.2.2 Where possible, the sampling program should con- X = specimen mean value,

¯

sider the location and type of log source from which the pieces CV = coefficient of variation, s/ X,

0.05 = precision of estimate, and

originated, including types of processing methods or marketing

t = value of the t statistic from Table 1.

practices with respect to any influence they may have on the

¯

Often the values of s, X, and t or CV and t are not known

representative nature of the sample. Samples may be collected

¯

before the testing program begins. However, s and X,orCV,

from stock at mills, centers of distribution, at points of end use

may be approximated by using the results of some other test

or directly from current production at the grading chains of

program, or they may simply be guessed (see example, Note

manufacturing facilities.

1).

3.3 Sampling Procedure:

NOTE 1—An example of initial sample size calculation is:

3.3.1 Random Sampling— The sampling unit is commonly

the individual piece of lumber. When this is not the case, see

TABLE 1 Values of the t Statistics Used in Calculating

3.3.3. The sampling shall assure random selection of sampling

A

Confidence Intervals

units from the population described in 3.2 with all members of

df

the population sharing equal probability of selection. The

CI =75% CI =95% CI =99%

n −1

principles of Practice E 105 shall be maintained. When sam-

1 2.414 12.706 63.657

pling current production, refer to Practice E 105 for a recom-

2 1.604 4.303 9.925

mended sampling procedure (see Appendix X3 of this practice 3 1.423 3.182 5.841

4 1.344 2.776 4.604

for an example of this procedure). If samples are selected from

5 1.301 2.571 4.032

inventory, random number tables may be used to determine

which pieces will be taken for the sample.

6 1.273 2.447 3.707

7 1.254 2.365 3.499

3.3.2 Sampling with Unequal Probabilities—Under some

8 1.240 2.306 3.355

circumstances, it may be advisable to sample with unequal but 9 1.230 2.262 3.250

10 1.221 2.228 3.169

known probabilities. Where this is done, the general principles

of Practice E 105 shall be maintained, and the sampling

11 1.214 2.201 3.106

method shall be completely reported. 12 1.209 2.179 3.055

13 1.204 2.160 3.012

3.3.3 Sequential Sampling—When trying to characterize

14 1.200 2.145 2.977

how a certain population of lumber may perform in a structure,

15 1.197 2.131 2.947

it may be deemed more appropriate to choose a sampling unit,

16 1.194 2.120 2.921

such as a package, that is more representative of how the

17 1.191 2.110 2.898

lumber will be selected for use. Such a composite sampling 18 1.189 2.101 2.878

19 1.187 2.093 2.861

unit might consist of a sequential series of pieces chosen to

20 1.185 2.086 2.845

permit estimation of the properties of the unit as well as the

pieces. Where this is done, the principles in 3.3.1 and 3.3.2

21 1.183 2.080 2.831

22 1.182 2.074 2.891

apply to these composite sampling units and the sampling

23 1.180 2.069 2.807

method shall be completely reported.

24 1.179 2.064 2.797

25 1.178 2.060 2.787

3.4 Sample Size:

3.4.1 Selection of a sample size depends upon the property

26 1.177 2.056 2.779

or properties to be estimated, the actual variation in properties 27 1.176 2.052 2.771

28 1.175 2.048 2.763

occurring in the population, and the precision with which the

29 1.174 2.045 2.756

property is to be estimated. For the five allowable stresses and

30 1.173 2.042 2.750

the modulus of elasticity various percentiles of the population

40 1.167 2.021 2.704

may be estimated. For all properties, nonparametric or para-

60 1.162 2.000 2.660

metric techniques are applicable. Commonly the mean modu-

120 1.156 1.980 2.617

‘ 1.150 1.960 2.576

lus of elasticity and the mean compression perpendicular to the

A

grain stress for the grade are estimated. For the four other Adapted from Ref (8). For calculating other confidence levels, see Ref (8).

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 2915

Sampling a grade of lumber for modulus of elasticity (E). Assuming a

limit will fall above (or below) the population value, corre-

95 % confidence level, the t statistic can be approximated by 2.

sponding to the required content, is controlled by the confi-

s = 300 000 psi (2067 MPa)

dence level selected, the larger the sample size the more likely

¯

X = assigned E of the grade = 1 800 000 psi (12 402 MPa)

the tolerance limit will be close to the population value. It is,

CV = (300 000/1 800 000) = 0.167

therefore, desirable to select a sample size as large as possible

t =2

2 commensurate with the cost of sampling and testing (see also

n = 3 0.167 5 44.622 ~45 pieces!

S D

0.05

4.7).

Calculate the sample mean and standard deviation and use them to

3.4.3.2 If a parametric approach is used, then a tolerance

estimate a new sample size from Eq 1, where the value of t is taken from

limit with stated content and confidence can be obtained for

Table 1. If the second sample size exceeds the first, the first sample was

any sample size; however, the limitation expressed in 3.4.3.1

insufficient; obtain and test the additional specimens.

applies. That is, although the frequency that the tolerance limit

NOTE 2—More details of this two-stage method are given in Ref (8).

falls above (or below) the population value, corresponding to

3.4.3 To determine sample size based on a tolerance limit

the required content is controlled, the probability that the

(TL), the desired content (C) (Note 3) and associated confi-

tolerance limit will be close to the population value depends on

dence level must be selected. The choice of a specified content

the sample size. For example, if normality is assumed, the

and confidence is dependent upon the end-use of the material,

¯

parametric tolerance limit (PTL) will be of the form PTL = X

economic considerations, current design practices, code re-

− Ks, (see Ref (8)), and the standard error (SE) of this statistic

quirements, etc. For example, a content of 95 % and a

may be approximated by the following equation:

confidence level of 75 % may be appropriate for a specific

property of structural lumber. Different confidence levels may

1 K

SE 5 s 1 (2)

˛

be suitable for different products or specific end uses. Appro-

n 2 n 2 1!

~

priate content and confidence levels shall be selected before the

where:

sampling plan is designed.

s = standard deviation of specimen values,

NOTE 3—The content, C, is an estimate of the proportion of the

n = sample size, and

population that lies above the tolerance limit. For example, a tolerance

K = confidence level factor.

limit with a content of 95 % describes a level at which 95 % of the

The sample size, n, may be chosen to make this quantity

population lies above the tolerance limit. The confidence with which this

sufficiently small for the intended end use of the material (Note

inference is to be made is a separate statement.

4).

3.4.3.1 To determine the sample size for near-minimum

NOTE 4—An example of sample size calculation where the purpose is

properties, the nonparametric tolerance limit concept of Ref (8)

to estimate a near minimum property is shown in the following calcula-

may be used (Table 2). This will provide the sample size

tion:

suitable for several options in subsequent near-minimum

Estimate the sample size, n, for a compression parallel strength test in

analyses. Although the frequency with which the tolerance

which normality will be assumed. A CV of 22 % and a mean C of 4600

psi are assumed based on other tests. The target PTL of the lumber grade

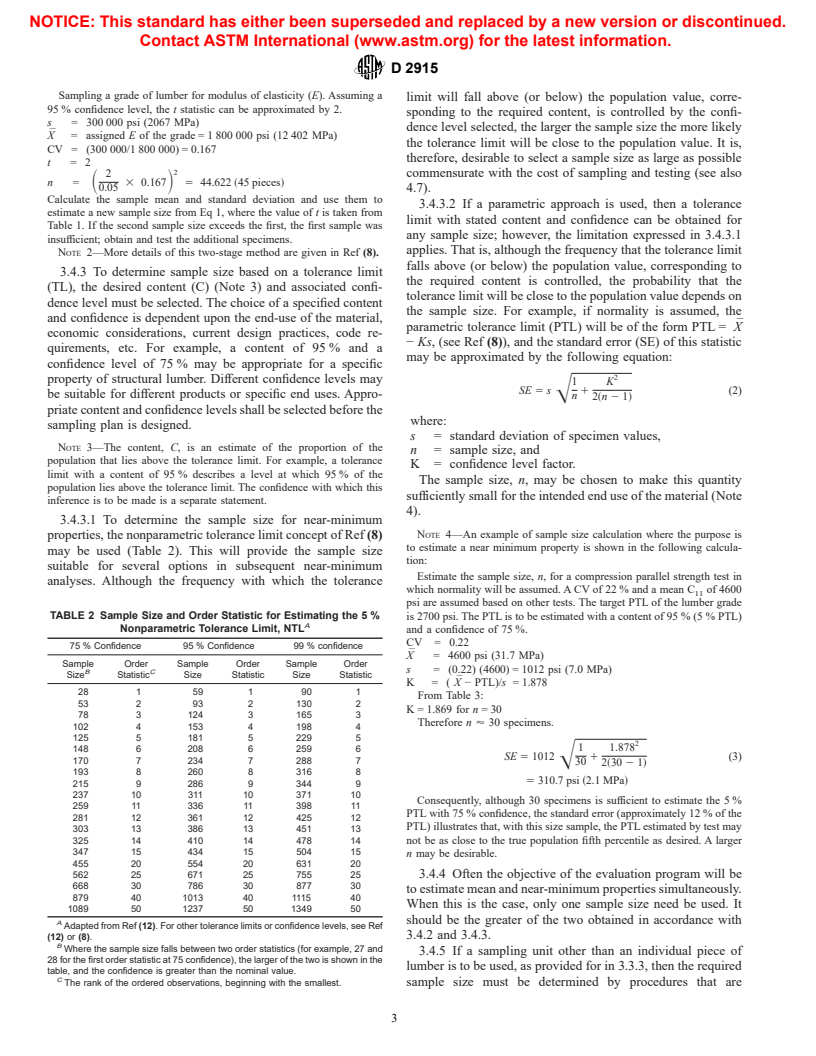

TABLE 2 Sample Size and Order Statistic for Estimating the 5 % is 2700 psi. The PTL is to be estimated with a content of 95 % (5 % PTL)

A

Nonparametric Tolerance Limit, NTL

and a confidence of 75 %.

CV = 0.22

75 % Confidence 95 % Confidence 99 % confidence

¯

X = 4600 psi (31.7 MPa)

Sample Order Sample Order Sample Order

s = (0.22) (4600) = 1012 psi (7.0 MPa)

B C

Size Statistic Size Statistic Size Statistic

¯

K=( X − PTL)/s = 1.878

28 1 59 1 90 1

From Table 3:

53 2 93 2 130 2

K = 1.869 for n=30

78 3 124 3 165 3

Therefore n ’ 30 specimens.

102 4 153 4 198 4

125 5 181 5 229 5

1 1.878

148 6 208 6 259 6

SE 5 1012 1 (3)

˛

170 7 234 7 288 7

2~30 2 1!

193 8 260 8 316 8

5 310.7 psi ~2.1 MPa!

215 9 286 9 344 9

237 10 311 10 371 10

Consequently, although 30 specimens is sufficient to estimate the 5 %

259 11 336 11 398 11

PTL with 75 % confidence, the standard error (approximately 12 % of the

281 12 361 12 425 12

PTL) illustrates that, with this size sample, the PTL estimated by test may

303 13 386 13 451 13

325 14 410 14 478 14 not be as close to the true population fifth percentile as desired. A larger

347 15 434 15 504 15

n may be desirable.

455 20 554 20 631 20

562 25 671 25 755 25 3.4.4 Often the objective of the evaluation program will be

668 30 786 30 877 30

to estimate mean and near-minimum properties simultaneously.

879 40 1013 40 1115 40

When this is the case, only one sample size need be used. It

1089 50 1237 50 1349 50

should be the greater of the two

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.