ASTM E2142-08

(Test Method)Standard Test Methods for Rating and Classifying Inclusions in Steel Using the Scanning Electron Microscope

Standard Test Methods for Rating and Classifying Inclusions in Steel Using the Scanning Electron Microscope

SIGNIFICANCE AND USE

This test method is established to cover automated SEM/EDX-based procedures for:

Rating the inclusion content of steels based on procedures listed in Standards E 45 and E 1245, with the significant difference that the composition of the individual inclusions, as determined by X-ray analysis, is utilized to sort them into chemical classes.

Determining the number, size and morphological distribution of inclusions in steels sorted by chemical class.

Methods 1 and 2 of this test method are primarily intended for rating the inclusion content of steels deoxidized with silicon or aluminum, both silicon and aluminum, or vacuum-treated steels without either silicon or aluminum additions. Guidelines are provided to rate inclusions in steel treated with rare earth additions or calcium-bearing compounds (13.4). When such steels are evaluated, the test report should describe the nature of the inclusions rated according to each inclusion category (A, B, C, D).

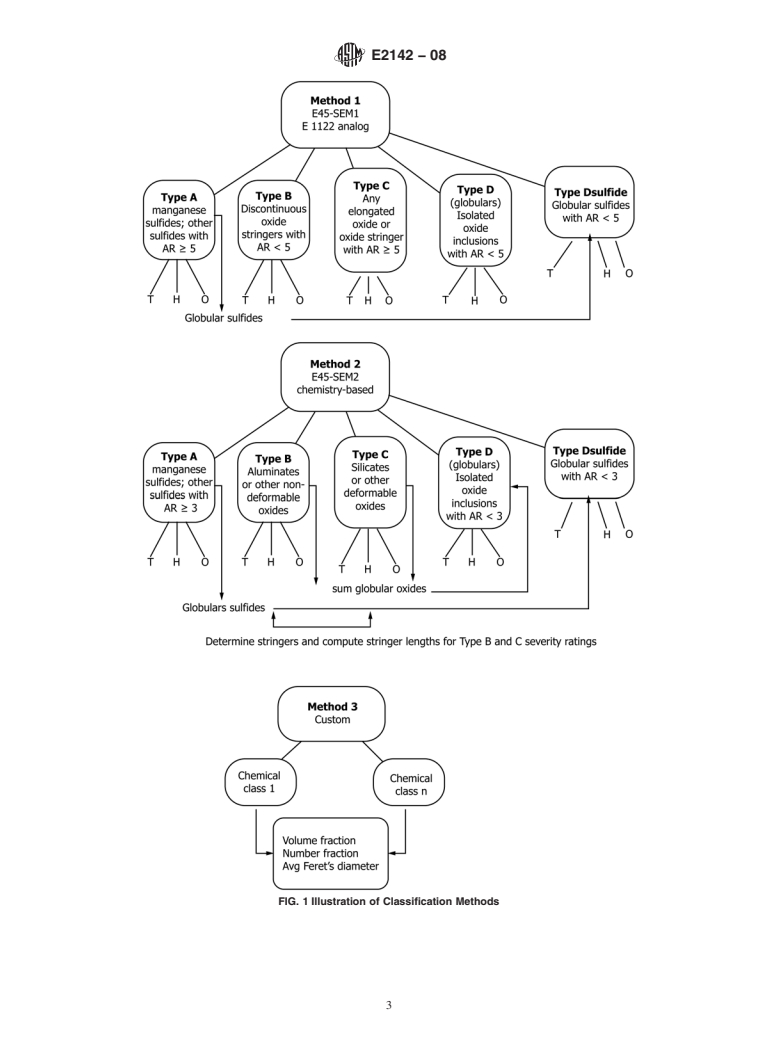

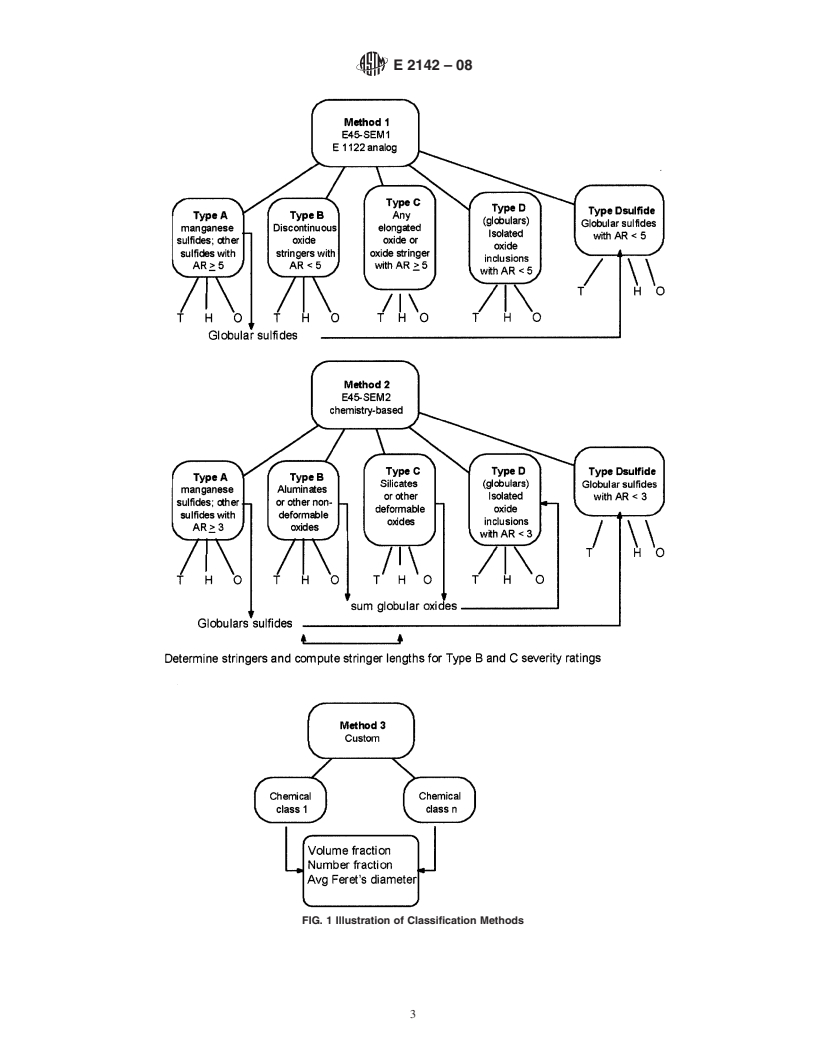

Methods 1 and 2 will provide a quantitative rating of the inclusion content in half-severity number increments from 0 to 5 for each inclusion type and thickness (Method D of Test Method E 45), and in tabulated in Table 2. Test Method E 45 ratings by SEM may differ from those determined following E 45 because of the use of chemistry in the classifications. In order to differentiate E 45 ratings obtained using the SEM from traditional ratings using light microscopy, the ratings obtained using Method 1 or 2 of this Test Method shall be identified as E 45-SEM1 and E 45-SEM2, respectively.

Method 3 defines procedures to analyze and report inclusions by arbitrary size distribution and chemical classifications. It may be made applicable to any material by appropriate choice of these classifications.

Method 3 determines and reports basic (as used in Test Method E 1245) stereological measurements (for example, volume fraction of sulfides and oxides, the number of sulfides or oxides per square millimeter, and so forth). T...

SCOPE

1.1 This test method covers procedures to obtain particle size distribution, chemical classification, and Test Methods E 45 ratings of inclusions in steels using an automated scanning electron microscope (SEM) with X-ray analysis and automatic image analysis capabilities.

1.2 There are three discrete methods described. Method 1 is the SEM analog of Test Method E 45, which uses image analysis and light microscopy to produce automated Test Methods E 45 ratings. Method 2 produces similar ratings based predominantly on sorting inclusions by chemistry into the traditional classes defined in Test Methods E 45. Method 3 is recommended when explicit detail is needed on particular inclusion types, not necessarily defined in Test Methods E 45, such as to verify the composition of inclusions in inclusion-engineered steel. Method 3 reports stereological parameters such as volume or number fraction, rather than Test Methods E 45 type ratings.

1.3 This test method deals only with the recommended test methods and nothing in it should be construed as defining or establishing limits of acceptability for any grade of steel or other alloy where the method is appropriate.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E2142 − 08

StandardTest Methods for

Rating and Classifying Inclusions in Steel Using the

1

Scanning Electron Microscope

This standard is issued under the fixed designation E2142; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

1.1 This test method covers procedures to obtain particle 2.1 ASTM Standards:

size distribution, chemical classification, and Test Methods E3Guide for Preparation of Metallographic Specimens

E45ratingsofinclusionsinsteelsusinganautomatedscanning E7Terminology Relating to Metallography

electron microscope (SEM) with X-ray analysis and automatic E45Test Methods for Determining the Inclusion Content of

image analysis capabilities. Steel

E766Practice for Calibrating the Magnification of a Scan-

1.2 Therearethreediscretemethodsdescribed.Method1is

ning Electron Microscope

the SEM analog of Test Method E45, which uses image

E768Guide for Preparing and Evaluating Specimens for

analysis and light microscopy to produce automated Test

Automatic Inclusion Assessment of Steel

Methods E45 ratings. Method 2 produces similar ratings based

E1245Practice for Determining the Inclusion or Second-

predominantly on sorting inclusions by chemistry into the

Phase Constituent Content of Metals byAutomatic Image

traditional classes defined in Test Methods E45. Method 3 is

Analysis

recommended when explicit detail is needed on particular

E1508 Guide for Quantitative Analysis by Energy-

inclusion types, not necessarily defined in Test Methods E45,

Dispersive Spectroscopy

such as to verify the composition of inclusions in inclusion-

2.2 Adjuncts:

engineered steel. Method 3 reports stereological parameters

ANSI/IEEE STD 759IEEE Standard Test Procedure for

such as volume or number fraction, rather than Test Methods

3

Semiconductor X-Ray Energy Spectrometers

E45 type ratings.

3. Terminology

1.3 This test method deals only with the recommended test

methods and nothing in it should be construed as defining or

3.1 Definitions—For definitions of terms used in this test

establishing limits of acceptability for any grade of steel or

method, see Terminology E7.

other alloy where the method is appropriate.

3.2 Definitions of Terms Specific to This Standard:

1.4 The values stated in SI units are to be regarded as

3.2.1 Analysis Rules—

standard. No other units of measurement are included in this

3.2.1.1 acquisition analysis rules—include the criteria to

standard.

terminate X-ray collection (counts or time, or both), the list of

1.5 This standard does not purport to address all of the

elements to be analyzed, the number of fields or particles to be

safety concerns, if any, associated with its use. It is the

analyzed,morphologiesofparticlesfromwhichspectrawillbe

responsibility of the user of this standard to establish appro-

collected,etc.(seeAppendixX1foramorecompletelistingof

priate safety and health practices and determine the applica-

typical Acquisition Rules).

bility of regulatory limitations prior to use.

3.2.1.2 post-acquisition analysis rules—define ratios of

X-rayintensitiesorelementalcompositionsrequiredtoidentify

1 2

These test methods are under the jurisdiction of ASTM Committee E04 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Metallography and are the direct responsibility of Subcommittee E04.11 on X-Ray contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

and Electron Metallography. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Oct. 1, 2008. Published October 2008. Originally the ASTM website.

3

approved in 2001. Last previous edition approved in 2001 as E2142–01. DOI: Available from Institute of Electrical and Electronics Engineers, Inc. (IEEE),

10.1520/E2142-08. 445 Hoes Ln., P.O. Box 1331, Piscataway, NJ 08854-1331, http://www.ieee.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E2142 − 08

aninclusionasbelongingtoaparticularchemicalclassification vided as thin, heavy and oversized, according to their width

and, for Methods 1 and 2 herein, define the main inclusion (tabulated in Table 1). E45-equivalent ratings are determined

class (A, B, or C) to which each chemical classification andrecorded,andreportedparticlesareusuallylimitedtothose

belongs. ≥ 2 µm in size.

4.3.2 The inclusion classification strategy in Method 2 is

3.2.2 chemical classification—defined compositional cat-

based predominantly on chemistry, but uses morphology when

eg

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:E2142–01 Designation: E 2142 – 08

Standard Test Methods for

Rating and Classifying Inclusions in Steel Using the

1

Scanning Electron Microscope

This standard is issued under the fixed designation E 2142; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers procedures to obtain particle size distribution, chemical classification, and Test Methods E 45

ratings of inclusions in steels using an automated scanning electron microscope (SEM) with X-ray analysis and automatic image

analysis capabilities.

1.2 There are three discrete methods described. Method 1 is the SEM analog of E1122Test Method E 45, which uses image

analysis and light microscopy to produce automated Test Methods E 45 ratings. Method 2 produces similar ratings based

predominantly on sorting inclusions by chemistry into the traditional classes defined in Test Methods E 45. Method 3 is

recommended when explicit detail is needed on particular inclusion types, not necessarily defined in Test Methods E 45, such as

to verify the composition of inclusions in inclusion-engineered steel. Method 3 reports stereological parameters such as volume

or number fraction, rather than Test Methods E 45 type ratings.

1.3 This test method deals only with the recommended test methods and nothing in it should be construed as defining or

establishing limits of acceptability for any grade of steel or other alloy where the method is appropriate.

1.4The values stated in SI units are to be regarded as the standard. Values in parentheses are conversions and are approximate,

and for information only.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

E 3Practice Guide for Preparation of Metallographic Specimens

E 7 Terminology Relating to Metallography

E 45 Test Methods for Determining the Inclusion Content of Steel

E 766 Practice for Calibrating the Magnification of a Scanning Electron Microscope

2

E 768Practice for Preparing and Evaluating Specimens for Automated Inclusion Analysis of Steel

2

E1122Practice for Obtaining Inclusion Ratings Using Automatic Image Analysis Guide for Preparing and Evaluating

Specimens for Automatic Inclusion Assessment of Steel

E 1245 Practice for Determining the Inclusion or Second-Phase Constituent Content of Metals by Automatic Image Analysis

2

E 1508Guide for QuantitativeAnalysis by Energy DispersiveAnalysis Guide for QuantitativeAnalysis by Energy-Dispersive

Spectroscopy

2.2 Adjuncts:

3

ANSI/IEEE STD 759 IEEE Standard Test Procedure for Semiconductor X-Ray Energy Spectrometers

1

These test methods are under the jurisdiction of ASTM Committee E04 on Metallography and are the direct responsibility of Subcommittee E04.11 on X-Ray and

Electron Metallogrpahy jointly with E04.09 on Steel Inclusions.

Current edition approved April 10, 2001. Published June 2001.

1

These test methods are under the jurisdiction of ASTM Committee E04 on Metallography and are the direct responsibility of Subcommittee E04.11 on X-Ray and

Electron Metallography.

Current edition approved Oct. 1, 2008. Published October 2008. Originally approved in 2001. Last previous edition approved in 2001 as E2142–01.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 03.01.volume information, refer to the standard’s Document Summary page on the ASTM website.

3

This standard is available from The Institute of Electrical and Electronics Engineers, Inc., 345 East 47th Street, New York, NY 10017.

3

Available from Institute of Electrical and Electronics Engineers, Inc. (IEEE), 445 Hoes Ln., P.O. Box 1331, Piscataway, NJ 08854-1331, http://www.ieee.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E2142–08

3. Terminology

3.1 Definitio

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.