ASTM E136-22

(Test Method)Standard Test Method for Assessing Combustibility of Materials Using a Vertical Tube Furnace at 750 °C

Standard Test Method for Assessing Combustibility of Materials Using a Vertical Tube Furnace at 750 °C

SIGNIFICANCE AND USE

5.1 Materials that pass this test by complying with the criteria in Section 15 are typically classified as noncombustible materials.

5.2 While actual building fire exposure conditions are not duplicated, this test method will assist in indicating those materials which do not act to aid combustion or add appreciable heat to an ambient fire.

5.3 Materials passing the test are permitted limited flaming and other indications of combustion.

SCOPE

1.1 This fire-test-response test method covers the determination under specified laboratory conditions of the combustibility of building materials. Materials passing this test are typically classified as noncombustible materials.

1.2 Limitations of this fire-test response test method are shown below.

1.2.1 This test method does not apply to laminated or coated materials.

1.2.2 This test method is not suitable or satisfactory for materials that soften, flow, melt, intumesce or otherwise separate from the measuring thermocouple.

1.2.3 This test method does not provide a measure of an intrinsic property.

1.2.4 This test method does not provide a quantitative measure of heat generation or combustibility; it simply serves as a test method with selected (end point) measures of combustibility.

1.2.5 The test method does not measure the self-heating tendencies of materials.

1.2.6 In this test method materials are not being tested in the nature and form used in building applications. The test specimen consists of a small, specified volume that is either (1) cut from a thick sheet; (2) assembled from multiple thicknesses of thin sheets; or (3) placed in a container if composed of granular powder or loose-fiber materials.

1.2.7 Results from this test method apply to the specific test apparatus and test conditions and are likely to vary when changes are made to one or more of the following: (1) the size, shape, and arrangement of the specimen; (2) the distribution of organic content; (3) the exposure temperature; (4) the air supply; (5) the location of thermocouples.

1.3 This test method includes two options, both of which use a furnace to expose test specimens of building materials to a temperature of 750 °C (1382 °F).

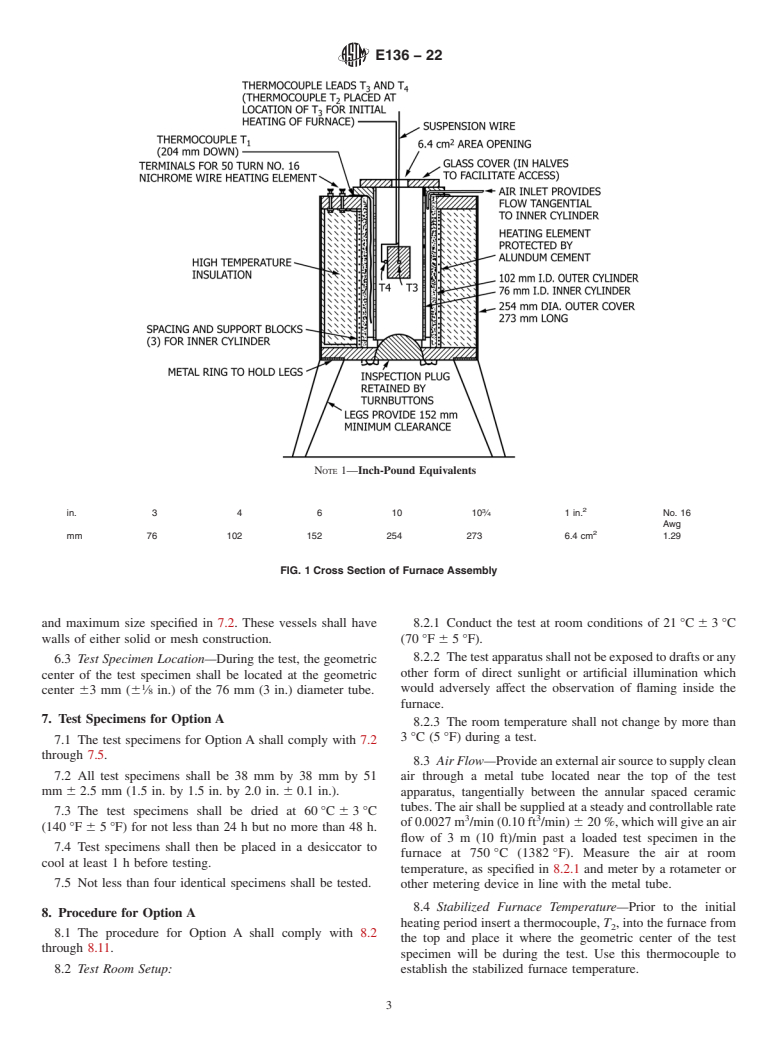

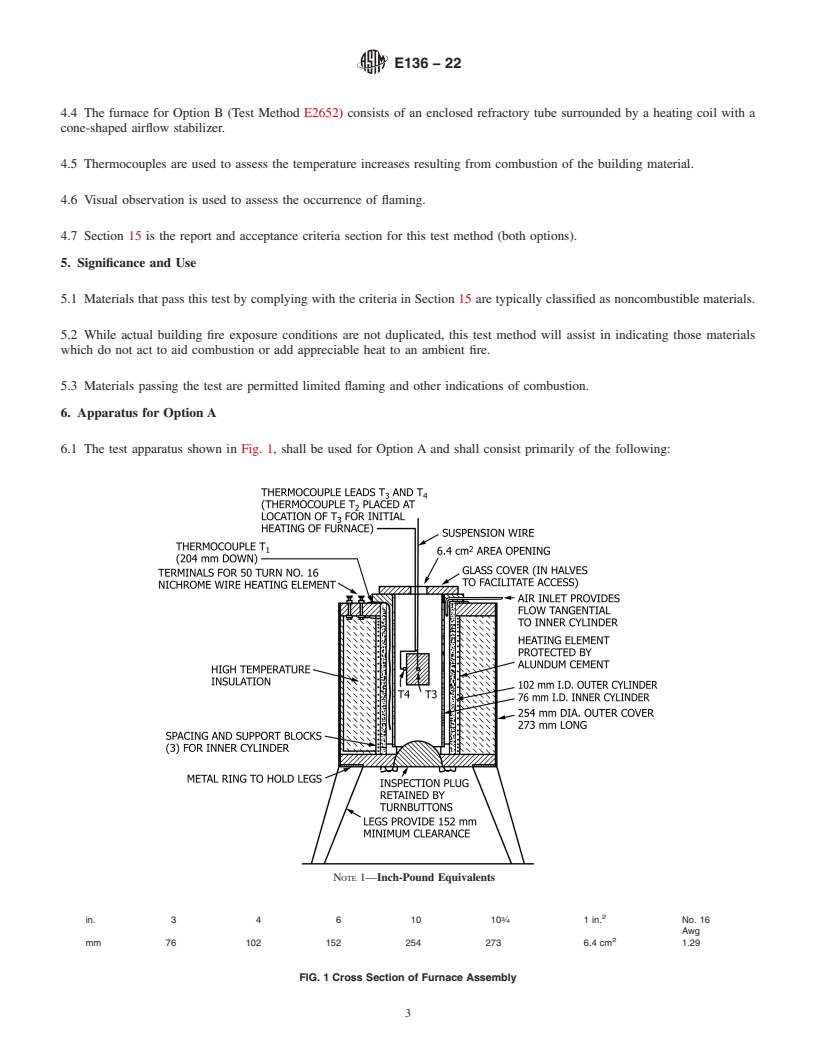

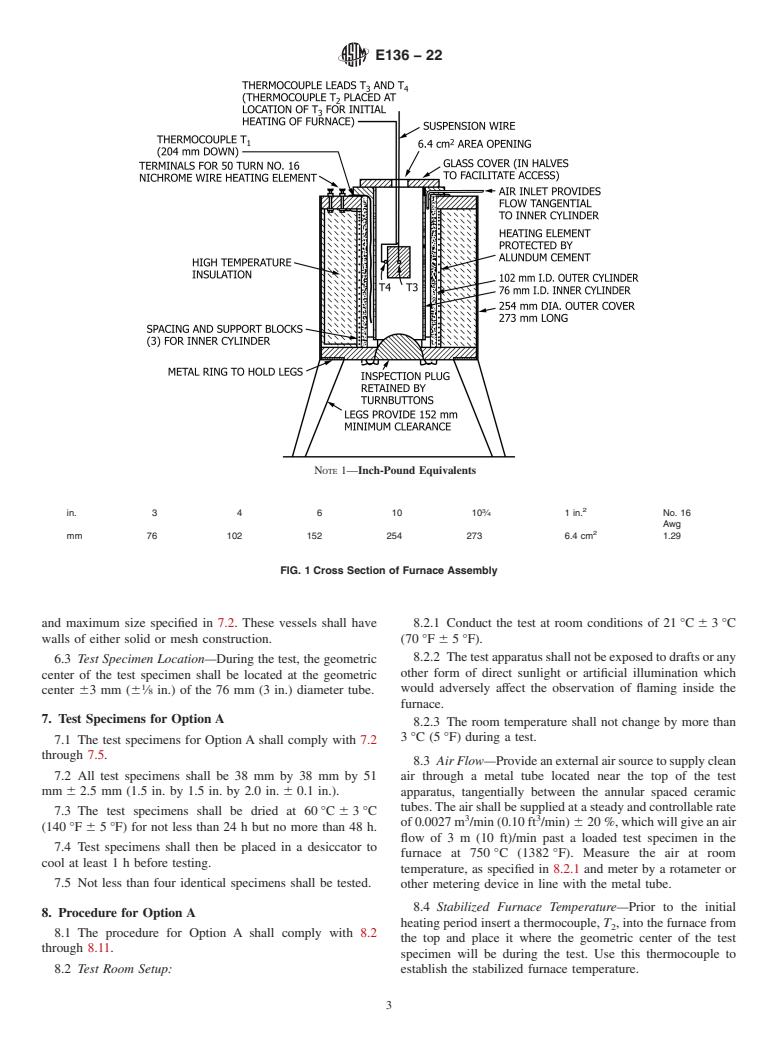

1.3.1 The furnace for the apparatus for Option A consists of a ceramic tube containing an electric heating coil, and two concentric vertical refractory tubes.

1.3.2 The furnace for the apparatus for Option B (Test Method E2652) consists of an enclosed refractory tube surrounded by a heating coil with a cone-shaped airflow stabilizer.

1.4 This test method references notes and footnotes that provide explanatory information. These notes and footnotes, excluding those in tables and figures, shall not be considered as requirements of this test method.

1.5 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.6 This standard is used to measure and describe the response of materials, products, or assemblies to heat and flame under controlled conditions, but does not by itself incorporate all factors required for fire-hazard or fire-risk assessment of the materials, products, or assemblies under actual fire conditions.

1.7 Fire testing is inherently hazardous. Adequate safeguards for personnel and property shall be employed in conducting these tests.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.9 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barri...

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E136 − 22 An American National Standard

Standard Test Method for

Assessing Combustibility of Materials Using a Vertical Tube

1

Furnace at 750 °C

This standard is issued under the fixed designation E136; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* organic content; (3) the exposure temperature; (4) the air

supply; (5) the location of thermocouples.

1.1 This fire-test-response test method covers the determi-

nation under specified laboratory conditions of the combusti-

1.3 This test method includes two options, both of which

bility of building materials. Materials passing this test are

use a furnace to expose test specimens of building materials to

typically classified as noncombustible materials.

a temperature of 750 °C (1382 °F).

1.3.1 The furnace for the apparatus for OptionAconsists of

1.2 Limitations of this fire-test response test method are

a ceramic tube containing an electric heating coil, and two

shown below.

concentric vertical refractory tubes.

1.2.1 Thistestmethoddoesnotapplytolaminatedorcoated

materials. 1.3.2 The furnace for the apparatus for Option B (Test

Method E2652) consists of an enclosed refractory tube sur-

1.2.2 This test method is not suitable or satisfactory for

materials that soften, flow, melt, intumesce or otherwise roundedbyaheatingcoilwithacone-shapedairflowstabilizer.

separate from the measuring thermocouple.

1.4 This test method references notes and footnotes that

1.2.3 This test method does not provide a measure of an

provide explanatory information. These notes and footnotes,

intrinsic property.

excludingthoseintablesandfigures,shallnotbeconsideredas

1.2.4 This test method does not provide a quantitative

requirements of this test method.

measure of heat generation or combustibility; it simply serves

1.5 The values stated in SI units are to be regarded as

as a test method with selected (end point) measures of

standard. The values given in parentheses are for information

combustibility.

only.

1.2.5 The test method does not measure the self-heating

tendencies of materials.

1.6 This standard is used to measure and describe the

1.2.6 Inthistestmethodmaterialsarenotbeingtestedinthe

response of materials, products, or assemblies to heat and

nature and form used in building applications. The test speci-

flame under controlled conditions, but does not by itself

men consists of a small, specified volume that is either (1) cut

incorporate all factors required for fire-hazard or fire-risk

from a thick sheet; (2) assembled from multiple thicknesses of

assessment of the materials, products, or assemblies under

thinsheets;or (3)placedinacontainerifcomposedofgranular

actual fire conditions.

powder or loose-fiber materials.

1.7 Fire testing is inherently hazardous. Adequate safe-

1.2.7 Results from this test method apply to the specific test

guards for personnel and property shall be employed in

apparatus and test conditions and are likely to vary when

conducting these tests.

changes are made to one or more of the following: (1) the size,

shape, and arrangement of the specimen; (2) the distribution of

1.8 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

1 priate safety, health, and environmental practices and deter-

This test method is under the jurisdiction of ASTM Committee E05 on Fire

mine the applicability of regulatory limitations prior to use.

Standards and is the direct responsibility of Subcommittee E05.23 on Combustibil-

ity.

1.9 This international standard was developed in accor-

Current edition approved Oct. 1, 2022. Published October 2022. Originally

dance with internationally recognized principles on standard-

approved in 1958. Last previous edition approved in 2019 as E136 – 19a. DOI:

10.1520/E0136-22. ization established in the Decision on Principles for the

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E136 − 22

Development of International Standards, Guides and Recom- 5. Significance and Use

mendations issued by the World Trade Organization Technical

5.1 Materials that pass this test by complying w

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E136 − 19a E136 − 22 An American National Standard

Standard Test Method for

Assessing Combustibility of Materials Using a Vertical Tube

1

Furnace at 750°C750 °C

This standard is issued under the fixed designation E136; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This fire-test-response test method covers the determination under specified laboratory conditions of the combustibility of

building materials. Materials passing this test are typically classified as noncombustible materials.

1.2 Limitations of this fire-test response test method are shown below.

1.2.1 This test method does not apply to laminated or coated materials.

1.2.2 This test method is not suitable or satisfactory for materials that soften, flow, melt, intumesce or otherwise separate from the

measuring thermocouple.

1.2.3 This test method does not provide a measure of an intrinsic property.

1.2.4 This test method does not provide a quantitative measure of heat generation or combustibility; it simply serves as a test

method with selected (end point) measures of combustibility.

1.2.5 The test method does not measure the self-heating tendencies of materials.

1.2.6 In this test method materials are not being tested in the nature and form used in building applications. The test specimen

consists of a small, specified volume that is either (1) cut from a thick sheet; (2) assembled from multiple thicknesses of thin sheets;

or (3) placed in a container if composed of granular powder or loose-fiber materials.

1.2.7 Results from this test method apply to the specific test apparatus and test conditions and are likely to vary when changes

are made to one or more of the following: (1) the size, shape, and arrangement of the specimen; (2) the distribution of organic

content; (3) the exposure temperature; (4) the air supply; (5) the location of thermocouples.

1.3 This test method includes two options, both of which use a furnace to expose test specimens of building materials to a

temperature of 750°C (1382°F).750 °C (1382 °F).

1.3.1 The furnace for the apparatus for Option A consists of a ceramic tube containing an electric heating coil, and two concentric

vertical refractory tubes.

1

This test method is under the jurisdiction of ASTM Committee E05 on Fire Standards and is the direct responsibility of Subcommittee E05.23 on Combustibility.

Current edition approved Dec. 15, 2019Oct. 1, 2022. Published January 2020October 2022. Originally approved in 1958. Last previous edition approved in 2019 as

E136 – 19E136 – 19a. DOI: 10.1520/E0136-19A.10.1520/E0136-22.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E136 − 22

1.3.2 The furnace for the apparatus for Option B (Test Method E2652) consists of an enclosed refractory tube surrounded by a

heating coil with a cone-shaped airflow stabilizer.

1.4 This test method references notes and footnotes that provide explanatory information. These notes and footnotes, excluding

those in tables and figures, shall not be considered as requirements of this test method.

1.5 The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.6 This standard is used to measure and describe the response of materials, products, or assemblies to heat and flame under

controlled conditions, but does not by itself incorporate all factors required for fire-hazard or fire-risk assessment of the materials,

products, or assemblies under actual fire conditions.

1.7 Fire testing is inherently hazardous. Adequate safeguards for personnel and property shall be employed in conducting these

tests.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.9 This international standard was developed in accordance with internationally recognized principles on standardization

esta

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E136 − 22 An American National Standard

Standard Test Method for

Assessing Combustibility of Materials Using a Vertical Tube

1

Furnace at 750 °C

This standard is issued under the fixed designation E136; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* organic content; (3) the exposure temperature; (4) the air

supply; (5) the location of thermocouples.

1.1 This fire-test-response test method covers the determi-

nation under specified laboratory conditions of the combusti- 1.3 This test method includes two options, both of which

bility of building materials. Materials passing this test are use a furnace to expose test specimens of building materials to

typically classified as noncombustible materials. a temperature of 750 °C (1382 °F).

1.3.1 The furnace for the apparatus for Option A consists of

1.2 Limitations of this fire-test response test method are

a ceramic tube containing an electric heating coil, and two

shown below.

concentric vertical refractory tubes.

1.2.1 This test method does not apply to laminated or coated

1.3.2 The furnace for the apparatus for Option B (Test

materials.

Method E2652) consists of an enclosed refractory tube sur-

1.2.2 This test method is not suitable or satisfactory for

rounded by a heating coil with a cone-shaped airflow stabilizer.

materials that soften, flow, melt, intumesce or otherwise

separate from the measuring thermocouple. 1.4 This test method references notes and footnotes that

1.2.3 This test method does not provide a measure of an provide explanatory information. These notes and footnotes,

intrinsic property. excluding those in tables and figures, shall not be considered as

1.2.4 This test method does not provide a quantitative requirements of this test method.

measure of heat generation or combustibility; it simply serves

1.5 The values stated in SI units are to be regarded as

as a test method with selected (end point) measures of

standard. The values given in parentheses are for information

combustibility.

only.

1.2.5 The test method does not measure the self-heating

1.6 This standard is used to measure and describe the

tendencies of materials.

response of materials, products, or assemblies to heat and

1.2.6 In this test method materials are not being tested in the

flame under controlled conditions, but does not by itself

nature and form used in building applications. The test speci-

incorporate all factors required for fire-hazard or fire-risk

men consists of a small, specified volume that is either (1) cut

assessment of the materials, products, or assemblies under

from a thick sheet; (2) assembled from multiple thicknesses of

actual fire conditions.

thin sheets; or (3) placed in a container if composed of granular

powder or loose-fiber materials. 1.7 Fire testing is inherently hazardous. Adequate safe-

1.2.7 Results from this test method apply to the specific test guards for personnel and property shall be employed in

apparatus and test conditions and are likely to vary when conducting these tests.

changes are made to one or more of the following: (1) the size,

1.8 This standard does not purport to address all of the

shape, and arrangement of the specimen; (2) the distribution of

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

1

priate safety, health, and environmental practices and deter-

This test method is under the jurisdiction of ASTM Committee E05 on Fire

Standards and is the direct responsibility of Subcommittee E05.23 on Combustibil-

mine the applicability of regulatory limitations prior to use.

ity.

1.9 This international standard was developed in accor-

Current edition approved Oct. 1, 2022. Published October 2022. Originally

dance with internationally recognized principles on standard-

approved in 1958. Last previous edition approved in 2019 as E136 – 19a. DOI:

10.1520/E0136-22. ization established in the Decision on Principles for the

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E136 − 22

Development of International Standards, Guides and Recom- 5. Significance and Use

mendations issued by the World Trade Organization Technical

5.1 Materials that pass this test by complying with the

Barriers to Trade (TBT) Committee.

criteria in Section 15 are typically classified

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.