ASTM D807-05

(Practice)Standard Practice for Assessing the Tendency of Industrial Boiler Waters to Cause Embrittlement (USBM Embrittlement Detector Method)

Standard Practice for Assessing the Tendency of Industrial Boiler Waters to Cause Embrittlement (USBM Embrittlement Detector Method)

SCOPE

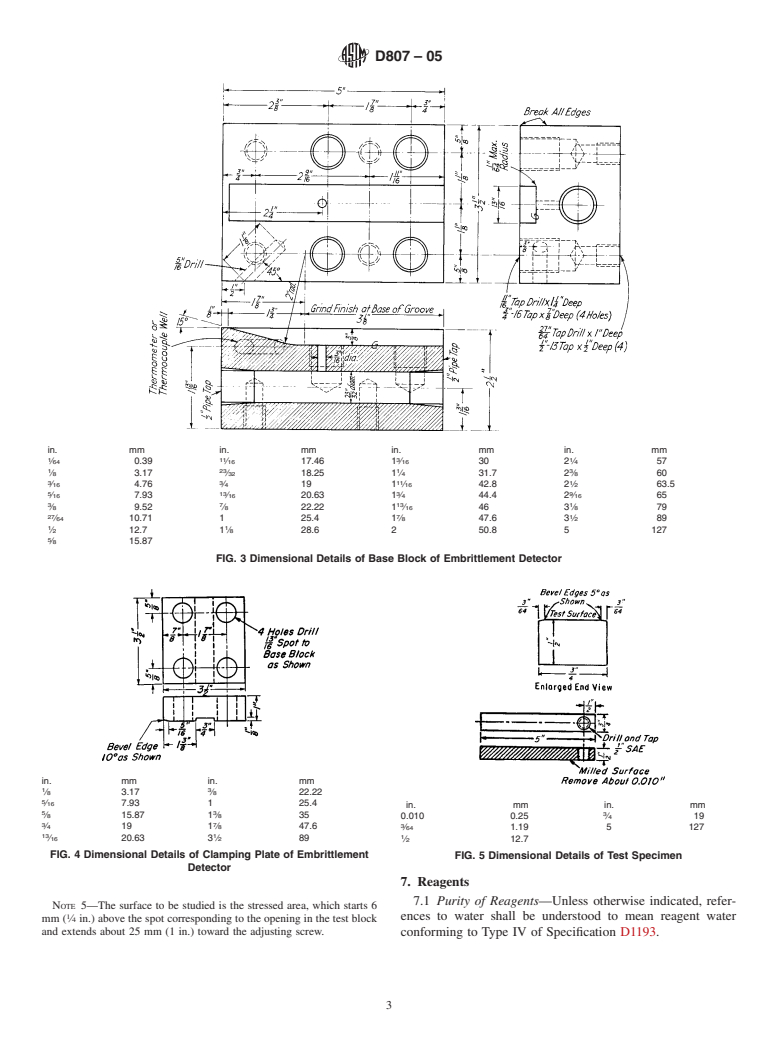

1.1 This practice, known as the embrittlement-detector method, covers the apparatus and procedure for determining the embrittling or nonembrittling characteristics of the water in an operating boiler. The interpretation of the results shall be restricted to the limits set forth in Section . Note 1The embrittlement detector was designed to reproduce closely the conditions existing in an actual boiler seam. It is considered probable that the individual conditions of leakage, concentration, and stress in the boiler seam can equal those in the detector. The essential difference between the detector and the boiler is that the former is so constructed and operated that these three major factors act simultaneously, continuously, and under the most favorable circumstances to produce cracking; whereas, in the boiler the three factors are brought together only under unique circumstances. Furthermore, in the detector any cracking is produced in a small test surface that can be inspected thoroughly, while the susceptible areas in a boiler are large and can be inspected only with difficulty. In these respects the embrittlement detector provides an accelerated test of the fourth condition necessary for embrittlement, the embrittling nature of the boiler water.

Note 2

Cracks in a specimen after being subjected to this test indicate that the boiler water can cause embrittlement cracking, but not that the boiler in question necessarily has cracked or will crack.

1.2 The effectiveness of treatment to prevent cracking, as well as an indication of whether an unsafe condition exists, are shown by this practice. Such treatments are evaluated in terms of method specimen resistance to failure.

1.3 The practice may be applied to embrittlement resistance testing of steels other than boiler plate, provided that a duplicate, unexposed specimen does not crack when bent 90 on a 2-in. (51-mm) radius.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D807–05

Standard Practice for

Assessing the Tendency of Industrial Boiler Waters to

1

Cause Embrittlement (USBM Embrittlement Detector

2

Method)

This standard is issued under the fixed designation D807; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.2 The effectiveness of treatment to prevent cracking, as

3 wellasanindicationofwhetheranunsafeconditionexists,are

1.1 This practice, known as the embrittlement-detector

shown by this practice. Such treatments are evaluated in terms

method, covers the apparatus and procedure for determining

of method specimen resistance to failure.

theembrittlingornonembrittlingcharacteristicsofthewaterin

1.3 The practice may be applied to embrittlement resistance

an operating boiler. The interpretation of the results shall be

testing of steels other than boiler plate, provided that a

restricted to the limits set forth in Section 8.6.

duplicate, unexposed specimen does not crack when bent 90°

NOTE 1—Theembrittlementdetectorwasdesignedtoreproduceclosely

on a 2-in. (51-mm) radius.

the conditions existing in an actual boiler seam. It is considered probable

1.4 This standard does not purport to address all of the

that the individual conditions of leakage, concentration, and stress in the

safety concerns, if any, associated with its use. It is the

boiler seam can equal those in the detector. The essential difference

responsibility of the user of this standard to establish appro-

betweenthedetectorandtheboileristhattheformerissoconstructedand

priate safety and health practices and determine the applica-

operated that these three major factors act simultaneously, continuously,

andunderthemostfavorablecircumstancestoproducecracking;whereas,

bility of regulatory limitations prior to use.

in the boiler the three factors are brought together only under unique

circumstances. Furthermore, in the detector any cracking is produced in a 2. Referenced Documents

small test surface that can be inspected thoroughly, while the susceptible

4

2.1 ASTM Standards:

areas in a boiler are large and can be inspected only with difficulty. In

A108 Specification for Steel Bar, Carbon and Alloy, Cold-

these respects the embrittlement detector provides an accelerated test of

Finished

thefourthconditionnecessaryforembrittlement,theembrittlingnatureof

A515/A515M Specification for PressureVessel Plates, Car-

the boiler water.

NOTE 2—Cracksinaspecimenafterbeingsubjectedtothistestindicate

bon Steel, for Intermediate- and Higher-Temperature Ser-

that the boiler water can cause embrittlement cracking, but not that the

vice

boiler in question necessarily has cracked or will crack.

D1129 Terminology Relating to Water

D1193 Specification for Reagent Water

E3 Guide for Preparation of Metallographic Specimens

1

E883 Guide for Reflected−Light Photomicrography

United States Bureau of Mines. DOI: 10.1520/D0807-05.

2

This test method is under the jurisdiction ofASTM Committee D19 on Water E1351 Practice for Production and Evaluation of Field

and is the direct responsibility of Subcommittee D19.03 on Sampling of Water and

Metallographic Replicas

Water-Formed Deposits,Analysis of Water for Power Generation and Process Use,

On-Line Water Analysis, and Surveillance of Water.

3. Terminology

Current edition approved Nov. 1, 2005. Published November 2005. Originally

approved in 1944. Last previous edition approved in 2000 as D807–00.

3.1 Definitions:

3

This test method was developed during an investigation conducted under a

3.1.1 Theterm embrittlement crackinginthistestmethodis

cooperative agreement between the Joint Research Committee on Boiler Feedwater

defined in accordance with Terminology D1129 as follows:

Studies and the United States Bureau of Mines.

For information on the development of this test method reference may be made 3.1.1.1 embrittlement cracking—aformofmetalfailurethat

to the following:

occurs in steam boilers at riveted joints and at tube ends, the

Schroeder, W. C. and Berk,A.A. “Intercrystalline Cracking of Boiler Steel and

cracking being predominantly intercrystalline.

Its Prevention,” Bulletin 443, U.S. Bureau of Mines, 1941.

Schroeder, W. C., Berk, A. A. and Stoddard, C. K. “Embrittlement Detector

NOTE 3—This form of cracking, which has been known as “caustic

Testing on Boilers,” Power Plant Engineering, Vol 45, August, 1941, pp. 69–76.

embrittlement,”isbelievedtoresultfromtheactionofcertainconstituents

“Embrittlement Symposium,” Transactions of the Am. Soc. Mech. Engrs., Vol

64, 1942, pp. 393–444.

Whirl, S. F. and Purcell, T. E. “Protection Against Caustic Embrittlement by

4

CoordinatedPh

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.