ASTM E363-83(2003)e1

(Test Method)Standard Test Methods for Chemical Analysis of Chromium and Ferrochromium

Standard Test Methods for Chemical Analysis of Chromium and Ferrochromium

SIGNIFICANCE AND USE

These test methods for the chemical analysis of metals and alloys are primarily intended to test such materials for compliance with compositional specifications. It is assumed that all who use these test methods will be trained analysts capable of performing common laboratory procedures skillfully and safely. It is expected that work will be performed in a properly equipped laboratory.

SCOPE

1.1 These test methods cover the chemical analysis of chromium and ferrochromium having chemical compositions within the following limits:ElementConcentration, %Aluminum0.25 maxAntimony0.005 maxArsenic0.005 maxBismuth0.005 maxBoron0.005 maxCarbon9.00 maxChromium51.0 to 99.5Cobalt0.10 maxColumbium0.05 maxCopper0.05 maxLead0.005 maxManganese0.75 maxMolybdenum0.05 maxNickel0.50 maxNitrogen6.00 maxPhosphorus0.03 maxSilicon12.00 maxSilver0.005 maxSulfur0.07 maxTantalum0.05 maxTin0.005 maxTitanium0.50 maxVanadium0.50 maxZinc0.005 maxZirconium0.05 max

1.2 The analytical procedures appear in the following order: SectionsArsenic by the Molybdenum Blue Photometric Method9-19Lead by the Dithizone Photometric Method20-30Chromium by the Sodium Peroxide Fusion-Titrimetric Method31-37

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of whoever uses this standard to consult and establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in Section 5.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:E363–83(Reapproved 2003)

Standard Test Methods for

Chemical Analysis of Chromium and Ferrochromium

This standard is issued under the fixed designation E363; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Warnings were moved from notes to section text editorially December 2002.

1. Scope mine the applicability of regulatory limitations prior to use.

Specific hazard statements are given in Section 5.

1.1 These test methods cover the chemical analysis of

chromium and ferrochromium having chemical compositions

2. Referenced Documents

within the following limits:

2.1 ASTM Standards:

Element Concentration, %

A101 Specification for Ferrochromium

Aluminum 0.25 max

A481 Specification for Chromium Metal

Antimony 0.005 max

E29 Practice for Using Significant Digits in Test Data to

Arsenic 0.005 max

Determine Conformance with Specifications

Bismuth 0.005 max

Boron 0.005 max

E32 Practices for Sampling Ferroalloys and SteelAdditives

Carbon 9.00 max

for Determination of Chemical Composition

Chromium 51.0 to 99.5

E50 Practices for Apparatus, Reagents, and Safety Consid-

Cobalt 0.10 max

Columbium 0.05 max

erations for Chemical Analysis of Metals, Ores, and

Copper 0.05 max

Related Materials

Lead 0.005 max

E60 Practice for Analysis of Metals, Ores, and Related

Manganese 0.75 max

Molybdenum 0.05 max

Materials by Molecular Absorption Spectrometry

Nickel 0.50 max

E173 Practice for Conducting Interlaboratory Studies of

Nitrogen 6.00 max

Phosphorus 0.03 max Test Methods for Chemical Analysis of Metals

Silicon 12.00 max

E360 Test Methods for Chemical Analysis of Silicon and

Silver 0.005 max

Ferrosilicon

Sulfur 0.07 max

E361 Test Methods for the Determination of Arsenic and

Tantalum 0.05 max

Tin 0.005 max

Lead in Ferromanganese

Titanium 0.50 max

Vanadium 0.50 max

3. Significance and Use

Zinc 0.005 max

Zirconium 0.05 max

3.1 These test methods for the chemical analysis of metals

and alloys are primarily intended to test such materials for

1.2 The analytical procedures appear in the following order:

compliance with compositional specifications. It is assumed

Sections

that all who use these test methods will be trained analysts

Arsenic by the Molybdenum Blue Photometric Method 9-19

capable of performing common laboratory procedures skill-

Lead by the Dithizone Photometric Method 20-30

fully and safely. It is expected that work will be performed in

Chromium by the Sodium Peroxide Fusion-Titrimetric Method 31-37

a properly equipped laboratory.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4. Apparatus, Reagents, and Photometric Practice

responsibility of whoever uses this standard to consult and

4.1 Apparatus and reagents required for each determination

establish appropriate safety and health practices and deter-

are listed in separate sections preceding the procedure. The

1 2

These test methods are under the jurisdiction of ASTM Committee E01 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Analytical Chemistry for Metals, Ores, and Related Materials and are the direct contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

responsibility of Subcommittee E01.01 on Iron, Steel, and Ferroalloys. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved June 10, 2003. Published July 2003. Originally the ASTM website.

approved in 1970. Last previous edition approved in 2002 as E363 – 83 (2002). Withdrawn. The last approved version of this historical standard is referenced

DOI: 10.1520/E0363-83R03E01. on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

E363–83 (2003)

TABLE 1 Statistical Information—Arsenic

apparatus, standard solutions, and certain other reagents used

in more than one procedure are referred to by number and shall Repeatability (R , Reproduci-

Ferroalloy Type Arsenic Found, %

E173) bility (R , E173)

conform to the requirements prescribed in Practices E50,

1. 70Cr-1Si-5C 0.0015 0.0001 0.0005

except that photometers shall conform to the requirements

prescribed in Practice E60.

4.2 Photometric practices prescribed in these test methods

17. Procedure

shall conform to Practice E60.

17.1 Proceed as directed in 17.1 through 17.4 of Test

5. Safety Hazards Methods E360.

5.1 For precautions to be observed in the use of certain

18. Calculation

reagents in these test methods, refer to Practices E50.

18.1 Proceed as directed in Section 18 of Test Methods

E360.

6. Sampling

6.1 For procedures for sampling the material, and for

19. Precision and Bias

particle size of the sample for chemical analysis, refer to

19.1 Ninelaboratoriescooperatedintestingthismethodand

Practices E32.

obtained the data summarized inTable 1. Samples with arsenic

concentrations near the upper limit of the scope were not

7. Rounding Calculated Values

available for testing. The user is cautioned to verify, by the use

7.1 Calculated values shall be rounded to the desired num-

of reference materials, if available, that the precision and bias

ber of places as directed in 6.4 to 6.6, Rounding Procedure, of

of this method is adequate for the contemplated use.

Practice E29.

LEAD BY THE DITHIZONE PHOTOMETRIC

8. Interlaboratory Studies

METHOD

8.1 These test methods have been evaluated in accordance

20. Scope

withPracticeE173,unlessotherwisenotedintheprecisionand

bias section.

20.1 This method covers the determination of lead in

chromium and ferrochromium in concentrations from 0.001 to

ARSENIC BY THE MOLYBDENUM BLUE

0.05 %.

PHOTOMETRIC METHOD

21. Summary of Method

9. Scope

21.1 See Section 21 of Test Methods E361.

9.1 This method covers the determination of arsenic in

22. Concentration Range

chromium and ferrochromium in concentrations from 0.001 to

0.005 %. 22.1 See Section 22 of Test Methods E361.

23. Stability of Color

10. Summary of Method

23.1 See Section 23 of Test Methods E361.

10.1 See Section 10 of Test Methods E360.

24. Interferences

11. Concentration Range

24.1 See Section 24 of Test Methods E361.

11.1 See Section 11 of Test Methods E360.

25. Apparatus

12. Stability of Color

25.1 See Section 25 of Test Methods E361.

12.1 See Section 12 of Test Methods E360.

26. Reagents

13. Interferences

26.1 Proceed as directed in Section 26 of Test Methods

13.1 See Section 13 of Test Methods E360.

E361.

14. Apparatus

27. Preparation of Calibration Curve

14.1 See Section 14 of Test Methods E360.

27.1 Proceed as directed in 27.1 through 27.5 of Test

Methods E361.

15. Reagents

28. Procedure

15.1 Proceed as directed in 15.1 through 15.9 of Test

Methods E360.

28.1 Test Solution:

28.1.1 Transferasample,selectedinaccordancewith28.1.1

16. Preparation of Calibration Curve

of Test Methods E361 and weighed to the nearest 0.1 mg, to a

16.1 Proceed as directed in 16.1 through 16.5 of Test 250-mL beaker. Add 30 mL of HCl (1 + 1) and heat until

Methods E360. dissolution is nearly complete. In the case of high-carbon

´1

E363–83 (2003)

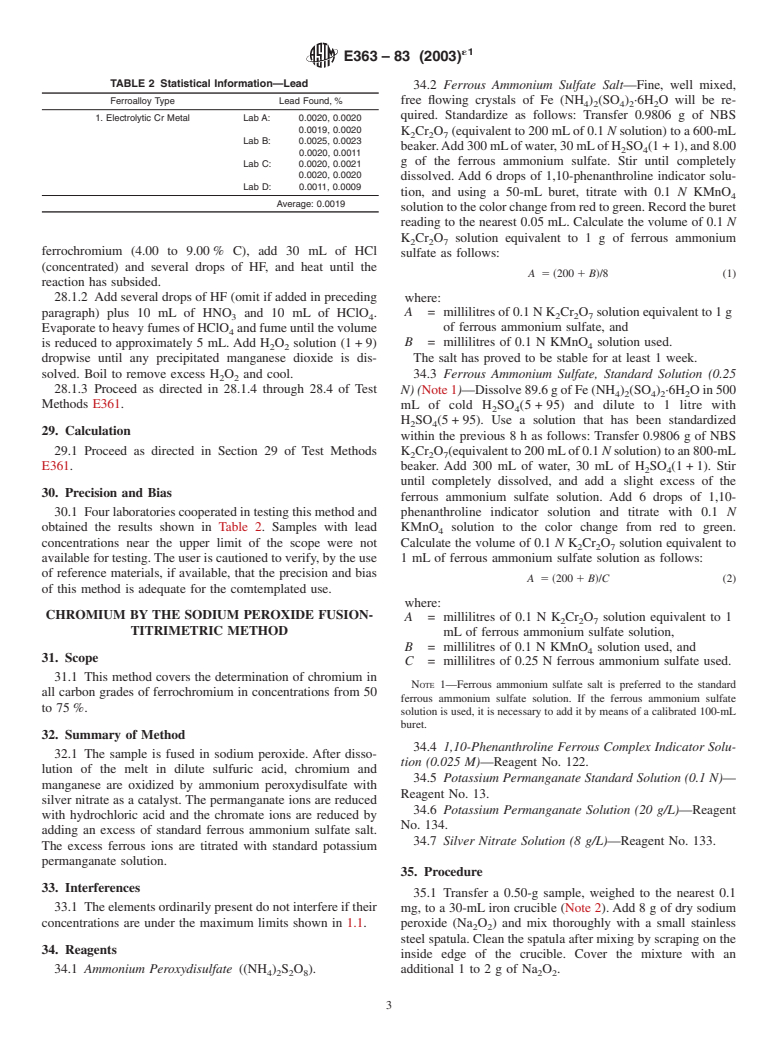

TABLE 2 Statistical Information—Lead

34.2 Ferrous Ammonium Sulfate Salt—Fine, well mixed,

Ferroalloy Type Lead Found, % free flowing crystals of Fe (NH ) (SO ) ·6H O will be re-

4 2 4 2 2

quired. Standardize as follows: Transfer 0.9806 g of NBS

1. Electrolytic Cr Metal Lab A: 0.0020, 0.0020

0.0019, 0.0020

K Cr O (equivalent to 200 mLof 0.1 N solution) to a 600-mL

2 2 7

Lab B: 0.0025, 0.0023

beaker.Add300mLofwater,30mLofH SO (1 + 1),and8.00

2 4

0.0020, 0.0011

g of the ferrous ammonium sulfate. Stir until completely

Lab C: 0.0020, 0.0021

0.0020, 0.0020

dissolved. Add 6 drops of 1,10-phenanthroline indicator solu-

Lab D: 0.0011, 0.0009

tion, and using a 50-mL buret, titrate with 0.1 N KMnO

Average: 0.0019

solutiontothecolorchangefromredtogreen.Recordtheburet

reading to the nearest 0.05 mL. Calculate the volume of 0.1 N

K Cr O solution equivalent to1gof ferrous ammonium

2 2 7

ferrochromium (4.00 to 9.00 % C), add 30 mL of HCl

sulfate as follows:

(concentrated) and several drops of HF, and heat until the

A 5 ~200 1 B!/8 (1)

reaction has subsided.

28.1.2 Add several drops of HF (omit if added in preceding where:

paragraph) plus 10 mL of HNO and 10 mL of HClO . A = millilitres of 0.1 N K Cr O solution equivalent to 1 g

2 2 7

3 4

Evaporate to heavy fumes of HClO and fume until the volume of ferrous ammonium sulfate, and

B = millilitres of 0.1 N KMnO solution used.

is reduced to approximately 5 mL. Add H O solution (1 + 9)

2 2

dropwise unti

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.