ASTM F2273-11(2016)

(Test Method)Standard Test Methods for Bicycle Forks

Standard Test Methods for Bicycle Forks

SIGNIFICANCE AND USE

5.1 These tests are used to determine the conformance of a bicycle fork sample to a standard specified for each use classification.

SCOPE

1.1 These test methods describe mechanical tests for determining the following performance properties:

1.1.1 Compression Load,

1.1.2 Bending Load,

1.1.3 Impact Resistance, and

1.1.4 Bending Fatigue Life (followed by Impact Resistance).

1.2 The values stated in SI units are to be regarded as standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F2273 − 11 (Reapproved 2016) An American National Standard

Standard Test Methods for

Bicycle Forks

This standard is issued under the fixed designation F2273; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope the fork upper tube(s) or fork blades. Some suspension forks

have an upper and a lower crown, while other forks have only

1.1 These test methods describe mechanical tests for deter-

one.

mining the following performance properties:

1.1.1 Compression Load, 3.1.4 dropout—theforkcomponentusedtosupportthefront

wheel(s) at the axle(s).

1.1.2 Bending Load,

1.1.3 Impact Resistance, and

3.1.5 dropout centerline—the front hub mounting axis that

1.1.4 Bending Fatigue Life (followed by Impact Resis-

passes through both right and left dropouts.

tance).

3.1.6 tire clearance—the distance between the top surface

1.2 The values stated in SI units are to be regarded as

of the tire and the bottom surface of the fork crown with no

standard.

compressive force applied to the fork.

1.3 This standard does not purport to address all of the

3.1.7 crown-to-axle clearance—the distance between the

safety concerns, if any, associated with its use. It is the

fork axle centerline and the bottom surface of the crown with

responsibility of the user of this standard to establish appro-

no compressive load applied to the fork.

priate safety and health practices and determine the applica-

3.1.8 head set—thebearingcup,cones,andothersupporting

bility of regulatory limitations prior to use.

componentsforallowingrotationoftheforkaboutthesteering

axis.

2. Referenced Documents

2 3.1.9 limit trip or stop—a deflection of the fork, which

2.1 ASTM Standards:

exceeds the allowable displacement values and causes the

E4Practices for Force Verification of Testing Machines

machine to stop running.

F2043Classification for Bicycle Usage

3.1.10 suspension fork—front fork incorporating compli-

3. Terminology

ance in the axial direction, parallel to the steer tube.

3.1 Definitions of Terms Specific to This Standard:

3.1.11 rigid fork—front fork that is not designed to be

3.1.1 bicycle fork (fork)—the mechanism between the head compliant in the axial direction.

tube and the front axle, including the steerer tube, crown(s),

shock absorbers, lower tubes, and upper tubes.

4. Summary of Test Methods

3.1.2 steer tube—the structural fork component typically

4.1 Compression Load Test—In this test the fork is com-

housed inside the bicycle head tube, connected to the fork

pressed in a direction parallel to the steerer tube. The distance

crown.Thesteerertubetransmitssteeringinputsfromtherider

from the bottom surface of the crown to the axle centerline is

totheforkandconnectstheforktothebicycleframebymeans

measured.

of headset bearings.

4.2 Bending Load Test—In this test the fork is restrained by

3.1.3 fork crown(s), or crown(s)—the primary structural

thesteerertubeandaloadisappliedinadirectionperpendicu-

fork component responsible for connecting the steerer tube to

lar to the steerer tube axis, at the midpoint of the dropout

centerline.Thedeflectionismeasuredatthedropoutcenterline

in a direction perpendicular to the steerer tube axis.

These test methods are under the jurisdiction of ASTM Committee F08 on

SportsEquipment,PlayingSurfaces,andFacilitiesandisthedirectresponsibilityof

4.3 Impact Resistance Test—In this test a fork is fixtured

Subcommittee F08.10 on Bicycles.

with the steerer tube oriented horizontally, and supported by

Current edition approved Oct. 1, 2016. Published October 2016. Originally

bearings.Aweight is dropped from a prescribed height onto a

approved in 2003. Last previous edition approved in 2011 as F2273–11. DOI:

10.1520/F2273-11R16.

fixture attached to the fork dropouts in line with the dropout

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

centerline. Permanent deflection is measured at the dropout

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

centerline in a direction perpendicular to the steerer tube axis.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. The ability of the connection between the steerer tube and

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2273 − 11 (2016)

crown to support torque applied about the axis of the steerer 6. Apparatus

tube is also evaluated.

6.1 Compression Load Test:

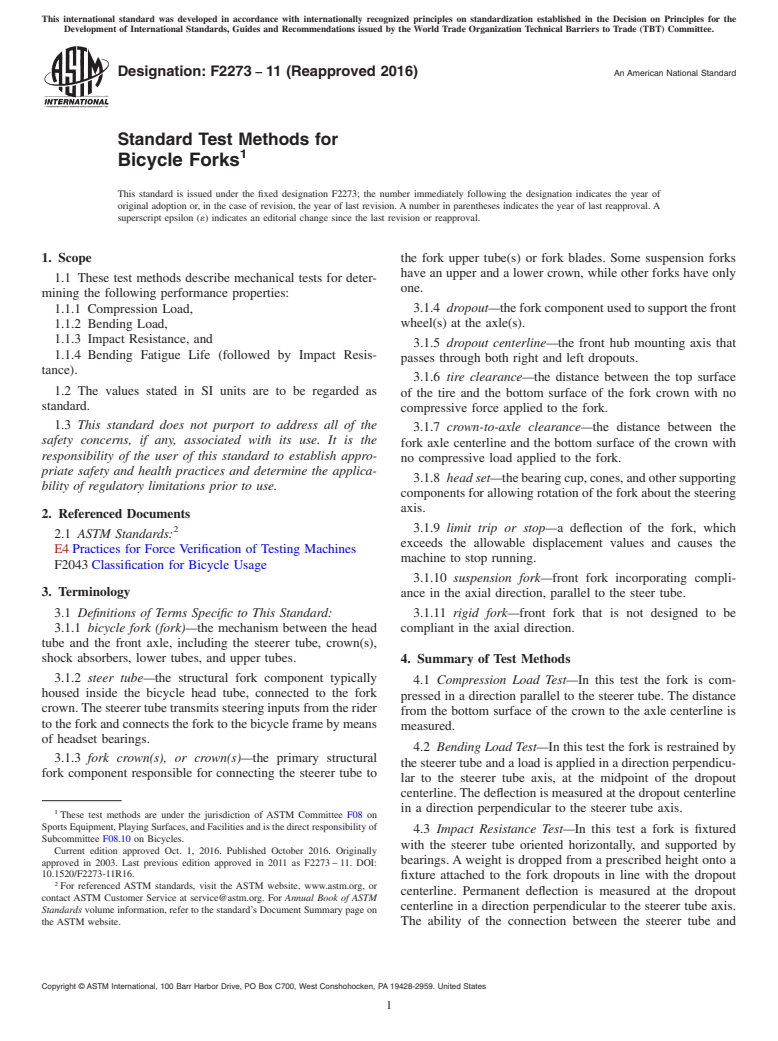

4.4 Fatigue Plus Impact Test—Inthistestaforkisrestrained 6.1.1 A fixture similar to Fig. 1 is required.

by the steerer tube and a fully reversed load is applied in a 6.1.2 The load shall be applied to the top of the crown and

direction perpendicular to the steerer tube axis at the midpoint along the centerline of the steerer tube (Fig. 1).

of the dropout centerline.The test is suspended and the sample 6.1.3 If necessary, either a roller or linkage system shall be

inspected if displacements exceed a prescribed value, or after used to allow translation of the dropouts while the fork is

the specified number of cycles, whichever comes first. If the compressed.

test sample reaches the target cycle count, it is subsequently 6.1.4 Thedistancefromthedropoutcenterlinetothenearest

subjected to a frontal impact as described in 4.3. If inspection surface of the crown on steerer tube centerline shall be

of the sample reveals a structural crack or fracture before measured (Fig. 1).

reaching the target cycle count, or if the specified displace-

6.2 Bending Load Test:

ments during the cyclic loading are exceeded, the test is

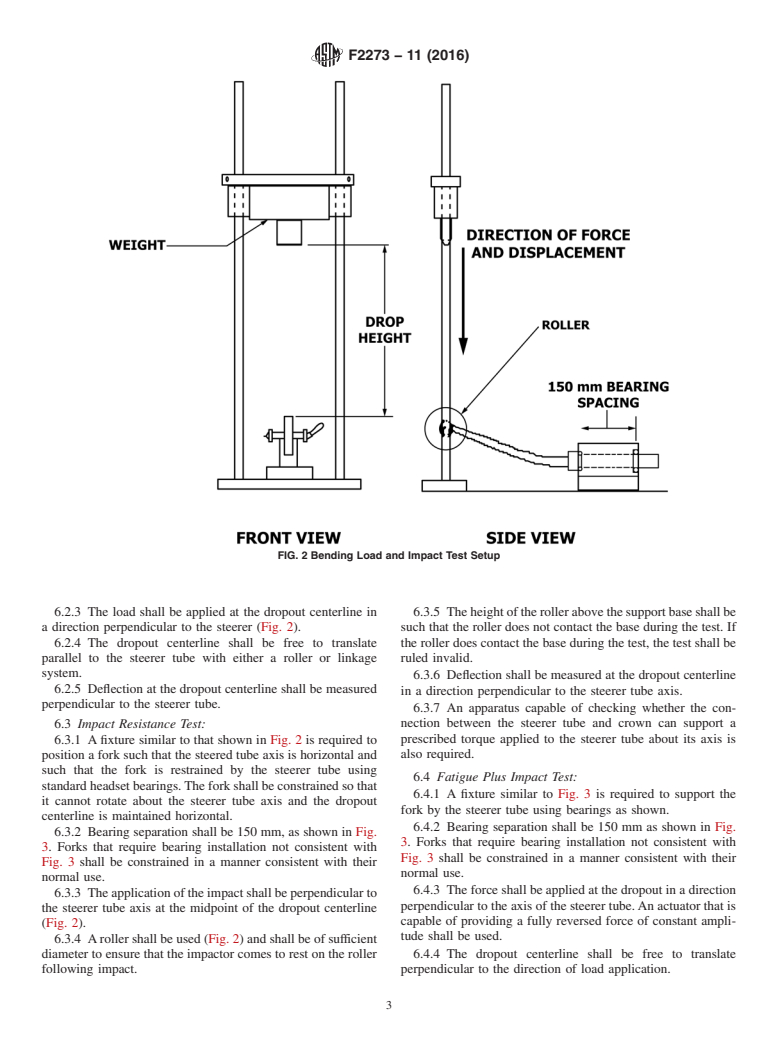

6.2.1 Afixture similar to that shown in Fig. 2 is required to

concluded and the number of cycles reached before failure is

position a fork such that the steerer tube axis is horizontal and

recorded.

such that the fork is restrained by the steerer tube using

standard headset bearings.

5. Significance and Use

6.2.2 Bearing separation shall be 150 mm as shown in Fig.

5.1 These tests are used to determine the conformance of a 2. Forks that require bearing installation not consistent with

bicycle fork sample to a standard specified for each use Fig. 2 shall be constrained in a manner consistent with their

classification. normal use.

NOTE 1—For some fork designs, a dropout support that allows translation may be required.

FIG. 1 Typical Compression Test Apparatus

F2273 − 11 (2016)

FIG. 2 Bending Load and Impact Test Setup

6.2.3 The load shall be applied at the dropout centerline in 6.3.5 Theheightoftherollerabovethesupportbaseshallbe

a direction perpendicular to the steerer (Fig. 2). such that the roller does not contact the base during the test. If

6.2.4 The dropout centerline shall be free to translate the roller does contact the base during the test, the test shall be

parallel to the steerer tube with either a roller or linkage ruled invalid.

system.

6.3.6 Deflection shall be measured at the dropout centerline

6.2.5 Deflection at the dropout centerline shall be measured

in a direction perpendicular to the steerer tube axis.

perpendicular to the steerer tube.

6.3.7 An apparatus capable of checking whether the con-

6.3 Impact Resistance Test: nection between the steerer tube and crown can support a

prescribed torque applied to the steerer tube about its axis is

6.3.1 Afixture similar to that shown in Fig. 2 is required to

position a fork such that the steered tube axis is horizontal and also required.

such that the fork is restrained by the steerer tube using

6.4 Fatigue Plus Impact Test:

standardheadsetbearings.Theforkshallbeconstrainedsothat

6.4.1 A fixture similar to Fig. 3 is required to support the

it cannot rotate about the steerer tube axis and the dropout

fork by the steerer tube using bearings as shown.

centerline is maintained horizontal.

6.4.2 Bearing separation shall be 150 mm as shown in Fig.

6.3.2 Bearing separation shall be 150 mm, as shown in Fig.

3. Forks that require bearing installation not consistent with

3. Forks that require bearing installation not consistent with

Fig. 3 shall be constrained in a manner consistent with their

Fig. 3 shall be constrained in a manner consistent with their

normal use.

normal use.

6.4.3 Theforceshallbeappliedatthedropoutinadirection

6.3.3 Theapplicationoftheimpactshallbeperpendicularto

perpendicular to the axis of the steerer tube.An actuator that is

the steerer tube axis at the midpoint of the dropout centerline

capable of providing a fully reversed force of constant ampli-

(Fig. 2).

tude shall be used.

6.3.4 Arollershallbeused(Fig.2)andshallbeofsufficient

diameter to ensure that the impactor comes to rest on the roller 6.4.4 The dropout centerline shall be free to translate

following impact. perpendicular to the direction of load application.

F2273 − 11 (2016)

FIG. 3 Fatigue Test Setup

6.4.5 The ability of the actuator to produce the specified 10.1.3 Measure the distance from the axle centerline to the

force shall be verified per Practices E4. nearest bottom surface of the crown on the steerer tube

centerline and record.

7. Test Specimens

10.1.4 Apply a specified compression load and hold for

measurement.

7.1 Preparation of Specimens—The forks shall be set to the

10.1.5 Remeasure the distance from the dropout centerline

maximum fully extended length.

to the bottom of the crown and record.

7.2 Fork Adjustment:

10.2 Bending Load Test:

7.2.1 The fork shall be tested with the standard spring rate

10.2.1 Adjust spring preload and damping to the minimum

and all pr

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.