ASTM D5468-02(2007)

(Test Method)Standard Test Method for Gross Calorific and Ash Value of Waste Materials (Withdrawn 2016)

Standard Test Method for Gross Calorific and Ash Value of Waste Materials (Withdrawn 2016)

SIGNIFICANCE AND USE

This test method is used to compute the calorific value and estimated ash content of the waste material represented by the sample for incineration purposes or as fuel for cement kilns.

The gross calorific and ash value may be used for evaluating the effectiveness of any beneficiation process.

SCOPE

1.1 This test method covers the determination of the gross calorific value of waste materials by either an isoperibol, aneroid, air-jacketed isoperibol, or adiabatic bomb calorimeter using electronic temperature sensors, automatic calorimeter controllers, and subsequent analysis of the residue for ash. After calorific analysis, the bomb washings may be collected for subsequent elemental analysis.

1.2 The values stated in SI units are regarded as the standard.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in Section 8.

WITHDRAWN RATIONALE

This test method covered the determination of the gross calorific value of waste materials by either an isoperibol, aneroid, air-jacketed isoperibol, or adiabatic bomb calorimeter using electronic temperature sensors, automatic calorimeter controllers, and subsequent analysis of the residue for ash.

Formerly under the jurisdiction of Committee D34 on Waste Management, this test method was withdrawn in January 2016 in accordance with section 10.5.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5468 −02(Reapproved 2007)

Standard Test Method for

Gross Calorific and Ash Value of Waste Materials

This standard is issued under the fixed designation D5468; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 calorific value—theheatproducedbycombustionofa

unit quantity of a specimen under specified conditions. It is

1.1 This test method covers the determination of the gross

expressed in this test method in joules per kilogram (J/kg).

calorific value of waste materials by either an isoperibol,

Calorific value may also be expressed in calories per gram

aneroid, air-jacketed isoperibol, or adiabatic bomb calorimeter

(cal/g) or in the British thermal units per pound (Btu/lb), when

using electronic temperature sensors, automatic calorimeter

required. The unit equivalents are given in Table 1.

controllers, and subsequent analysis of the residue for ash.

After calorific analysis, the bomb washings may be collected

3.1.2 calorimeter—as used in this test method, is not only

for subsequent elemental analysis.

the bomb and its contents, but it also includes the bucket,

electronic temperature sensing devices, ignition leads, water,

1.2 The values stated in SI units are regarded as the

and stirrer when using water.

standard.

3.1.2.1 adiabatic calorimeter—a calorimeter that has a

1.3 This standard does not purport to address all of the

jacket temperature adjusted to follow the calorimeter tempera-

safety concerns, if any, associated with its use. It is the

ture as closely as possibly so as to maintain zero thermal head.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

3.1.2.2 calorimeter jacket—the insulating medium sur-

bility of regulatory limitations prior to use. Specific hazard

rounding the calorimeter.

statements are given in Section 8.

3.1.2.3 isoperibol calorimeter—the calorimeter has a jacket

2. Referenced Documents

of uniform and constant temperature.

2.1 ASTM Standards:

3.1.3 gross calorific value (gross heat of combustion), Qv

D121Terminology of Coal and Coke

(gross)—theheatproducedbycombustionofunitquantityofa

D240Test Method for Heat of Combustion of Liquid Hy-

solid or liquid fuel when burned at constant volume in an

drocarbon Fuels by Bomb Calorimeter

oxygen bomb calorimeter under specified conditions with the

D1018Test Method for Hydrogen In Petroleum Fractions

resulting water condensed to a liquid.

D1193Specification for Reagent Water

3.1.4 heat capacity—the quantity of heat required to raise a

D3177TestMethodsforTotalSulfurintheAnalysisSample

system one degree in temperature either at constant volume or

of Coal and Coke (Withdrawn 2012)

constant pressure.

D4239Test Method for Sulfur in the Analysis Sample of

Coal and Coke Using High-Temperature Tube Furnace

3.1.5 heat of formation—the increase in heat content result-

Combustion

ing from the formation of 1 mole of a substance from its

E144Practice for Safe Use of Oxygen Combustion Bombs

elements at constant pressure.

3. Terminology 3.1.6 net calorific value (net heat of combustion at constant

pressure), Qp—the heat produced by combustion of unit

3.1 Definitions:

quantity of a solid or liquid fuel when burned at a constant

pressure of 0.1 MPa (1 atm), under conditions such that all the

This test method is under the jurisdiction ofASTM Committee D34 on Waste

water in the products remain in the form of vapor.

ManagementandisthedirectresponsibilityofSubcommitteeD34.03onTreatment,

Recovery and Reuse.

3.1.7 static calorimeter—a calorimeter without a thermo-

Current edition approved Feb. 1, 2007. Published March 2007. Originally

approved in 1993. Last previous edition approved in 2002 as D5468–02. DOI: stated jacket.

10.1520/D5468-02R07.

3.2 Definitions of Terms Specific to This Standard:

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3.2.1 corrected temperature rise—the temperature of the

Standards volume information, refer to the standard’s Document Summary page on

calorimeter caused by the process that occurs inside the bomb,

the ASTM website.

3 which is, the observed temperature change corrected for

The last approved version of this historical standard is referenced on

www.astm.org. various effects.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5468−02 (2007)

TABLE 1 Calorific Value

capable of withstanding a hydrostatic pressure test of 20 MPa

1 Btu = 1055.06 J 1 J/g = 0.430 Btu/lb (3000 psig) at room temperature without stressing any part

A

1 cal = 4.1868 J 1 J/g = 0.239 cal/g

beyond its elastic limit.

A

International tables calorie.

6.3 Balance—Alaboratory balance having the capability to

weightthesampletothenearest0.0001g.Thebalanceshallbe

checked for accuracy at the beginning of each week that the

3.2.2 heat capacity, energy equivalent, or water

calorimeter tests will be made.

equivalent—the energy required to raise the temperature of the

calorimeter one arbitrary unit. This is the quantity that, when 6.4 Calorimeter Vessel (Bucket)—Made of metal with a

multiplied by the corrected temperature, rises, then when tarnish-resistant coating, with all outer surfaces highly pol-

adjusted for extraneous heat effects and divided by the mass of ished. For calorimeters having a bucket it may be a separate

component or integral component of the bomb. It shall be of

the sample, gives the gross calorific value.

such construction that the environment of the calorimeter’s

4. Summary of Test Method

entireouterboundariesismaintainedatauniformtemperature.

4.1 Calorific value is determined in this test method by

6.5 Jacket—An insulated container that keeps the inner

burning a weighed sample under controlled conditions, in

perimeter of the jacket at constant temperature (isoperibol), or

oxygen, in a calibrated calorimeter. The calorimeter is stan-

at the same temperature as the calorimeter (adiabatic), or is

dardized by burning a specified amount of benzoic acid. The

monitored continuously for temperature changes (aneroid).

calorific value of the test specimen is computed from tempera-

6.6 Temperature Sensing Device—Thermometers such as

ture observations made before, during, and after combustion

platinumresistance,thermistors,ormercurialthermometersare

and making proper allowances for heat contribution by other

satisfactory and may be used if properly calibrated.

processes.

NOTE 1—Temperature is measured in either degrees Celsius, degrees

4.2 After disassembly of the bomb, estimate the ash content

Fahrenheit, ohms, or other arbitrary units instead of degrees. Consistent

by one of two of the following procedures:

units must be used in standardization and the actual calorific value

4.2.1 Dry the fuel capsule at 200°C for 5 to 10 min and

determination.

weigh to provide an estimation of the ash content of the waste

6.7 Sample Holder—An open crucible of platinum, quartz,

material.

oracceptablebase-metalalloy.Thebasemetalcruciblesshould

4.2.2 Wipe any moisture from the exterior surface of the

be heat-treated for 24 h at 500°C to ensure the capsules are

capsule and weigh to provide an estimation of the ash content

completely oxidized.

of the waste material.

6.8 Ignition Fuse—The ignition fuse shall be 100 mm of

5. Significance and Use

0.16-mm diameter or smaller (No. 34B&S gage), nickel-

chromium alloy (Chromel C) alloy, platinum, cotton thread, or

5.1 This test method is used to compute the calorific value

iron wire. The same length or mass of ignition fuse shall be

and estimated ash content of the waste material represented by

used for all calibrations and calorific value determinations.

the sample for incineration purposes or as fuel for cement

kilns.

6.9 Firing Circuit—A6 to 24-V alternating or direct current

is required for ignition purposes. A step-down transformer

5.2 The gross calorific and ash value may be used for

connected to an alternating current lighting circuit, capacitors,

evaluating the effectiveness of any beneficiation process.

or batteries may be used.

6. Apparatus and Facilities

6.10 Buret—Used for the acid titration and shall have 0.1

6.1 TestRoom—Aroomorareafreefromdraftsandthatcan

mL divisions.

be kept at a constant temperature equal to 6 3°C, for all

6.11 Gelatin Capsules or Cellulose Tape—Used to mini-

calorimetric tests. The apparatus shall be shielded from direct

mize vaporization of volatile samples. These items should be

sunlightandradiationfromothersources.Thermostaticcontrol

halogen free.

of room temperature and controlled relative humidity are

6.12 pH Titrators or mV Meters—May be used for pH

desirable.

titration of wash solution.

6.2 Combustion Bomb—Constructed of materials that are

not affected by the combustion process or products sufficiently

7. Reagents

to introduce measurable heat input or alteration of end prod-

ucts.The bomb shall be designed so that all liquid combustion 7.1 Reagent Water—Conforming to conductivity require-

products can be completely recovered by washing the inner ments for Type II of Specification D1193, it shall be used for

surfaces. There shall be no gas leakage. The bomb shall be preparation of reagents and washing of the bomb interior.

D5468−02 (2007)

7.2 PurityorReagents—Reagent-gradechemicalsconform- feed to the bomb. Valves, gages, and gaskets must meet

ing to the specifications of the Committee on Analytical industry safety codes. Suitable reducing valves and adapters

ReagentsoftheAmericanChemicalSocietyshallbeusedinall for 3 to 4-MPa (300 to 500-psi) discharge pressure are

tests. obtainable from commercial sources of compressed gas equip-

ment. Check the pressure gage annually for accuracy or after

7.3 Benzoic Acid, Standard (C H —COOH)—Use pellets

6 5

any accidental over pressures that reach maximum gage

madefrombenzoicacidavailablefromtheNationalInstituteof

pressure.

Standards and Technology (NIST) or benzoic acid calibrated

against NIST standard material. The value of heat of combus- 8.5 During ignition of a sample, the operator must not

tion of benzoic acid, for use in the calibrations calculations, permit any portion of the operator’s body to extend over the

shall be in accordance with the certified value. calorimeter.

7.4 Methyl Orange, Methyl Red, or Methyl Purple 8.6 Exercise extreme caution not to exceed the bomb

Indicator—May be used to titrate the acid formed during manufacturer’s recommendations and to avoid damage to the

combustion. The indicator used shall be the same for both bomb when combustion aids are employed. Do not fire loose

calibration and calorific value determinations. fluffy material, such as unpelleted benzoic acid, unless thor-

oughly mixed with the sample.

7.5 Oxygen—Shall be free of combustible matter. Only

oxygen manufactured from liquid air, guaranteed to be greater 8.7 Do not fire the bomb if the bomb has been dropped or

than 99.5% pure, shall be used. Oxygen made by the electro- turned over after loading or if there is evidence of gas leakage

lytic process may contain a small amount of hydrogen, when the bomb is submerged in the calorimeter water.

rendering it unfit without purification by passage over copper

8.8 When volatile materials are present, explosive firings

oxide at 500°C.

can result and the procedure in 12.2 should be followed.

7.6 Standard Solution—Sodium carbonate (Na CO)or

2 3

9. Sampling

other suitable standard solution. Dissolve 3.76 g of sodium

carbonate that has been dried for 24 h at 105°C in water and

9.1 The sample shall be representative of the material of

dilute to 1 L. One millilitre of this solution is equivalent to 4.2

interest (see Appendix X3).

J (1.0 cal) in the acid titration when the entire rinse solution is

10. Standardization

used as the analytical sample.Alternatively, the titrant volume

is to be corrected by the volume fraction of the rinse that is

10.1 The calorimeter is standardized by combustion of

used as the analytical sample. (See 10.4.2.)

benzoic acid.

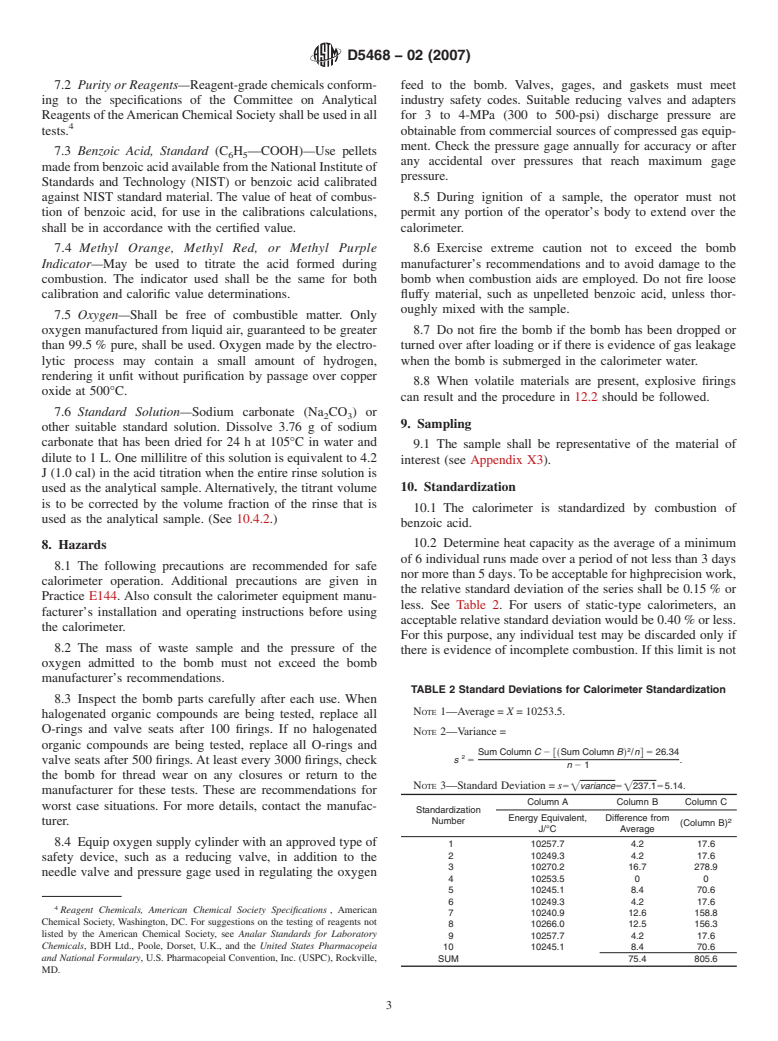

10.2 Determine heat capacity as the average of a minimum

8. Hazards

of 6 individual runs made over a period of not less than 3 days

8.1 The following precautions are recommended for safe

normorethan5days.Tobeacceptableforhighprecisionwork,

calorimeter operation. Additional precautions are given in

the relative standard deviation of the series shall be 0.15% or

Practice E144. Also consult the calorimeter equipment manu-

less. See Table 2. For users of static-type calorimeters, an

facturer’s installation and operating instructions before using

acceptablerelativestandarddeviationwouldbe0.40%orless.

the calorimeter.

For this purpose, any individual test may be discarded only if

8.2 The mass of waste sample and the pressure of the

there is evidence of incomplete combustion. If this limit is not

oxygen admitted to the bomb must not exceed the bomb

manufacturer’s recommendations.

TABLE 2 Standard Deviations for Calorimeter Standardization

8.3 Inspect the bomb parts carefully after each use. When

NOTE 1—Average=X=10253.5.

halogenated organic compounds are being tested, replace all

O-rings and valve seats after 100 firings. If no halogenated

NOTE 2—Variance=

organic compounds are being tested, replace all O-rings and

Sum Column C2 fsSum Column Bd /ng526.34

s 5 .

valve seats after 500 firings.At least every 3000 firings, check

n21

the bomb for thread wear on any closures or return to the

NOTE 3—Standard Deviation=s5 variance5 237.155.14.

œ œ

manufacturer for these tests. These are recommendations for

Column A Column B Column C

worst case situations. For more details, contact the manufac-

Standardization

Energy Equivalent, Difference from

Number

turer.

(Column B)

J/°C Average

8.4 Equip oxygen supply cylinder with an approved type of

1 10257.7 4.2 17.6

2 10249.3 4.2 17.6

safety device, such as a reducing valve, in addition to the

3 10270.2 16.7 278.9

needle valve and pressure gage used in regulating the oxygen

4 10253.5 0 0

5 10245.1 8.4 70.6

6 10249.3 4.2 17.6

Reagent Chemicals, American Chemical Society Specifications , American

7 10240.9 12.6 158.8

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

8 10266.0 12.5 156.3

listed by the American Chemical Society, see Analar Standards for Laboratory

9 10257.7 4.2 17.6

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

10 10245.1 8.4 70.6

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville, SUM 75.4 805

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.