ASTM D2170-01a(2006)

(Test Method)Standard Test Method for Kinematic Viscosity of Asphalts (Bitumens)

Standard Test Method for Kinematic Viscosity of Asphalts (Bitumens)

SIGNIFICANCE AND USE

The kinematic viscosity characterizes flow behavior. The method is used to determine the consistency of bitumen as one element in establishing the uniformity of shipments or sources of supply. The specifications are usually at temperatures of 60 and 135°C.

SCOPE

1.1 This test method covers procedures for the determination of kinematic viscosity of liquid asphalts (bitumens), road oils and distillation residues of liquid asphalts (bitumens) all at 60°C (140°F) and of asphalt cements at 135°C (275°F) (Note 1) in the range from 6 to 100 000 mm2/s (cSt).

1.2 Results of this test method can be used to calculate viscosity when the density of the test material at the test temperature is known or can be determined. See for the method of calculation.

Note 1—This test method is suitable for use at other temperatures and at lower kinematic viscosities, but the precision is based on determinations on liquid asphalts and road oils at 60°C (140°F) and on asphalt cements at 135°C (275°F) only in the viscosity range from 30 to 6000 mm 2/s (cSt).

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D2170–01a(Reapproved 2006)

Designation: 319/84 (89)

Standard Test Method for

Kinematic Viscosity of Asphalts (Bitumens)

This standard is issued under the fixed designation D2170; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope D445 Test Method for Kinematic Viscosity of Transparent

and Opaque Liquids (and Calculation of Dynamic Viscos-

1.1 This test method covers procedures for the determina-

ity)

tion of kinematic viscosity of liquid asphalts (bitumens), road

D446 Specifications and Operating Instructions for Glass

oilsanddistillationresiduesofliquidasphalts(bitumens)allat

Capillary Kinematic Viscometers

60°C (140°F) and of asphalt cements at 135°C (275°F) (Note

D2162 Practice for Basic Calibration of Master Viscom-

1) in the range from 6 to 100 000 mm /s (cSt).

eters and Viscosity Oil Standards

1.2 Results of this test method can be used to calculate

D2493 Standard Viscosity-Temperature Chart for Asphalts

viscosity when the density of the test material at the test

E1 Specification forASTM Liquid-in-GlassThermometers

temperature is known or can be determined. SeeAnnexA1 for

E77 Test Method for Inspection and Verification of Ther-

the method of calculation.

mometers

NOTE 1—This test method is suitable for use at other temperatures and

atlowerkinematicviscosities,buttheprecisionisbasedondeterminations

3. Terminology

on liquid asphalts and road oils at 60°C (140°F) and on asphalt cements

2 3.1 Definitions:

at135°C(275°F)onlyintheviscosityrangefrom30to6000mm /s(cSt).

3.1.1 density—the mass per unit volume of liquid and the

3 3

1.3 This standard does not purport to address all of the

cgsunitofdensityis1g/cm .TheSIunitofdensityis1kg/m .

safety concerns, if any, associated with its use. It is the

3.1.2 kinematic viscosity—the ratio of the viscosity to the

responsibility of the user of this standard to establish appro-

density of a liquid. It is a measure of the resistance to flow of

priate safety and health practices and determine the applica-

a liquid under gravity. The SI unit of kinematic viscosity is

bility of regulatory limitations prior to use. 2 2

m /s; for practical use, a submultiple (mm /s) is more conve-

nient. The cgs unit of kinematic viscosity is 1 cm /s and is

2. Referenced Documents

−2

calledastokes(symbolSt).Thecentistokes(1cSt=10 St)is

2.1 ASTM Standards:

1mm /s and is often used.

C670 Practice for Preparing Precision and Bias Statements

3.1.3 Newtonian liquid—a liquid in which the rate of shear

for Test Methods for Construction Materials

is proportional to the shearing stress. The constant ratio of the

D92 Test Method for Flash and Fire Points by Cleveland

shearingstresstotherateofshearistheviscosityoftheliquid.

Open Cup Tester

If the ratio is not constant, the liquid is non-Newtonian.

D341 Test Method for Viscosity-Temperature Charts for

3.1.4 viscosity—the ratio between the applied shear stress

Liquid Petroleum Products

and rate of shear is called the coefficient of viscosity. This

coefficient is a measure of the resistance to flow of a liquid. It

is commonly called the viscosity of the liquid. The cgs unit of

1 2

This test method is under the jurisdiction of ASTM Committee D04 on Road

viscosity is 1 g/cm·s (1 dyne·s/cm ) and is called a poise (P).

and Paving Materials and is the direct responsibility of Subcommittee D04.44 on

The SI unit of viscosity is 1 Pa·s (1 N·s/m ) and is equivalent

Rheological Tests. In the IP this test method is under the jurisdiction of the

to 10 P.

Standardization Committee.

Current edition approved Dec. 1, 2006. Published December 2006. Originally

4. Summary of Test Method

approved in 1963. Last previous edition approved in 2002 as D2170–02.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.1 The time is measured for a fixed volume of the liquid to

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

flow through the capillary of a calibrated glass capillary

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. viscometer under an accurately reproducible head and at a

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D2170–01a (2006)

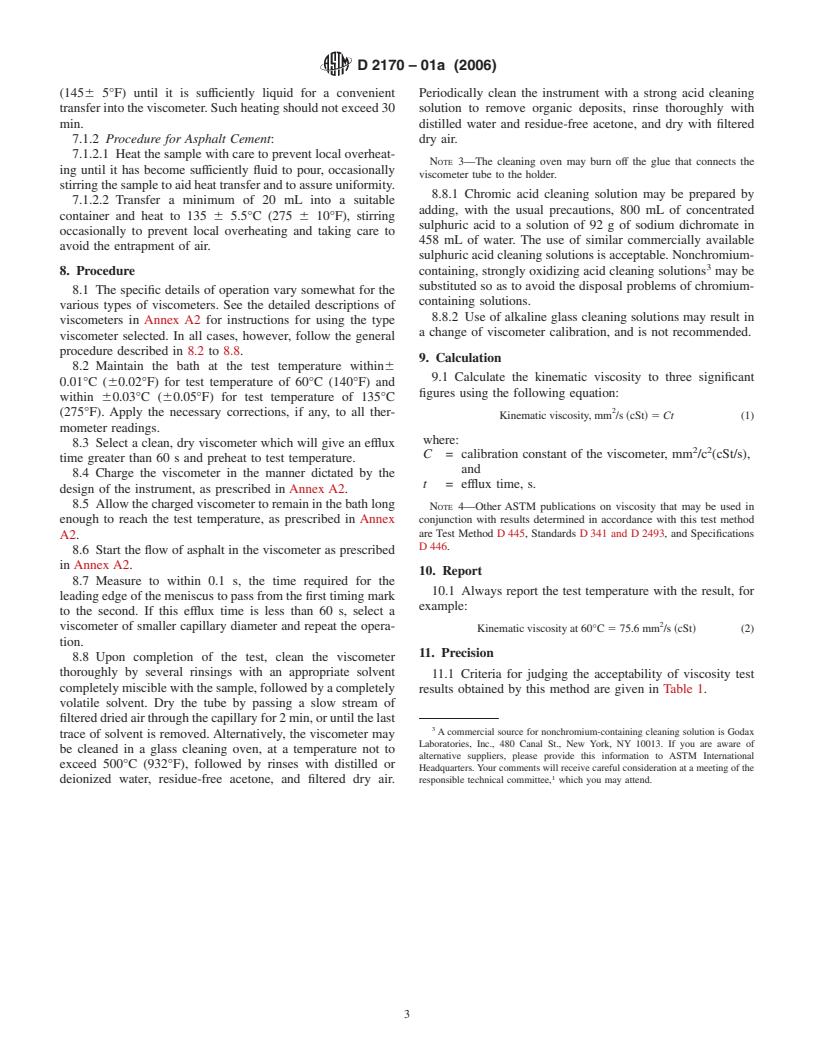

TABLE 1 Acceptability of Test Results for Kinematic Viscosity

closely controlled temperature.The kinematic viscosity is then

calculated by multiplying the efflux time in seconds by the

NOTE 1—The values given in column 2 are the coefficients of variation

viscometer calibration factor.

that have been found to be appropriate for the materials and conditions of

testdescribedincolumn1.Thevaluesgivenincolumn3arethelimitsthat

should not be exceeded by the difference between the results of two

5. Significance and Use

properly conducted tests.

5.1 The kinematic viscosity characterizes flow behavior.

Acceptable

Themethodisusedtodeterminetheconsistencyofbitumenas

Coefficient of

Range

Material and Type Index Variation (% of

one element in establishing the uniformity of shipments or

of Two Results

A

mean)

A

(% of mean)

sources of supply. The specifications are usually at tempera-

tures of 60 and 135°C. Single-operator precision:

Asphalt cements at 135°C 0.64 1.8

(275°F)

6. Apparatus

Liquid asphalts at 60°C (140°F):

below 3000 mm /s (cSt) 0.53 1.5

6.1 Viscometers, capillary-type, made of borosilicate glass,

3000 to 6000 mm /s (cSt) 0.71 2.0

annealed, suitable for this test are described in Annex A2 and

6000 mm /s (cSt) and above 3.2 8.9

include the following: Multilaboratory precision:

Asphalt cements at 135°C 3.1 8.8

6.1.1 Cannon-Fenske viscometer for opaque liquids,

(275°F)

6.1.2 Zeitfuchs cross-arm viscometer,

Liquid asphalts at 60°C (140°F):

6.1.3 Lantz-Zeitfuchs viscometer, below 3000 mm /s (cSt) 1.06 3.0

2 B

3000 to 6000 mm /s (cSt) 3.11 9.0

6.1.4 BS U-Tube modified reverse flow viscometer.

2 B

above 6000 mm /s (cSt) 3.6 10.0

6.2 Calibrated viscometers are available from commercial

A

These numbers represent, respectively, the (1s %) and (d2s %) limits as

suppliers. Details regarding calibration of viscometers are

described in Practice C 670.

B

given in Annex A3.

Based on less than 30 degrees of freedom.

6.3 Thermometers—Calibrated liquid-in-glass thermom-

eters of an accuracy after correction of 0.02°C (0.04°F) can be

60°C (140°F). USPWhite Oil with a flash point above 215°C (420°F) has

used or any other thermometric device of equal accuracy.

been found suitable for determinations at 135°C (275°F). The flash point

ASTM Kinematic Viscosity Thermometers 47C and 47F and

is determined in accordance with Test MethodD92.

IP35Cand35Faresuitableforuseat60°C(140°F)andASTM

6.5 Timer—A stop watch or other spring-activated timing

KinematicViscosityThermometers110Cand110Faresuitable

device graduated in divisions of 0.1 s or less and accurate to

for use at 135°C (275°F).

within 0.05% when tested over intervals of not less than 15

6.3.1 The specified thermometers are standardized at“ total

min.

immersion,”whichmeansimmersiontothetopofthemercury

6.6 Electrical Timing Devices may be used only on electri-

column with the remainder of the stem and the expansion

cal circuits the frequencies of which are controlled to an

chamber at the top of the thermometer exposed to room

accuracy of 0.05% or better.

temperature. The practice of completely submerging the ther-

6.6.1 Alternating currents, the frequencies of which are

mometer is not recommended. When thermometers are com-

intermittently and not continuously controlled, as provided by

pletely submerged, corrections for each individual thermom-

somepublicpowersystems,cancauselargeerrors,particularly

eter based on calibration under conditions of complete

over short timing intervals, when used to actuate electrical

submergence must be determined and applied. If the thermom-

timing devices.

eter is completely submerged in the bath during use, the

pressure of the gas in the expansion chamber will be higher or

7. Preparation of Sample

lower than during standardization, and may cause high or low

7.1 To minimize loss of volatile constituents and to obtain

readings on the thermometer.

reproducible results, proceed as follows:

6.3.2 It is essential that liquid-in-glass thermometers be

7.1.1 Procedure for LiquidAsphalt (Bitumen) and Road Oil:

calibrated periodically using the technique given in Test

7.1.1.1 Allow sealed samples, as received, to reach room

MethodE77 (see Appendix X1).

temperature.

6.4 Bath—A bath suitable for immersion of the viscometer

7.1.1.2 Open the sample container and mix the sample

sothattheliquidreservoirorthetopofthecapillary,whichever

thoroughly by stirring for 30 s taking care to avoid the

isuppermost,isatleast20mmbelowtheupperbathlevel,and

entrapmentofair.Ifthesampleistooviscousforsuchstirring,

with provisions for visibility of the viscometer and the ther-

place the sample in the tightly sealed container in a bath or

mometer. Firm supports for the viscometer shall be provided,

oven maintained at 63 6 3°C (145 6 5°F) until it becomes

or the viscometer may be an integral part of the bath. The

sufficiently liquid for stirring.

efficiency of the stirring and the balance between heat losses

7.1.1.3 Immediately charge the viscometer, or, if the test is

and heat input must be such that the temperature of the bath

to be made at a later time, pour approximately 20 mLinto one

medium does not vary by more than 60.03°C (60.05°F) over

or more clean, dry containers having a capacity of approxi-

the length of the viscometer, or from viscometer to viscometer

mately 30 mL and immediately seal with an airtight closure.

in the various bath positions at 60°C (140°F). The variation at

7.1.1.4 For materials with kinematic viscosities at 60°C

135°C (275°F) must not exceed 60.03°C (60.05°F). 2

(140°F) above 800 mm /s (cSt), heat the 20-mL sample in the

NOTE 2—Distilled water is a suitable bath liquid for determinations at sealed container in an oven or bath maintained at 63 6 3°C

D2170–01a (2006)

(1456 5°F) until it is sufficiently liquid for a convenient Periodically clean the instrument with a strong acid cleaning

transferintotheviscometer.Suchheatingshouldnotexceed30 solution to remove organic deposits, rinse thoroughly with

min. distilled water and residue-free acetone, and dry with filtered

7.1.2 Procedure for Asphalt Cement: dry air.

7.1.2.1 Heat the sample with care to prevent local overheat-

NOTE 3—The cleaning oven may burn off the glue that connects the

ing until it has become sufficiently fluid to pour, occasionally

viscometer tube to the holder.

stirringthesampletoaidheattransferandtoassureuniformity.

8.8.1 Chromic acid cleaning solution may be prepared by

7.1.2.2 Transfer a minimum of 20 mL into a suitable

adding, with the usual precautions, 800 mL of concentrated

container and heat to 135 6 5.5°C (275 6 10°F), stirring

sulphuric acid to a solution of 92 g of sodium dichromate in

occasionally to prevent local overheating and taking care to

458 mL of water. The use of similar commercially available

avoid the entrapment of air.

sulphuricacidcleaningsolutionsisacceptable.Nonchromium-

8. Procedure

containing, strongly oxidizing acid cleaning solutions may be

substituted so as to avoid the disposal problems of chromium-

8.1 The specific details of operation vary somewhat for the

containing solutions.

various types of viscometers. See the detailed descriptions of

8.8.2 Use of alkaline glass cleaning solutions may result in

viscometers in Annex A2 for instructions for using the type

a change of viscometer calibration, and is not recommended.

viscometer selected. In all cases, however, follow the general

procedure described in 8.2 to 8.8.

9. Calculation

8.2 Maintain the bath at the test temperature within6

9.1 Calculate the kinematic viscosity to three significant

0.01°C (60.02°F) for test temperature of 60°C (140°F) and

figures using the following equation:

within 60.03°C (60.05°F) for test temperature of 135°C

(275°F). Apply the necessary corrections, if any, to all ther-

Kinematicviscosity,mm /s ~cSt!5 Ct (1)

mometer readings.

where:

8.3 Select a clean, dry viscometer which will give an efflux

2 2

C = calibration constant of the viscometer, mm /c (cSt/s),

time greater than 60 s and preheat to test temperature.

and

8.4 Charge the viscometer in the manner dictated by the

t = efflux time, s.

design of the instrument, as prescribed in Annex A2.

8.5 Allowthechargedviscometertoremaininthebathlong

NOTE 4—Other ASTM publications on viscosity that may be used in

enough to reach the test temperature, as prescribed in Annex conjunction with results determined in accordance with this test method

are Test Method D445, Standards D341 and D2493, and Specifications

A2.

D446.

8.6 Start the flow of asphalt in the viscometer as prescribed

in Annex A2.

10. Report

8.7 Measure to within 0.1 s, the time required for the

10.1 Always report the test temperature with the result, for

leadingedgeofthemeniscustopassfromthefirsttimingmark

example:

to the second. If this efflux time is less than 60 s, select a

viscometer of smaller capillary diameter and repeat the opera-

Kinematicviscosityat60°C 575.6mm /s ~cSt! (2)

tion.

11. Precision

8.8 Upon completion of the test, clean the viscometer

thoroughly by several rinsings with an appropriate solvent

11.1 Criteria for judging the acceptability of viscosity test

completelymisciblewiththesample,followedbyacompletely

results obtained by this method are given in Table 1.

volatile solvent. Dry the tube by passing a slow stream of

filtereddriedairthroughthecapillaryfor2min,oruntilthelast

Acommercial source for nonchromium-containing cleaning solution is Godax

trace of solvent is removed.Alternatively, the viscometer may

Laboratories, Inc., 480 Canal St., New York, NY 10013. If you are aware of

be cleaned in a glass cleaning oven, at a temperature not to

alternative suppliers, please provide this information to ASTM International

exceed 500°C (932°F), followed by rinses with distilled or

Headquarters.Your comments will receive careful consideration at a meeting of the

deionized water, residue-free acetone, and filtered dry air. responsible technical committee, which you may attend.

D2170–01a (2006)

ANNEXES

(Mandatory Information)

A1. CALCULATION OF VISCOSITY OFA NEWTONIAN LIQUID

A1.1 TheviscosityofaNewtonianliquidiscalculatedfrom 0.00061/°C (0.00034/°F).

its kinem

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.