ASTM D2170-07

(Test Method)Standard Test Method for Kinematic Viscosity of Asphalts (Bitumens)

Standard Test Method for Kinematic Viscosity of Asphalts (Bitumens)

SIGNIFICANCE AND USE

The kinematic viscosity characterizes flow behavior. The method is used to determine the consistency of bitumen as one element in establishing the uniformity of shipments or sources of supply. The specifications are usually at temperatures of 60 and 135°C.

SCOPE

1.1 This test method covers procedures for the determination of kinematic viscosity of liquid asphalts (bitumens), road oils and distillation residues of liquid asphalts (bitumens) all at 60°C (140°F) and of asphalt cements at 135°C (275°F) (Note 1) in the range from 6 to 100 000 mm2/s (cSt).

1.2 Results of this test method can be used to calculate viscosity when the density of the test material at the test temperature is known or can be determined. See Annex A1 for the method of calculation.

Note 1—This test method is suitable for use at other temperatures and at lower kinematic viscosities, but the precision is based on determinations on liquid asphalts and road oils at 60°C (140°F) and on asphalt cements at 135°C (275°F) only in the viscosity range from 30 to 6000 mm2/s (cSt).

1.3 Warning—Mercury has been designated by United States Environmental Protection Agency (EPA) and many state agencies as a hazardous material that can cause central nervous system, kidney and liver damage. Mercury, or its vapor, may be hazardous to health and corrosive to materials. Caution should be taken when handling mercury and mercury containing products. See the applicable product Material Safety Data Sheet (MSDS) for details and EPA’s website—http://www.epa.gov/mercury/faq.htm—for additional information. Users should be aware that selling mercury, mercury containing products, or both, in your state may be prohibited by state law.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D2170–07

Designation: 319/84 (89)

Standard Test Method for

1

Kinematic Viscosity of Asphalts (Bitumens)

This standard is issued under the fixed designation D2170; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2. Referenced Documents

2

1.1 This test method covers procedures for the determina- 2.1 ASTM Standards:

tion of kinematic viscosity of liquid asphalts (bitumens), road C670 Practice for Preparing Precision and Bias Statements

oilsanddistillationresiduesofliquidasphalts(bitumens)allat for Test Methods for Construction Materials

60°C (140°F) and of asphalt cements at 135°C (275°F) (Note D92 Test Method for Flash and Fire Points by Cleveland

2

1) in the range from 6 to 100 000 mm /s (cSt). Open Cup Tester

1.2 Results of this test method can be used to calculate D341 Test Method for Viscosity-Temperature Charts for

viscosity when the density of the test material at the test Liquid Petroleum Products

temperature is known or can be determined. SeeAnnexA1 for D445 Test Method for Kinematic Viscosity of Transparent

the method of calculation. and Opaque Liquids (and Calculation of Dynamic Viscos-

ity)

NOTE 1—This test method is suitable for use at other temperatures and

D446 Specifications and Operating Instructions for Glass

atlowerkinematicviscosities,buttheprecisionisbasedondeterminations

Capillary Kinematic Viscometers

on liquid asphalts and road oils at 60°C (140°F) and on asphalt cements

2

D2162 PracticeforBasicCalibrationofMasterViscometers

at135°C(275°F)onlyintheviscosityrangefrom30to6000mm /s(cSt).

and Viscosity Oil Standards

1.3 Warning—Mercury has been designated by United

D2493 Standard Viscosity-Temperature Chart for Asphalts

StatesEnvironmentalProtectionAgency(EPA)andmanystate

E1 Specification for ASTM Liquid-in-Glass Thermometers

agenciesasahazardousmaterialthatcancausecentralnervous

E77 Test Method for Inspection and Verification of Ther-

system,kidneyandliverdamage.Mercury,oritsvapor,maybe

mometers

hazardous to health and corrosive to materials. Caution should

be taken when handling mercury and mercury containing

3. Terminology

products. See the applicable product Material Safety Data

3.1 Definitions:

Sheet (MSDS) for details and EPA’s website—http://

3.1.1 density—the mass per unit volume of liquid and the

www.epa.gov/mercury/faq.htm—for additional information.

3 3

cgsunitofdensityis1g/cm .TheSIunitofdensityis1kg/m .

Users should be aware that selling mercury, mercury contain-

3.1.2 kinematic viscosity—the ratio of the viscosity to the

ing products, or both, in your state may be prohibited by state

density of a liquid. It is a measure of the resistance to flow of

law.

a liquid under gravity. The SI unit of kinematic viscosity is

1.4 This standard does not purport to address all of the

2 2

m /s; for practical use, a submultiple (mm /s) is more conve-

safety concerns, if any, associated with its use. It is the

2

nient. The cgs unit of kinematic viscosity is 1 cm /s and is

responsibility of the user of this standard to establish appro-

−2

called a stoke (symbol St). The centistoke (1 cSt=10 St) is

priate safety and health practices and determine the applica-

2

1mm /s and is often used.

bility of regulatory limitations prior to use.

3.1.3 Newtonian liquid—a liquid in which the rate of shear

is proportional to the shearing stress. The constant ratio of the

1

This test method is under the jurisdiction of ASTM Committee D04 on Road

and Paving Materials and is the direct responsibility of Subcommittee D04.44 on

Rheological Tests. In the IP this test method is under the jurisdiction of the

2

Standardization Committee. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Dec. 1, 2007. Published December 2007. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1963. Last previous edition approved in 2006 as D2170–01a (2006). Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/D2170-07. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D2170–07

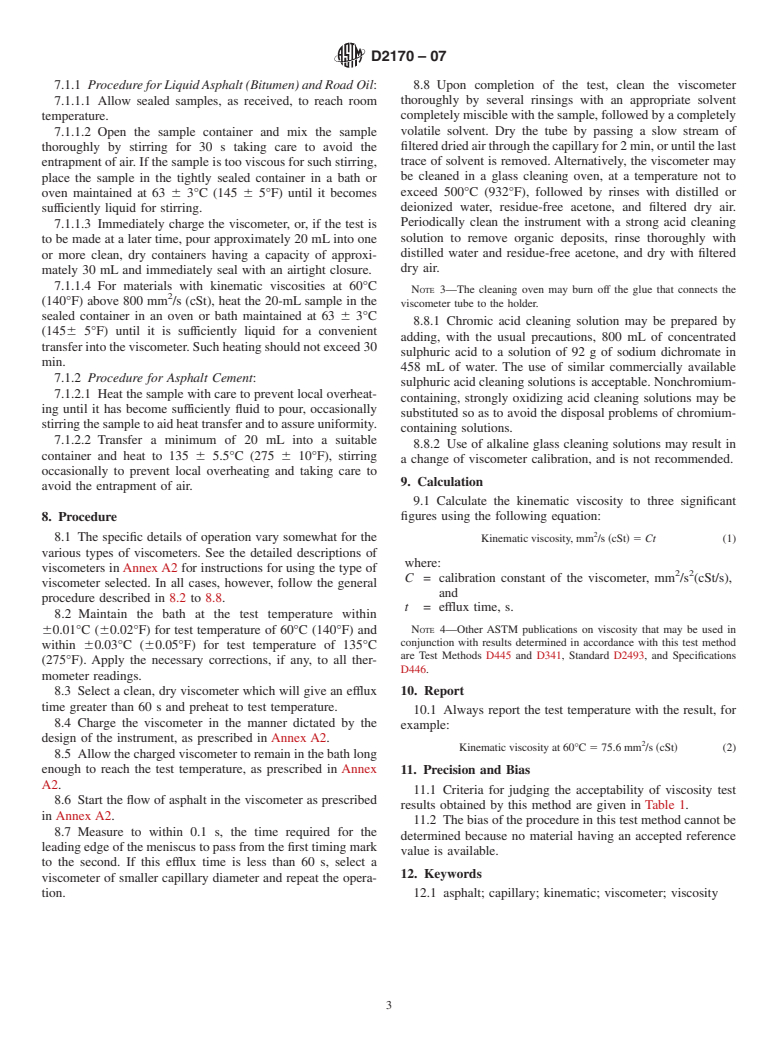

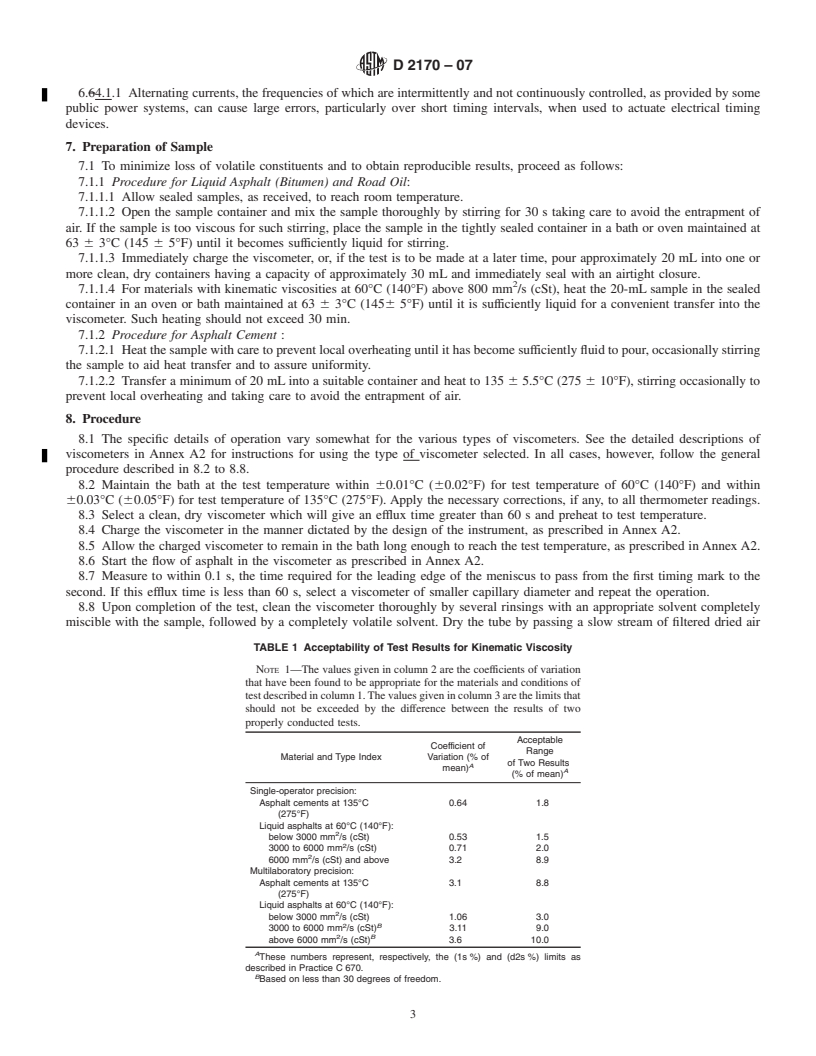

TABLE 1 Acceptability of Test Results for Kinematic Viscosity

shearingstresstotherateofshearistheviscosityoftheliquid.

If the ratio is not constant, the liquid is non-Newtonian.

NOTE 1—The values given in column 2 are the coefficients of variation

3.1.4 viscosity—the ratio between the appli

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D2170–01a(Reapproved 2006) Designation:D2170–07

Designation: 319/84 (89)

Standard Test Method for

1

Kinematic Viscosity of Asphalts (Bitumens)

This standard is issued under the fixed designation D2170; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This test method covers procedures for the determination of kinematic viscosity of liquid asphalts (bitumens), road oils and

distillationresiduesofliquidasphalts(bitumens)allat60°C(140°F)andofasphaltcementsat135°C(275°F)(Note1)intherange

2

from 6 to 100 000 mm /s (cSt).

1.2 Results of this test method can be used to calculate viscosity when the density of the test material at the test temperature

is known or can be determined. See Annex A1 for the method of calculation.

NOTE 1—This test method is suitable for use at other temperatures and at lower kinematic viscosities, but the precision is based on determinations on

2

liquid asphalts and road oils at 60°C (140°F) and on asphalt cements at 135°C (275°F) only in the viscosity range from 30 to 6000 mm /s (cSt).

1.3

1.3 Warning—MercuryhasbeendesignatedbyUnitedStatesEnvironmentalProtectionAgency(EPA)andmanystateagencies

as a hazardous material that can cause central nervous system, kidney and liver damage. Mercury, or its vapor, may be hazardous

to health and corrosive to materials. Caution should be taken when handling mercury and mercury containing products. See the

applicable product Material Safety Data Sheet (MSDS) for details and EPA’s website—http://www.epa.gov/mercury/faq.htm—for

additional information. Users should be aware that selling mercury, mercury containing products, or both, in your state may be

prohibited by state law.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

C670 Practice for Preparing Precision and Bias Statements for Test Methods for Construction Materials

D92 Test Method for Flash and Fire Points by Cleveland Open Cup Tester

D341 Test Method for Viscosity-Temperature Charts for Liquid Petroleum Products

D445 Test Method for Kinematic Viscosity of Transparent and Opaque Liquids (and Calculation of Dynamic Viscosity)

D446 Specifications and Operating Instructions for Glass Capillary Kinematic Viscometers

D2162 Practice for Basic Calibration of Master Viscometers and Viscosity Oil Standards

D2493 Standard Viscosity-Temperature Chart for Asphalts

E1 Specification for ASTM Liquid-in-Glass Thermometers

E77 Test Method for Inspection and Verification of Thermometers

3. Terminology

3.1 Definitions:

3 3

3.1.1 density—the mass per unit volume of liquid and the cgs unit of density is 1 g/cm . The SI unit of density is 1 kg/m .

1

ThistestmethodisunderthejurisdictionofASTMCommitteeD04onRoadandPavingMaterialsandisthedirectresponsibilityofSubcommitteeD04.44onRheological

Tests. In the IP this test method is under the jurisdiction of the Standardization Committee.

Current edition approved Dec. 1, 2006.2007. Published December 2006.2007. Originally approved in 1963. Last previous edition approved in 20022006 as D2170–01a

(2006).

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D2170–07

3.1.2 kinematic viscosity—theratiooftheviscositytothedensityofaliquid.Itisameasureoftheresistancetoflowofaliquid

2 2

undergravity.TheSIunitofkinematicviscosityism /s;forpracticaluse,asubmultiple(mm /s)ismoreconvenient.Thecgsunit

2 −2 2

of kinematic viscosity is 1 cm /s and is called a stokesstoke (symbol St).The centistokes (1 cSt=10 St) is 1 mm /s and is often

used.

3.1.3 Newtonian liquid—a liquid in which the rate of shear is proportional to the shearing stress. The constant ratio of the

shearing stress to the rate

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.