ASTM D5150-92(2013)

(Test Method)Standard Test Method for Hiding Power of Architectural Paints Applied by Roller

Standard Test Method for Hiding Power of Architectural Paints Applied by Roller

SIGNIFICANCE AND USE

5.1 Laboratory hiding power measurements of architectural coatings generally employ blade-type applicators that lay down films of highly uniform thickness. But practical applicators, such as rollers, pads, and brushes, typically apply films that lack uniformity due to incomplete leveling, resulting in the practical hiding power of most paints being less than that measured on films applied with a drawdown blade. This test method simulates practical application procedures and conditions so as to provide an indication of the actual hiding performance obtainable when a paint is applied by an experienced worker. It is not intended to duplicate painting as done by the average consumer.

5.2 Since the rheological characteristics of a paint and its interaction with the applicator are influencing factors, rank order correlation between this test and one done by drawdown might not be obtained.

SCOPE

1.1 This test method measures the ability of a paint to hide or obscure a surface to which it has been applied by a practical application procedure. This test method covers the use of a paint roller, but the concept is expected to work equally well when the application tool is a paint brush or paint pad.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D5150 − 92 (Reapproved 2013)

Standard Test Method for

Hiding Power of Architectural Paints Applied by Roller

This standard is issued under the fixed designation D5150; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 hiding power, n—theabilityofapaintorpaintmaterial

as used to hide or obscure a surface to which it has been

1.1 This test method measures the ability of a paint to hide

uniformly applied (see Terminology D16).

or obscure a surface to which it has been applied by a practical

application procedure. This test method covers the use of a

4. Summary of Test Method

paint roller, but the concept is expected to work equally well

when the application tool is a paint brush or paint pad. 4.1 The test paint is applied with a roller at a specified

spreading rate onto a test chart consisting of a series of light to

1.2 The values stated in inch-pound units are to be regarded

dark grey stripes. After drying, a second coat is applied in the

as standard. The values given in parentheses are mathematical

same manner over half of the chart. After the second coat has

conversions to SI units that are provided for information only

dried, both the single- and double-coated areas are evaluated

and are not considered standard.

for hiding as judged by the darkest stripe in each area that is

1.3 This standard does not purport to address all of the

completely or almost completely obscured.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

5. Significance and Use

priate safety and health practices and determine the applica-

5.1 Laboratory hiding power measurements of architectural

bility of regulatory limitations prior to use.

coatingsgenerallyemployblade-typeapplicatorsthatlaydown

2. Referenced Documents films of highly uniform thickness. But practical applicators,

2 such as rollers, pads, and brushes, typically apply films that

2.1 ASTM Standards:

lack uniformity due to incomplete leveling, resulting in the

D16 TerminologyforPaint,RelatedCoatings,Materials,and

practical hiding power of most paints being less than that

Applications

measured on films applied with a drawdown blade. This test

D1475 Test Method For Density of Liquid Coatings, Inks,

method simulates practical application procedures and condi-

and Related Products

tions so as to provide an indication of the actual hiding

D2244 Practice for Calculation of Color Tolerances and

performance obtainable when a paint is applied by an experi-

Color Differences from Instrumentally Measured Color

enced worker. It is not intended to duplicate painting as done

Coordinates

by the average consumer.

D3924 Specification for Environment for Conditioning and

Testing Paint, Varnish, Lacquer, and Related Materials 5.2 Since the rheological characteristics of a paint and its

D3925 Practice for Sampling Liquid Paints and Related interaction with the applicator are influencing factors, rank

order correlation between this test and one done by drawdown

Pigmented Coatings

E1347 Test Method for Color and Color-Difference Mea- might not be obtained.

surement by Tristimulus Colorimetry

6. Apparatus

3. Terminology

6.1 Balance, accurate to 0.1 g.

3.1 Definitions:

6.2 A Weight/Gallon Cup, or any other type of pycnometer

suitable for determining paint density to 0.1 lb/gal.

This test method is under the jurisdiction of ASTM Committee D01 on Paint

6.3 Paint Roller, 3-in. (75-mm), frame, preferably one per

and Related Coatings, Materials, andApplications and is the direct responsibility of

Subcommittee D01.42 on Architectural Coatings.

paint to be tested.

Current edition approved July 1, 2013. Published July 2013. Originally approved

6.4 Paint Roller Cover, 3-in. (75-mm) length, with a short

in 1991. Last previous edition approved in 2009 as D5150 – 92 (2009). DOI:

3 1

10.1520/D5150-92R13.

nap ( ⁄16 to ⁄4 in. (4.8 to 6.4 mm) constructed from a woven

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

fabric. New unused roller covers are preferred but used roller

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

covers may be used but must be thoroughly cleaned so the

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. resulting appearance is like a new roller cover. When two or

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5150 − 92 (2013)

9. Procedure

9.1 Determine the weight/gallon of each paint being tested

to 0.1 lb in accordance with Test Method D1475.

NOTE 1—The gallon unit referred to in this test method is the U.S.

Gallon.

9.2 Use the following equation to determine the amount of

paint required for each coat on 3 ft of chart area:

1362 3Paint Density lb/gal

~ !

2 2

Grams for 3 ft 2787 m 5

~ !

Desired Spreading Rate ft /gal

~ !

The spreading rate may be either the manufacturer’s recom-

mended spreading rate for each paint, or the same spreading

rate for all paints under test according to agreement between

2 2

producer and user. A spreading rate of 450 ft /gal (11.0 m /L)

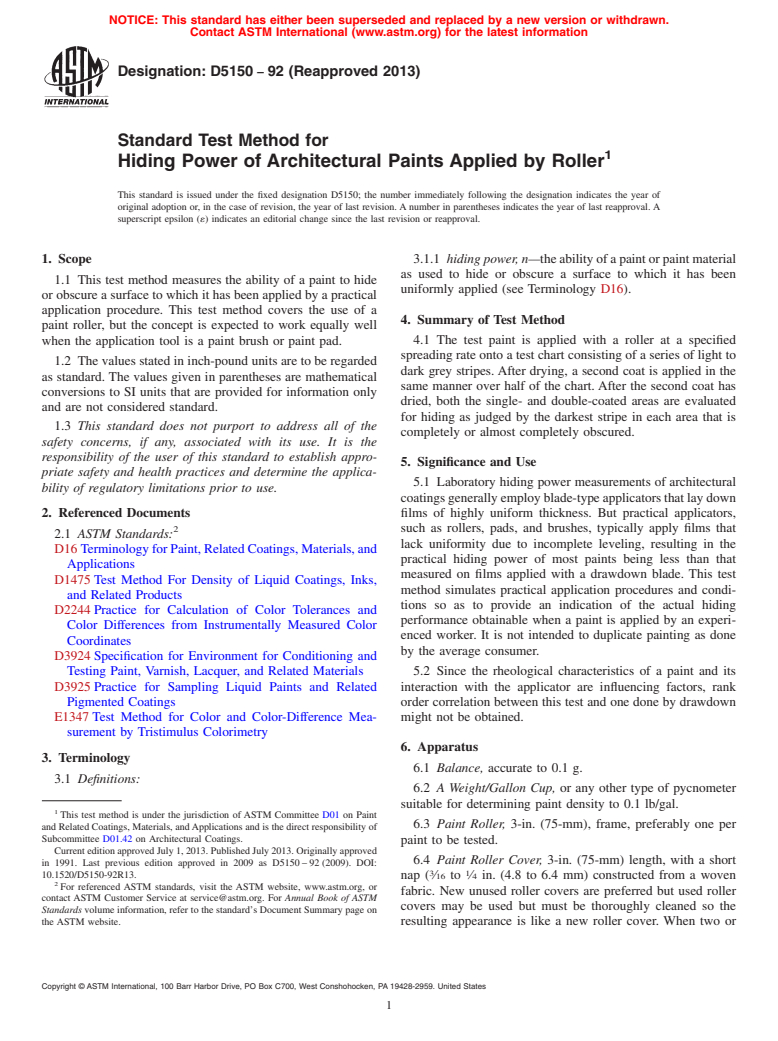

FIG. 1 Practical Opacity Chart in Accordance with Footnote 5 is suggested if there is no other preference. Include spreading

and Appendix X1

rate(s) used in the report.

9.3 At a convenient height, tape a test chart with the long

direction horizontal, to a surface that is vertical or within 5° of

vertical (top sloping away from the operator). The tape should

be placed on the vertical, numbered border stripes that are

2 2

outside the 6 ft (5575 cm ) test area of the chart.

9.4 Prepare the paint roller for use in the test by the

following procedure:

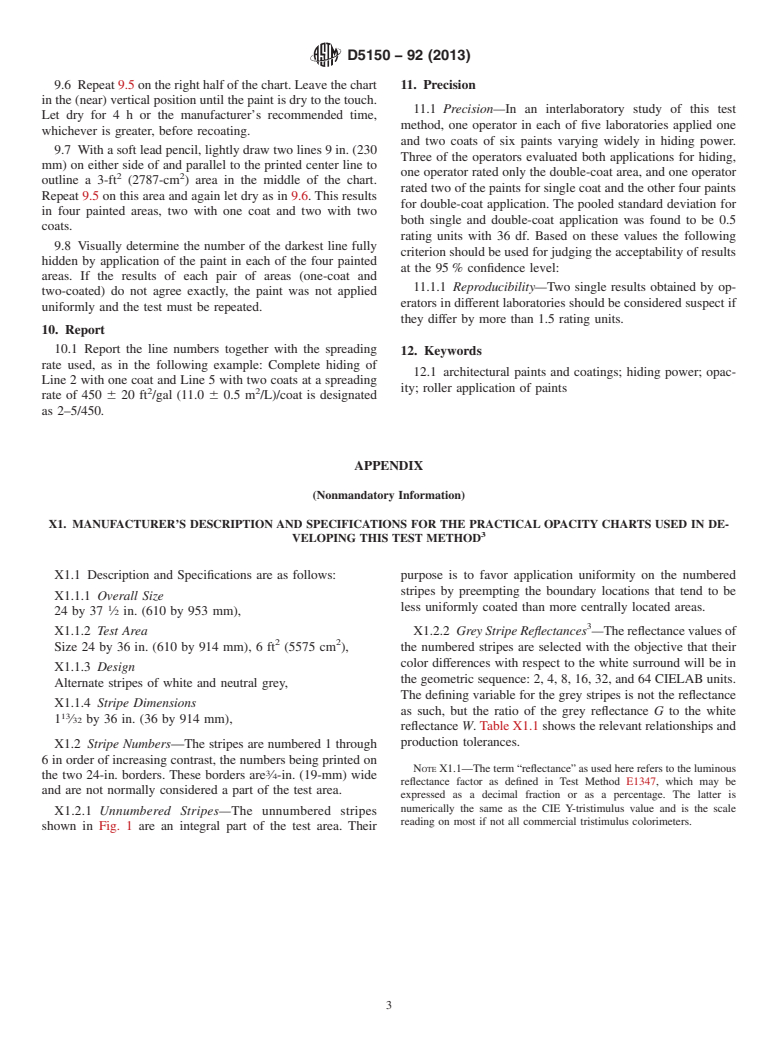

9.4.1 Load the roller cover with paint from the tray by

rolling it through paint so that just the nap is submersed (see

Fig. 2).

9.4.2 Roll out the loaded cover onto a scrap surface, in an

upward and downward motion, within an area no larger than

FIG. 2 Loading the Roller

1-ft (0.3-m) high by the 3-in. (75-mm) width of the roller

cover.

more coatings are being tested with the latter type of roller 9.4.3 Reloadtherollercoverandrollitoutagaininthesame

cover, each should have been used approximately the same manner as 9.4.2 and over the same area. Do not increase the

number of times and should be well dried out from previous area except as necessary to control excess dripping of paint.

applications.

9.4.4 Repeat the procedure as necessary until the following

conditions are met:

6.5 Paint Tray.

9.4.4.1 Reloading the paint roller cover does not result in

7. Materials

increased paint pickup.

9.4.4.2 Thereissomuchpaintonthesurfacebeingusedthat

7.1 Practical Opacity Charts—These are smooth surface,

sealed paper test charts on which are printed a 6-step series of the fully-loaded paint roller cover cannot transfer any more

paint to the surface.

grey stripes of increasing darkness numbered from 1 to 6. The

2 2

test area is 6 ft (5575 cm ). For more complete details see Fig.

9.4.5 Now immediately perform the test.

1 and the manufacturer’s description in the appendix.

9.5 Load the roller cover fully, just short of dripping and

7.2 Masking Tape.

weigh. Either weigh the paint and roller before and after, or the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.