ASTM F1545-97

(Specification)Standard Specification for Plastic-Lined Ferrous Metal Pipe, Fittings, and Flanges

Standard Specification for Plastic-Lined Ferrous Metal Pipe, Fittings, and Flanges

SCOPE

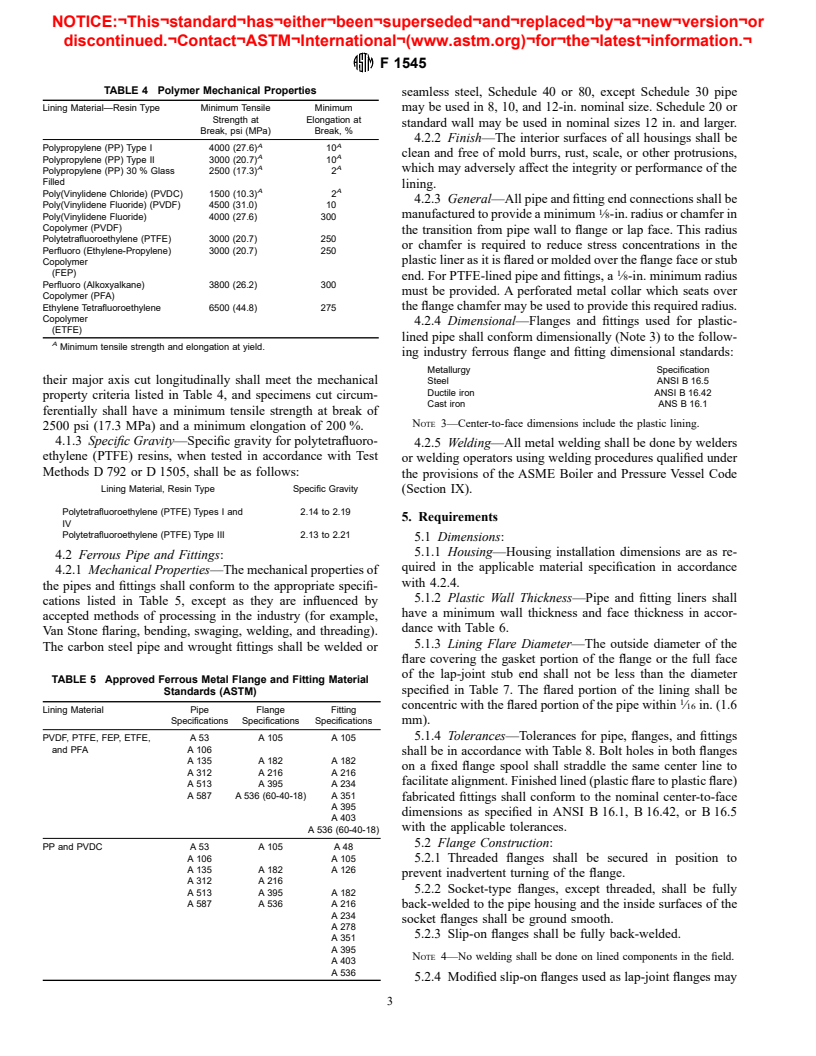

1.1 This specification covers factory-made plastic-lined ferrous metal pipe, fittings, and flanges intended primarily for conveying corrosive fluids. Requirements for materials, workmanship, dimensions, design, fabrication, working pressure and temperatures, test methods, qualification requirements, and markings are included.

1.1.1 This specification does not define the suitability of different liner materials to various chemical and operating environments. Refer to the manufacturer's chemical resistance data for suitability recommendations.

1.1.2 This specification does not include products coated with plastics.

1.2 This specification covers plastic-lined pipe, flanges, and fittings as listed in Table 1. Pressure limitations shall be in accordance with ANSI/ASME B16 Standards, except reduced pressure limitations may be established by the manufacturer, considering both pressure and temperature limitations of the ferrous metal housing and the sealing ability of the liner.

Note 1—In this specification, propylene plastics cover those materials defined as both polypropylene plastics and propylene plastics in Terminology F 412. Both materials are identified as "PP" on the product. Note that this is at variance with Terminology D 1600, where "PP" is the abbreviation for polypropylene.

1.3 The plastic-lined flanged pipe and fitting assemblies are limited to temperatures shown in Table 2. End users should consult with manufacturers as to the likely result of using a particular lined piping component at temperatures below the rated minimum.

Note 2—The temperature limitations are based on noncorrosive test conditions. Use in specific aggressive environments may alter temperature limitations. In such instances, specific temperature limits shall be established by mutual agreement between the purchaser and the manufacturer.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are provided for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or

withdrawn. Contact ASTM International (www.astm.org) for the latest information.

Designation: F 1545 – 97 An American National Standard

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

1

Plastic-Lined Ferrous Metal Pipe, Fittings, and Flanges

This standard is issued under the fixed designation F 1545; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

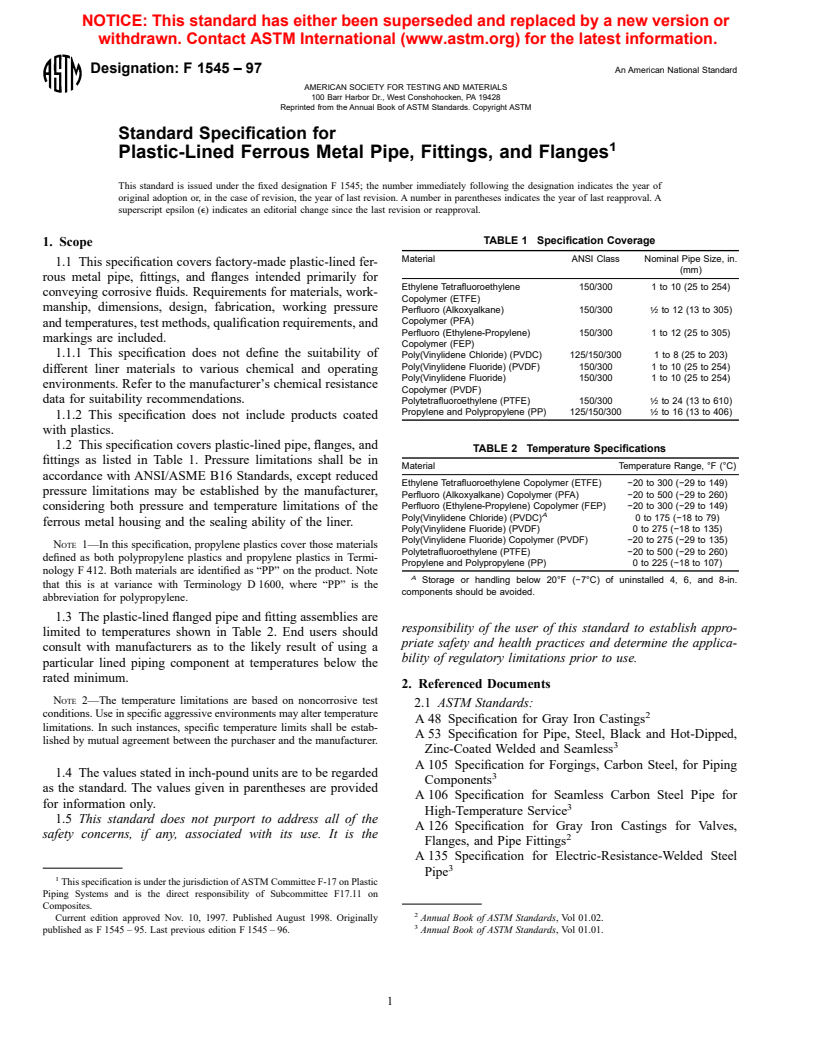

TABLE 1 Specification Coverage

1. Scope

Material ANSI Class Nominal Pipe Size, in.

1.1 This specification covers factory-made plastic-lined fer-

(mm)

rous metal pipe, fittings, and flanges intended primarily for

Ethylene Tetrafluoroethylene 150/300 1 to 10 (25 to 254)

conveying corrosive fluids. Requirements for materials, work-

Copolymer (ETFE)

1

manship, dimensions, design, fabrication, working pressure

Perfluoro (Alkoxyalkane) 150/300 ⁄2 to 12 (13 to 305)

Copolymer (PFA)

and temperatures, test methods, qualification requirements, and

Perfluoro (Ethylene-Propylene) 150/300 1 to 12 (25 to 305)

markings are included.

Copolymer (FEP)

1.1.1 This specification does not define the suitability of Poly(Vinylidene Chloride) (PVDC) 125/150/300 1 to 8 (25 to 203)

Poly(Vinylidene Fluoride) (PVDF) 150/300 1 to 10 (25 to 254)

different liner materials to various chemical and operating

Poly(Vinylidene Fluoride) 150/300 1 to 10 (25 to 254)

environments. Refer to the manufacturer’s chemical resistance

Copolymer (PVDF)

1

data for suitability recommendations.

Polytetrafluoroethylene (PTFE) 150/300 ⁄2 to 24 (13 to 610)

1

Propylene and Polypropylene (PP) 125/150/300 ⁄2 to 16 (13 to 406)

1.1.2 This specification does not include products coated

with plastics.

1.2 This specification covers plastic-lined pipe, flanges, and

TABLE 2 Temperature Specifications

fittings as listed in Table 1. Pressure limitations shall be in

Material Temperature Range, °F (°C)

accordance with ANSI/ASME B16 Standards, except reduced

Ethylene Tetrafluoroethylene Copolymer (ETFE) −20 to 300 (−29 to 149)

pressure limitations may be established by the manufacturer,

Perfluoro (Alkoxyalkane) Copolymer (PFA) −20 to 500 (−29 to 260)

Perfluoro (Ethylene-Propylene) Copolymer (FEP) −20 to 300 (−29 to 149)

considering both pressure and temperature limitations of the

A

Poly(Vinylidene Chloride) (PVDC) 0 to 175 (−18 to 79)

ferrous metal housing and the sealing ability of the liner.

Poly(Vinylidene Fluoride) (PVDF) 0 to 275 (−18 to 135)

Poly(Vinylidene Fluoride) Copolymer (PVDF) −20 to 275 (−29 to 135)

NOTE 1—In this specification, propylene plastics cover those materials

Polytetrafluoroethylene (PTFE) −20 to 500 (−29 to 260)

defined as both polypropylene plastics and propylene plastics in Termi-

Propylene and Polypropylene (PP) 0 to 225 (−18 to 107)

nology F 412. Both materials are identified as “PP” on the product. Note

A

Storage or handling below 20°F (−7°C) of uninstalled 4, 6, and 8-in.

that this is at variance with Terminology D 1600, where “PP” is the

components should be avoided.

abbreviation for polypropylene.

1.3 The plastic-lined flanged pipe and fitting assemblies are

responsibility of the user of this standard to establish appro-

limited to temperatures shown in Table 2. End users should

priate safety and health practices and determine the applica-

consult with manufacturers as to the likely result of using a

bility of regulatory limitations prior to use.

particular lined piping component at temperatures below the

rated minimum.

2. Referenced Documents

NOTE 2—The temperature limitations are based on noncorrosive test

2.1 ASTM Standards:

conditions. Use in specific aggressive environments may alter temperature

2

A 48 Specification for Gray Iron Castings

limitations. In such instances, specific temperature limits shall be estab-

A 53 Specification for Pipe, Steel, Black and Hot-Dipped,

lished by mutual agreement between the purchaser and the manufacturer.

3

Zinc-Coated Welded and Seamless

A 105 Specification for Forgings, Carbon Steel, for Piping

1.4 The values stated in inch-pound units are to be regarded

3

Components

as the standard. The values given in parentheses are provided

A 106 Specification for Seamless Carbon Steel Pipe for

for information only.

3

High-Temperature Service

1.5 This standard does not purport to address all of the

A 126 Specification for Gray Iron Castings for Valves,

safety concerns, if any, associated with its use. It is the

2

Flanges, and Pipe Fittings

A 135 Specification for Electric-Resistance-Welded Steel

3

Pipe

1

This specification is under the jurisdiction of ASTM Committee F-17 on Plastic

Piping Systems and is the direct responsibility of Subcommitte

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.