ASTM F1342/F1342M-05(2022)

(Test Method)Standard Test Method for Protective Clothing Material Resistance to Puncture

Standard Test Method for Protective Clothing Material Resistance to Puncture

SIGNIFICANCE AND USE

5.1 This test method evaluates puncture resistance of protective clothing materials which may include plastics or elastomeric films, coated fabrics, flexible materials, laminates, or textile materials.

5.2 This test method is not intended to measure puncture resistance of all types of punctures encountered using protective clothing material. This test method involves a procedure where a puncture probe of specified dimensions is used for puncturing specimens.

5.3 This test method evaluates puncture resistance of protective clothing materials, specifically for puncture forced on specimens perpendicular to material surface. There is no supporting structure under the material specimen.

5.4 Evaluation of puncture resistance for snag-type puncture should be performed in accordance with Test Method D2582.

SCOPE

1.1 This test method determines the puncture resistance of a protective clothing material specimen by measuring the force required to cause a pointed puncture probe to penetrate through the specimen. This test method describes three protocols that may be used: Method A, Method B, and Method C.

1.1.1 Method A requires the use of Probe A only. The probe used for testing shall be recorded in the test report.

1.1.1.1 Probe A may be used to measure puncture resistance for the following types of materials:

(1) Elastomeric materials,

(2) Textiles, and

(3) Coated materials.

1.1.2 Method B requires the use of Probe B. The probe used for testing shall be recorded in the test report.

1.1.2.1 Probe B may be used to measure puncture resistance for the following types of materials:

(1) Textiles.

(2) Coated materials.

Note 1: Probe B is not suited for measuring the puncture resistance of unsupported elastomeric materials.

1.2 The values stated in SI units are to be regarded as the standard. The values in inch-pound units in brackets are for information purposes only. The values stated in each system may not be exact equivalents; therefore, each system must be used independently of the other, without combining values in any way.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F1342/F1342M − 05 (Reapproved 2022)

Standard Test Method for

Protective Clothing Material Resistance to Puncture

ThisstandardisissuedunderthefixeddesignationF1342/F1342M;thenumberimmediatelyfollowingthedesignationindicatestheyear

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

1.1 This test method determines the puncture resistance of a

protective clothing material specimen by measuring the force

2. Referenced Documents

required to cause a pointed puncture probe to penetrate through

2.1 ASTM Standards:

the specimen. This test method describes three protocols that

D2582 Test Method for Puncture-Propagation Tear Resis-

may be used: Method A, Method B, and Method C.

tance of Plastic Film and Thin Sheeting

1.1.1 MethodArequires the use of ProbeAonly. The probe

D3767 Practice for Rubber—Measurement of Dimensions

used for testing shall be recorded in the test report.

1.1.1.1 ProbeAmay be used to measure puncture resistance

3. Terminology

for the following types of materials:

3.1 Definitions:

(1) Elastomeric materials,

3.1.1 protective clothing material, n—any element,

(2) Textiles, and

constituent, or substance from which protective clothing is

(3) Coated materials.

composed or can be made.

1.1.2 Method B requires the use of Probe B.The probe used

for testing shall be recorded in the test report.

4. Summary of Test Method

1.1.2.1 Probe B may be used to measure puncture resistance

4.1 A material specimen is placed in a stationary support

for the following types of materials:

assembly that is in turn affixed to the lower arm of a tension

(1) Textiles.

testing machine.

(2) Coated materials.

4.2 A pointed puncture probe of set dimensions is mounted

NOTE 1—Probe B is not suited for measuring the puncture resistance of

to the test fixture and the whole assembly is attached to the

unsupported elastomeric materials.

compression cell of the testing machine.

1.2 The values stated in SI units are to be regarded as the

standard. The values in inch-pound units in brackets are for 4.3 The puncture probe is moved at a constant velocity until

information purposes only. The values stated in each system it punctures the material specimen.

may not be exact equivalents; therefore, each system must be

4.4 The force required to puncture the material specimen is

used independently of the other, without combining values in

measured by the compression cell. The elongation (or deflec-

any way.

tion) of the specimen prior to puncture is also measured. The

1.3 This standard does not purport to address all of the

reported puncture resistance is the average of twelve test

safety concerns, if any, associated with its use. It is the

replicates.

responsibility of the user of this standard to establish appro-

5. Significance and Use

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

5.1 This test method evaluates puncture resistance of pro-

1.4 This international standard was developed in accor-

tective clothing materials which may include plastics or

dance with internationally recognized principles on standard-

elastomeric films, coated fabrics, flexible materials, laminates,

ization established in the Decision on Principles for the

or textile materials.

Development of International Standards, Guides and Recom-

5.2 This test method is not intended to measure puncture

resistance of all types of punctures encountered using protec-

tive clothing material. This test method involves a procedure

This test method is under the jurisdiction ofASTM Committee F23 on Personal

Protective Clothing and Equipment and is the direct responsibility of Subcommittee

F23.20 on Physical. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Feb. 1, 2022. Published February 2022. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1991. Last previous edition approved in 2013 as F1342/F1342M – 05 Standards volume information, refer to the standard’s Document Summary page on

ɛ1

(2013) . DOI: 10.1520/F1342_F1342M-05R22. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1342/F1342M − 05 (2022)

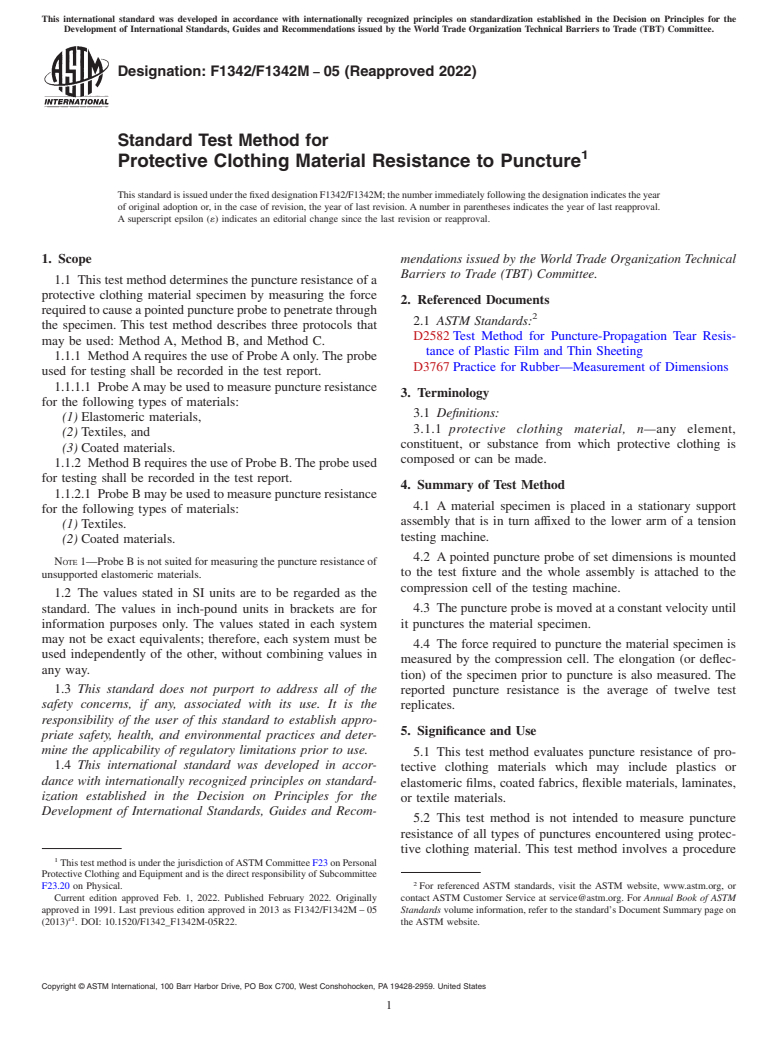

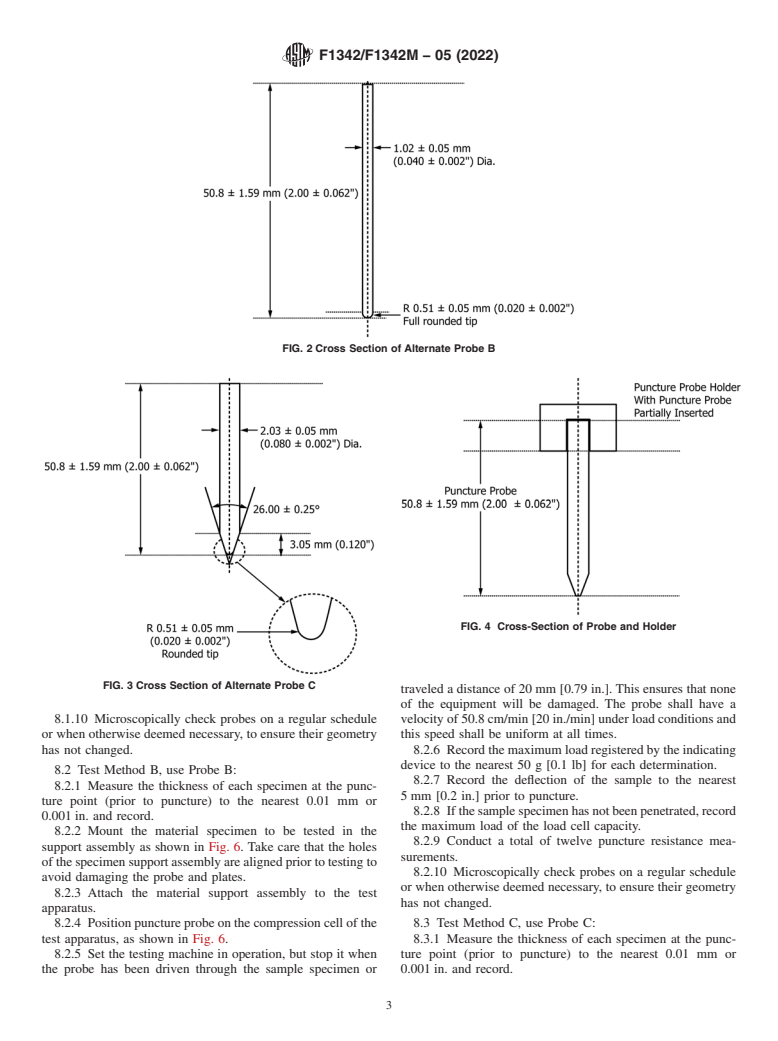

where a puncture probe of specified dimensions is used for 6.3.3 Probe C, shall be fabricated to meet the dimensions

puncturing specimens. shown in Fig. 3. The puncture probe shall be fabricated from

stainless steel with a Rockwell Hardness of not less than 35.

5.3 This test method evaluates puncture resistance of pro-

6.3.4 See Fig. 4 for cross section of probe and holder.

tective clothing materials, specifically for puncture forced on

specimens perpendicular to material surface. There is no

6.4 Specimen Support Assembly, shall consist of two flat

supporting structure under the material specimen.

metal specimen support plates (see Fig. 5) that clamp together

so the sample specimen is held tightly between them. It shall

5.4 Evaluationofpunctureresistanceforsnag-typepuncture

also consist of a machine interface plate that can be connected

should be performed in accordance with Test Method D2582.

to the testing machine. There should be enough distance to

6. Apparatus allow for 25 mm [1 in.] of travel of the probe.

6.4.1 Each plate shall have one to three chamfered holes

6.1 Thickness Gauge, suitable for measuring thickness to

measuring 6.4 mm [0.25 in.] for ProbeAand 10 mm [0.39 in.]

the nearest 0.01 mm [or the nearest 0.001 in.], as specified in

forProbesBandC.Forefficiencyintesting,threeholesspaced

Practice D3767, shall be used to determine the thickness of

at the points for a 60° equilateral triangle may be used, such

each protective clothing specimen tested.

that each hole is 25 mm [1 in.] from the other and from the

6.2 Testing Machine, shall meet the following criteria:

edge of the specimen plate, as shown in Fig. 5.

6.2.1 It shall be capable of holding the specimen securely

6.4.2 The two specimen support plates shall be connected to

between the two clamps and be capable of straining the

the testing machine using a machine interface plate.

specimen with a uniform movement.

6.2.2 A machine capable of providing load versus elonga-

7. Test Specimens

tion data until point of rupture shall be used.

7.1 Four to twelve test specimens, of dimensions to the

6.2.3 The error of the machine shall not exceed 2 % at any

reading within its loading range. specimen support assembly, shall be prepared. The samples

should be of a size that will not show puckering or slippage of

6.2.4 It shall be outfitted with a compression cell. The

samples during the test. No sample conditioning is required.

testing machine may be configured with the compression cell

on either the lower or upper arm. The compression cell shall

7.2 Use the specimen support plate as a template to cut test

have a range sufficient enough to penetrate the specimen.

specimens.

6.3 Puncture Probes:

6.3.1 Probe A, shall be fabricated to meet the dimensions

8. Procedure

shown in Fig. 1. The puncture probe shall be fabricated

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.