ASTM G34-01(2007)

(Test Method)Standard Test Method for Exfoliation Corrosion Susceptibility in 2XXX and 7XXX Series Aluminum Alloys (EXCO Test)

Standard Test Method for Exfoliation Corrosion Susceptibility in 2XXX and 7XXX Series Aluminum Alloys (EXCO Test)

SIGNIFICANCE AND USE

This test method was originally developed for research and development purposes; however, it is referenced, in specific material specifications, as applicable for evaluating production material (refer to Section 14 on Precision and Bias).

Use of this test method provides a useful prediction of the exfoliation corrosion behavior of these alloys in various types of outdoor service, especially in marine and industrial environments.4 The test solution is very corrosive and represents the more severe types of environmental service, excluding, of course, unusual chemicals not likely to be encountered in natural environments.

The exfoliation ratings were arbitrarily chosen to illustrate a wide range in resistance to exfoliation in this test. However, it remains to be determined whether correlations can be established between EXCO test ratings and realistic service conditions for a given alloy. It is an ongoing activity of the Task Group on Exfoliation Corrosion of Aluminum Alloys (G01.05.02.08) to maintain outdoor exposure tests for this purpose. For example, it has been reported5 that samples of Al-Zn-Mg-Cu alloys rated EA or P in a 48-h EXCO test did not develop more than a slight amount of incipient exfoliation (EA) during six- to nine-year exposures to seacoast atmospheres, whereas, ED rated materials in most cases developed severe exfoliation within a year in the seacoast atmosphere. It is anticipated that additional comparisons will become available as the outdoor tests are extended.

SCOPE

1.1 This test method covers a procedure for constant immersion exfoliation corrosion (EXCO) testing of high-strength 2XXX and 7XXX series aluminum alloys.

Note 1—This test method was originally developed for research and development purposes; however, it is referenced, in specific material specifications, as applicable for evaluating production material (refer to Section 14 on Precision and Bias).

1.2 This test method applies to all wrought products such as sheet, plate, extrusions, and forgings produced from conventional ingot metallurgy process.

1.3 This test method can be used with any form of specimen or part that can be immersed in the test solution.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G34 − 01(Reapproved 2007)

Standard Test Method for

Exfoliation Corrosion Susceptibility in 2XXX and 7XXX

Series Aluminum Alloys (EXCO Test)

ThisstandardisissuedunderthefixeddesignationG34;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2.2 ASTM Adjuncts:

Illustrations (Enlarged Glossy Prints)

1.1 This test method covers a procedure for constant im-

mersion exfoliation corrosion (EXCO) testing of high-strength

3. Terminology

2XXX and 7XXX series aluminum alloys.

3.1 Definitions:

NOTE 1—This test method was originally developed for research and

3.1.1 exfoliation—corrosion that proceeds laterally from the

development purposes; however, it is referenced, in specific material

sites of initiation along planes parallel to the surface, generally

specifications, as applicable for evaluating production material (refer to

at grain boundaries, forming corrosion products that force

Section 14 on Precision and Bias).

metal away from the body of the material giving rise to a

1.2 This test method applies to all wrought products such as

layered appearance (Terminology G15).

sheet, plate, extrusions, and forgings produced from conven-

4. Summary of Test Method

tional ingot metallurgy process.

4.1 This test method provides an accelerated exfoliation

1.3 Thistestmethodcanbeusedwithanyformofspecimen

corrosion test for 2XXX and 7XXX series aluminum alloys

or part that can be immersed in the test solution.

that involves the continuous immersion of test materials in a

1.4 This standard does not purport to address all of the

solution containing 4 M sodium chloride, 0.5 M potassium

safety concerns, if any, associated with its use. It is the

nitrate, and 0.1 M nitric acid at 25 6 3°C (77 6 5°F). The

responsibility of the user of this standard to establish appro-

susceptibility to exfoliation is determined by visual

priate safety and health practices and determine the applica-

examination, with performance ratings established by refer-

bility of regulatory limitations prior to use.

ence to standard photographs.

2. Referenced Documents

5. Significance and Use

2.1 ASTM Standards: 5.1 This test method was originally developed for research

D1193 Specification for Reagent Water

and development purposes; however, it is referenced, in

E3 Guide for Preparation of Metallographic Specimens specific material specifications, as applicable for evaluating

G15 Terminology Relating to Corrosion and Corrosion Test-

productionmaterial(refertoSection14onPrecisionandBias).

ing (Withdrawn 2010)

5.2 Use of this test method provides a useful prediction of

G112 Guide for Conducting Exfoliation Corrosion Tests in

the exfoliation corrosion behavior of these alloys in various

Aluminum Alloys

types of outdoor service, especially in marine and industrial

environments. The test solution is very corrosive and repre-

sents the more severe types of environmental service,

This test method is under the jurisdiction of ASTM Committee G01 on excluding, of course, unusual chemicals not likely to be

Corrosion of Metals and is the direct responsibility of Subcommittee G01.05 on

encountered in natural environments.

Laboratory Corrosion Tests.

Current edition approved May 1, 2007. Published May 2007. Originally

approved in 1972. Last previous edition approved in 2001 as G34–01. DOI:

10.1520/G0034-01R07. Available from ASTM International Headquarters. Order Adjunct No.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or ADJG003402. Original adjunct produced in 1980.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Ketcham, S. J., and Jeffrey, P. W., “Exfoliation Corrosion Testing of 7178 and

Standards volume information, refer to the standard’s Document Summary page on 7075AluminumAlloys” (Report ofASTM G01.05 Interlaboratory Testing Program

the ASTM website. in Cooperation with the Aluminum Association); and Sprowls, D. O., Walsh, J. D.,

The last approved version of this historical standard is referenced on and Shumaker, M. B., “Simplified Exfoliation Testing of Aluminum Alloys,”

www.astm.org. Localized Corrosion—Cause of Metal Failure, ASTM STP 516, ASTM, 1972.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

G34 − 01 (2007)

5.3 The exfoliation ratings were arbitrarily chosen to illus- 9. Test Specimens

trate a wide range in resistance to exfoliation in this test.

9.1 Specimens may be of any practical size or shape.

However, it remains to be determined whether correlations can

Nevertheless, for the results to be of most significance a

be established between EXCO test ratings and realistic service

specimen size of at least 50 by 100 mm (2 by 4 in.), or the

conditions for a given alloy. It is an ongoing activity of the

equivalent, is recommended.

Task Group on Exfoliation Corrosion of Aluminum Alloys

9.2 The edges of sawed specimens need not be machined,

(G01.05.02.08) to maintain outdoor exposure tests for this

but specimens obtained by blanking or shearing shall have

purpose. For example, it has been reported that samples of

edges dressed by machining or filling to a depth equal to the

Al-Zn-Mg-CualloysratedEAorPina48-hEXCOtestdidnot

thickness of the specimen to remove cold-worked metal.

develop more than a slight amount of incipient exfoliation

(EA) during six- to nine-year exposures to seacoast atmo-

9.3 Remove the cladding of alclad sheet by machining the

spheres, whereas, ED rated materials in most cases developed

test surface; remove or mask the cladding on the back side

severe exfoliation within a year in the seacoast atmosphere. It

(non-test surface) also.

is anticipated that additional comparisons will become avail-

9.4 When removing test specimens from extrusions and

able as the outdoor tests are extended.

forgings, take care to avoid specimen locations underneath

flanges, ribs, etc., where the grain structure is usually variable.

6. Apparatus

6.1 Any suitable glass, plastic, or similarly inert container

10. Standardization

can be used to contain the solution and specimens during the

10.1 To provide an indication when some inadvertent de-

period of test. Depending upon the shape and size of the

viation from the correct test conditions occurs, it is necessary

specimens, rods or racks of glass, plastic, or any inert sub-

to expose to the test at regular intervals a control specimen of

stance shall be used to support the specimen above the bottom

a material with known resistance. This control should exhibit

of the container. The container should be fitted with a loose-

the same degree of exfoliation each time it is included in the

fitting cover to reduce evaporation.

test.

7. Reagents

10.2 The control may be any material of the alloy type

included in the scope of this test method, preferably one with

7.1 Purity of Reagents—The test solution shall be prepared

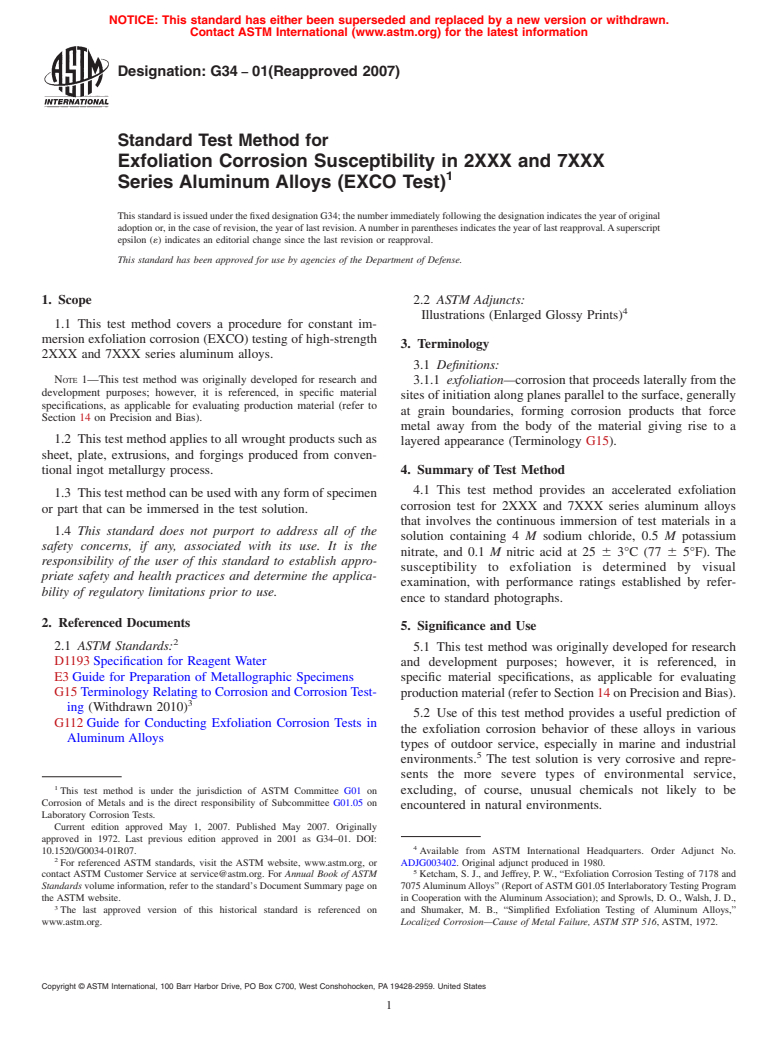

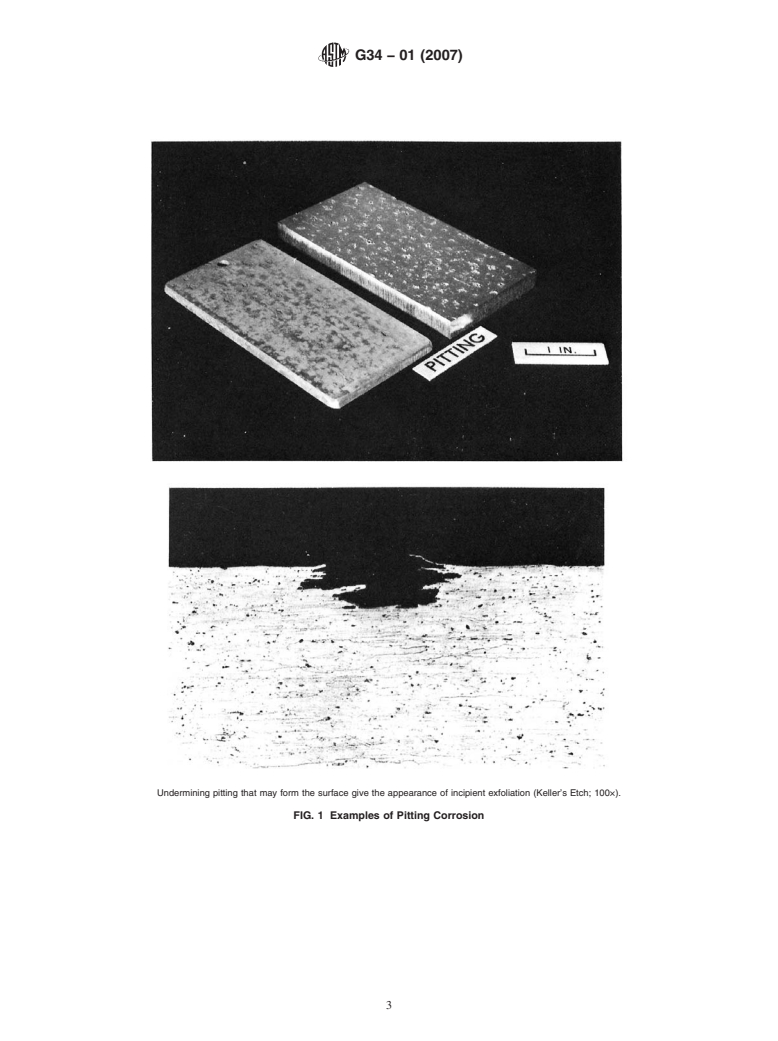

with reagent grade sodium chloride (NaCl), potassium nitrate an intermediate degree of susceptibility (Fig. 1 and Fig. 2).

(KNO ), and nitric acid (HNO ).

3 3

11. Procedure

7.2 Purity of Water—Distilled or deionized water shall be

used to prepare test solution.The water purity must conform to 11.1 Degrease the specimens with a suitable solvent.

Specification D1193, Type IV reagent water, except that for

11.2 Mask the back surfaces of the specimens to minimize

this method, the values of chloride and sodium can be

corrosionofnon-testareas.Protectivecoatingsmusthavegood

disregarded.

adherence to avoid crevice corrosion beneath the coating; also,

7.3 A test solution of the following composition shall be they should not contain leachable ions or protective oils that

used:

willinfluencethecorrosionofthetestsurface.(SeeFigs.1-6.)

NaCl (4.0 M)

11.3 Use the solution in sufficient quantity to provide a

KNO (0.5 M)

3 2

volume-to-metal surface area ratio of 10 to 30 mL/cm (65 to

HNO (0.1 M)

200 mL/in. ). Include all exposed metal area in the determina-

Dissolve 234 g of NaCl, 50 g of KNO in water, and add 6.3

tion of total surface area.

mL of concentrated HNO (70 weight %). Dilute to 1 L. This

solution has an apparent pH of 0.4.

11.4 Use fresh solution at the start of each test. Do not

change the solution even though the pH increases during the

7.4 The solution shall be maintained at a temperature of 25

test.ItisnormalforthepHtoincreasefromtheinitialapparent

6 3°C (77 6 5°F).

value of 0.4 to about 3 during the first several hours depending

upon the amount of corrosion that occurs.

8. Sampling

11.5 Immerse the specimens in the solution using rods or

8.1 Sampling procedures are not considered applicable to

racks of inert material to support the specimens above the

this test method, as they are often covered by product specifi-

bottom of the container. Place the test surface upward in a

cations. It is assumed that the test specimens are removed from

horizontal position to prevent loss of exfoliated metal from the

representative samples of materials.

surface of the specimen. Do not concurrently immerse in the

same container alloys containing less than 0.25 % copper with

Sprowls, D. O., Summerson, T. J., and Loftin, F. E., “Exfoliation Corrosion

those containing greater amounts of copper.

Testing of 7075 and 7178 Aluminum Alloys—Interim Report on Atmospheric

Exposure Tests” (Report of ASTM G01.05.02 Interlaboratory Testing Program in 11.6 The following maximum periods of exposure are

Cooperation with theAluminumAssociation); and Lifka, B.W. and Sprowls, D. O.,

recommended for testing the alloy types indicated:

“Relationship of Accelerated Test Methods for Exfoliation Resistance in 7XXX

2XXX Series 96 h

Series Aluminum Alloys With Exposure to a Seacoast Atmosphere,” Corrosion in

7XXX Series 48 h

Natural Environments, ASTM STP 558, ASTM, 1974.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.