ASTM C467-97(2002)

(Classification)Standard Classification of Mullite Refractories

Standard Classification of Mullite Refractories

SIGNIFICANCE AND USE

The mullite content of an alumina-silica refractory material has an important influence on volume stability, load bearing properties, and its satisfactory use in refractory applications. This classification is considered useful for purchase specifications and quality control.

SCOPE

1.1 This classification covers refractory products consisting predominantly of mullite (3 Al2O32 SiO2) crystals that are formed by either converting any of the sillimanite group of minerals, or synthesizing from appropriate materials in a melt or sinter process.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

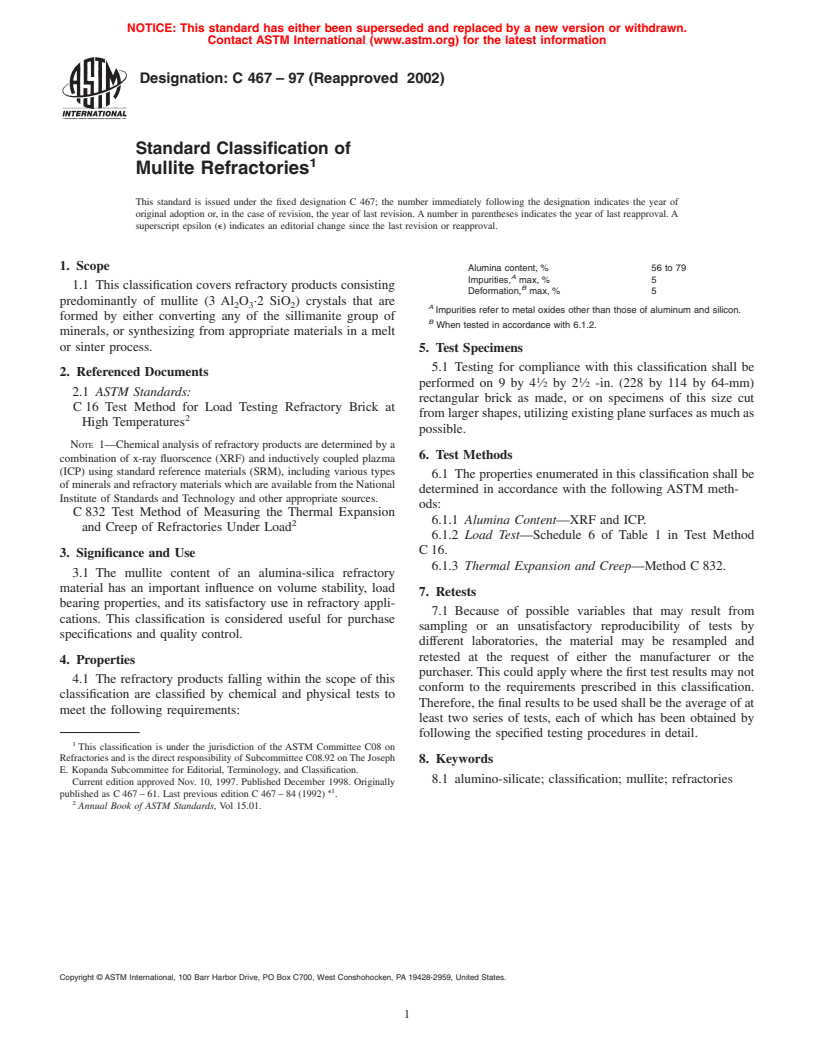

Designation: C 467 – 97 (Reapproved 2002)

Standard Classification of

Mullite Refractories

This standard is issued under the fixed designation C 467; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

Alumina content, % 56 to 79

A

Impurities, max, % 5

1.1 This classification covers refractory products consisting

B

Deformation, max, % 5

predominantly of mullite (3 Al O ·2 SiO ) crystals that are

2 3 2

A

Impurities refer to metal oxides other than those of aluminum and silicon.

formed by either converting any of the sillimanite group of

B

When tested in accordance with 6.1.2.

minerals, or synthesizing from appropriate materials in a melt

or sinter process.

5. Test Specimens

5.1 Testing for compliance with this classification shall be

2. Referenced Documents

1 1

performed on 9 by 4 ⁄2 by 2 ⁄2 -in. (228 by 114 by 64-mm)

2.1 ASTM Standards:

rectangular brick as made, or on specimens of this size cut

C 16 Test Method for Load Testing Refractory Brick at

from larger shapes, utilizing existing plane surfaces as much as

High Temperatures

possible.

NOTE 1—Chemical analysis of refractory products are determined by a

6. Test Methods

combination of x-ray fluorscence (XRF) and inductively coupled plazma

(ICP) using standard reference materials (SRM), including various types

6.1 The properties enumerated in this classification shall be

of minerals and refractory materials which are available from the National

determined in accordance with the following ASTM meth-

Institute of Standards and Technology and other appropriate sources.

ods:

C 832 Test Method of Measuring the Thermal Expansion

6.1.1 Alumina Content—XRF and ICP.

and Creep of Refractories Under Load

6.1.2 Load Test—Schedule 6 of Table 1 in Test Method

C 16.

3. Significance and Use

6.1.3 Thermal Expansion and Creep—Method C 832.

3.1 The mullite content of an alumina-silica refractory

material has an important influence on volume stability, load

7. Retests

bearing properties, and its satisfactory use in refractory appli-

7.1 Because of possible variables that may result from

cations. This classification is considered useful for purchase

sampling or an unsatisfactory reproducibility of tests by

specifications and quality control.

different

...

This May Also Interest You

SIGNIFICANCE AND USE

3.1 The cold strength of a refractory material is an indication of its suitability for use in refractory construction. (It is not a measure of performance at elevated temperatures.)

3.2 These test methods are for determining the room temperature flexural strength in three-point bending (cold modulus of rupture) or compressive strength (cold crushing strength), or both, for all refractory products.

3.3 Considerable care must be used to compare the results of different determinations of the cold crushing strength or modulus of rupture. The specimen size and shape, the nature of the specimen faces (that is, as-formed, sawed, or ground), the orientation of those faces during testing, the loading geometry, and the rate of load application may all significantly affect the numerical results obtained. Comparisons of the results between different determinations should not be made if one or more of these parameters differ between the two determinations.

3.4 The relative ratio of the largest grain size to the smallest specimen dimension may significantly affect the numerical results. For example, smaller cut specimens containing large grains may present different results than the bricks from which they were cut. Under no circumstances should 6 in. by 1 in. by 1 in. (152 mm by 25 mm by 25 mm) specimens be prepared and tested for materials containing grains with a maximum grain dimension exceeding 0.25 in. (6.4 mm).

3.5 This test method is useful for research and development, engineering application and design, manufacturing process control, and for developing purchasing specifications.

SCOPE

1.1 These test methods cover the determination of the cold crushing strength and the modulus of rupture (MOR) of dried or fired refractory shapes of all types.

1.2 The test methods appear in the following sections:

Test Method

Sections

Cold Crushing Strength

4 to 8

Modulus of Rupture

9 to 13

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard6 pagesEnglish languagesale 15% off

- Standard6 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

3.1 Insulating firebrick (IFB) are classified by their bulk density and reheat change (see Classification C155). This test method defines thermal stability by measurement of IFB's reheat change following 24 h at a test temperature.

3.2 Since this test exposes the entire sample to an isothermal temperature condition, the user should be aware that most applications for IFB involve a thermal gradient which may cause the IFB's dimensions to change differentially.

SCOPE

1.1 This test method covers the determination of the permanent linear (and volume) change of insulating firebrick upon reheating under prescribed conditions.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard4 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

3.1 The hydration of dead-burned dolomite grains is an important aspect of both manufacturing and using such grains. Moisture from any source will cause the grains to partially disintegrate, eventually making the dead-burned dolomite unfit for use. This test method may prove useful for determining, in a relative manner, which grains are more resistant to hydration than others.

3.2 Data from one laboratory might help in establishing internal limits for determining whether a particular batch of grain is suitable for refractory production. However, this test method takes great care to run, and is not recommended as a quality control test. Possibly, a specification might be developed between two parties if sufficient care in establishing the bias between the laboratories is carried out.

SCOPE

1.1 This test method covers the determination of the amount of hydration of a granular dead-burned refractory dolomite when exposed to moist air.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard2 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

2.1 This test method compares relative resistance to hydration of basic refractory brick and shapes in laboratory tests.

2.2 This test method allows an estimate to be made of the relative potential for hydration.

2.3 The test method is used in industry and in some cases it is used for specification purposes.

2.4 The results must be carefully used as a means of predicting whether or not basic brick or shapes will hydrate under actual conditions of storage or service.

SCOPE

1.1 This test method covers measurement of the relative resistance of basic brick and shapes to hydration.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard3 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

3.1 Apparent porosity, water absorption, apparent specific gravity, and bulk density are primary properties of refractory shapes. These properties are widely used in the evaluation and comparison of product quality and as part of the criteria for selection and use of refractory products in a variety of industrial applications. These test methods are used for determining any or all of these properties and are particularly useful for testing hydratable products.

3.2 These test methods are primary standard methods that are suitable for use in quality control, research and development, establishing criteria for and evaluating compliance with specifications, and providing data for design purposes.

3.3 Fundamental assumptions inherent in these test methods are:

3.3.1 The test specimens conform to the requirements for size, configuration, and original faces,

3.3.2 The open pores of the test specimens are fully impregnated with liquid during the vacuum-pressure treatment, and

3.3.3 The blotting of the saturated test specimens is performed as specified in a consistent and uniform manner to avoid withdrawing liquid from the pores.

3.3.4 Deviation from any of these assumptions adversely affects the test results.

3.4 In laboratory studies involving castable specimen, a bias was noted between formed 2 in. by 2 in. by 2 in. (50 mm by 50 mm by 50 mm) and specimens quartered from larger 9 in. by 4.5 in. by 2.5 in. (228 mm by 114 mm by 64 mm) cast specimens. Additionally, an error in the apparent porosity determination was found on castables whenever the specimens were heated to 1500 °F (816 °C) and then exposed to water as a saturation media. The error was attributed to reactivity of cement with water and subsequent re-hydration of cement phases. The higher the cement level of the castable, the greater the error noted. It was concluded that an error in porosity values could occur for refractory materials having a potential to form hydrated species with water. T...

SCOPE

1.1 These test methods cover the determination of the following properties of refractory shapes:

1.1.1 Apparent porosity,

1.1.2 Liquid absorption,

1.1.3 Apparent specific gravity, and

1.1.4 Bulk density.

1.2 These test methods are applicable to all refractory shapes except those that chemically react with both water and mineral spirits. When testing a material capable of hydration or other chemical reaction with water but which does not chemically react with mineral spirits, mineral spirits is substituted for water and appropriate corrections for the density differences are applied when making calculations.

1.3 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3.1 Exception—The apparatus used in this standard is only available in SI units.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

Note 1: Test Methods C20 cover procedures for testing properties of refractories that are not attacked by water.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard5 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

4.1 The true specific gravity of a material is the ratio of its true density, determined at a specific temperature, to the true density of water, determined at a specific temperature. Thus, the true specific gravity of a material is a primary property which is related to chemical and mineralogical composition.

4.2 This test method is particularly useful for hydratable materials that are not suitable for test with Test Method C135.

4.3 For refractory raw materials and products, the true specific gravity is a useful value for: classification, detecting differences in chemical composition between supposedly like samples, indicating mineralogical phases or phase changes, calculating total porosity when the bulk density is known, and for any other test method that requires this value for the calculation of results.

4.4 This test method is a primary standard method which is suitable for use in specifications, quality control, and research and development. It can also serve as a referee test method in purchasing contracts or agreements.

4.5 Fundamental assumptions inherent in this test method are the following:

4.5.1 The sample is representative of the material in general,

4.5.2 The total sample has been reduced to the particle size specified,

4.5.3 No contamination has been introduced during processing of the sample,

4.5.4 The ignition of the sample has eliminated all free or combined water without inducing sintering or alteration,

4.5.5 An inert gas (helium) has been used in the test, and

4.5.6 The test method has been conducted in a meticulous manner.

4.5.7 Deviation from any of these assumptions negates the usefulness of the results.

4.6 In interpreting the results of this test method, it must be recognized that the specified sample particle size is significantly finer than specified for Test Method C135. Even this finer particle size for the sample does not preclude the presence of some closed pores, and the amount of residual close...

SCOPE

1.1 This test method covers the determination of the true specific gravity of solid materials, and is particularly useful for materials that easily hydrate which are not suitable for test with Test Method C135. This test method may be used as an alternate for Test Methods C135, C128, and C188 for determining true specific gravity.

1.2 Units—The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.2.1 Exception—In 7.3, the equivalent SI unit is expressed in parentheses.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard3 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

3.1 Refractory brick are used as modular units in furnace construction and should not deviate significantly from the intended configuration with respect to size, bulk density, flat surfaces, and right angles. These test methods are particularly suited for use under field conditions and provide a means to determine whether the brick meets the requirements considered necessary to assure a satisfactory refractory construction.

SCOPE

1.1 These test methods cover procedures for measuring size, dimensional measurement, bulk density, warpage, and squareness of rectangular dense refractory brick and rectangular insulating firebrick. More precise determination of bulk density of refractory brick can be made by Test Methods C20. Stack height is generally determined only for dense refractories.

Note 1: Test Methods C830 and Test Method C914 are also used to determine bulk density of refractory brick, by different procedures.

1.2 The test methods appear in the following order:

Sections

Size and Bulk Density

4 through 7

Warpage of Refractory Brick

8 through 10

Squareness of Refractory Brick

11 through 14

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard4 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

4.1 This test method was developed for use both by manufacturers as a process control tool for the production of AZS fusion-cast refractories, and by glass manufacturers in the selection of refractories and design of glass-melting furnaces.

4.2 The results may be considered as representative of the potential for an AZS refractory (specifically, in the tested region) to contribute to glass defect formation during the furnace production operation.

4.3 The procedures and results may be applied to other refractory types or applications (that is, reheat furnace skid rail brick) in which glass exudation is considered to be important.

SCOPE

1.1 This test method covers a procedure for causing the exudation of a glassy phase to the surface of fusion-cast specimens by subjecting them to temperatures corresponding to glass furnace operating temperatures.

1.2 This test method covers a procedure for measuring the exudate as the percent of volume increase of the specimen after cooling.

1.3 Units—The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3.1 Exception—The balance required for this test method uses only SI units (Section 7).

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard4 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

2.1 This test method provides a guide for evaluating the resistance of refractories in glass-melting furnace superstructures to vapor attack. This test method may also be useful for evaluating refractories in other applications where vapor attack occurs.

2.2 An electric-heated furnace is recommended. Water vapor and other atmospheric components in a gas- or fuel-fired furnace may participate in the chemical and physical reactions being studied. Results may differ, therefore, depending upon the nature and type of firing employed.

2.3 The degree of correlation between this test method and service performance is not fully determinable. This is intended to be an accelerated test method that generates a substantial degree of reaction in a relatively short amount of time. This acceleration may be accomplished by changing the composition and/or concentration of the reactants, increasing temperatures, or by performing the test in an isothermal environment.

2.4 Since the test method may not accurately simulate the service environment, observed results of this test method may not be representative of those found in service. It is imperative that the user understand and consider how the results of this test method may differ from those encountered in service. This is particularly likely if the reaction products, their nature, or their degree differ from those normally found in the actual service environment.

2.5 It is incumbent upon the user to understand that this is an aggressive, accelerated test method and to be careful in interpreting the results. If, for example, the reaction species have never been found in a real-world furnace, then this test method should not necessarily be considered valid to evaluate the refractory in question.

SCOPE

1.1 This test method covers a procedure for comparing the behavior of refractories in contact with vapors under conditions intended to simulate the environment within a glass-melting or other type of furnace when refractories are exposed to vapors from raw batch, molten glass, fuel, fuel contaminants, or other sources. This procedure is intended to accelerate service conditions for the purpose of determining in a relatively short time the interval resistance to fluxing, bloating, shrinkage, expansion, mineral conversion, disintegration, or other physical changes that may occur.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard3 pagesEnglish languagesale 15% off

SIGNIFICANCE AND USE

3.1 Fireclay steel-teeming nozzles and sleeves are classified by volume reheat change. Bloating of some refractories results in irregular reheat dimensions, which are difficult to measure. This practice determines the volume without depending upon physical linear measurements.

3.2 Blast furnace checkers that have irregular cross-sections are classified by “creep properties.” This practice determines the average cross-sectional area.

SCOPE

1.1 This practice covers the methods of calculating areas, volumes, and linear changes of irregularly shaped refractory specimens.

1.2 The specimens must have a constant cross-sectional area over a length (L).

1.3 The values stated in SI units are to be regarded as the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

- Standard2 pagesEnglish languagesale 15% off

- Standard2 pagesEnglish languagesale 15% off

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.