ASTM D6611-16

(Test Method)Standard Test Method for Wet and Dry Yarn-on-Yarn Abrasion Resistance

Standard Test Method for Wet and Dry Yarn-on-Yarn Abrasion Resistance

SIGNIFICANCE AND USE

5.1 This test method is intended for testing dry and wet abrasion resistance of manufactured fiber yarns. This test method is especially useful for ropes intended for use in the marine environment. The test method has been used with yarns having linear densities ranging from 70 to 300 tex, but may be used with yarns outside these ranges.

5.2 Yarn to yarn friction is known to have a significant influence on abrasion resistance. To determine the coefficient of friction, use Test Method D3412.

5.3 Limited interlaboratory correlation testing has been conducted to date. Single-laboratory testing, in accordance with ASTM practices, has now been conducted. Test results should be used with caution.

5.4 This test method is intended to provide additional data for specific applications such as mentioned in 5.1 and is not intended for quality control or test reports.

5.5 If there are differences of practical significance between reported test results for two or more laboratories, comparative tests should be performed to determine if there is a statistical bias between them, using competent statistical assistance. As a minimum the test samples used should be as homogeneous as possible, be drawn from the material from which the disparate test results were obtained, and be randomly assigned in equal numbers to each laboratory for testing. Other materials with established test values may be used for this purpose. The test results from the two or more laboratories should be compared using a statistical test for unpaired data, at a probability level chosen prior to testing. If a bias is found, either its cause must be found and corrected, or future test results must be adjusted in consideration of the known bias.

5.6 This test method is conducted at one or several applied tensions that may depend upon the yarn material and size. The number and magnitudes of applied tensions and the number of eight specimen sets generally are agreed upon in a material specification or c...

SCOPE

1.1 This test method describes the measurement of abrasion resistance properties for manufactured fiber yarns in dry and wet conditions.

1.2 This test method applies to manufactured yarns used in rope making.

1.3 The values stated in SI units are to be regarded as standard. The values given in parentheses are provided for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6611 − 16

Standard Test Method for

1

Wet and Dry Yarn-on-Yarn Abrasion Resistance

This standard is issued under the fixed designation D6611; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2 For terminology related to industrial fibers and metallic

reinforcements, see Terminology D6477.

1.1 This test method describes the measurement of abrasion

resistance properties for manufactured fiber yarns in dry and 3.3 For definitions of other textile terms used in this test

wet conditions. method, refer to Terminology D123.

1.2 This test method applies to manufactured yarns used in

4. Summary of Test Method

rope making.

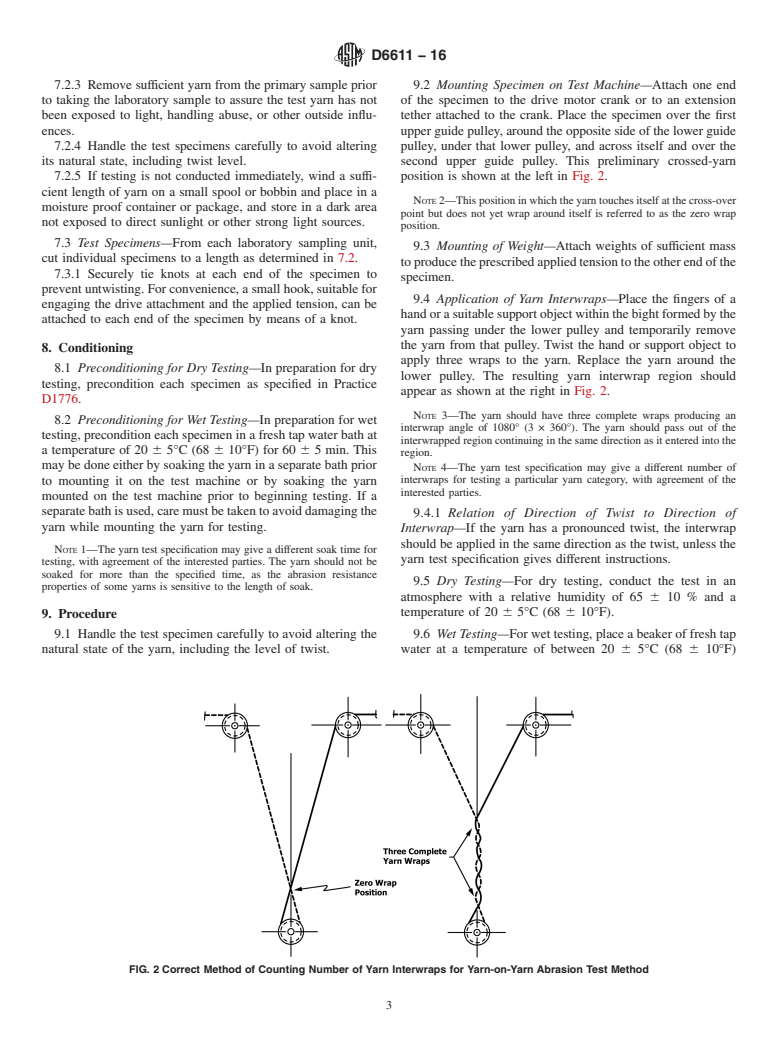

4.1 A length of yarn is interwrapped in contact with itself

1.3 The values stated in SI units are to be regarded as

between three pulleys that are positioned in a defined geometry

standard. The values given in parentheses are provided for

to produce a specific intersection angle. A weight is attached to

information only.

one end of the yarn to apply a prescribed tension. The other end

1.4 This standard does not purport to address all of the

is drawn back and forth through a defined stroke at a defined

safety concerns, if any, associated with its use. It is the

speed until the yarn fails due to abrasion upon itself within the

responsibility of the user of this standard to establish appro-

interwrapped region. The yarn abrasion test can be conducted

priate safety and health practices and determine the applica-

in either the dry state or the wet state.

bility of regulatory limitations prior to use.

5. Significance and Use

2. Referenced Documents

5.1 This test method is intended for testing dry and wet

2

2.1 ASTM Standards:

abrasion resistance of manufactured fiber yarns. This test

D123 Terminology Relating to Textiles

method is especially useful for ropes intended for use in the

D1776 Practice for Conditioning and Testing Textiles

marine environment. The test method has been used with yarns

D2904 Practice for Interlaboratory Testing of a Textile Test

having linear densities ranging from 70 to 300 tex, but may be

Method that Produces Normally Distributed Data (With-

used with yarns outside these ranges.

3

drawn 2008)

5.2 Yarn to yarn friction is known to have a significant

D3412 Test Method for Coefficient of Friction, Yarn to Yarn

influence on abrasion resistance. To determine the coefficient

D6477 Terminology Relating to Tire Cord, Bead Wire, Hose

of friction, use Test Method D3412.

Reinforcing Wire, and Fabrics

5.3 Limited interlaboratory correlation testing has been

3. Terminology

conducted to date. Single-laboratory testing, in accordance

with ASTM practices, has now been conducted. Test results

3.1 The following terms are relevant to this standard:

should be used with caution.

abrasion, apex angle, applied tension, cycles to failure (CTF),

dry, rope, wet.

5.4 This test method is intended to provide additional data

for specific applications such as mentioned in 5.1 and is not

intended for quality control or test reports.

1

This test method is under the jurisdiction of ASTM Committee D13 on Textiles

5.5 If there are differences of practical significance between

and is the direct responsibility of Subcommittee D13.19 on Industrial Fibers and

reported test results for two or more laboratories, comparative

Metallic Reinforcements.

Current edition approved July 1, 2016. Published August 2016. Originally tests should be performed to determine if there is a statistical

approved in 2000. Last previous edition approved in 2007 as D6611–00 (2007)

bias between them, using competent statistical assistance. As a

which was withdrawn Jan. 2016 and reinstated in July 2016. DOI: 10.1520/D6611-

minimum the test samples used should be as homogeneous as

16.

2

possible, be drawn from the material from which the disparate

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

test results were obtained, and be randomly assigned in equal

Standards volume information, refer to the standard’s Document Summary page on

numbers to each laboratory for testing. Other materials with

the ASTM website.

3 established test values may be used for this purpose. The test

The last approved version of this historical standard is referenced on

www.astm.org. results from the two or more laboratories should be compared

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6611 − 16

using a statis

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.