ASTM E789-95

(Test Method)Standard Test Method for Dust Explosions in a 1.2-Litre Closed Cylindrical Vessel

Standard Test Method for Dust Explosions in a 1.2-Litre Closed Cylindrical Vessel

SCOPE

1.1 This test method covers the determination of the ignition of a dust dispersed in air, within a closed vessel.

1.2 This test method provides a measure of dust explosion pressure and rate of pressure rise. It does not provide a definitive determination of the flammability of a dust and has other severe limitations which are identified in Section 5. The preferred method for the design of safety equipment is Test Method E1226.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific safety precautions see Section 7.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 789 – 95

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Dust Explosions in a 1.2-Litre Closed Cylindrical Vessel

This standard is issued under the fixed designation E 789; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Significance and Use

1.1 This test method covers the determination of the ignition 4.1 This test method provides a procedure for measuring

of a dust dispersed in air, within a closed vessel. pressure and rate of pressure rise.

1.2 This test method provides a measure of dust explosion 4.2 This test method may be used to determine whether a

pressure and rate of pressure rise. It does not provide a dust will ignite using an electric arc ignition source.

definitive determination of the flammability of a dust and has

5. Limitation

other severe limitations which are identified in Section 5. The

preferred method for the design of safety equipment is Test 5.1 The values determined by this test method are specific to

the material tested and equipment and procedure used and are

Method E 1226.

1.3 This standard does not purport to address all of the not to be considered inherent, fundamental properties.

5.2 The size and shape of the vessel have a direct bearing on

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- the data obtained. Extrapolation to vessels having a different

volume and shape should not be made.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. For specific safety 5.3 The data cannot be used for direct calculation of

explosion venting or containment.

precautions see Section 7.

1.4 The values stated in inch-pound units are to be regarded 5.4 A dust cloud that does not ignite by this test method may

still be flammable. This test method does not provide a

as the standard. The values in parentheses are for information

only. definitive determination of the flammability of a dust.

6. Apparatus

2. Referenced Documents

2.1 ASTM Standards: 6.1 The equipment consists of a verticall mounted closed

steel combustion chamber (commonly known as the Hartmann

D 3173 Test Method for Moisture in the Analysis Sample of

Coal and Coke tube), a dust dispersion system using clean air, ignition source,

pressure sensor, and recording system.

D 3175 Test Method for Volatile Matter in the Analysis

Sample of Coal and Coke 6.2 Fig. 1 is a schematic diagram of the apparatus.

6.3 Construction details and tables are presented in the

E 1226 Test Method for Pressure and Rate of Pressure Rise

for Combustible Dusts annexes.

2.2 Other ASTM Document: 6.4 The pressure transducer should be installed and operated

according to the manufacturer’s recommendations.

STP 447A Manual on Test Sieving Methods

3. Summary of Test Method 7. Safety Precautions

7.1 Prior to handling a dust material, the toxicity of the

3.1 A dust cloud is formed in a closed steel combustion

chamber by a jet of clean compressed air and ignited by a sample and its combustion products must be considered; this

information is generally obtained from the manufacturer or

continuous electric arc.

3.2 The pressure is detected by a transducer and recorded by supplier. Appropriate safety precautions must be taken if the

material has toxic or irritating characteristics. Tests using this

appropriate measuring equipment from which pressure and rate

of pressure rise may be determined. apparatus must be in a ventilated hood or other area having

adequate ventilation.

7.2 Before initiating a test check and secure the Hartmann

This test method is under the jurisdiction of ASTM Committee E-27 on Hazard

apparatus, fittings, and gaskets to prevent leakage.

Potential of Chemicals and is the direct responsibility of Subcommittee E27.05 on

7.3 All testing should start using 0.1 g of sample to prevent

Dusts.

over-pressurization due to high-energy materials. No experi-

Current edition approved Nov. 10, 1995. Published January 1996. Originally

published as E 789 – 81. Last previous edition E 789 – 89.

emtns should be run so that the explosion pressure exceeds 175

Annual Book of ASTM Standards, Vol 05.05

psig (1.21 MPa).

Annual Book of ASTM Standards, Vol 14.02.

7.4 In assembling the electricl circuitry for this apparatus,

E 789

NOTE 1—Cam switch timer operates solenoid valve, spark ignition, and recording oscillograph.

FIG. 1 Schematic of Apparatus for Determining Pressure and Rate of Pressure in a Dust Explosion

during any grinding or pulverizing. In sieving the material, the operator

standard wiring and grounding procedures must be followed.

must verify that there is no selective separation of components in a dust

Since the high-voltage spark circuit presents an electric shock

that is not a pure substance.

hazard, adequate interlock and shielding must be employed to

prevent contact.

8.4 The moisture content of the test sample should not

7.5 All enclosures containing electrical equipment should

exceed 5 % in order to avoid test results being noticeably

be connected to a common ground, and shielded cables should

influenced.

be used.

NOTE 3—There is no single method for determining the moisture

7.6 The operator should work from a protected location in

content or for drying the sample. ASTM lists many methods for moisture

case of vessel or electrical failure.

determination in the Annual Book of ASTM Standards. Sample drying is

equally complex due to the presence of volatiles, lack of or varying

8. Sampling and Test Specimen

porosity such as coal (see Test Methods D 3173 and D 3175), and

8.1 It is not practical to specify a single method of sampling

sensitivity of the sample to heat. Therefore, each must be dried in a

dust for test purposes since the character of the material and its

manner that will not modify or destroy the integrity of the sample.

Hygroscopic materials must be desiccated.

available form affect selection of the sampling procedure.

Generally accepted sampling procedures should be used as

9. Calibration and Standardization

described in STP 447A.

8.2 Tests may be run on an as-received sample. However,

9.1 Calibration of the air dispersion system should be made

due to possible accumulation of fines at some location in a

to establish proper air flow into the dispersion cup and

processing system, it is recommended that the test sample be at

combustion bomb. A cylindrical calibration chamber as de-

least 95 % minus 200 mesh (74 μm).

tailed in Fig. A1.13 is secured to the combustion chamber base

after setting the mushroom four turns counterclockwise from

NOTE 1—It may be desirable in certain instances to conduct dust

its closed position. A pressure transducer is connected to the

explosion tests on materials as sampled from a process, since (a) process

dust streams may contain a wide range of particle sizes or have a calibration chamber. The air (100 psig, 690 kPa) in the

well-defined specific moisture content making it desirable to test the

dispersion reservoir is then released and a pressure-time record

material in the as-received state, (b) materials consisting of a mixture of

of the event is obtained from the appropriate measuring

chemicals may be selectively separated on sieves making it desirable to

equipment. The maximum pressure and rate of pressure rise

test the as-received material, (c) certain fibrous materials which may not

determined from this record should be within the following

pass through a relatively coarse screen may produce dust explosions if

limits:

tested in the as-received state, (d) when a material is tested in the

as-received state it should be recognized that the test results may not

9.1.1 Maximum Pressure: 256 2 psig (172 6 14 kPa)

represent the most severe dust explosion possible. Any process change

9.1.2 Maximum Rate of Pressure Rise: 975 6 50 psi/s

resulting in a higher fraction of fines than normal or drier product than

(6.726 0.34 MPa/s).

normal will increase the potential hazard from dust explosions.

9.2 A standardization of the equipment before starting the

8.3 To achieve this particle fineness ($95 % minus 200

3 3

testing and at the end of the day with 0.75 oz/ft (kg/m )of

mesh) the sample may be ground or pulverized or it may be

lycopodium is necessary. The test equipment must read a

sieved.

pressure of 100 6 12 psig (690 6 83 kPa) and rate of 6300

NOTE 2—The operator should consider the thermal stability of the dust psi/s 6 20 % before using.

E 789

10. Procedure

10.1 Separate the steel combustion chamber from the dis-

persion cup base. Clear the dispersion system with several

blasts of air. Remove the spark electrodes and insulators from

the tube and dry clean them with sandpaper, steel wool, emery

cloth, or similar material. Recheck the electrodes and repoint as

necessary. Clean the inside of the tube with a wire brush or

similar device and remove the loosened residue from the

preceding test with a blast of high-pressure air or a vacuum

cleaner. Thoroughly clean the dispersion cup, mushroom, and

pressure transducer.

10.2 Remove the mushroom and check the mushroom insert

(Fig. A1.7) making sure it is flush with the top of the air

dispersion cup (A1.6). Reinsert the mushroom by turning it

clockwise until the cap is snug against the dispersion cup; then

turn the mushroom counterclockwise four complete turns.

10.3 Spread a weighed amount of dust into a uniformly thin

layer around the bottom of the dispersion cup. Determine

concentration by dividing the weight of dust used by the

FIG. 2 Pressure Versus Time—Data Analysis

3 3

volume of the steel combustion chamber 75 in. (0.00123 m ).

Explosion tests are normally made at calculated dust concen-

3 3 12.1.2 Size distribution (sieve analysis) of the sample as

trations of 0.1, 0.2, 0.5, 1.0, and 2.0 oz/ft (or kg/m ).

received and as tested.

NOTE 4—To convert gram weight per 75 in. to ounces per cubic feet

12.1.3 Moisture content of the as-received and as-tested

multiply by 0.813.

material.

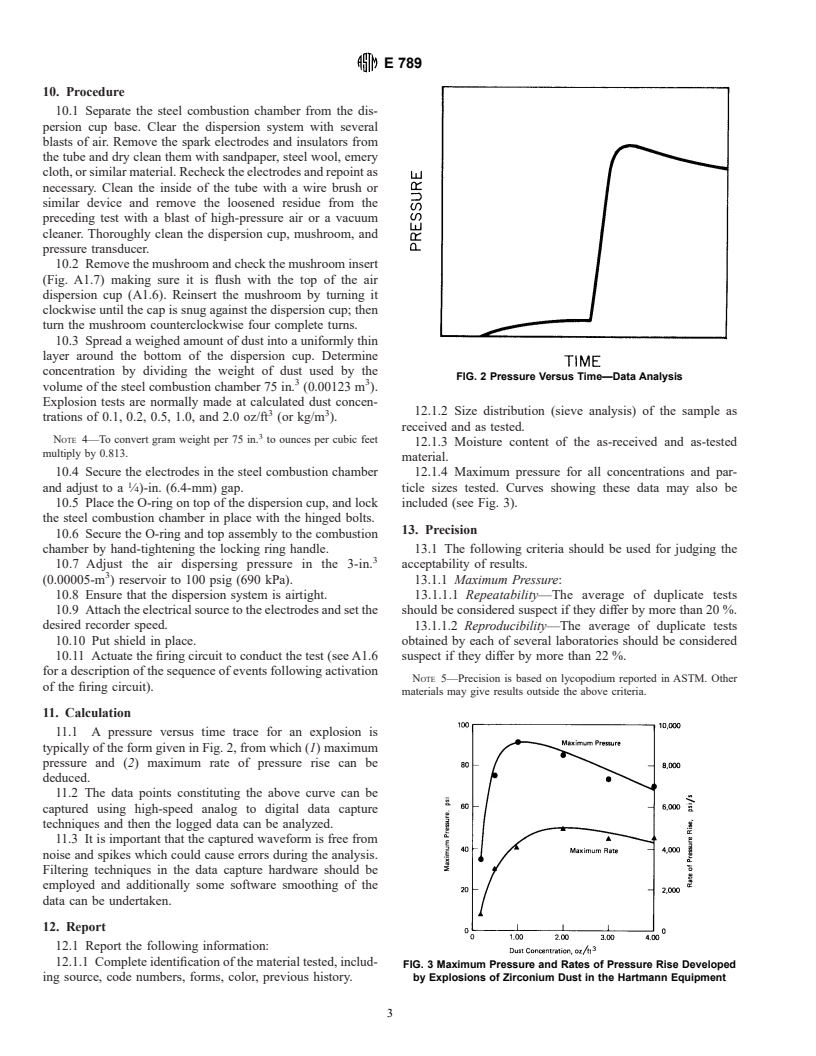

10.4 Secure the electrodes in the steel combustion chamber 12.1.4 Maximum pressure for all concentrations and par-

and adjust to a ⁄4)-in. (6.4-mm) gap. ticle sizes tested. Curves showing these data may also be

10.5 Place the O-ring on top of the dispersion cup, and lock included (see Fig. 3).

the steel combustion chamber in place with the hinged bolts.

13. Precision

10.6 Secure the O-ring and top assembly to the combustion

chamber by hand-tightening the locking ring handle. 13.1 The following criteria should be used for judging the

10.7 Adjust the air dispersing pressure in the 3-in. acceptability of results.

(0.00005-m ) reservoir to 100 psig (690 kPa). 13.1.1 Maximum Pressure:

10.8 Ensure that the dispersion system is airtight. 13.1.1.1 Repeatability—The average of duplicate tests

10.9 Attach the electrical source to the electrodes and set the should be considered suspect if they differ by more than 20 %.

desired recorder speed. 13.1.1.2 Reproducibility—The average of duplicate tests

10.10 Put shield in place. obtained by each of several laboratories should be considered

10.11 Actuate the firing circuit to conduct the test (see A1.6 suspect if they differ by more than 22 %.

for a description of the sequence of events following activation

NOTE 5—Precision is based on lycopodium reported in ASTM. Other

of the firing circuit).

materials may give results outside the above criteria.

11. Calculation

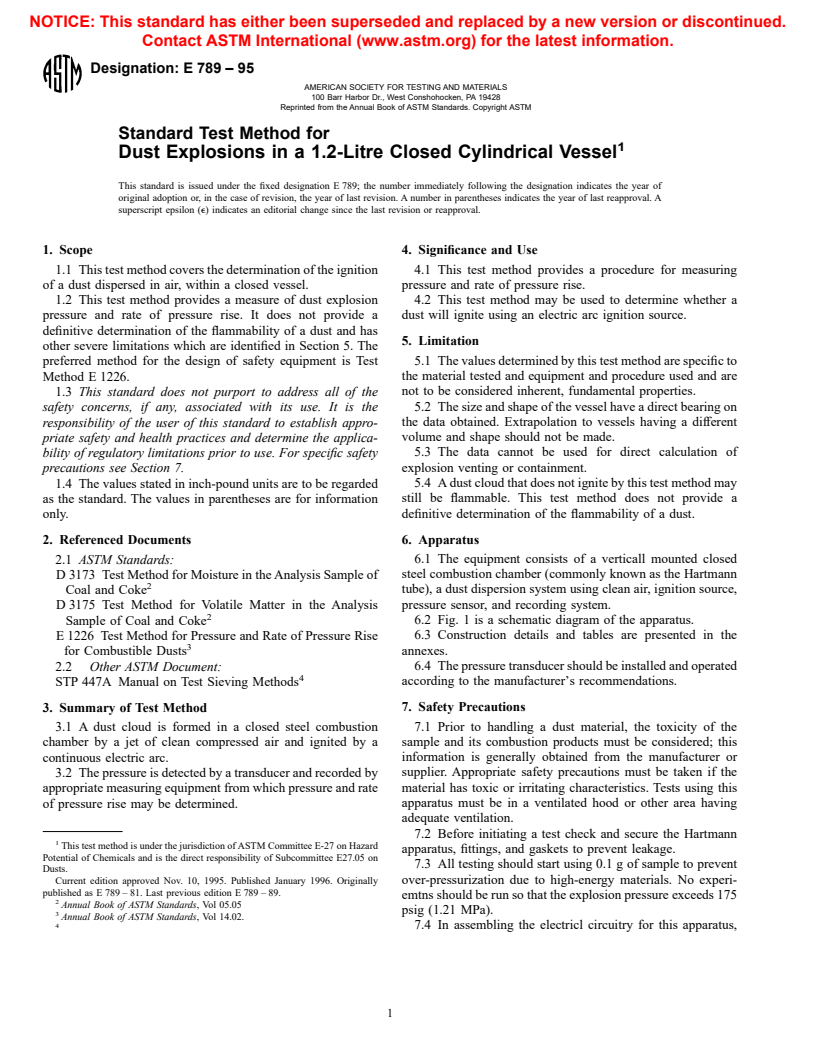

11.1 A pressure versus time trace for an explosion is

typically of the form given in Fig. 2, from which (1) maximum

pressure and (2) maximum rate of pressure rise can be

deduced.

11.2 The data points constituting the above curve can be

captured using high-speed analog to digital data capture

techniques and then the logged data can be analyzed.

11.3 It is important that the captured waveform is free from

noise and spikes which could cause errors during the analysis.

Filtering techniques in the data capture hardware should be

employed and additionally some software smoothing of the

data can be undertaken.

12. Report

12.1 Report the following information:

12.1.1 Complete identification of the material tested, includ-

FIG. 3 Maximum Pressure and Rates of Pressure Rise Developed

ing source, code numbers, forms, color, previous history. by Explosions of Zirconium Dust in the Hartmann Equipment

E 789

14. Keywords

14.1 dust explosion; dust ignition

ANNEXES

(Mandatory Information)

A1. METHOD OF OPERATION OF HARTMANN EQUIPMENT AND DETAILED DRAWINGS

A1.1 Fig. 1 is a schematic of the test apparatus and A1.3.1 The maximum pressure that can be developed in the

associated electronic instrumentation. Detailed constructional closed combustion tube from the introduction of the dispersing

drawings of each part of the apparatus are shown in Figs. air is 6.5 psig (45 kPa). Due to the rapid development of the

A1.1-A1.13. Part numbers and the figure for the drawings of explosion and action of the check valve, the pressure from the

each part are listed in Table A1.1. To serve as a guide, auxiliary dispersing air at the time of ignition is normally 2 to 3 psig (14

TABLE A1.1 Listing of Constructional Drawings for the Hartmann Apparatus

NOTE 1—Make combustion chamber base, six of one piece.

NOTE 2—Combustion chamber assembly, Parts 1, 12, 16, and 6, may be chromium-plated inside and outside except threads of Parts 12 and 16.

NOTE 3—All sliding fits shall be Class 3 medium fit ASA classification of fits. Nominal allowances are indicated.

Fig. Part Number To Fit Method of

Nomenclature Material

No. No. Required Part No. Assembling

Fig. A1.1 1 Hartmann combustion chamber 1 Seamless carbon mechanical steel . .

tubing

Fig. A1.2 . Hartmann base support and air control system 1 . 1 .

Fig. A1.3 2 Pressure transducer adapter ring 1 brass 1 slide fit

Fig. A1.3 3 Locking ring 1 brass 1 12 threads per inch

Fig. A1.3 4 Locking ring handle 3 brass 3 silver solder

Fig. A1.3 5 Electrode holder locknut wrench 1 steel 18 .

Fig. A1.4 6 Combustion chamber base 1 steel 1 12 threads per inch

Fig. A1.5 7 Holding lug screws 4 hardened steel 8 ⁄4-20 thread

Fig. A1.5 8 Holding lug base 4 steel 10 slide fit

Fig. A1.6 9A Dispersion cup 1 brass 6 slide fit

Fig. A1.7 9B Mushroom 1 brass 9C 2-56 thread

Fig. A1.7 9C Mushroom insert 1 brass 9A snug fit

Fig. A1.8 10 Dispersion cup base 1 brass 9A 6-

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.