ASTM A609/A609M-91(2007)

(Practice)Standard Practice for Castings, Carbon, Low-Alloy, and Martensitic Stainless Steel, Ultrasonic Examination Thereof

Standard Practice for Castings, Carbon, Low-Alloy, and Martensitic Stainless Steel, Ultrasonic Examination Thereof

ABSTRACT

This test method deals with the procedures for the standard practice of performing pulse-echo ultrasonic examination of heat-treated carbon, low-alloy, and martensitic stainless steel castings by the longitudinal-beam technique. Calibration shall be executed by either flat-bottomed hole or back-wall reflection. The instrument to be used for examination shall be the ultrasonic, pulsed, reflection type. Personnel and equipment qualifications, materials preparation, casting and test conditions, data recording methods, and the acceptance standards for both types of testing procedure are all detailed thoroughly.

SCOPE

1.1 This practice covers the standards and procedures for the pulse-echo ultrasonic examination of heat-treated carbon, low-alloy, and martensitic stainless steel castings by the longitudinal-beam technique.

1.2 This practice is to be used whenever the inquiry, contract, order, or specification states that castings are to be subjected to ultrasonic examination in accordance with Practice A 609/A 609M.

1.3 This practice contains two procedures for ultrasonic inspection of carbon, low-alloy, and martensitic stainless steel castings; that is, Procedure A and Procedure B. Procedure A is the original A 609/A 609M practice and requires calibration using a series of test blocks containing flat bottomed holes. It also provides supplementary requirements for angle beam testing. Procedure B requires calibration using a back wall reflection from a series of solid calibration blocks.

Note 1-Ultrasonic examination and radiography are not directly comparable. This examination technique is intended to complement Guide E 94 in the detection of discontinuities.

1.4 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with this practice.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A609/A609M – 91 (Reapproved 2007)

Standard Practice for

Castings, Carbon, Low-Alloy, and Martensitic Stainless

Steel, Ultrasonic Examination Thereof

This standard is issued under the fixed designationA609/A609M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 2. Referenced Documents

2 3

1.1 This practice covers the standards and procedures for 2.1 ASTM Standards:

the pulse-echo ultrasonic examination of heat-treated carbon, A217/A217M Specification for Steel Castings, Martensitic

low-alloy, and martensitic stainless steel castings by the Stainless and Alloy, for Pressure-Containing Parts, Suit-

longitudinal-beam technique. able for High-Temperature Service

1.2 This practice is to be used whenever the inquiry, E94 Guide for Radiographic Examination

contract, order, or specification states that castings are to be E317 Practice for Evaluating Performance Characteristics

subjected to ultrasonic examination in accordance with Prac- of Ultrasonic Pulse-EchoTesting Instruments and Systems

tice A609/A609M. without the Use of Electronic Measurement Instruments

1.3 This practice contains two procedures for ultrasonic 2.2 Other Document:

inspection of carbon, low-alloy, and martensitic stainless steel SNT-TC-1A Recommended Practice for Non-Destructive

castings; that is, ProcedureAand Procedure B. ProcedureAis Testing Personnel Qualification and Certification

the original A609/A609M practice and requires calibration

3. Ordering Information

using a series of test blocks containing flat bottomed holes. It

3.1 Theinquiryandordershouldspecifywhichprocedureis

also provides supplementary requirements for angle beam

testing. Procedure B requires calibration using a back wall tobeused.Ifaprocedureisnotspecified,ProcedureAshallbe

used.

reflection from a series of solid calibration blocks.

3.2 Procedure A—Flat-Bottomed Hole Calibration Proce-

NOTE 1—Ultrasonic examination and radiography are not directly

dure:

comparable.ThisexaminationtechniqueisintendedtocomplementGuide

3.2.1 When this practice is to be applied to an inquiry,

E94 in the detection of discontinuities.

contract, or order, the purchaser shall furnish the following

1.4 The values stated in either inch-pound units or SI units

information:

are to be regarded separately as standard. Within the text, the

3.2.1.1 Quality levels for the entire casting or portions

SI units are shown in brackets. The values stated in each

thereof,

system are not exact equivalents; therefore, each system must

3.2.1.2 Sections of castings requiring longitudinal-beam

beusedindependentlyoftheother.Combiningvaluesfromthe

examination,

two systems may result in nonconformance with this practice.

3.2.1.3 Sections of castings requiring dual element exami-

1.5 This standard does not purport to address all of the

nation,

safety concerns, if any, associated with its use. It is the

3.2.1.4 Sectionsofcastingsrequiringsupplementaryexami-

responsibility of the user of this standard to establish appro-

nation, using the angle-beam procedure described in Supple-

priate safety and health practices and determine the applica-

mentary Requirement S1 in order to achieve more complete

bility of regulatory limitations prior to use.

examination, and

3.2.1.5 Anyrequirementsadditionaltotheprovisionsofthis

practice.

This practice is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel and RelatedAlloys and is the direct responsibility of Subcommittee

A01.18 on Castings. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 1, 2007. Published December 2007. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1970. Last previous edition approved in 2002 as A609/A609M–91 Standards volume information, refer to the standard’s Document Summary page on

(2002). DOI: 10.1520/A0609_A0609M-91R07. the ASTM website.

2 4

For ASME Boiler and Pressure Vessel Code applications, see related Specifi- AvailablefromAmericanSocietyforNondestructiveTesting(ASNT),P.O.Box

cation SA-609 of Section II of that Code. 28518, 1711 Arlingate Ln., Columbus, OH 43228-0518, http://www.asnt.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A609/A609M – 91 (2007)

3.3 Procedure B: Back-Wall Reflection Calibration

Procedure—Whenthisprocedureistobeappliedtoaninquiry,

contract, or order, the purchaser shall designate the quality

levels for the entire casting or applicable portions.

PROCEDURE A—FLAT-BOTTOMED HOLE

CALIBRATION PROCEDURE

4. Apparatus

4.1 Electronic Apparatus:

4.1.1 An ultrasonic, pulsed, reflection type of instrument

that is capable of generating, receiving, and amplifying fre-

quencies of at least 1 to 5 MHz.

4.1.2 The ultrasonic instrument shall provide linear presen-

tation (within 65%) for at least 75% of the screen height

(sweep line to top of screen). Linearity shall be determined in

accordance with Practice E317 or equivalent electronic means.

4.1.3 The electronic apparatus shall contain a signal attenu-

ator or calibrated gain control that shall be accurate over its

useful range to 610% of the nominal attenuation or gain ratio

toallowmeasurementofsignalsbeyondthelinearrangeofthe

instrument.

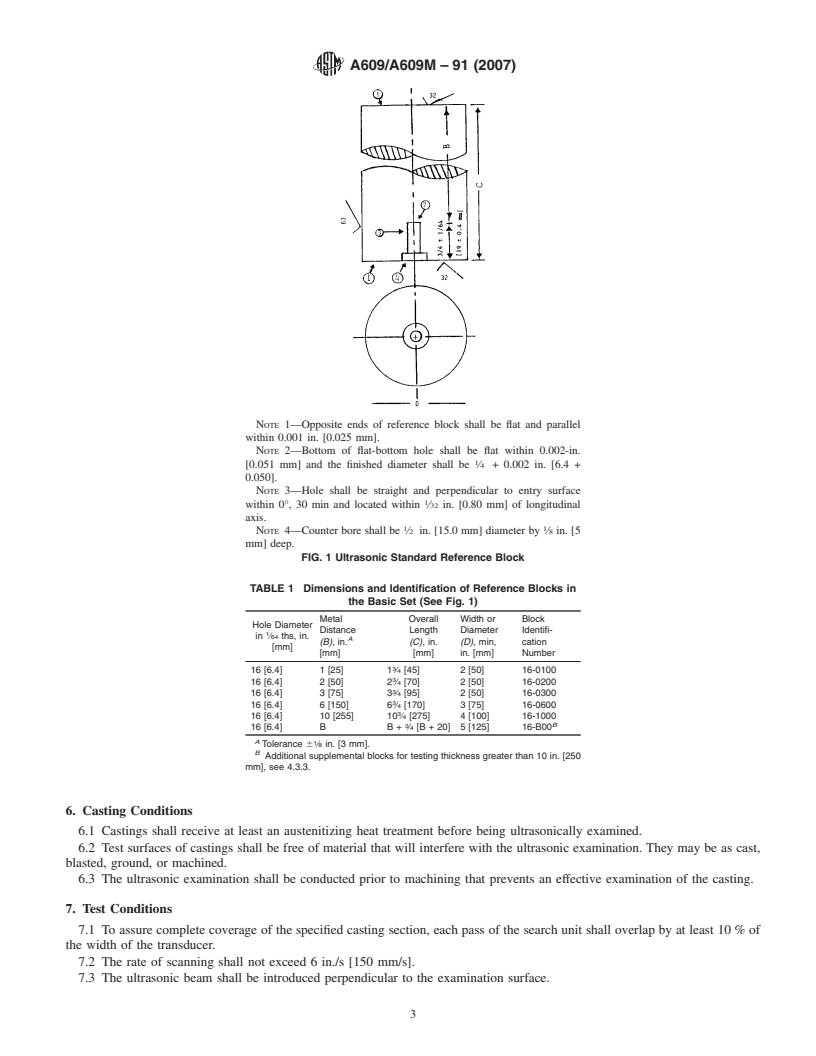

NOTE 1—Opposite ends of reference block shall be flat and parallel

within 0.001 in. [0.025 mm].

4.2 Search Units:

NOTE 2—Bottom of flat-bottom hole shall be flat within 0.002-in.

4.2.1 Longitudinal Wave,internallygrounded,havinga½to

[0.051 mm] and the finished diameter shall be ⁄4 + 0.002 in. [6.4 +

1! in. [13 to 28 mm] diameter or 1-in. [25-mm] square

0.050].

piezo-electric elements. Based on the signals-to-noise ratio of

NOTE 3—Hole shall be straight and perpendicular to entry surface

the response pattern of the casting, a frequency in the range

within 0°, 30 min and located within ⁄32 in. [0.80 mm] of longitudinal

from1to5MHzshallbeused.Thebackgroundnoiseshallnot

axis.

1 1

exceed 25% of the distance amplitude correction curve NOTE 4—Counter bore shall be ⁄2 in. [15.0 mm] diameter by ⁄8 in. [5

mm] deep.

(DAC).Transducers shall be utilized at their rated frequencies.

FIG. 1 Ultrasonic Standard Reference Block

4.2.2 Dual-Element,5-MHz,½by1-in.[13by25-mm],12°

includedanglesearchunitsarerecommendedforsections1in.

TABLE 1 Dimensions and Identification of Reference Blocks in

[25 mm] and under.

the Basic Set (See Fig. 1)

4.2.3 Other frequencies and sizes of search units may be

Metal Overall Width or Block

used for evaluating and pinpointing indications.

Hole Diameter

Distance Length Diameter Identifi-

in ⁄64 ths, in.

A

4.3 Reference Blocks:

(B),in. (C),in. (D), min, cation

[mm]

[mm] [mm] in. [mm] Number

4.3.1 Referenceblockscontainingflat-bottomholesshallbe

16 [6.4] 1 [25] 1 ⁄4 [45] 2 [50] 16-0100

used to establish test sensitivity in accordance with 8.2.

16 [6.4] 2 [50] 2 ⁄4 [70] 2 [50] 16-0200

4.3.2 Reference blocks shall be made from cast steels that

16 [6.4] 3 [75] 3 ⁄4 [95] 2 [50] 16-0300

give an acoustic response similar to the castings being exam- 3

16 [6.4] 6 [150] 6 ⁄4 [170] 3 [75] 16-0600

ined. 16 [6.4] 10 [255] 10 ⁄4 [275] 4 [100] 16-1000

3 B

16 [6.4] B B + ⁄4 [B + 20] 5 [125] 16-B00

4.3.3 The design of reference blocks shall be in accordance

A

Tolerance 6 ⁄8 in. [3 mm].

withFig.1,andthebasicsetshallconsistofthoseblockslisted

B

Additional supplemental blocks for testing thickness greater than 10 in. [250

inTable 1.When section thicknesses over 15 in. [380-mm] are

mm], see 4.3.3.

to be inspected, an additional block of the maximum test

thickness shall be made to supplement the basic set.

5. Personnel Requirements

4.3.4 Machined blocks with ⁄32-in. [2.4-mm] diameter flat-

bottom holes at depths from the entry surface of ⁄8 in. [3 mm], 5.1 The manufacturer shall be responsible for assigning

1 1 3 3

⁄2 in. [13 mm], or ⁄2 t and ⁄4 in. [19 mm], or ⁄4 t (where t =

qualified personnel to perform ultrasonic examination in con-

thickness of the block) shall be used to establish the DAC for formance with the requirements of this practice.

the dual-element search units (see Fig. 2).

5.2 Personnel performing ultrasonic examinations in accor-

4.3.5 Each reference block shall be permanently identified dance with this practice shall be familiar with the following:

alongthesideoftheblockindicatingthematerialandtheblock

5.2.1 Ultrasonic terminology,

identification. 5.2.2 Instrument calibration,

4.4 Couplant—A suitable couplant having good wetting 5.2.3 Effect of transducer material, size, frequency, and

characteristics shall be used between the search unit and mode on test results,

examination surface. The same couplant shall be used for 5.2.4 Effect of material structure (grain size, cleanliness,

calibrations and examinations. etc.) on test results,

A609/A609M – 91 (2007)

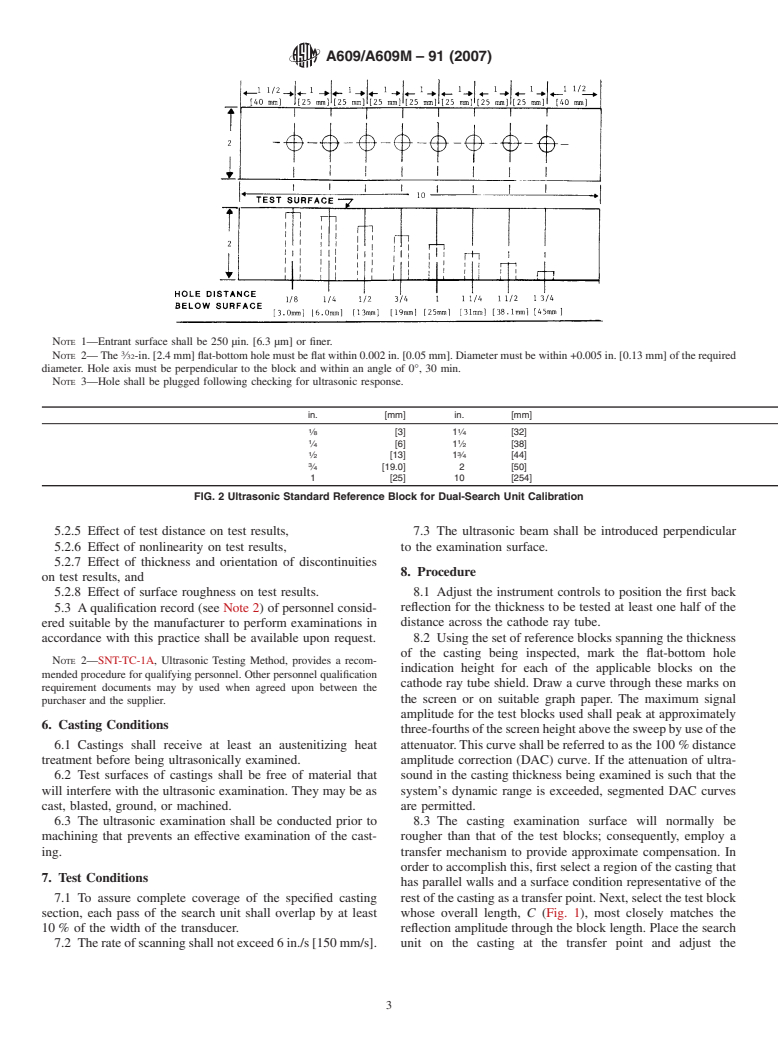

NOTE 1—Entrant surface shall be 250 µin. [6.3 µm] or finer.

NOTE 2—The ⁄32-in.[2.4mm]flat-bottomholemustbeflatwithin0.002in.[0.05mm].Diametermustbewithin+0.005in.[0.13mm]oftherequired

diameter. Hole axis must be perpendicular to the block and within an angle of 0°, 30 min.

NOTE 3—Hole shall be plugged following checking for ultrasonic response.

in. [mm] in. [mm]

1 1

⁄8 [3] 1 ⁄4 [32]

1 1

⁄4 [6] 1 ⁄2 [38]

1 3

⁄2 [13] 1 ⁄4 [44]

⁄4 [19.0] 2 [50]

1 [25] 10 [254]

FIG. 2 Ultrasonic Standard Reference Block for Dual-Search Unit Calibration

5.2.5 Effect of test distance on test results, 7.3 The ultrasonic beam shall be introduced perpendicular

5.2.6 Effect of nonlinearity on test results, to the examination surface.

5.2.7 Effect of thickness and orientation of discontinuities

8. Procedure

on test results, and

5.2.8 Effect of surface roughness on test results. 8.1 Adjust the instrument controls to position the first back

reflection for the thickness to be tested at least one half of the

5.3 Aqualification record (see Note 2) of personnel consid-

ered suitable by the manufacturer to perform examinations in distance across the cathode ray tube.

8.2 Usingthesetofreferenceblocksspanningthethickness

accordance with this practice shall be available upon request.

of the casting being inspected, mark the flat-bottom hole

NOTE 2—SNT-TC-1A, Ultrasonic Testing Method, provides a recom-

indication height for each of the applicable blocks on the

mended procedure for qualifying personnel. Other personnel qualification

cathode ray tube shield. Draw a curve through these marks on

requirement documents may by used when agreed upon between the

the screen or on suitable graph paper. The maximum signal

purchaser and the supplier.

amplitude for the test blocks used shall peak at approximately

6. Casting Conditions

three-fourthsofthescreenheightabovethesweepbyuseofthe

6.1 Castings shall receive at least an austenitizing heat attenuator.Thiscurveshallbereferredtoasthe100%distance

treatment before being ultrasonically examined. amplitude correction (DAC) curve. If the attenuation of ultra-

6.2 Test surfaces of castings shall be free of material that sound in the casting thickness being examined is such that the

will interfere with the ultrasonic examination. They may be as system’s dynamic range is exceeded, segmented DAC curves

cast, blasted, ground, or machined. are permitted.

6.3 The ultrasonic examination shall be conducted prior to 8.3 The casting examination surface will normally be

machining that prevents an effective examination of the cast- rougher than that of the test blocks; consequently, employ a

ing. transfer mechanism to provide approximate compensation. In

order to accomplish this, first select a region of the casting that

7. Test Conditions

has parallel walls and a surface condition representative of the

7.1 To assure complete coverage of the specified casting restofthecastingasatransferpoint.Next,selectthetestblock

section, each pass of the search unit shall overlap by at least whose overall length, C (Fig. 1), most closely matches the

10% of the width of the transducer. reflection amplitude through the block length. Place the search

7.2 Therateofscanningshallnotexceed6in./s[150mm/s]. unit on the casting at the transfer point and adjust the

A609/A609M – 91 (2007)

TABLE 2 Rejection Level

instrument gain until the back reflection amplitude through the

casting matches that through the test block. Using this transfer

NOTE 1—The areas in the table refer to the surface area on the casting

technique, the examination sensitivity in the casting may be

overwhichacontinuousindicationexceedingtheamplitudereferenceline

expected to be within 630% or less of that given by the test or a continuous loss of back reflection of 75% or greater is maintained.

NOTE 2— Areas shall be measured from the center of the search unit.

blocks.

NOTE 3—In certain castings, because of very long test distances or

8.4 Do not change those instrument controls and the test

curvature of the test surface, the casting surface area over which a given

frequency set during calibration, except the attenuator, or

discontinuity is detected may be considerably larger or smaller than the

calibrated gain control, during acceptance examination of a

actual area of the discontinuity in the casting; in such cases a graphic plot

given thickness of the casting. Make a periodic calibration

that incorporates a consideration of beam spread should be used for

during the inspection by checking the amplitude of response

realistic evaluation of the discontinuity.

2 2

from the ⁄4-in. [6.4-mm] diameter flat-bottom hole in the test

Area, in. [cm ]

Ultrasonic Testing Length, max,

(see 10.2.1 and

block utilized for the transfer.

Quality Level in. [mm]

10.2.2)

NOTE 3—The attenuator or calibrated gain control may be used to

1 0.8 [5] 1.5 [40]

changethesignalamplitudeduringexaminationtopermitsmallamplitude

2 1.5 [10] 2.2 [55]

signalstobemorereadilydetected.Signalevaluationismadebyreturning 3 3 [20] 3.0 [75]

4 5 [30] 3.9 [100]

the attenuator or calibrated gain control to its original setting.

5 8 [50] 4.8 [120]

6 12 [80] 6.0 [150]

8.5 During examination of areas of the casting having

7 16 [100] 6.9 [175]

parallel walls, recheck areas showing 75% or greater loss of

back reflection to determine whether loss of back reflection is

due to poor contact, insufficient couplant, misoriented discon-

10.2.2 No reduction of back reflection of 75% or greater

tinuity, etc. If the reason for loss of back reflection is not

that has been dete

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:A 609/A 609M–91 (Reapproved 2002) Designation: A609/A609M – 91

(Reapproved 2007)

Standard Practice for

Castings, Carbon, Low-Alloy, and Martensitic Stainless

Steel, Ultrasonic Examination Thereof

This standard is issued under the fixed designationA609/A609M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This practice covers the standards and procedures for the pulse-echo ultrasonic examination of heat-treated carbon,

low-alloy, and martensitic stainless steel castings by the longitudinal-beam technique.

1.2 This practice is to be used whenever the inquiry, contract, order, or specification states that castings are to be subjected to

ultrasonic examination in accordance with Practice A609/A609M.

1.3 Thispracticecontainstwoproceduresforultrasonicinspectionofcarbon,low-alloy,andmartensiticstainlesssteelcastings;

that is, ProcedureAand Procedure B. ProcedureAis the originalA609/A609M practice and requires calibration using a series of

test blocks containing flat bottomed holes. It also provides supplementary requirements for angle beam testing. Procedure B

requires calibration using a back wall reflection from a series of solid calibration blocks.

NOTE 1—Ultrasonic examination and radiography are not directly comparable.This examination technique is intended to complement Guide E 94E94

in the detection of discontinuities.

1.4 Thevaluesstatedineitherinch-poundunitsorSIunitsaretoberegardedseparatelyasstandard.Withinthetext,theSIunits

are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used

independently of the other. Combining values from the two systems may result in nonconformance with this practice.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

A217/A217M Specification for Steel Castings, Martensitic Stainless and Alloy, for Pressure-Containing Parts, Suitable for

High-Temperature Service

E94 Guide for Radiographic Examination

E317 Practice for Evaluating Performance Characteristics of Ultrasonic Pulse-Echo ExaminationTesting Instruments and

Systems Withoutwithout the Use of Electronic Measurement Instruments

2.2 Other Document:

SNT-TC-1A Recommended Practice for Non-Destructive Testing Personnel Qualification and Certification

3. Ordering Information

3.1 The inquiry and order should specify which procedure is to be used. If a procedure is not specified, Procedure A shall be

used.

3.2 Procedure A—Flat-Bottomed Hole Calibration Procedure:

This practice is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.18

on Castings.

Current edition approved March 10, 2002. Published July 1992. Originally published as A 609–70. Last previous edition A 609/A 609M–90.

Current edition approved Nov. 1, 2007. Published December 2007. Originally approved in 1970. Last previous edition approved in 2002 as A609/A609M–91 (2002).

DOI: 10.1520/A0609_A0609M-91R07.

For ASME Boiler and Pressure Vessel Code applications, see related Specification SA-609 of Section II of that Code.

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

, Vol 01.02.volume information, refer to the standard’s Document Summary page on the ASTM website.

Annual Book of ASTM Standards, Vol 03.03.

Available from American Society for Nondestructive Testing (ASNT), P.O. Box 28518, 1711 Arlingate Ln., Columbus, OH 43228-0518, http://www.asnt.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

A609/A609M – 91 (2007)

3.2.1 When this practice is to be applied to an inquiry, contract, or order, the purchaser shall furnish the following information:

3.2.1.1 Quality levels for the entire casting or portions thereof,

3.2.1.2 Sections of castings requiring longitudinal-beam examination,

3.2.1.3 Sections of castings requiring dual element examination,

3.2.1.4 Sections of castings requiring supplementary examination, using the angle-beam procedure described in Supplementary

Requirement S1 in order to achieve more complete examination, and

3.2.1.5 Any requirements additional to the provisions of this practice.

3.3 Procedure B: Back-Wall Reflection Calibration Procedure—When this procedure is to be applied to an inquiry, contract, or

order, the purchaser shall designate the quality levels for the entire casting or applicable portions.

PROCEDURE A—FLAT-BOTTOMED HOLE CALIBRATION PROCEDURE

4. Apparatus

4.1 Electronic Apparatus:

4.1.1 An ultrasonic, pulsed, reflection type of instrument that is capable of generating, receiving, and amplifying frequencies

of at least 1 to 5 MHz.

4.1.2 The ultrasonic instrument shall provide linear presentation (within 65%) for at least 75% of the screen height (sweep

line to top of screen). Linearity shall be determined in accordance with Practice E 317E317 or equivalent electronic means.

4.1.3 The electronic apparatus shall contain a signal attenuator or calibrated gain control that shall be accurate over its useful

rangeto 610%ofthenominalattenuationorgainratiotoallowmeasurementofsignalsbeyondthelinearrangeoftheinstrument.

4.2 Search Units:

4.2.1 Longitudinal Wave, internally grounded, havinga½to1! in. [13 to 28 mm] diameter or 1-in. [25-mm] square

piezo-electric elements. Based on the signals-to-noise ratio of the response pattern of the casting, a frequency in the range from

1 to 5 MHz shall be used. The background noise shall not exceed 25% of the distance amplitude correction curve (DAC).

Transducers shall be utilized at their rated frequencies.

4.2.2 Dual-Element,5-MHz,½by1-in.[13by25-mm],12°includedanglesearchunitsarerecommendedforsections1in.[25

mm] and under.

4.2.3 Other frequencies and sizes of search units may be used for evaluating and pinpointing indications.

4.3 Reference Blocks:

4.3.1 Reference blocks containing flat-bottom holes shall be used to establish test sensitivity in accordance with 8.2.

4.3.2 Reference blocks shall be made from cast steels that give an acoustic response similar to the castings being examined.

4.3.3 The design of reference blocks shall be in accordance with Fig. 1, and the basic set shall consist of those blocks listed

inTable 1.When section thicknesses over 15 in. [380-mm] are to be inspected, an additional block of the maximum test thickness

shall be made to supplement the basic set.

3 1 1

4.3.4 Machined blocks with ⁄32-in. [2.4-mm] diameter flat-bottom holes at depths from the entry surface of ⁄8 in. [3 mm], ⁄2

1 3 3

in. [13 mm], or ⁄2 t and ⁄4 in. [19 mm], or ⁄4 t (where t = thickness of the block) shall be used to establish the DAC for the

dual-element search units (see Fig. 2).

4.3.5 Each reference block shall be permanently identified along the side of the block indicating the material and the block

identification.

4.4 Couplant—Asuitable couplant having good wetting characteristics shall be used between the search unit and examination

surface. The same couplant shall be used for calibrations and examinations.

5. Personnel Requirements

5.1 The manufacturer shall be responsible for assigning qualified personnel to perform ultrasonic examination in conformance

with the requirements of this practice.

5.2 Personnel performing ultrasonic examinations in accordance with this practice shall be familiar with the following:

5.2.1 Ultrasonic terminology,

5.2.2 Instrument calibration,

5.2.3 Effect of transducer material, size, frequency, and mode on test results,

5.2.4 Effect of material structure (grain size, cleanliness, etc.) on test results,

5.2.5 Effect of test distance on test results,

5.2.6 Effect of nonlinearity on test results,

5.2.7 Effect of thickness and orientation of discontinuities on test results, and

5.2.8 Effect of surface roughness on test results.

5.3 A qualification record (see Note 2) of personnel considered suitable by the manufacturer to perform examinations in

accordance with this practice shall be available upon request.

NOTE 2—SNT-TC-1A, Ultrasonic Testing Method, provides a recommended procedure for qualifying personnel. Other personnel qualification

requirement documents may by used when agreed upon between the purchaser and the supplier.

A609/A609M – 91 (2007)

NOTE 1—Opposite ends of reference block shall be flat and parallel

within 0.001 in. [0.025 mm].

NOTE 2—Bottom of flat-bottom hole shall be flat within 0.002-in.

[0.051 mm] and the finished diameter shall be ⁄4 + 0.002 in. [6.4 +

0.050].

NOTE 3—Hole shall be straight and perpendicular to entry surface

within 0°, 30 min and located within ⁄32 in. [0.80 mm] of longitudinal

axis.

1 1

NOTE 4—Counter bore shall be ⁄2 in. [15.0 mm] diameter by ⁄8 in. [5

mm] deep.

FIG. 1 Ultrasonic Standard Reference Block

TABLE 1 Dimensions and Identification of Reference Blocks in

the Basic Set (See Fig. 1)

Metal Overall Width or Block

Hole Diameter

Distance Length Diameter Identifi-

in ⁄64 ths, in.

A

(B),in. (C),in. (D), min, cation

[mm]

[mm] [mm] in. [mm] Number

16 [6.4] 1 [25] 1 ⁄4 [45] 2 [50] 16-0100

16 [6.4] 2 [50] 2 ⁄4 [70] 2 [50] 16-0200

16 [6.4] 3 [75] 3 ⁄4 [95] 2 [50] 16-0300

16 [6.4] 6 [150] 6 ⁄4 [170] 3 [75] 16-0600

16 [6.4] 10 [255] 10 ⁄4 [275] 4 [100] 16-1000

3 B

16 [6.4] B B + ⁄4 [B + 20] 5 [125] 16-B00

A

Tolerance 6 ⁄8 in. [3 mm].

B

Additional supplemental blocks for testing thickness greater than 10 in. [250

mm], see 4.3.3.

6. Casting Conditions

6.1 Castings shall receive at least an austenitizing heat treatment before being ultrasonically examined.

6.2 Test surfaces of castings shall be free of material that will interfere with the ultrasonic examination. They may be as cast,

blasted, ground, or machined.

6.3 The ultrasonic examination shall be conducted prior to machining that prevents an effective examination of the casting.

7. Test Conditions

7.1 To assure complete coverage of the specified casting section, each pass of the search unit shall overlap by at least 10% of

the width of the transducer.

7.2 The rate of scanning shall not exceed 6 in./s [150 mm/s].

7.3 The ultrasonic beam shall be introduced perpendicular to the examination surface.

A609/A609M – 91 (2007)

NOTE 1—Entrant surface shall be 250 µin. [6.3 µm] or finer.

NOTE 2—The ⁄32-in.[2.4mm]flat-bottomholemustbeflatwithin0.002in.[0.05mm].Diametermustbewithin+0.005in.[0.13mm]oftherequired

diameter. Hole axis must be perpendicular to the block and within an angle of 0°, 30 min.

NOTE 3—Hole shall be plugged following checking for ultrasonic response.

in. [mm] in. [mm]

1 1

⁄8 [3] 1 ⁄4 [32]

1 1

⁄4 [6] 1 ⁄2 [38]

1 3

⁄2 [13] 1 ⁄4 [44]

⁄4 [19.0] 2 [50]

1 [25] 10 [254]

FIG. 2 Ultrasonic Standard Reference Block for Dual-Search Unit Calibration

8. Procedure

8.1 Adjust the instrument controls to position the first back reflection for the thickness to be tested at least one half of the

distance across the cathode ray tube.

8.2 Usingthesetofreferenceblocksspanningthethicknessofthecastingbeinginspected,marktheflat-bottomholeindication

height for each of the applicable blocks on the cathode ray tube shield. Draw a curve through these marks on the screen or on

suitable graph paper. The maximum signal amplitude for the test blocks used shall peak at approximately three-fourths of the

screen height above the sweep by use of the attenuator.This curve shall be referred to as the 100% distance amplitude correction

(DAC) curve. If the attenuation of ultrasound in the casting thickness being examined is such that the system’s dynamic range is

exceeded, segmented DAC curves are permitted.

8.3 The casting examination surface will normally be rougher than that of the test blocks; consequently, employ a transfer

mechanism to provide approximate compensation. In order to accomplish this, first select a region of the casting that has parallel

walls and a surface condition representative of the rest of the casting as a transfer point. Next, select the test block whose overall

length, C (Fig. 1), most closely matches the reflection amplitude through the block length. Place the search unit on the casting at

the transfer point and adjust the instrument gain until the back reflection amplitude through the casting matches that through the

test block. Using this transfer technique, the examination sensitivity in the casting may be expected to be within 630% or less

of that given by the test blocks.

8.4 Do not change those instrument controls and the test frequency set during calibration, except the attenuator, or calibrated

gain control, during acceptance examination of a given thickness of the casting. Make a periodic calibration during the inspection

bycheckingtheamplitudeofresponsefromthe ⁄4-in.[6.4-mm]diameterflat-bottomholeinthetestblockutilizedforthetransfer.

NOTE 3—The attenuator or calibrated gain control may be used to change the signal amplitude during examination to permit small amplitude signals

to be more readily detected. Signal evaluation is made by returning the attenuator or calibrated gain control to its original setting.

8.5 During examination of areas of the casting having parallel walls, recheck areas showing 75% or greater loss of back

reflection to determine whether loss of back reflection is due to poor contact, insufficient couplant, misoriented discontinuity, etc.

If the reason for loss of back reflection is not evident, consider the area questionable and further investigate.

9. Report

9.1 The manufacturer’s report of final ultrasonic examination shall contain the following data and shall be furnished to the

purchaser:

9.1.1 Thetotalnumber,location,amplitude,andareawhenpossibletodelineateboundariesbymonitoringthemovementofthe

A609/A609M – 91 (2007)

center of the search unit of all

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.