ASTM D3585-08(2013)

(Specification)Standard Specification for ASTM Reference Fluid for Coolant Tests

Standard Specification for ASTM Reference Fluid for Coolant Tests

ABSTRACT

This specification covers a reference ethylene glycol-base test fluid to be used in providing base line data for ASTM coolant test procedures. The reference test fluid concentrate shall be prepared to conform to the requirements as to chemical composition prescribed. The materials used to prepare the reference test fluid shall meet the requirements specified. The formulated reference test fluid concentrate shall conform to the requirements for laboratory test performance prescribed.

SIGNIFICANCE AND USE

5.1 The data obtained for the reference test fluid are intended to be used by laboratory personnel to determine their capability to perform tests properly. If a particular determination does not fall within the prescribed limits, it has to be assumed that an error occurred in the application of the test procedure.

5.2 The coolant composition given in this specification is not intended to be a commercial product.

SCOPE

1.1 This specification covers a reference ethylene glycol-base test fluid to be used in providing base line data for ASTM coolant test procedures.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3585 −08 (Reapproved 2013)

Standard Specification for

ASTM Reference Fluid for Coolant Tests

This standard is issued under the fixed designation D3585; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D1177 Test Method for Freezing Point of Aqueous Engine

Coolants

1.1 This specification covers a reference ethylene glycol-

D1287 TestMethodforpHofEngineCoolantsandAntirusts

base test fluid to be used in providing base line data forASTM

D1384 Test Method for Corrosion Test for Engine Coolants

coolant test procedures.

in Glassware

1.2 This standard does not purport to address all of the

D1613 Test Method for Acidity in Volatile Solvents and

safety concerns, if any, associated with its use. It is the

Chemical Intermediates Used in Paint, Varnish, Lacquer,

responsibility of the user of this standard to establish appro-

and Related Products

priate safety and health practices and determine the applica-

D1881 Test Method for Foaming Tendencies of Engine

bility of regulatory limitations prior to use.

Coolants in Glassware

D3634 Test Method for Trace Chloride Ion in Engine Cool-

2. Referenced Documents

ants

2.1 ASTM Standards:

D5827 Test Method for Analysis of Engine Coolant for

D501 Test Methods of Sampling and Chemical Analysis of

Chloride and Other Anions by Ion Chromatography

Alkaline Detergents

D5931 Test Method for Density and Relative Density of

D538 Specification for Trisodium Phosphate (Discontinued

Engine Coolant Concentrates and Aqueous Engine Cool-

2001) (Withdrawn 2001)

ants by Digital Density Meter

D891 TestMethodsforSpecificGravity,Apparent,ofLiquid

E202 Test Methods for Analysis of Ethylene Glycols and

Industrial Chemicals

Propylene Glycols

D1078 Test Method for Distillation Range of Volatile Or-

ganic Liquids 3. Chemical Composition Requirements

D1119 Test Method for Percent Ash Content of Engine

3.1 The reference test fluid concentrate shall be prepared to

Coolants

conform to the requirements as to chemical composition

D1120 Test Method for Boiling Point of Engine Coolants

prescribed in Table 1.

D1121 Test Method for Reserve Alkalinity of Engine Cool-

ants and Antirusts

4. Ingredient Requirements

D1122 Test Method for Density or Relative Density of

4.1 The materials used to prepare the reference test fluid

EngineCoolantConcentratesandEngineCoolantsByThe

shall meet the requirements given in Annex A1 – Annex A5.

Hydrometer

D1123 Test Methods for Water in Engine Coolant Concen-

5. Significance and Use

trate by the Karl Fischer Reagent Method

5.1 The data obtained for the reference test fluid are

D1176 Practice for Sampling and Preparing Aqueous Solu-

intended to be used by laboratory personnel to determine their

tions of Engine Coolants orAntirusts forTesting Purposes

capability to perform tests properly. If a particular determina-

tion does not fall within the prescribed limits, it has to be

ThisspecificationisunderthejurisdictionofASTMCommitteeD15onEngine

assumed that an error occurred in the application of the test

Coolants and Related Fluids and is the direct responsibility of Subcommittee

procedure.

D15.01 on Reference Test Materials.

Current edition approved Oct. 1, 2013. Published October 2013. Originally 5.2 The coolant composition given in this specification is

approved in 1989. Last previous edition approved in 2008 as D3585 – 08. DOI:

not intended to be a commercial product.

10.1520/D3585-08R13.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

6. Chemical and Physical Requirements

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

6.1 The formulated reference test fluid concentrate shall

the ASTM website.

conform to the requirements for physical and chemical prop-

The last approved version of this historical standard is referenced on

www.astm.org. erties prescribed in Table 2.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D3585−08 (2013)

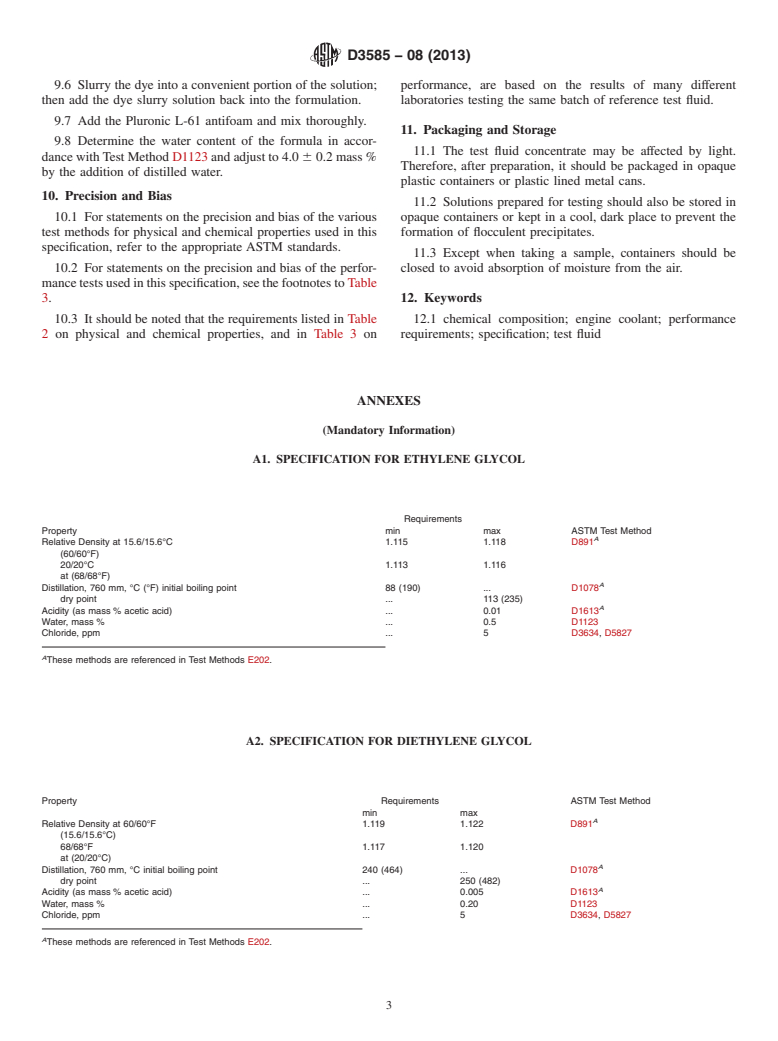

TABLE 1 Chemical Composition Requirements

NOTE 1—The reference coolant shall be colored blue-green usingAlizarine Cyanine Green G Extra 100 % added in the proportion of 0.3 g of dye/gal

of coolant.

A 3

Ingredient Mass % lb/100 gal kg/m

Ethylene glycol 89.86 847.9 1016.0

Diethylene glycol 5.00 47.2 56.5

Sodium tetraborate, pentahydrate 3.06 28.9 34.6

Trisodium phosphate, dodecahydrate 0.30 2.8 3.4

Sodium mercaptobenzothiazole solution 0.40 3.8 4.5

(50 mass % aqueous)

B

Pluronic L-61

C

Water 0.02 0.2 0.2

1.36 12.8 15.4

A

Based on a test fluid relative density of 1.133 at 60/60°F (15.5/15.5°C).

B

A nonionic polyol manufactured by BASF Corporation, 100 Cherry Hill Rd., Parsippany, NJ 07054.

C

Calculated value; the total water content (water originally present in the base materials, added water, water of hydration, and water of reaction and quantitative

interference by the reaction of the reagent used (in Test Method D1123) with the ingredients) should be adjusted to 4.0 ± 0.2 mass % as the final step in the preparation.

TABLE 2 Physical and Chemical Requirements

Requirements

Property ASTM Test Method

min max

pH, concentrate 6.1 6.3 D1287

33 volume % solution 7.7 8.0

50 volume % solution 7.5 7.8

Reserve alkalinity, mL 26.5 27.5 D1121

Water content, weight % 3.8 4.2 D1123

Freezing protection: D1177

Concentrate −23°C (−9°F) −25°C (−13°F)

33 volume % solution −18°C (0°F) −19°C (−2°F)

50 volume % solution −36°C (−33°F) −38°C (−36°F)

Relative Density at 15.6°C 1.131 1.134 D1122, D5931

at 20°C 1.129 1.132 D891

Boiling point, °C (°F) 330 (166) 340 (171) D1120

Ash, weight % 1.4 1.6 D1119

Chloride, ppm − 25 D3634, D5827

A

TABLE 3 Performance Requirements

7. Performance Requirements

Mass Loss, max,

Test ASTM Test Method

B

mg/Specimen

7.1 The formulated reference test fluid concentrate shall

Corrosion in glassware D1384

conform to the requirements for laboratory test performance

Copper 5

prescribed in Table 3.

Solder 5

Brass 5

Steel 5

8. Sampling

Cast iron 5

8.1 To obtain a sample of the concentrated reference test Aluminum 15

C

Foaming volume 75 mL, max D1881

fluid from the storage container, allow the material to come to

D

break time 5 s, max

room temperature (not below 68°F (20°C)) and shake well

A

Average data for triplicate tests.

before withdrawing the sample. B

Themultilaboratorystandarddeviationhasbeenfoundtobe1.8mgforallmetals

that lose an average of less than 3 mg per specimen. Therefore, results of two

8.2 All aqueous solutions to be used for test purposes shall

properlyconductedtestsfromtwodifferentlaboratoriesonsamplesofthesamelot

be prepared in accordance with Section 5 of Test Method

of reference test fluid should not differ by more than 4.1 mg, provided the average

loss is less than 3 mg per specimen. The multilaboratory standard deviation has

D1176.

been found to be 59 % of the obtained value on metals that lose an average of

more than 3 mg per specimen. Therefore, results of two properly conducted tests

9. Mixing Procedure

from two different laboratories on samples of the same lot of reference test fluid

should not differ by more than 167 %, provided the average loss is greater than 3

9.1 We

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.