ASTM D7975-14

(Test Method)Standard Test Method for Determination of Vapor Pressure of Crude Oil: VPCRx-F(Tm°C)(Manual Expansion Field Method)

Standard Test Method for Determination of Vapor Pressure of Crude Oil: <brk/>VPCR<inf >x</inf>-F(Tm°C)(Manual Expansion Field Method)

SIGNIFICANCE AND USE

5.1 Vapor pressure of crude oil at various vapor/liquid ratios is an important physical property for transport, storage, and refinery operations.

5.2 Vapor pressure of crude oil is important to crude oil producers, regulators, transporters and refiners for general handling, transportation, and initial refinery treatment.

5.3 The direct sample collection and subsequent, in place, vapor pressure measurement without the need for further sample handling eliminates the potential loss of light hydrocarbon material from the sample. The combination of sampling and testing may produce higher results than Test Method D323.

5.4 Chilling and air saturation of the sample prior to the vapor pressure measurement (as required in Test Method D323) is not required in this test method.

SCOPE

1.1 This test method covers the use of manual vapor pressure instruments to determine the vapor pressure of crude oils exerted in a vacuum. This test method is suitable for testing samples that exert a vapor pressure between 25 kPa and 180 kPa at 37.8 °C at vapor/liquid ratios from 4:1 to 0.25:1 (X = 4 to 0.25, see 3.2.4).

Note 1: This test method is suitable for the determination of the vapor pressure of crude oils at temperatures from 0 °C to 60 °C and pressures up to 500 kPa, but the precision and bias statements (see Section 15) may not be applicable.

1.2 This test method is meant primarily for use under field conditions for immediate evaluation of vapor pressure for storage, transport, or operational uses.

1.3 This test method is not intended for use in custody transfer applications. Test Method D6377 shall be used for custody transfer applications.

1.4 This test method provides a reasonable confirmation for the presence of light ends in the source material given that the partial pressure of low boiling components contribute significantly to total vapor pressure.

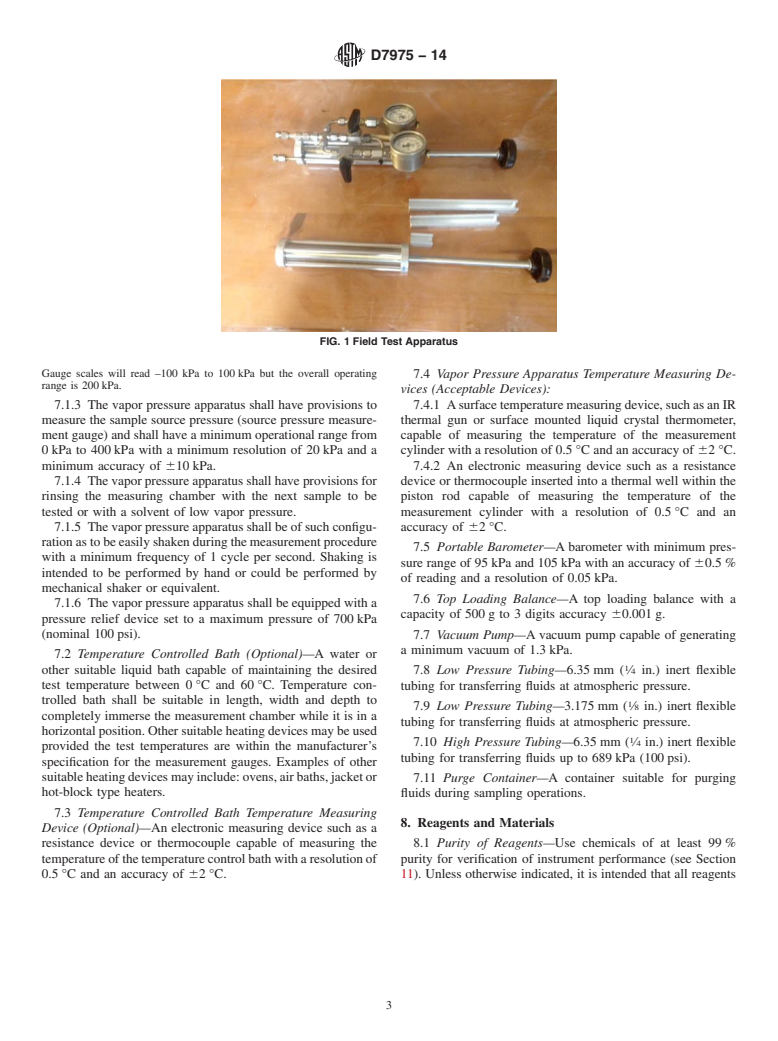

1.5 This test method allows both sample collection and subsequent vapor pressure measurement of crude oil samples directly from the sample source. The collected sample may also be transferred to an automated vapor pressure instrument such as used for Test Method D6377. The field test apparatus is suitable for transportation provided suitable over-pack is used to meet the regulations for the transportation of dangerous goods in the transportation jurisdiction(s).

1.6 This test method allows the determination of vapor pressure for crude oil samples having pour points below 0 °C and flow at the sampling conditions to allow inlet to the apparatus.

1.7 The values stated in SI units are to be regarded as standard.

1.7.1 Exception—Other units of measurement are included in this standard for ease of use in multiple jurisdictions.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7975 − 14

Standard Test Method for

Determination of Vapor Pressure of Crude Oil:

1

VPCR -F(Tm°C) (Manual Expansion Field Method)

x

This standard is issued under the fixed designation D7975; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.7.1 Exception—Other units of measurement are included

in this standard for ease of use in multiple jurisdictions.

1.1 This test method covers the use of manual vapor

1.8 This standard does not purport to address all of the

pressure instruments to determine the vapor pressure of crude

safety concerns, if any, associated with its use. It is the

oilsexertedinavacuum.Thistestmethodissuitablefortesting

responsibility of the user of this standard to establish appro-

samples that exert a vapor pressure between 25 kPa and

priate safety and health practices and determine the applica-

180 kPa at 37.8 °C at vapor/liquid ratios from 4:1 to 0.25:1 (X

bility of regulatory limitations prior to use.

= 4 to 0.25, see 3.2.4).

NOTE 1—This test method is suitable for the determination of the vapor

pressure of crude oils at temperatures from 0 °C to 60 °C and pressures up

2. Referenced Documents

to 500 kPa, but the precision and bias statements (see Section 15) may not

2

2.1 ASTM Standards:

be applicable.

D323 TestMethodforVaporPressureofPetroleumProducts

1.2 This test method is meant primarily for use under field

(Reid Method)

conditions for immediate evaluation of vapor pressure for

D1193 Specification for Reagent Water

storage, transport, or operational uses.

D5191 Test Method for Vapor Pressure of Petroleum Prod-

1.3 This test method is not intended for use in custody

ucts (Mini Method)

transfer applications. Test Method D6377 shall be used for

D5853 Test Method for Pour Point of Crude Oils

custody transfer applications.

D6377 Test Method for Determination of Vapor Pressure of

Crude Oil: VPCR (Expansion Method)

1.4 This test method provides a reasonable confirmation for

x

the presence of light ends in the source material given that the

3. Terminology

partial pressure of low boiling components contribute signifi-

cantly to total vapor pressure.

3.1 Definitions:

3.1.1 vapor/liquid ratio (V/L), n—the ratio of the vapor

1.5 This test method allows both sample collection and

volumetotheliquidvolumeofspecimen,inequilibrium,under

subsequent vapor pressure measurement of crude oil samples

specified conditions.

directly from the sample source. The collected sample may

also be transferred to an automated vapor pressure instrument

3.2 Definitions of Terms Specific to This Standard:

such as used for Test Method D6377. The field test apparatus

3.2.1 dead crude oil, n—a term usually employed for crude

is suitable for transportation provided suitable over-pack is

oils that, when exposed to normal atmospheric pressure at

usedtomeettheregulationsforthetransportationofdangerous

room temperature, will not result in actual boiling of the

goods in the transportation jurisdiction(s).

sample.

3.2.1.1 Discussion—These crudes will have vapor pressures

1.6 This test method allows the determination of vapor

below atmospheric pressure at room temperature.

pressure for crude oil samples having pour points below 0 °C

3.2.1.2 Discussion—This method will provide vapor pres-

and flow at the sampling conditions to allow inlet to the

sureinformationthatwillallowtheusertodetermineifacrude

apparatus.

oil is considered “dead” or “live.” A crude oil shall always be

1.7 The values stated in SI units are to be regarded as

considered “live” until the vapor pressure can be established.

standard.

Sampling and handling of dead crude oils can usually be done

1

This test method is under the jurisdiction of ASTM Committee D02 on

2

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Subcommittee D02.08 on Volatility. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved Dec. 1, 2014. Published February 2015. DOI: 10.1520/ Standards volume information, refer to the standard’s Document Summary page on

D7975-14. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7975 − 14

without concern in normal, non-pressurized sample containers, 4.4 For the purpose of transportation, a lower V/L ratio is

such as cans and other atmospheric containers. desirable to simulate the vapor pressure in vessel with 20 %

outage. Filling the measurement

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.