ASTM D3942-03(2008)

(Test Method)Standard Test Method for Determination of the Unit Cell Dimension of a Faujasite-Type Zeolite

Standard Test Method for Determination of the Unit Cell Dimension of a Faujasite-Type Zeolite

SIGNIFICANCE AND USE

Zeolites Y and X, particularly for catalyst and adsorbent applications, are a major article of manufacture and commerce. Catalysts and adsorbents comprising these zeolites in various forms plus binder and other components have likewise become important. Y-based catalysts are used for fluid catalytic cracking (FCC) and hydrocracking of petroleum, while X-based adsorbents are used for desiccation, sulfur compound removal, and air separation.

The unit cell dimension of a freshly synthesized faujasite-type zeolite is a sensitive measure of composition which, among other uses, distinguishes between the two synthetic faujasite-type zeolites, X and Y. The presence of a matrix in a Y-containing catalyst precludes determination of the zeolite framework composition by direct elemental analysis.

Users of the test method should be aware that the correlation between framework composition and unit cell dimension is specific to a given cation form of the zeolite. Steam or thermal treatments, for example, may alter both composition and cation form. The user must therefore determine the correlation that pertains to his zeolite containing samples. In addition, one may use the test method solely to determine the unit cell dimension, in which case no correlation is needed.

Other crystalline components may be present in the sample whose diffraction pattern may cause interference with the selected faujasite-structure diffraction peaks. If there is reason to suspect the presence of such components, then a full diffractometer scan should be obtained and analyzed to select faujasite-structure peaks free of interference.

SCOPE

1.1 This test method covers the determination of the unit cell dimension of zeolites having the faujasite crystal structure, including synthetic Y and X zeolites, their modifications such as the various cation exchange forms, and the dealuminized, decationated, and ultra stable forms of Y. These zeolites have cubic symmetry with a unit cell parameter usually within the limits of 24.2 and 25.0 Å (2.42 and 2.50 nm).

1.2 The samples include zeolite preparation in the various forms, and catalysts and adsorbents containing these zeolites. The zeolite may be present in amounts as low as 5 %, such as in a cracking catalyst.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3942 − 03(Reapproved 2008)

Standard Test Method for

Determination of the Unit Cell Dimension of a Faujasite-

Type Zeolite

This standard is issued under the fixed designation D3942; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope formsplusbinderandothercomponentshavelikewisebecome

important. Y-based catalysts are used for fluid catalytic crack-

1.1 This test method covers the determination of the unit

ing (FCC) and hydrocracking of petroleum, while X-based

celldimensionofzeoliteshavingthefaujasitecrystalstructure,

adsorbents are used for desiccation, sulfur compound removal,

including synthetic Y and X zeolites, their modifications such

and air separation.

as the various cation exchange forms, and the dealuminized,

decationated, and ultra stable forms of Y. These zeolites have 4.2 The unit cell dimension of a freshly synthesized

cubic symmetry with a unit cell parameter usually within the faujasite-type zeolite is a sensitive measure of composition

limits of 24.2 and 25.0 Å (2.42 and 2.50 nm). which, among other uses, distinguishes between the two

synthetic faujasite-type zeolites, X and Y. The presence of a

1.2 The samples include zeolite preparation in the various

matrixinaY-containingcatalystprecludesdeterminationofthe

forms, and catalysts and adsorbents containing these zeolites.

zeolite framework composition by direct elemental analysis.

The zeolite may be present in amounts as low as 5%, such as

in a cracking catalyst. 4.3 Users of the test method should be aware that the

correlation between framework composition and unit cell

1.3 This standard does not purport to address all of the

dimension is specific to a given cation form of the zeolite.

safety concerns, if any, associated with its use. It is the

Steam or thermal treatments, for example, may alter both

responsibility of the user of this standard to establish appro-

composition and cation form. The user must therefore deter-

priate safety and health practices and determine the applica-

mine the correlation that pertains to his zeolite containing

bility of regulatory limitations prior to use.

samples. In addition, one may use the test method solely to

2. Referenced Documents

determinetheunitcelldimension,inwhichcasenocorrelation

2 is needed.

2.1 ASTM Standards:

E691Practice for Conducting an Interlaboratory Study to 4.4 Other crystalline components may be present in the

Determine the Precision of a Test Method sample whose diffraction pattern may cause interference with

the selected faujasite-structure diffraction peaks. If there is

3. Summary of Test Method

reason to suspect the presence of such components, then a full

diffractometer scan should be obtained and analyzed to select

3.1 A sample of the zeolite Y or X, or catalyst containing

faujasite-structure peaks free of interference.

zeolite is mixed with powdered silicon. The zeolite unit cell

dimension is calculated from the X-ray diffraction pattern of

5. Apparatus

the mixture, using the silicon reflections as a reference.

5.1 X-Ray Diffractometer, able to scan at 0.25° 2θ/min. 2θ

4. Significance and Use

values in the following discussions were based on data

4.1 ZeolitesYandX,particularlyforcatalystandadsorbent obtained with a copper tube, although other tubes such as

applications,areamajorarticleofmanufactureandcommerce.

molybdenum can be used.

Catalysts and adsorbents comprising these zeolites in various

NOTE 1—A step-scanning accessory, to scan at a rate of 0.25° or less

2θ/min, will increase the accuracy of the determination and will facilitate

measurement in samples of low zeolite content.

This test method is under the jurisdiction of ASTM Committee D32 on

Catalysts and is the direct responsibility of Subcommittee D32.05 on Zeolites.

Current edition approved April 1, 2008. Published May 2008. Originally

approved in 1980. Last previous edition approved in 2003 as D3942–03. DOI: Three correlations have been published for pure synthetic faujasite-type

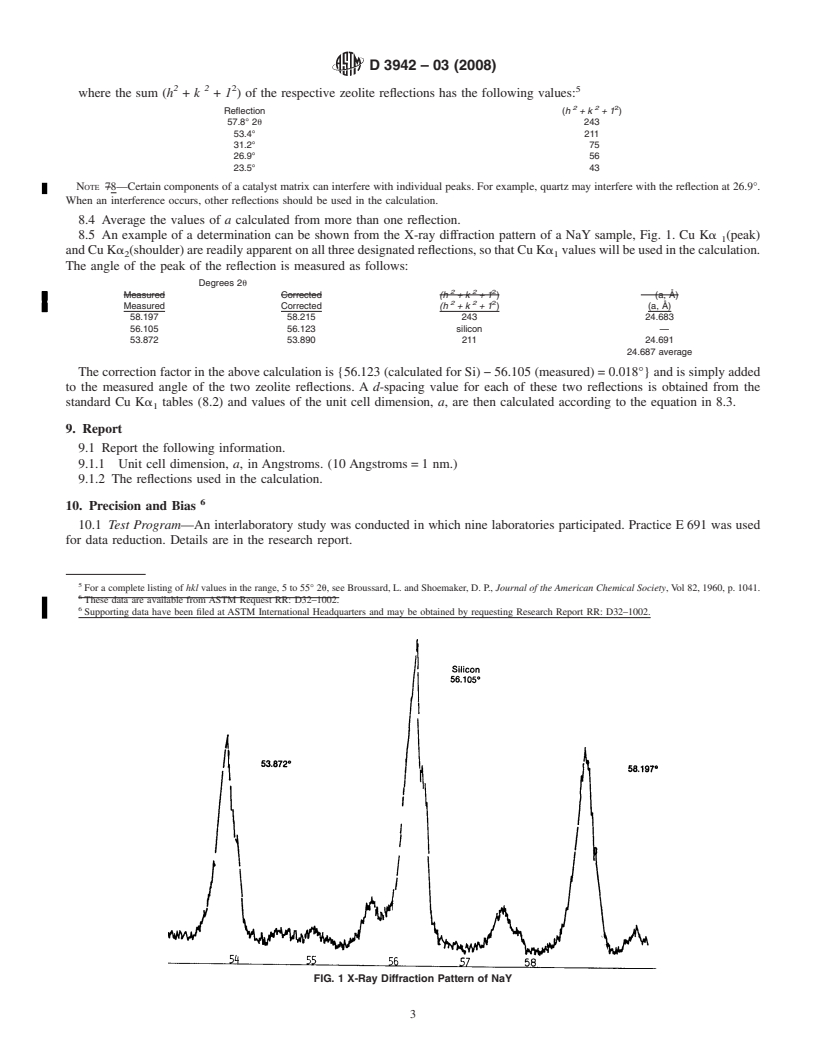

10.1520/D3942-03R08. zeolites in the sodium or calcium form: Breck, D. W. and Flanigen, E. M. in “

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Molecular Sieves,” Society of Chemical Industry , London, 1968, p. 47, Wright A.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM C., Rupert, J. P. and Granquist W. T. Amer. Mineral., Vol 53, 1968, p. 1293; and

Standards volume information, refer to the standard’s Document Summary page on Dempsy,E.,Kuehl,G.H.,andOlson,D.H.,JournalofthePhysicalChemistry,Vol

the ASTM website. 73, 1968, p. 387.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D3942 − 03 (2008)

NOTE 7—The corresponding calculated angles when lower angle

5.2 Drying Oven, set at 110°C.

reflections must be used are 28.443° 2θ (Cu Kα ) and 28.467° 2θ (Cu

5.3 Hydrator, maintained at 35% relative humidity by a

Kα).

saturated solution of salts such as CaCl ·6H O maintained at

2 2

8.2 Convert the corrected angles of reflection to d-spacing

23°C 6 3°C.

values using the equation:

6. Reagents and Materials λ

d 5 (1)

hkl

2sinθ

6.1 Siliconpowder,finelygroundorball-milledtoaparticle

diameter less than 5 µm as determined by microscope. NIST

where:

offers a Standard Reference Material (silicon) as an X-ray

d = distance between reflecting planes having the Miller

hkl

internal standard (SMR 640) suitable for powder diffraction

indices hkl, Å(nm×10), and

measurements.

λ = wavelength of X-ray radiation which is 1.54178 Å

(0.154178 nm) for Cu Kα and 1.54060 Å (0.154060

7. Procedure

nm) for Cu Kα . Note that the angle of reflection

7.1 Place about 1.5 g of powdered zeolite sample in the measured from the X-ray diffraction pattern is 2θ,

drying oven at 110°C for 1 h.

while the angle used in this calculation is only θ.

8.3 Calculate the unit cell dimension, a, of the zeolite using

NOTE2—Thedryingstepeliminatesexcesswaterfromthesampleprior

to equilibration at constant-humidity hydration. Most catalyst samples, the equation:

whenreceived,willnotcontainexcesswater.Somesensitivesamplesmay

2 2 2 2 1/2

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D3942–97 Designation: D 3942 – 03 (Reapproved 2008)

Standard Test Method for

Determination of the Unit Cell Dimension of a Faujasite-

Type Zeolite

This standard is issued under the fixed designation D3942; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of the unit cell dimension of zeolites having the faujasite crystal structure,

including synthetic Y and X zeolites, their modifications such as the various cation exchange forms, and the dealuminized,

decationated, and ultra stable forms of Y. These zeolites have cubic symmetry with a unit cell parameter usually within the limits

of 24.2 and 25.0 Å (2.42 and 2.50 nm).

1.2 The samples include zeolite preparation in the various forms, and catalysts and adsorbents containing these zeolites. The

zeolite may be present in amounts as low as 5%, such as in a cracking catalyst.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Summary of Test Method

3.1 AsampleofthezeoliteYorX,orcatalystcontainingzeoliteismixedwithpowderedsilicon.Thezeoliteunitcelldimension

is calculated from the X-ray diffraction pattern of the mixture, using the silicon reflections as a reference.

4. Significance and Use

4.1 Zeolites Y and X, particularly for catalyst and adsorbent applications, are a major article of manufacture and commerce,

use of which has developed since the 1960s. commerce. Catalysts and adsorbents comprising these zeolites in various forms plus

binderandothercomponentshavelikewisebecomeimportantinthisperiod.important.Y-basedcatalystsareusedforfluidcatalytic

cracking(FCC)andhydrocrackingofpetroleum,whileX-basedadsorbentsareusedfordesiccation,sulfurcompoundremoval,and

air separation.

4.2 The unit cell dimension of a freshly synthesized faujasite-type zeolite is a sensitive measure of composition which, among

other uses, distinguishes between the two synthetic faujasite-type zeolites, X and Y. The presence of a matrix in a Y-containing

catalyst precludes determination of the zeolite framework composition by direct elemental analysis.

4.3 Users of the test method should be aware that the correlation between framework composition and unit cell dimension is

specific to a given cation form of the zeolite. Steam or thermal treatments, for example, may alter both composition and cation

form. The user must therefore determine the correlation that pertains to his zeolite containing samples. In addition, one may use

the test method solely to determine the unit cell dimension, in which case no correlation is needed.

4.4 Other crystalline components may be present in the sample whose diffraction pattern may cause interference with the

selected faujasite-structure diffraction peaks. If there is reason to suspect the presence of such components, then a full

diffractometer scan should be obtained and analyzed to select faujasite-structure peaks free of interference.

This test method is under the jurisdiction of ASTM Committee D-32 on Catalysts and is the direct responsibility of Subcommittee D32.05 on Zeolites.

Current edition approved March 10, 1997. Published October 1997. Originally published as D3942–80. Last previous edition D3942–91.

This test method is under the jurisdiction of ASTM Committee D32 on Catalysts and is the direct responsibility of Subcommittee D32.05 on Zeolites.

Current edition approved April 1, 2008. Published May 2008. Originally approved in 1980. Last previous edition approved in 2003 as D3942–03.

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.ForAnnualBookofASTMStandards

, Vol 14.02.volume information, refer to the standard’s Document Summary page on the ASTM website.

Three correlations have been published for pure synthetic faujasite-type zeolites in the sodium or calcium form: Breck, D. W. and Flanigen, E. M. in “ Molecular

Sieves”,Sieves,” Society of Chemical Industry , London, 1968, p. 47, Wright A. C., Rupert, J. P. and Granquist W. T. Amer. Mineral., Vol 53, 1968, p. 1293; and Dempsy,

E., Kuehl, G. H., and Olson, D. H., Journal of the Physical Chemistry, Vol 73, 1968, p. 387.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D 3942 – 03 (2008)

5. Apparatus

5.1 X-RayDiffractometer,abletoscanat0.25°2u/min.2uvaluesinthefollowingdiscussionswerebasedondataobtainedwith

a copper tube, although other tubes such as molybdenum can be used.

NOTE 1—A step-scanning accessory, to scan at a rate of 0.25° or less 2u/min, will increase the accuracy of the determination and will facilitate

measurement in samples of low zeolite content.

5.2 Drying Oven, set at 110°C.

5.3 Hydrator, maintained at 35% relative humidity by a saturated solution of salts such as CaCl ·6H O maintained at 23°C 6

2 2

3°C.

6. Reagents and Materials

6.1 Siliconpowder,finelygroundorball-milledtoaparticlediameterlessthan5µmasdeterminedbymicroscope.NISToffers

a Standard Reference Material (silicon) as an X-ray internal standard (SMR 640) suitable for powder diffraction measurements.

7. Procedure

7.1 Place about 1.5 g of powdered zeolite sample in the drying oven at 110°C for 1 h.

NOTE 2—The drying step eliminates excess water from the sample prior to equilibration at constant-humidity hydration. Most catalyst samples, when

received, will not contain excess water. Some sensitive samples may require a lower activation temperature.

7.2 Blend1gofpowderedzeolitesamplewithabout0.05gofsiliconinamortarandgrinduntilintimatelymixed.Placeathin

bed of the mixed sample in the hydrator for at least 16 h. Some samples may require a longer equilibration time.

7.3 Pack the hydrated sample in the diffractometer mount.

7.4 Determine the X-ray diffraction pattern across the range from 50 to 60° 2u.

NOTE 3—Smaller slits are desirable for better

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.