ASTM D5558-95(2023)

(Test Method)Standard Test Method for Determination of the Saponification Value of Fats and Oils

Standard Test Method for Determination of the Saponification Value of Fats and Oils

SIGNIFICANCE AND USE

2.1 This test method is intended for use in the determination of the saponification value of fats and oils used in the manufacture of fat liquors for the purpose of quality assurance.

SCOPE

1.1 This test method covers the determination of the saponification value of fats and oils.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

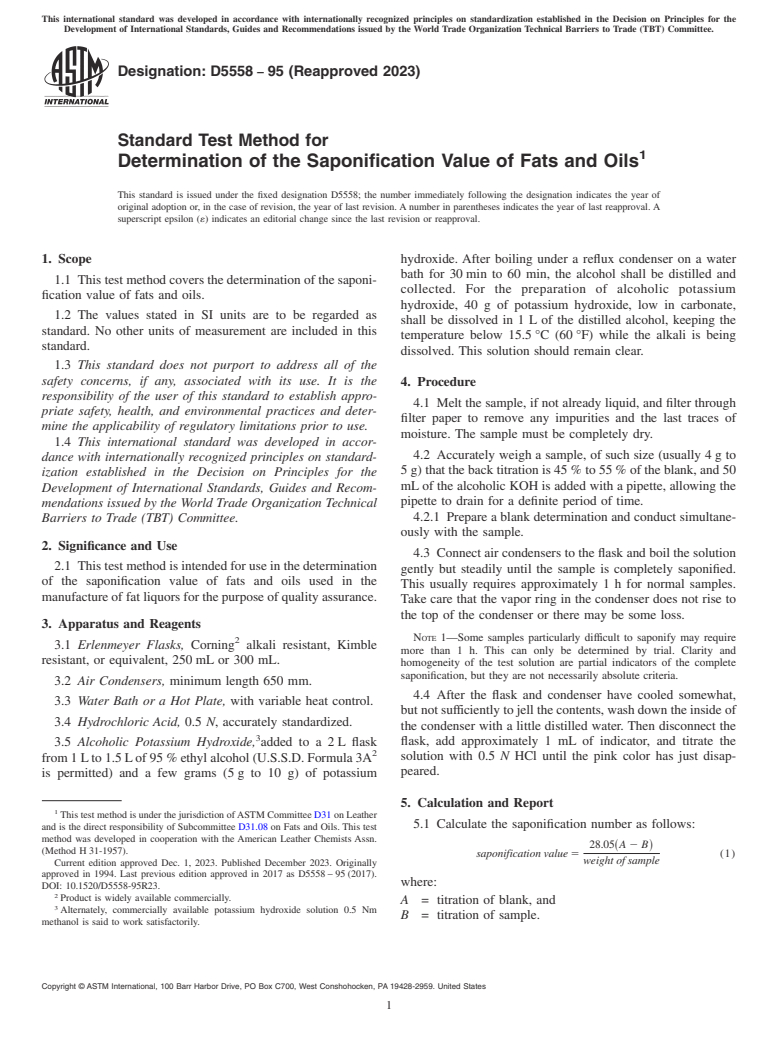

Designation: D5558 − 95 (Reapproved 2023)

Standard Test Method for

Determination of the Saponification Value of Fats and Oils

This standard is issued under the fixed designation D5558; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope hydroxide. After boiling under a reflux condenser on a water

bath for 30 min to 60 min, the alcohol shall be distilled and

1.1 This test method covers the determination of the saponi-

collected. For the preparation of alcoholic potassium

fication value of fats and oils.

hydroxide, 40 g of potassium hydroxide, low in carbonate,

1.2 The values stated in SI units are to be regarded as

shall be dissolved in 1 L of the distilled alcohol, keeping the

standard. No other units of measurement are included in this

temperature below 15.5 °C (60 °F) while the alkali is being

standard.

dissolved. This solution should remain clear.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4. Procedure

responsibility of the user of this standard to establish appro-

4.1 Melt the sample, if not already liquid, and filter through

priate safety, health, and environmental practices and deter-

filter paper to remove any impurities and the last traces of

mine the applicability of regulatory limitations prior to use.

moisture. The sample must be completely dry.

1.4 This international standard was developed in accor-

4.2 Accurately weigh a sample, of such size (usually 4 g to

dance with internationally recognized principles on standard-

5 g) that the back titration is 45 % to 55 % of the blank, and 50

ization established in the Decision on Principles for the

mL of the alcoholic KOH is added with a pipette, allowing the

Development of International Standards, Guides and Recom-

pipette to drain for a definite period of time.

mendations issued by the World Trade Organization Technical

4.2.1 Prepare a blank determination and conduct simultane-

Barriers to Trade (TBT) Committee.

ously with the sample.

2. Significance and Use

4.3 Connect air condensers to the flask and boil the solution

2.1 This test method is intended for use in the determination

gently but steadily until the sample is completely saponified.

of the saponification value of fats and oils used in the

This usually requires approximately 1 h for normal samples.

manufacture of fat liquors for the purpose of quality assurance.

Take care that the vapor ring in the condenser does not rise to

the top of the condenser or there may be some loss.

3. Apparatus and Reagents

NOTE 1—Some samples particularly difficult to saponify may require

3.1 Erlenmeyer Flasks, Corning alkali resistant, Kimble

more than 1 h. This can only be determined by trial. Clarity and

resistant, or equivalent, 250 mL or 300 mL.

homogeneity of the test solution are partial indicators of the complete

saponification, but they are not necessarily absolute criteria.

3.2 Air Condensers, minimum length 650 mm.

4.4 After the flask and condenser have cooled somewhat,

3.3 Water Bath or a Hot Plate, with variable heat control.

but not sufficiently to jell th

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.