ASTM D4030-99

(Specification)Standard Specification for Glass Fiber Cord and Sewing Thread

Standard Specification for Glass Fiber Cord and Sewing Thread

SCOPE

1.1 This specification covers the requirements for continuous glass filament sewing thread; and continuous filament cord, untreated and neoprene treated.

1.2 This specification is intended to assist ultimate users by designating the types of these products that are typical in the industry.

1.3 This specification shows the values in both inch-pound units and in SI units. "Inch-pound units" is the technically correct name for the customary units used in the United States. "SI" units is the technically correct name for the system of metric units known as the International System of Units. The values stated in inch-pound units are to be regarded as standard; the values in SI units are provided as information only.

1.4 The following precautionary caveat pertains only to the test methods portion, Sections 22 through 33, of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Note 1-This specification is one of a series to provide a substitute for Military Specifications: MIL-Y-1140H Yarn, Cord, Sleeving, Cloth, and Tape-Glass MIL-C-9084C Cloth, Glass Finished for Resin Laminates

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 4030 – 99

Standard Specification for

Glass Fiber Cord and Sewing Thread

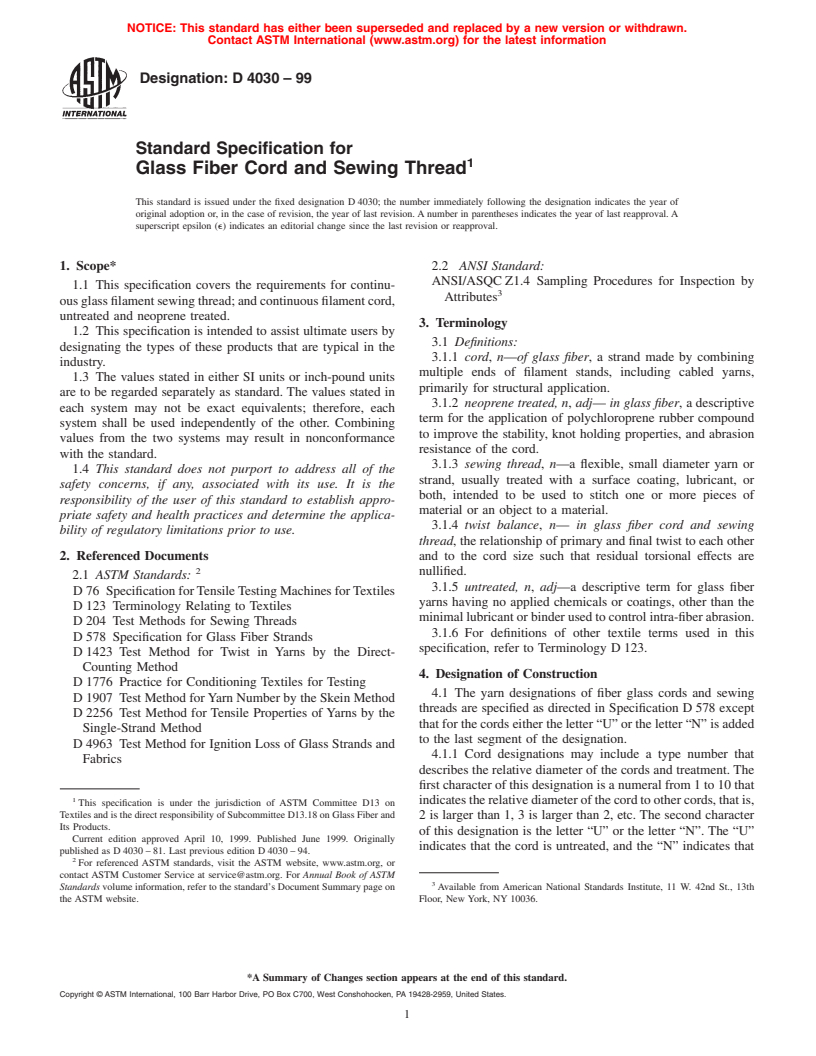

This standard is issued under the fixed designation D 4030; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope* 2.2 ANSI Standard:

ANSI/ASQC Z1.4 Sampling Procedures for Inspection by

1.1 This specification covers the requirements for continu-

Attributes

ousglassfilamentsewingthread;andcontinuousfilamentcord,

untreated and neoprene treated.

3. Terminology

1.2 This specification is intended to assist ultimate users by

3.1 Definitions:

designating the types of these products that are typical in the

3.1.1 cord, n—of glass fiber, a strand made by combining

industry.

multiple ends of filament stands, including cabled yarns,

1.3 The values stated in either SI units or inch-pound units

primarily for structural application.

are to be regarded separately as standard. The values stated in

3.1.2 neoprene treated, n, adj— in glass fiber, a descriptive

each system may not be exact equivalents; therefore, each

term for the application of polychloroprene rubber compound

system shall be used independently of the other. Combining

to improve the stability, knot holding properties, and abrasion

values from the two systems may result in nonconformance

resistance of the cord.

with the standard.

3.1.3 sewing thread, n—a flexible, small diameter yarn or

1.4 This standard does not purport to address all of the

strand, usually treated with a surface coating, lubricant, or

safety concerns, if any, associated with its use. It is the

both, intended to be used to stitch one or more pieces of

responsibility of the user of this standard to establish appro-

material or an object to a material.

priate safety and health practices and determine the applica-

3.1.4 twist balance, n— in glass fiber cord and sewing

bility of regulatory limitations prior to use.

thread, the relationship of primary and final twist to each other

2. Referenced Documents and to the cord size such that residual torsional effects are

nullified.

2.1 ASTM Standards:

3.1.5 untreated, n, adj—a descriptive term for glass fiber

D 76 SpecificationforTensileTestingMachinesforTextiles

yarns having no applied chemicals or coatings, other than the

D 123 Terminology Relating to Textiles

minimallubricantorbinderusedtocontrolintra-fiberabrasion.

D 204 Test Methods for Sewing Threads

3.1.6 For definitions of other textile terms used in this

D 578 Specification for Glass Fiber Strands

specification, refer to Terminology D 123.

D 1423 Test Method for Twist in Yarns by the Direct-

Counting Method

4. Designation of Construction

D 1776 Practice for Conditioning Textiles for Testing

4.1 The yarn designations of fiber glass cords and sewing

D 1907 Test Method forYarn Number by the Skein Method

threads are specified as directed in Specification D 578 except

D 2256 Test Method for Tensile Properties of Yarns by the

that for the cords either the letter “U” or the letter “N” is added

Single-Strand Method

to the last segment of the designation.

D 4963 Test Method for Ignition Loss of Glass Strands and

4.1.1 Cord designations may include a type number that

Fabrics

describes the relative diameter of the cords and treatment. The

first character of this designation is a numeral from 1 to 10 that

indicatestherelativediameterofthecordtoothercords,thatis,

This specification is under the jurisdiction of ASTM Committee D13 on

Textiles and is the direct responsibility of Subcommittee D13.18 on Glass Fiber and

2 is larger than 1, 3 is larger than 2, etc. The second character

Its Products.

of this designation is the letter “U” or the letter “N”. The “U”

Current edition approved April 10, 1999. Published June 1999. Originally

indicates that the cord is untreated, and the “N” indicates that

published as D 4030 – 81. Last previous edition D 4030 – 94.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from American National Standards Institute, 11 W. 42nd St., 13th

the ASTM website. Floor, New York, NY 10036.

*ASummary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D4030–99

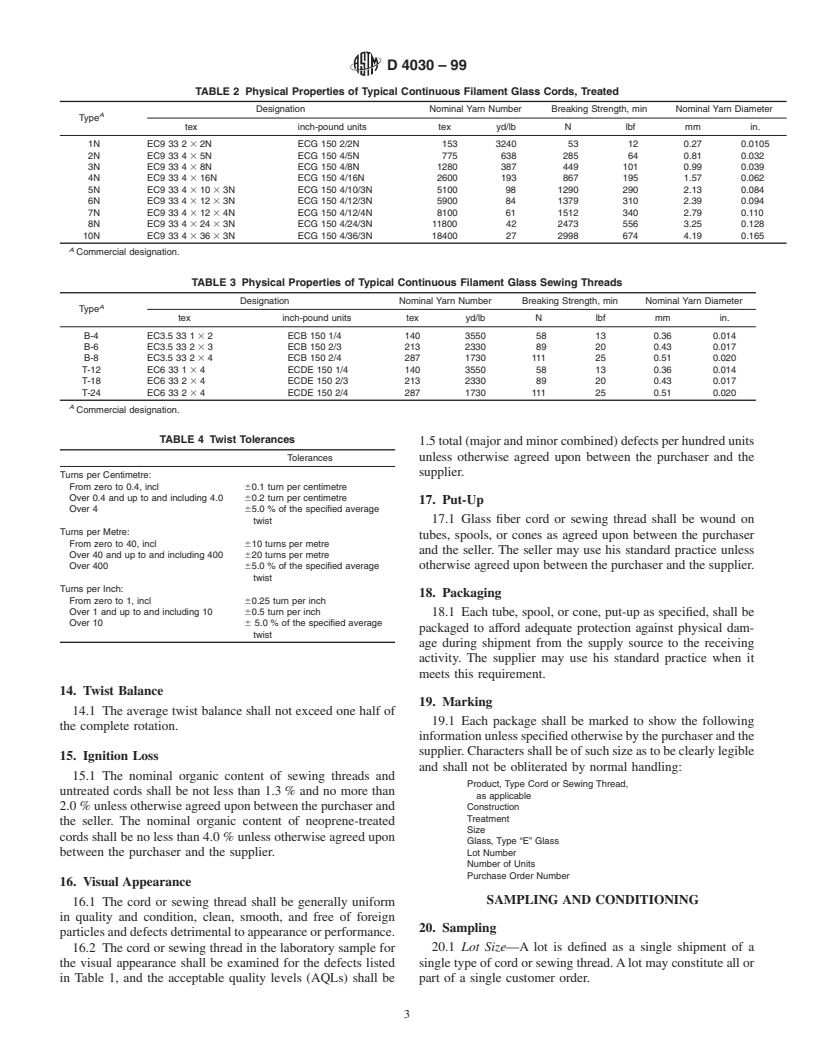

the cord is neoprene treated. The type number for cord is shall be within the interval: nominal yarn number 610 % of

included in Tables 1 and 2 to show its relationship to the nominal yarn number.

designation.

4.1.2 Sewing thread construction includes a type number 9. Strand Construction

that describes a manufacturer’s code and the size. The second

9.1 For strands listed in Table 1, Table 2, or Table 3, the

characterisanumeralandindicatestherelativediameterofthe

strand construction shall conform to the requirements of Table

sewing threads, that is, 4 is larger than 2, 6 is larger than 4, etc.

1, Table 2, or Table 3. For strands not listed in Table 1, Table

This type number for sewing thread is included in Table 3 to

2, or Table 3, the strand construction shall be agreed upon

show its relationship to designation.

between the purchaser and the supplier.

REQUIREMENTS

10. Direction of Twist

5. Material

10.1 For fiber glass cords the primary twist shall be“ Z”

5.1 The fiber shall be electrical grade, free of any free alkali

twist and the final twist shall be “S” twist unless otherwise

metaloxides,suchassodaorpotash,andforeignparticles,dirt, agreed upon between the purchaser and the seller. For fiber

and other impurities.

glass sewing threads the primary twist shall be “S” twist and

the final twist shall be “Z” twist unless otherwise agreed upon

6. Designation

between the purchaser and the supplier.

6.1 The nominal designation of fiber glass cords listed in

Table 1 or Table 2 shall conform to the requirements of Table 11. Twist Level

1 or Table 2. The nominal designation of fiber glass sewing

11.1 The nominal twist of fiber glass cords and sewing

threads listed in Table 3 shall conform to the requirements of

threads shall be agreed upon between the purchaser and the

Table 3. The nominal designations of other fiber glass cords or

supplier. The tolerances for the primary twist and for the final

sewingthreadsshallbeagreeduponbetweenthepurchaserand

twist shall conform to Table 4.

thesupplier.Therequirementsoftheindividualelementsofthe

designation are specified in Sections 7-9.

12. Breaking Strength

7. Filament Diameter 12.1 The minimum breaking strength for fiber glass cords

listed in Table 1 or Table 2 shall conform to the requirements

7.1 The nominal filament diameter of fiber glass cords shall

of Table 1 or Table 2. The minimum breaking strength of fiber

be designated by the letter designation “G”. The nominal

glass sewing thread listed in Table 3 shall conform to the

filament diameter of fiber glass sewing threads shall be

requirements of Table 3. The minimum breaking strength of

designatedbytheletterdesignation“B”to“DE”,asapplicable.

other fiber glass cords or sewing threads shall be agreed upon

The numerical values associated with letter designations are

between the purchaser and the supplier. No individual break

specified in Specification D 578. The average filament diam-

shall be less than the specified minimum breaking strength.

eter for the yarns in the cord or sewing thread shall conform to

Specification D 578 for the specified filament diameter.

13. Yarn Diameter

NOTE 1—Because of the application of fiber glass sewing threads, it is

13.1 The nominal yarn diameter for some generally avail-

desirable to utilize somewhat finer filament sizes.

able fiber glass cords are listed in Table 1 or Table 2, and the

8. Yarn Number

nominal yarn diameter for some generally available fiber glass

8.1 Since the yarn number in the designation does not sewing threads are listed in Table 3. The nominal yarn

include size, the nominal yarn number for strands including diameters are included for information only and are not

size is stated separately for strands listed inTable 1,Table 2, or considered a cause for rejection unless otherwise agreed upon,

Table 3. For strands not listed in those tables, the nominal yarn as when specified in an applicable material specification. In

number including size shall be agreed upon between the that case, the yarn diameter tolerances shall be agreed upon

purchaserandthesupplier.Theaverageyarnnumberforthelot between the purchaser and the supplier.

TABLE 1 Physical Properties of Typical Continuous Filament Glass Cords, Untreated

Designation Nominal Yarn Number Breaking Strength, min Nominal Yarn Diameter

A

Type

tex inch-pound units tex yd/lb N lbf mm in.

1U EC9 33 2 3 2U ECG 150 2/2U 137 3620 44 10 0.25 0.010

2U EC9 33 4 3 5U ECG 150 4/5U 710 700 249 56 0.66 0.026

3U EC9 33 4 3 8U ECG 150 4/8U 1165 425 418 94 0.86 0.034

4U EC9 33 4 3 16U ECG 150 4/16U 2400 210 827 186 1.32 0.02

5U EC9 33 4 3 10 3 3U ECG 150 4/10/3U 4700 105 1277 287 1.93 0.06

6U EC9 33 4 3 12 3 3U ECG 150 4/12/3U 5500 90 1401 315 2.11 0.083

7U EC9 33 4 3 12 3 4U ECG 150 4/12/4U 7400 67 1601 360 2.41 0.095

8U EC9 33 4 3 24 3 3U ECG 150 4/24/3U 11000 45 2571 578 3.02 0.119

10U EC9 33 4 3 36 3 3U ECG 150 4/36/3U 17100 29 3363 756 3.78 0.149

A

Commercial designation.

D4030–99

TABLE 2 Physical Properties of Typical Continuous Filament Glass Cords, Treated

Designation Nominal Yarn Number Breaking Strength, min Nominal Yarn Diameter

A

Type

tex inch-pound units tex yd/lb N lbf mm in.

1N EC9 33 2 3 2N ECG 150 2/2N 153 3240 53 12 0.27 0.0105

2N EC9 33 4 3 5N ECG 150 4/5N 775 638 285 64 0.81 0.032

3N EC9 33 4 3 8N ECG 150 4/8N 1280 387 449 101 0.99 0.039

4N EC9 33 4 3 16N ECG 150 4/16N 2600 193 867 195 1.57 0.062

5N EC9 33 4 3 10 3 3N ECG 150 4/10/3N 5100 98 1290 290 2.13 0.084

6N EC9 33 4 3 12 3 3N ECG 150 4/12/3N 5900 84 1379 310 2.39 0.094

7N EC9 33 4 3 12 3 4N ECG 150 4/12/4N 8100 61 1512 340 2.79 0.110

8N EC9 33 4 3 24 3 3N ECG 150 4/24/3N 11800 42 2473 556 3.25 0.128

10N EC9 33 4 3 36 3 3N ECG 150 4/36/3N 18400 27 2998 674 4.19 0.165

A

Commercial designation.

TABLE 3 Physical Properties of Typical Continuous Filament Glass Sewing Threads

Designation Nominal Yarn Number Breaking Strength, min Nominal Yarn Diameter

A

Type

tex inch-pound units tex yd/lb N lbf mm in.

B-4 EC3.5 33 1 3 2 ECB 150 1/4 140 3550 58 13 0.36 0.014

B-6 EC3.5 33 2 3 3 ECB 150 2/3 213 2330 89 20 0.43 0.017

B-8 EC3.5 33 2 3 4 ECB 150 2/4 287 1730 111 25 0.51 0.020

T-12 EC6 33 1 3 4 ECDE 150 1/4 140 3550 58 13 0.36 0.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.