ASTM D1123-99(2003)

(Test Method)Standard Test Methods for Water in Engine Coolant Concentrate by the Karl Fischer Reagent Method

Standard Test Methods for Water in Engine Coolant Concentrate by the Karl Fischer Reagent Method

SCOPE

1.1 These test methods cover the determination of the water present in new or unused glycol-based coolant concentrates using a manual (Test Method A) or an automatic (Test Method B) coulometric titrator procedure.

1.2 Many carbonyl compounds react slowly with the Fischer reagent, causing a fading end point and leading to high results. A modified Fischer reagent procedure is included that minimizes these undesirable and interfering reactions.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazards statements see Sections 8 and 16.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1123–99 (Reapproved 2003)

Standard Test Methods for

Water in Engine Coolant Concentrate by the Karl Fischer

Reagent Method

This standard is issued under the fixed designation D 1123; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3.1.1.1 Discussion—View the color by transmitted daylight

or by transmitted light from an artificial daylight lamp, such as

1.1 These test methods cover the determination of the water

one that complies with the specification given in Test Method

present in new or unused glycol-based coolant concentrates

D 156.

using a manual (Test MethodA) or an automatic (Test Method

3.1.2 instrument end point—for the purpose of these tests,

B) coulometric titrator procedure.

that point in the titration when two small platinum electrodes,

1.2 Many carbonyl compounds react slowly with the Fis-

upon which a potential of 20 to 50 mVhas been impressed, are

cher reagent, causing a fading end point and leading to high

depolarized by the addition of 0.05 mL of Fischer reagent (6

results. A modified Fischer reagent procedure is included that

mg of water/mL), causing a change of current flow of 10 to 20

minimizes these undesirable and interfering reactions.

µA that persists for at least 30 s.

1.3 This standard does not purport to address all of the

3.1.2.1 Discussion—This end point is sometimes incor-

safety problems, if any, associated with its use. It is the

rectly called the “dead stop,” which is the reverse of the above.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4. Summary of Test Methods

bilityofregulatorylimitationspriortouse.Forspecifichazards

4.1 These test methods are based essentially on the reduc-

statements see Sections 8 and 16.

tion of iodine by sulfur dioxide in the presence of water. This

2. Referenced Documents reaction can be used quantitatively only when pyridine and an

alcohol are present to react as follows:

2.1 ASTM Standards:

D 156 Test Method for Saybolt Color of Petroleum Prod- I 1 SO 1 H O→ SO 1 2HI (1)

2 2 2 3

ucts (Saybolt Chromometer Method)

D 1176 Test Method for Sampling and Preparing Aqueous

4.2 In order to determine water, Karl Fischer reagent is

Solutions of Engine Coolants or Antirusts for Testing

added to a solution of the sample in anhydrous high-purity

Purposes

methanol until all water present has been consumed. This is

D 1193 Specification for Reagent Water

evidenced by the persistence of the orange-red end point color,

E 203 Test Method for Water Using Karl Fischer Reagent

or alternatively by an indication on a galvanometer or similar

current-indicating device that records the depolarization of a

3. Terminology

pair of noble metal electrodes. The reagent is standardized by

3.1 Definitions:

the titration of water.

3.1.1 color end point—that point during the titration when

NOTE 1—It is believed that these methods give all the information

the color change from yellow to orange-red is sharp and easily

required for determining the water in coolant formulations. Should

repeated. The orange-red color must persist for at least 30 s in

additional information on water determinations be needed, reference

order to indicate an end point.

should be made to Test Method E 203.

5. Significance and Use

These test methods are under the jurisdiction of ASTM Committee D15 on

5.1 The total apparent water in engine coolant concentrate

Engine Coolants and are the direct responsibility of Subcommittee D15.04 on

as determined by Karl Fischer titrations consists of the fol-

Chemical Properties.

Current edition approved May 10, 1999. Published August 1999. Originally

lowing: (1) water present in the original glycol base; (2) water

published as D 1123 – 50. Last previous edition D 1123 – 93.

added (for example, inhibitor solutions); (3) water of hydration

Annual Book of ASTM Standards, Vol 05.01.

of inhibitors (for example, Na B O ·5H O); ( 4) water formed

Annual Book of ASTM Standards, Vol 15.05. 2 4 7 2

Annual Book of ASTM Standards, Vol 11.01. in the chemical reaction between borate and ethylene glycol,

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D1123–99 (2003)

producing boratediol condensate and water; and ( 5) quantita- 6.4 Buret Assembly for Fischer reagent, consisting of a 25

tive interference by the reaction of the reagent with inhibitors or 50-mL buret connected by means of glass (not rubber)

such as tetraborate or sodium hydroxide. connectors to a source of reagent; several types of automatic

dispensing burets may be used. Since the reagent loses

TEST METHOD A—MANUAL TITRATION

strength when exposed to moist air, all vents must be protected

against atmospheric moisture by adequate drying tubes con-

6. Apparatus

taining anhydrous calcium sulfate. All stopcocks and joints

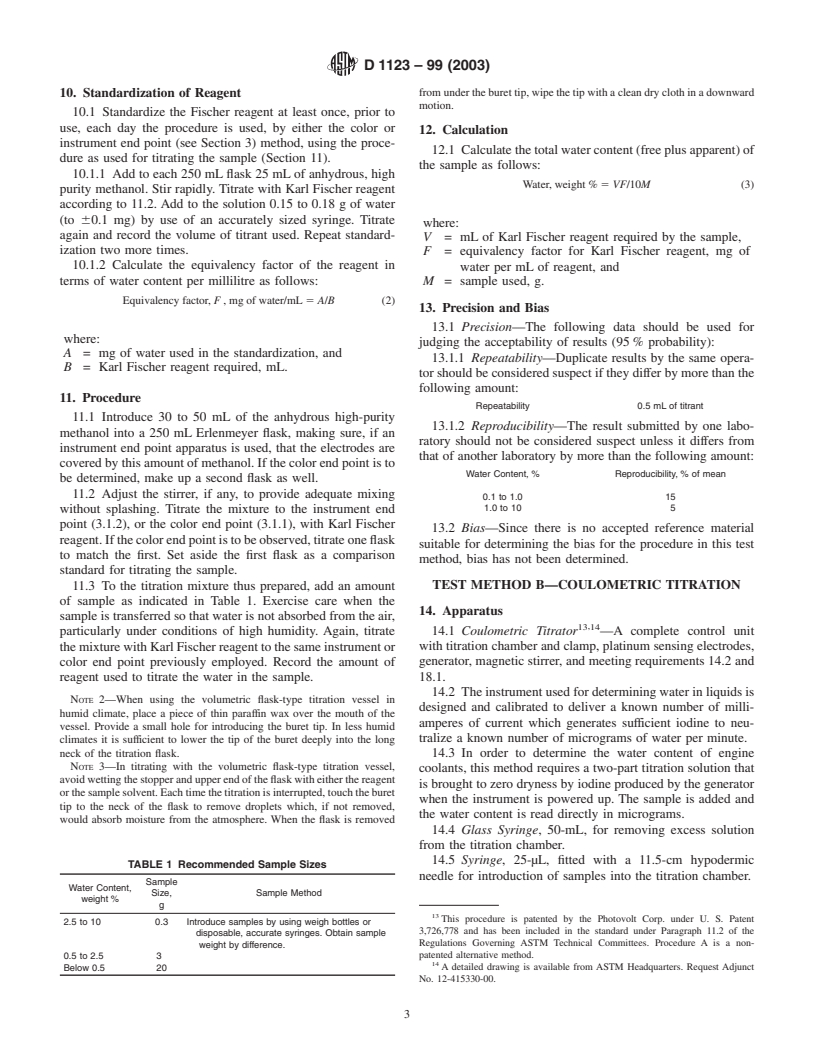

6.1 Titration Vessel— For color end point titrations, use a

should be lubricated with a lubricant not particularly reactive

100 or 250-mL volumetric flask, which need not be calibrated.

with the reagent.

For instrument end point, a 250-mL flask fitted with inter-

6.5 Weighing Bottle, of the Lunge or Grethen type, or

changeable electrodes (Fig. 1) may be used. This is particu-

equivalent.

larly good for titrations of coolant concentrate that is deeply

6.6 Some laboratory equipment suppliers offer a Karl Fis-

coloredfromdyeoranyothercause.Forpermanentlymounted

cher apparatus. The noted model or its equivalent has been

assemblies, the vessel should have a capacity about equal to

found to be suitable.

that of a 300-mLtall-form beaker and should be provided with

a tight-fitting closure to protect the sample and reagent from

7. Reagents

atmospheric moisture, a stirrer, and a means of adding sample

7.1 Purity of Reagents—Reagent grade chemicals shall be

and reagents and removing spent reaction mixture. It is

used in all tests. Unless otherwise indicated, it is intended that

desirable to have a means for cooling the titration vessel to ice

all reagents shall conform to the specifications of the Commit-

temperature.

tee onAnalytical Reagents of theAmerican Chemical Society,

6.2 Instrument Electrodes, platinum with a surface equiva- 11

where such specifications are available. Other grades may be

lent to two No. 26 wires, 4.76-mm long. The wires should be

used, provided it is first ascertained that the reagent is of

3 to 8 mm apart and so inserted in the vessel that the liquid will

sufficiently high purity to permit its use without lessening the

cover them.

accuracy of the determination.

6.3 Instrument Depolarization Indicator, having an internal

7.2 Unless otherwise indicated, references to water shall be

resistance of less than 5000 V and consisting of a means of

understood to mean reagent water, Type IV, conforming to

impressing and showing a voltage of 20 to 50 mV across the

Specification D 1193.

electrodes and capable of indicating a current flow of 10 to 20

7.3 Karl Fischer Reagent, equivalent to 5 mg of water/

µA by means of a galvanometer or radio tuning eye circuit. 12

mL.

7.4 Methanol (Warning—See 8.1.)—Anhydrous, high pu-

rity.

Flasks made by Rankin Glass Blowing Co., 3920 Franklin Canyon Rd.,

8. Hazards

Martinez, CA have been found satisfactory for this purpose.

A type similar to the Precision Scientific Co. “Aquatrator” or Fisher Scientific

8.1 Methanol—Poison; flammable; may be fatal or cause

Co. “FisherTitrimeter,” is suitable for the measurement of the instrument end point.

blindness if swallowed; cannot be made non-poisonous; harm-

ful if inhaled.

9. Sampling

9.1 A representative sample of the contents of the original

container shall be obtained as directed in Test Method D 1176;

even if two phases are present, the water-insoluble phase

should not be separated.

A type similar to Catalog No. J-821 of Scientific Glass Apparatus Co.,

Bloomfield, NJ, or Catalog No. 750 of Eck and Krebs, New York, NY, has been

specifically designed for this purpose and presents the minimum contact of reagent

with stopcock lubricant.

Indicating Drierite has been found satisfactory for this purpose.

Suitable lubricants includeApiezon N. (James G. Biddle and Co., Philadelphia,

PA); High Vacuum Silicone Grease (Dow Corning Co., Midland, MI); Sisco 300

(Swedish Iron and Steel Co., New York, NY).

MetrohmHerisau,KarlFischerTitratorTypeE-452availablefromBrinkmann

Instruments, Inc., Cantaigue Road, Westbury, NY 11590.

Reagent Chemicals, American Chemical Society Specifications, American

Chemical Society, Washington, DC. For suggestions on the testing of reagents not

listed by the American Chemical Society, see Analar Standards for Laboratory

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

MD.

NOTE 1—All dimensions in millimetres.

Reagents, as the pyridine-free hydranal reagent, available from Fisher Scien-

FIG. 1 Titration Flask Assembly tific, Pittsburgh, PA 15219.

D1123–99 (2003)

fromundertheburettip,wipethetipwithacleandryclothinadownward

10. Standardization of Reagent

motion.

10.1 Standardize the Fischer reagent at least once, prior to

use, each day the procedure is used, by either the color or

12. Calculation

instrument end point (see Section 3) method, using the proce-

12.1 Calculate the total water content (free plus apparent) of

dure as used for titrating the sample (Section 11).

the sample as follows:

10.1.1 Add to each 250 mL flask 25 mL of anhydrous, high

Water, weight % 5 VF/10M (3)

purity methanol. Stir rapidly. Titrate with Karl Fischer reagent

according to 11.2. Add to the solution 0.15 to 0.18 g of water

(to 60.1 mg) by use of an accurately sized syringe. Titrate

where:

again and record the volume of titrant used. Repeat standard-

V = mL of Karl Fischer reagent required by the sample,

ization two more times.

F = equivalency factor for Karl Fischer reagent, mg of

10.1.2 Calculate the equivalency factor of the reagent in

water per mL of reagent, and

terms of water content per millilitre as follows: M = sample used, g.

Equivalency factor, F , mg of water/mL 5 A/B (2)

13. Precision and Bias

13.1 Precision—The following data should be used for

where:

judging the acceptability of results (95 % probability):

A = mg of water used in the standardization, and

13.1.1 Repeatability—Duplicate results by the same opera-

B = Karl Fischer reagent required, mL.

tor should be considered suspect if they differ by more than the

following amount:

11. Procedure

Repeatability 0.5 mL of titrant

11.1 Introduce 30 to 50 mL of the anhydrous high-purity

13.1.2 Reproducibility—The result submitted by one labo-

methanol into a 250 mL Erlenmeyer flask, making sure, if an

ratory should not be considered suspect unless it differs from

instrument end point apparatus is used, that the electrodes are

that of another laboratory by more than the following amount:

covered by this amount of methanol. If the color end point is to

Water Content, % Reproducibility, % of mean

be determined, make up a second flask as well.

11.2 Adjust the stirrer, if any, to provide adequate mixing

0.1to1.0 15

1.0to10 5

without splashing. Titrate the mixture to the instrument end

point (3.1.2), or the color end point (3.1.1), with Karl Fischer

13.2 Bias—Since there is no accepted reference material

reagent.Ifthecolorendpointistobeobserved,titrateoneflask

suitable for determining the bias for the procedure in this test

to match the first. Set aside the first flask as a comparison

method, bias has not been determined.

standard for titrating the sample.

TEST METHOD B—COULOMETRIC TITRATION

11.3 To the titration mixture thus prepared, add an amount

of sample as indicated in Table 1. Exercise care when the

14. Apparatus

sample is transferred so that water is not absorbed from the air,

,

13 14

particularly under conditions of high humidity. Again, titrate 14.1 Coulometric Titrator —A complete control unit

with titration chamber and clamp, platinum sensing electrodes,

themixturewithKarlFischerreagenttothesameinstrumentor

color end point previously employed. Record the amount of generator, magnetic stirrer, and meeting requirements 14.2 and

18.1.

reagent used to titrate the water in the sample.

14.2 The instrument used for determining water in liquids is

NOTE 2—When using the volumetric flask-type titration vessel in

designed and calibrated to deliver a known number of milli-

humid climate, place a piece of thin paraffin wax over the mouth of the

amperes of current which generates sufficient iodine to neu-

vessel. Provide a small hole for introducing the buret tip. In less humid

tralize a known number of micrograms of water per minute.

climates it is sufficient to lower the tip of the buret deeply into the long

neck of the titration flask. 14.3 In order to determine the water content of engine

NOTE 3—In titrating with the volumetric flask-type titration vessel,

coolants, this method requires a two-part titration solution that

avoidwettingthestopperandupperendoftheflaskwitheitherthereagent

is brought to zero dryness by iodine produced by the generator

orthesamplesolvent.Eachtimethetitrationisinterrupted,touchtheburet

when the instrument is powered up. The sample is added and

tip to the neck of the flask to remove droplets which, if not removed,

the water content is read directly in micrograms.

would absorb moisture from the atmosphere. When the flask is removed

14.4 Glass Syringe, 50-mL, for removing excess solution

from the titration chamber.

14.5 Syringe, 25-µL, fitted with a 11.5-cm hypodermic

TABLE 1 Recommended Sample Sizes

needle for introduction of samples into the titration chamber.

Sample

Water Content,

Size, Sample Method

weight %

g

This procedure is patented by the Photovolt Corp. under U. S. Patent

2.5 to 10 0.3 Introduce samples by using weigh bottles or

3,726,778 and has been included in the standard under Paragraph 11.2 of the

disposable, accurate syringes. Obtain sample

Regulations Governing ASTM Technical Committees. Procedure A is a non-

weight by difference.

patented alternative method.

0.5to2.5 3

Below 0.5 20 A detailed drawing is available from ASTM Headquarters. Request Adjunct

No. 12-415330-00.

D1123–99 (2003)

14.6 Syringe,1-µL,fittedwitha11.5-cmhypodermicneedle 18. Verification of System by Direct Titration of Water

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.