ASTM D665-19

(Test Method)Standard Test Method for Rust-Preventing Characteristics of Inhibited Mineral Oil in the Presence of Water

Standard Test Method for Rust-Preventing Characteristics of Inhibited Mineral Oil in the Presence of Water

SIGNIFICANCE AND USE

5.1 In many instances, such as in the gears of a steam turbine, water can become mixed with the lubricant, and rusting of ferrous parts can occur. This test indicates how well inhibited mineral oils aid in preventing this type of rusting. This test method is also used for testing hydraulic and circulating oils, including heavier-than-water fluids. It is used for specification of new oils and monitoring of in-service oils.

Note 3: This test method was used as a basis for Test Method D3603. Test Method D3603 is used to test the oil on separate horizontal and vertical test rod surfaces, and can provide a more discriminating evaluation.

SCOPE

1.1 This test method covers the evaluation of the ability of inhibited mineral oils, particularly steam-turbine oils, to aid in preventing the rusting of ferrous parts should water become mixed with the oil. This test method is also used for testing other oils, such as hydraulic oils and circulating oils. Provision is made in the procedure for testing heavier-than-water fluids.

Note 1: For synthetic fluids, such as phosphate ester types, the plastic holder and beaker cover should be made of chemically resistant material suitable for the type of fluid tested.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see 7.4 – 7.6.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D665 − 19

Designation: 135/06

Standard Test Method for

Rust-Preventing Characteristics of Inhibited Mineral Oil in

1

the Presence of Water

This standard is issued under the fixed designation D665; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* 2. Referenced Documents

2

1.1 This test method covers the evaluation of the ability of

2.1 ASTM Standards:

inhibited mineral oils, particularly steam-turbine oils, to aid in

A108 Specification for Steel Bar, Carbon and Alloy, Cold-

preventing the rusting of ferrous parts should water become

Finished

mixed with the oil. This test method is also used for testing

A240/A240M Specification for Chromium and Chromium-

other oils, such as hydraulic oils and circulating oils. Provision

Nickel Stainless Steel Plate, Sheet, and Strip for Pressure

is made in the procedure for testing heavier-than-water fluids.

Vessels and for General Applications

NOTE 1—For synthetic fluids, such as phosphate ester types, the plastic D91 Test Method for Precipitation Number of Lubricating

holder and beaker cover should be made of chemically resistant material

Oils

suitable for the type of fluid tested.

D1193 Specification for Reagent Water

1.2 The values stated in SI units are to be regarded as

D2422 Classification of Industrial Fluid Lubricants by Vis-

standard. No other units of measurement are included in this

cosity System

standard.

D3603 Test Method for Rust-Preventing Characteristics of

1.3 This standard does not purport to address all of the Steam Turbine Oil in the Presence of Water (Horizontal

safety concerns, if any, associated with its use. It is the Disk Method)

responsibility of the user of this standard to establish appro-

D4057 Practice for Manual Sampling of Petroleum and

priate safety, health, and environmental practices and deter-

Petroleum Products

mine the applicability of regulatory limitations prior to use.

E1 Specification for ASTM Liquid-in-Glass Thermometers

For specific warning statements, see 7.4 – 7.6.

2.2 Other Documents:

1.4 This international standard was developed in accor-

Motor Fuels, Section I, Annex A2, Table 32, Reference

dance with internationally recognized principles on standard-

3

Materials and Blending Accessories

ization established in the Decision on Principles for the

Specifications-IP Standard Thermometers, Vol 2, Appendix

Development of International Standards, Guides and Recom-

4

A

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

Specifications for IP Standard Reference Liquids, Appendix

4

B

1

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of

2

Subcommittee D02.C0.02 on Corrosion and Water/Air Separability. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Dec. 1, 2019. Published January 2020. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

ɛ1

approved in 1942. Last previous edition approved in 2014 as D665 – 14 . DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D0665-19. the ASTM website.

3

This standard has been developed through the cooperative effort betweenASTM See 1996 Annual Book of ASTM Standards, Vol 05.04.

4

International and the Energy Institute, London. The EI and ASTM International AnnualBookofIPStandardMethodsforAnalysisandTestingofPetroleumand

logos imply that the ASTM International and EI standards are technically Related Products, Vol 2. Available from Energy Institute, 61 New Cavendish St.,

equivalent, but does not imply that both standards are editorially identical. London, WIG 7AR, U.K.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D665 − 19

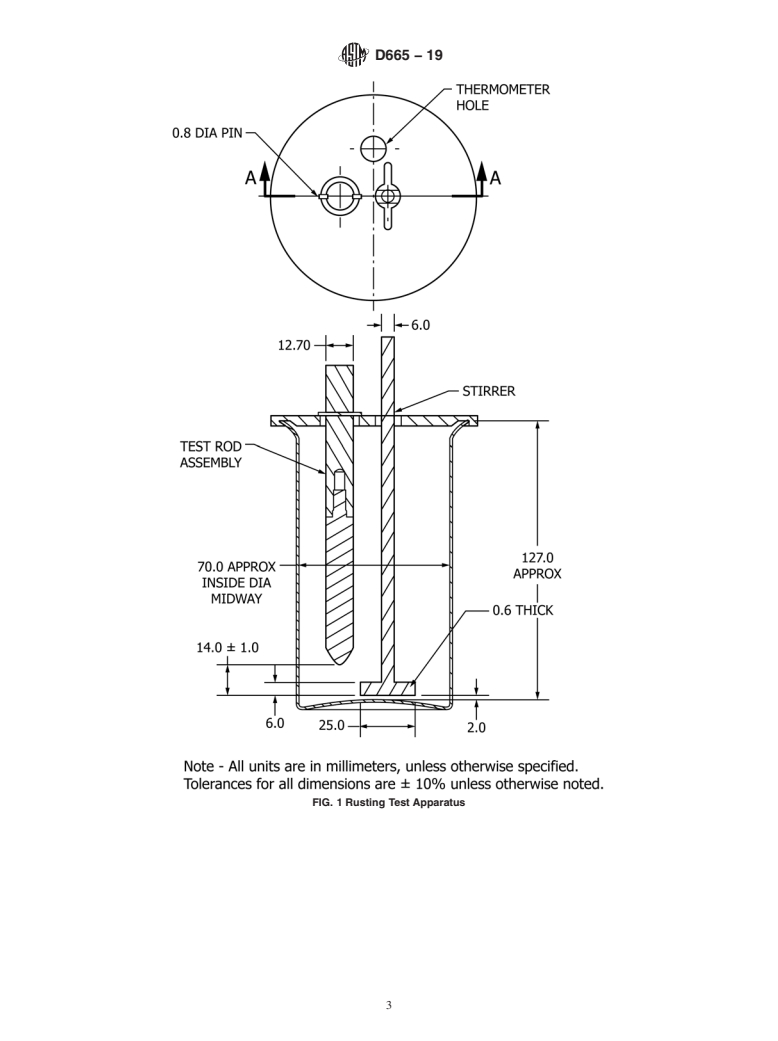

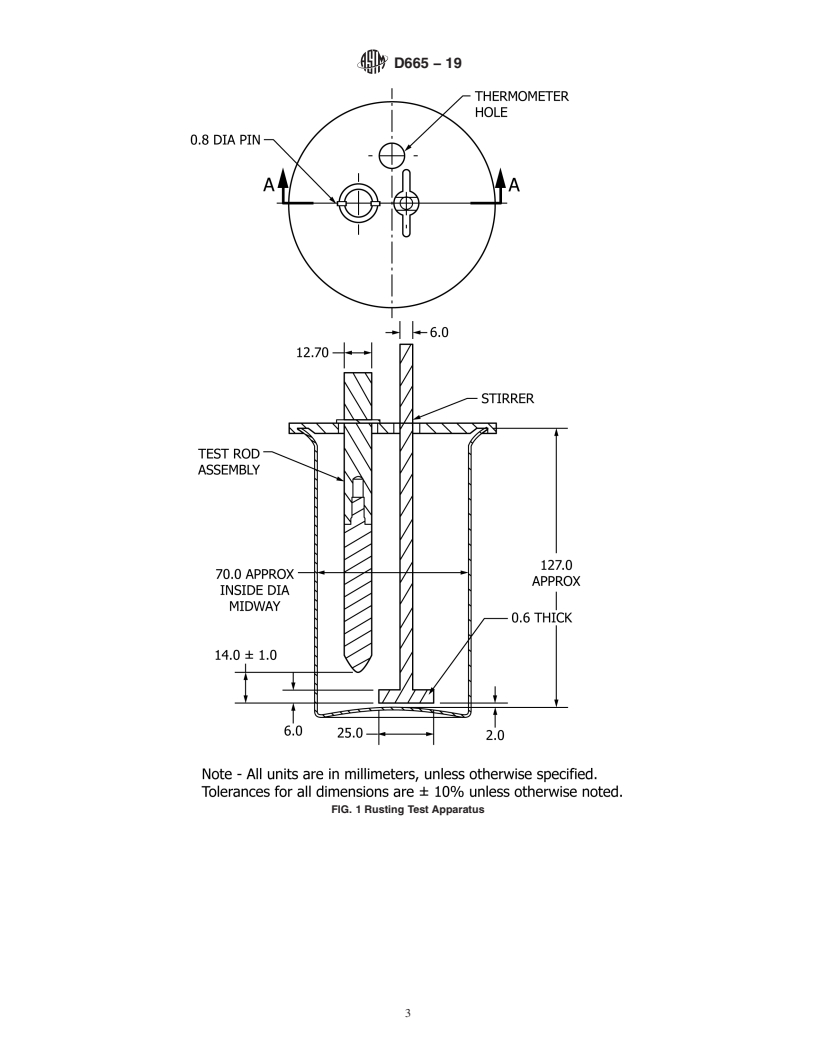

SAE Standard J405 Chemical Composition of SAEWrought 127 mm in height measured from the inside bottom center and

5

Stainless Steels approximately 70 mm inside diameter measured at the middle.

4

BS 871 Specification for abrasive papers and cloths

6.3 Beaker Cover—A flat beaker cover of glass or poly

BS 970 Part 1: Carbon and Carbon Manganese Steels

(methyl methacrylate)

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D665 − 14 D665 − 19

Designation: 135/06

Standard Test Method for

Rust-Preventing Characteristics of Inhibited Mineral Oil in

1

the Presence of Water

This standard is issued under the fixed designation D665; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1

ε NOTE—Subsection 7.3 was corrected editorially in February 2015.

1. Scope*

1.1 This test method covers the evaluation of the ability of inhibited mineral oils, particularly steam-turbine oils, to aid in

preventing the rusting of ferrous parts should water become mixed with the oil. This test method is also used for testing other oils,

such as hydraulic oils and circulating oils. Provision is made in the procedure for testing heavier-than-water fluids.

NOTE 1—For synthetic fluids, such as phosphate ester types, the plastic holder and beaker cover should be made of chemically resistant material suitable

for the type of fluid tested.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use. For specific warning statements, see 7.4 – 7.6.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

A108 Specification for Steel Bar, Carbon and Alloy, Cold-Finished

A240/A240M Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for Pressure Vessels and

for General Applications

D91 Test Method for Precipitation Number of Lubricating Oils

D1193 Specification for Reagent Water

D2422 Classification of Industrial Fluid Lubricants by Viscosity System

D3603 Test Method for Rust-Preventing Characteristics of Steam Turbine Oil in the Presence of Water (Horizontal Disk Method)

D4057 Practice for Manual Sampling of Petroleum and Petroleum Products

E1 Specification for ASTM Liquid-in-Glass Thermometers

2.2 Other Documents:

3

Motor Fuels, Section I, Annex A2, Table 32, Reference Materials and Blending Accessories

4

Specifications-IP Standard Thermometers, Vol 2, Appendix A

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products, Liquid Fuels, and Lubricants and is the direct responsibility of Subcommittee

D02.C0.02 on Corrosion and Water/Air Separability.

Current edition approved Oct. 1, 2014Dec. 1, 2019. Published November 2014January 2020. Originally approved in 1942. Last previous edition approved in 20122014

ɛ1

as D665 – 12.D665 – 14 . DOI: 10.1520/D0665-14E01.10.1520/D0665-19.

This standard has been developed through the cooperative effort between ASTM International and the Energy Institute, London. The EI and ASTM International logos

imply that the ASTM International and EI standards are technically equivalent, but does not imply that both standards are editorially identical.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

See 1996 Annual Book of ASTM Standards, Vol 05.04.

4

Annual Book of IP Standard Methods for Analysis and Testing of Petroleum and Related Products, Vol 2. Available from Energy Institute, 61 New Cavendish St., London,

WIG 7AR, U.K.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D665 − 19

4

Specifications for IP Standard Reference Liquids, Appendix B

5

SAE Standard J405 Chemical Composition of SAE Wrought Stainless Steels

4

BS 871 Specification f

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.