ASTM B313/B313M-02e1

(Specification)Standard Specification for Aluminum and Aluminum-Alloy Round Welded Tubes

Standard Specification for Aluminum and Aluminum-Alloy Round Welded Tubes

ABSTRACT

This specification covers aluminum and aluminum-alloy tubes made from formed sheet and seam welded by continuous methods. Chemical conformance shall be determined by analyzing samples taken at a time the ingots are poured, or samples taken from the finished or semi-finished product, following conditions set in the specification. The temper of the tubes shall be that of the sheet from which the tubes are formed, and the sheet shall conform to the specified tensile property requirements. The tube shall be subjected to tension, capability, and pressure tests.

SCOPE

1.1 This specification covers aluminum and aluminum-alloy tubes made from formed sheet and seam welded by continuous methods.

1.2 Alloy (Note 1) and temper designations are in accordance with ANSI H35.1 [H35.1M]. The equivalent Unified Numbering System alloy designations are those of preceded by A9, for example, A91100 for aluminum 1100 in accordance with Practice E 527.

Note 1—Throughout this specification use of the term alloyin the general sense includes aluminum as well as aluminum alloy.

Note 2—For the requirements for sheet see Specification B 209.

1.3 For acceptance criteria for inclusion of new aluminum and aluminum alloys in this specification, see Annex A2.

1.4 The values stated in either inch-pound or SI units are to be regarded separately as standards. The SI units are shown either in brackets or in separate tables. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from two systems will result in nonconformance with the specification.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

´1

Designation: B313/B313M – 02

Standard Specification for

1

Aluminum and Aluminum-Alloy Round Welded Tubes

This standard is issued under the fixed designation B313/B313M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

´ NOTE—Safety caveat added and editorial changes were made in November 2003

2

1. Scope* Aluminum- and Magnesium-Alloy Products

B557M TestMethodsforTensionTestingWroughtandCast

1.1 This specification covers aluminum and aluminum-alloy

2

Aluminum- and Magnesium-Alloy Products (Metric)

tubes made from formed sheet and seam welded by continuous

B660 Practices for Packaging/Packing of Aluminum and

methods.

2

Magnesium Products

1.2 Alloy (Note 1) and temper designations are in accor-

B666/B666M Practice for Identification Marking ofAlumi-

dance with ANSI H35.1 [H35.1M]. The equivalent Unified

2

num and Magnesium Products

Numbering System alloy designations are those of Table 1

B918 Practice for Heat Treatment of Wrought Aluminum

preceded by A9, for example, A91100 for aluminum 1100 in

3

Alloys

accordance with Practice E527.

E29 Practice for Using Significant Digits in Test Data to

NOTE 1—Throughout this specification use of the term alloy in the 4

Determine Conformance with Specifications

general sense includes aluminum as well as aluminum alloy.

E34 Test Methods for ChemicalAnalysis ofAluminum and

NOTE 2—For the requirements for sheet see Specification B209.

4

Aluminum-Base Alloys

1.3 For acceptance criteria for inclusion of new aluminum

E55 Practice for Sampling Wrought Nonferrous Metals and

4

and aluminum alloys in this specification, see Annex A2.

Alloys for Determination of Chemical Composition

1.4 The values stated in either inch-pound or SI units are to

E227 Test Method for Optical Emission Spectrometric

be regarded separately as standards. The SI units are shown

Analysis of Aluminum and Aluminum Alloys by the

56

either in brackets or in separate tables. The values stated in

Point-to-Plane Technique

each system are not exact equivalents; therefore, each system

E527 Practice for Numbering Metals and Alloys in the

4

must be used independently of the other. Combining values

Unified Numbering System (UNS)

from two systems will result in nonconformance with the

E607 Test Method for Atomic Emission Spectrometric

specification.

Analysis Aluminum Alloys by the Point to Plane Tech-

1.5 This standard does not purport to address all of the 4

nique Nitrogen Atmosphere

safety concerns, if any, associated with its use. It is the

E716 Practices for Sampling Aluminum and Aluminum

responsibility of the user of this standard to establish appro- 4

Alloys for Spectrochemical Analysis

priate safety and health practices and determine the applica-

E1251 Test Method for Analysis of Aluminum and Alumi-

bility of regulatory limitations prior to use.

num Alloys by Atomic Emission Spectrometry

2.3 ANSI Standards:

2. Referenced Documents

H35.1 Alloy and Temper Designation Systems for Alumi-

2.1 The following documents of the issue in effect on the 2

num

date of material purchase form a part of this specification to the

H35.1M Alloy and Temper Designation Systems for Alu-

extent referenced herein:

minum (Metric)

2

2.2 ASTM Standards:

H35.2 Dimensional Tolerances for Aluminum Mill Prod-

B209 Specification for Aluminum and Aluminum-Alloy 2

ucts

2

Sheet and Plate

H35.2M Dimensional Tolerances for Aluminum Mill Prod-

B557 Test Methods for Tension Testing Wrought and Cast

ucts (Metric)

2.4 Military Standard:

1

This specification is under the jurisdiction of the ASTM Committee B07 on

Light Metals andAlloys and is the direct responsibility of Subcommittee B07.03 on

3

Aluminum Alloy Wrought Products. Annual Book of ASTM Standards, Vol 14.02.

4

Current edition approved Nov. 11, 2003. Published January 2003. Originally Annual Book of ASTM Standards, Vol 03.05.

5

approved in 1956. Last previous edition approved in 2000 as B313/B313M–00. Withdrawn. The last approved version of this historical standard is referenced

DOI: 10.1520/B0313_B0313M-02E01. on www.astm.org.

2 6

Annual Book of ASTM Standards, Vol 02.02. Annual Book of ASTM Standards, Vol 01.01.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

´1

B313/B313M – 02

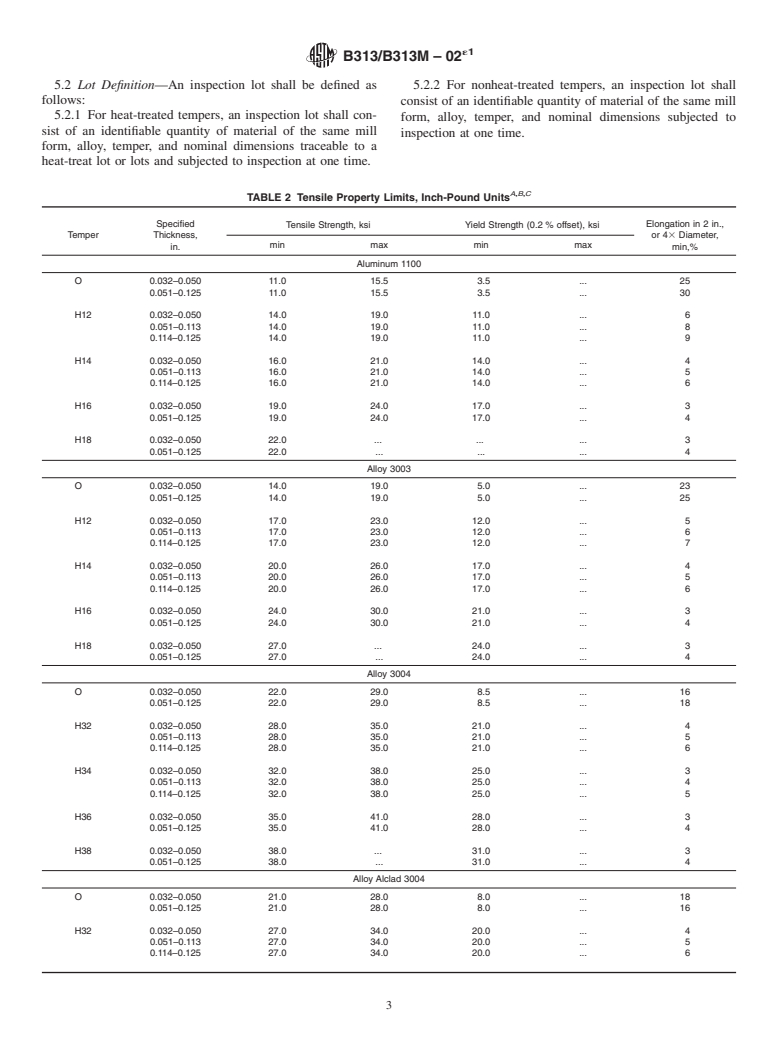

A,B,C

TABLE 1 Chemical Composition Limits

D

Other Elements

Tita-

Alloy Silicon Iron Copper Manganese Magnesium Chromium Zinc Aluminum

E

nium

Each Total

FF G

1100 0.05–0.20 0.05 . . 0.10 . 0.05 0.15 99.0 min

3003 0.6 0.7 0.0

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.