ASTM E990-98

(Specification)Standard Specification for Core-Splice Adhesive for Honeycomb Sandwich Shelter Panels

Standard Specification for Core-Splice Adhesive for Honeycomb Sandwich Shelter Panels

SCOPE

1.1 This specification covers core-splice adhesive for use with nonmetallic honeycomb cores in the fabrication of honeycomb sandwich panels used in relocatable shelters. The adhesive shall be used for new production or depot repair. The adhesive shall be suitable for forming bonds that can withstand long combinations of stress, temperature, and relative humidity expected to be encountered in service. The adhesive shall be used for bonding core segments and for bonding core segments to edge members and to integral members in a honeycomb sandwich panel. The adhesive shall not allow the transfer of water from one part of the panel to another either through or along the line of the adhesive.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 The following precautionary caveat pertains only to the test method portion, Section 5, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: E 990 – 98

Standard Specification for

Core-Splice Adhesive for Honeycomb Sandwich Structural

Panels

This standard is issued under the fixed designation E 990; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope E 865 Specification for Structural Film Adhesives for Hon-

eycomb Sandwich Panels

1.1 This specification covers core-splice adhesive for use

E 874 Practice for Adhesive Bonding of Aluminum Facings

with nonmetallic honeycomb cores in the fabrication of hon-

to Nonmetallic Honeycomb Core for Shelter Panels

eycomb sandwich panels used in relocatable structures. The

E 1091 Specification for Nonmetallic Honeycomb Core for

adhesive shall be used for new production or depot repair. The

Use in Shelter Panels

adhesive shall be suitable for forming bonds that can withstand

2.2 Federal Standards:

long combinations of stress, temperature, and relative humidity

MMM-A-132 Adhesives, Heat Resistant, Airframe Struc-

expected to be encountered in service. The adhesive shall be

tural, Metal-to-Metal

used for bonding core segments and for bonding core segments

QQ-A-250/4 Aluminum Alloy 2024, Plate and Sheet

to edge members and to integral members in a honeycomb

QQ-A-250/8d Aluminum Alloy 5052H34, Plate and Sheet

sandwich panel. The adhesive shall not allow the transfer of

QQ-A-250/11d Aluminum Alloy 6061T6, Plate and Sheet

water from one part of the panel to another either through or

2.3 Military Standards:

along the line of the adhesive.

MIL-S-8802 Sealing Compound, Temperature-Resistant,

1.2 The values stated in SI units are to be regarded as the

Integral Fuel Tanks, and Fuel Cell Cavities, High-

standard. The values given in parentheses are for information

Adhesion

only.

1.3 The following precautionary caveat pertains only to the

3. Materials and Manufacture

test method portion, Section 5, of this specification: This

3.1 The adhesive shall be free of foreign materials, be

standard does not purport to address all of the safety concerns,

noncorrosive to the metal parts, and have the structural

if any, associated with its use. It is the responsibility of the user

integrity equal to or better than that of an unspliced panel

of this standard to establish appropriate safety and health

section as specified in Table 1, Flexural Sheer.

practices and determine the applicability of regulatory limita-

tions prior to use.

4. Requirements

4.1 Material—The adhesive shall be thermosetting and

2. Referenced Documents

when tested in accordance with Section 5, shall meet the

2.1 ASTM Standards:

requirements of Table 1. The adhesive shall not have a

C 393 Test Method for Flexural Test of Flat Sandwich

2 deleterious effect on the panel nor on its component parts over

Constructions

the range of temperature at which the adhesive will be used.

D 792 Test Methods for Density and Specific Gravity (Rela-

3 This adhesive shall be compatible and capable of co-curing

tive Density) of Plastics by Displacement

with the structural film adhesive (Specification E 865) used to

E 864 Practice for Surface Preparation of Aluminum Alloys

fabricate the panel.

to be Adhesively Bonded in Honeycomb Shelter Panels

4.2 Form—The adhesive shall be of film form either 1.27

mm (0.051 in.) or 2.54 mm (0.100 in.) thick and shall be

This specification is under the jurisdiction of ASTM Committee E-6 on capable of expanding to at least 1.75 times its original

Performance of Buildings and is the direct responsibility of Subcommittee E06.53

thickness.

on Materials and Processes for Durable Rigid Wall Relocatable Structures.

4.3 Working Characteristics:

Current edition approved April 10, 1998. Published August 1998. Originally

published as E 990 – 84. Last previous edition E 990 – 93a.

Annual Book of ASTM Standards, Vol 15.03.

3 5

Annual Book of ASTM Standards, Vol 08.01. Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

Annual Book of ASTM Standards, Vol 04.11. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E 990

TABLE 1 Physical Properties Qualification Requirements

Reference

Table Requirements

Paragraph

Water migration 5.1 Not more than the volume of

the cavity (in cell)

Volatility 5.2 1 % maximum

Expansion 5.3 1.75 minimum ratio

Sag for 1.27 mm (0.05 in.) 5.4 3.8 mm (0.15 in.) maximum

uncured thickness

Sag for 2.54 mm (0.1 in.) 5.4 12.7 mm (0.500 in.) maximum

uncured thickness

3 3

Density (cured) 5.5 0.8 g per cm (50 lb/ft )

maximum

Flexural shear (assembly 5.6 Same as honeycomb core,

compatibility) minimum 1.24 MPa (180 psi)

L-direction

Tube shear (core splice 5.7 Minimum average 4.13 MPa

integrity) (600 psi)

Minimum individual 3.1 MPa

(450 psi)

4.3.1 Application—The adhesive shall be suitable for appli-

cation to core material, edge members, and integral parts in

accordance with the manufacturer’s instructions at tempera-

tures from 18 to 30°C (65 to 85°F) and at relative humidities of

up to 50 %.

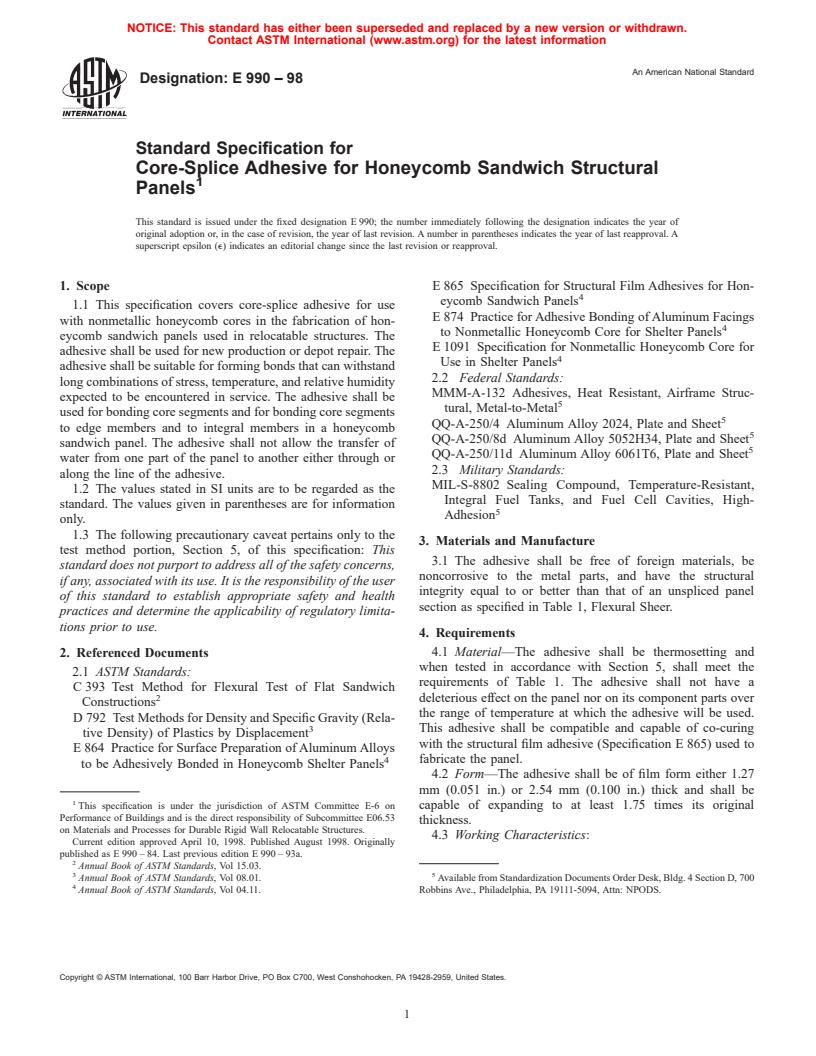

FIG. 1 Core Splice Adhesive Mold

4.3.2 Curing—The time, temperature, and pressure used to

cure the adhesive shall be as specified herein.

4.3.2.1 Curing Time and Temperature—The adhesive shall

NOTE 2—Depending on the expansion ratio and the unexpanded thick-

meet the requirements of this specification when cured in

ness of the material being tested, it may be necessary to install more than

accordance with manufacturer’s recommendation so long as one layer of adhesive. The size of the adhesive shall be calculated as

3 3

follows: Length 3 width 3 thickness 5 1.65 cm (0.65 in. ).

the time and bondline temperature do not exceed1hor 145°C

(293°F).

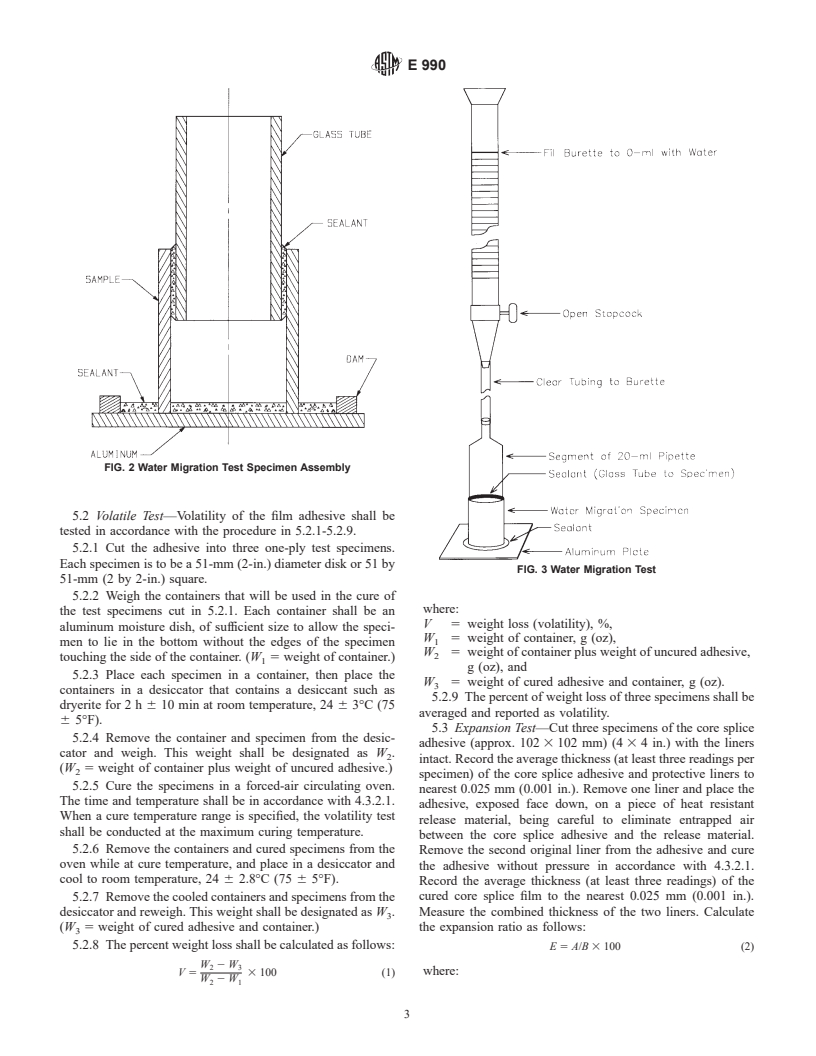

5.1.2 Prepare the sample (approximately 38 mm (1 ⁄2 in.)

4.3.2.2 Curing Pressure—The pressure required for curing

long) by cutting the cylinder of cured adhesive and visually

the adhesive shall be contact.

check to ensure that there are no cracks, pin holes, etc.

4.4 Storage Life—The adhesive shall have a minimum

5.1.3 Cover a piece of aluminum (approx. 50 3 50 3 6

storage life of 3 months from the date of receipt at the

mm) (2 3 2 3 ⁄4 in.) with MIL-S 8802, Class B-2 Sealant, or

fabricator facility when stored at −17.8°C (0°F) or below.

1 1

equivalent, to a depth of 3 to 6 mm ( ⁄8 to ⁄4 in.). Use a “dam,”

Under conditions in accordance with 4.3.1, the adhesive shall

such as vacuum-bagging putty or an aluminum foil tray, around

have a cumulative out-life of at least 5 days at 24 6 3°C (75

the edge of the aluminum to prevent the sealant from running

6 5°F).

off (see Fig. 2).

4.5 Properties—The properties of the test specimens pre-

5.1.4 Place the prepared sample of adhesive (5.1.2) on the

pared and tested as described herein shall conform to the

sealant and seat it gently into the sealer. Allow the sealant to

requirements of Table 1.

cure at room temperature overnight.

5.1.5 Install a glass tube approximately 38 mm (1 ⁄2 in.)

5. Test Methods

long approximately 19 mm ( ⁄4 in.) down into the hole in the

5.1 Water Migration Test:

top of the specimen, and seal between the glass tube and the

5.1.1 The core Splice Adhesive Mold is illustrated in Fig. 1

test specimen with MIL-S-8802, Class B-2 sealant, or equiva-

(Note 1). Apply a mold release agent to both the interior of the

lent. Allow the sealant to cure at room temperature overnight.

female portion and the exterior of the male portion of the mold.

5.1.6 Fill the cell in the sample through the glass tube with

Install a layer of adhesive (Note 2) on the entire length of the

distilled water using a hypodermic needle. Inject the water at

19.05 mm diameter part of the male portion of the mold so that

the bottom to ensure that the cell is full and that no air is

the layer of adhesive overlaps along a vertical seam. Close the

entrapped. Measure the volume required to fill the cell.

mold by lowering the female portion over the male portion

5.1.7 Connect a buret filled with distilled water to the glass

until it seats against the base of the male portion. A press may

tube using a clear polyethylene tubing (see Fig. 3). Adjust the

be used to help close the mold. Remove the mold from the

buret to a height of 914.4 mm (36 in.) above the top of the test

press and place in an oven. Cure in the oven at 121 6 5.6°C

specimen and ensure that there is no entrapped air.

(250 6 10°F) for 1 h minimum. Remove cured adhesive from

5.1.8 The water migration through the adhesive tube speci-

the mold.

men shall not exceed the number of millilitres required to fill

the cavity (approximately 12 mL (0.4 oz)) when subjected to a

NOTE 1—The mold may be made of aluminum, acrylic plastic, or other

suitable material. The outer shell may be fabricated as a split mold. 915 mm (36-in.) head for 24 h.

E 990

FIG. 2 Water Migration Test Specimen Assembly

5.2 Volatile Test—Volatility of the film adhesive shall be

tested in accordance with the procedure in 5.2.1-5.2.9.

5.2.1 Cut the adhesive into three one-ply test specimens.

Each specimen is to be a 51-mm (2-in.) diameter disk or 51 by

FIG. 3 Water Migration Test

51-mm (2 by 2-in.) square.

5.2.2 Weigh the containers that will be used in the cure of

where:

the test specimens cut in 5.2.1. Each container shall be an

V 5 weight loss (volatility), %,

aluminum moisture dish, of sufficient size to allow the speci-

W 5 weight of container, g (oz),

men to lie in the bottom without the edges of the specimen

W 5 weight of container plus weight of uncured adhesive,

touching the side of the container. (W 5 weight of container.)

g (oz), and

5.2.3 Place each specimen in a container, then place the

W 5 weight of cured adhesive and container, g (oz).

containers in a desiccator that contains a desiccant such as

5.2.9 The percent of weight loss of three specimens shall be

dryerite for 2 h 6 10 min at room temperature, 24 6 3°C (75

averaged and reported as volatility.

6 5°F).

5.3 Expansion Test—Cut three specimens of the core splice

5.2.4 Remove the container and specimen from the desic-

adhesive (approx. 102 3 102 mm) (4 3 4 in.) with the liners

cator and weigh. This weight shall be designated as W .

intact. Record the average thickness (at least three readings per

(W 5 weight of container plus weight of uncured adhesive.)

specimen) of the core splice adhesive and protective liners to

5.2.5 Cure the specimens in a forced-air circulating oven.

nearest 0.025 mm (0.001 in.). Remove one liner and place the

The time and temperature shall be in accordance with 4.3.2.1.

adhesive, exposed face down, on a piece of heat resistant

When a cure temperature range is specified, the volatility test

release material, being careful to eliminate entrapped air

shall be conducted at the maximum curing temperature.

between the core splice adhesive and the release material.

5.2.6 Remove the containers and cured specimens from the

Remove the second original liner from the adhesive and cure

oven while at cure temperature, and place in a desiccator and

the adhesive without pressure in accordance with 4.3.2.1.

cool to room temperature, 24 6 2.8°C (75 6 5°F).

Record the average thickness (at least three readings) of the

5.2.7 Remove the cooled containers and specimens from the cured core splice film to the nearest 0.025 mm (0.001 in.).

desiccator and reweigh. This weight shall be designated as W . Measure the combined thickness of the two liners. Calculate

(W 5 weight of cured adhesive and container.) the expansion ratio as follows:

5.2.8 The percent weight loss shall be calculated as follows:

E 5 A/B 3 100 (2)

W 2 W

2 3

where:

V 5 3 100 (1)

W 2 W

2 1

E 990

5.6.3 Sandwich specimens shall be tested at 24 6 2.8°C (75

E 5 expansion ratio,

6 5°F) in accordance with Test Method C 393 with modifica-

A 5 thickness of the cured film (no liner), mm (in.), and

tions as stated herein, using a 305-mm (12-in.) span (see Fig.

B 5 thickness of uncured film (with liners) minus the

combined thickness of liners, mm (in.). 3). The two upper loading points and the two support points

shall employ 51 by 76 by 6.4-mm (2 by 3 by ⁄4-in.) loading

5.4 Sag Test—Cut three specimens of the core splice adhe-

sive (approx. 102 by 102 mm) (4 by 4 in.). Remove both pieces blocks. The upper loading points shall be located at the

one-third span positions. The splice must be positioned at the

of liner material and place one edge of each specimen against

a 153-mm (6-in.) long scribed line on a clean aluminum plate maximum shear load location, which is approximately 51 mm

(2 in.) from the centerline of either bottom support point as

using hand pressure to ensure contact and to remove entrapped

air bubbles. Place the specimen vertically in an air circulating shown in Fig. 4. The load shall be applied through a constant

rate of movement of the head of the testing machine, and at

oven so that the scribe line is at the bottom of the specimen.

Cure in accordance with 4.3.2.1. After curing, measure the such a rate that the maximum load will occur between 3 and 5

min.

distance the material has sagged or slumped below the scribed

line and record. 5.7 Tube Shear Test:

5.7.1 Tube shear specimens shall be fabricated from drawn

5.5 Density—The density of the cured film adhesive shall be

tested in accordance with Test Methods D 792, Method A aluminum concentric tubes made from 5052-O, QQ-A-250/4

or alloy of comparable compressive strength. The outer tube

(Displacement of Water).

5.6 Shear Strength Test (Core Splice): shall have a 25-mm (1-in.) outside diameter and the inner tube

a 13-mm ( ⁄2-in.) outside diameter. Both tubes shall be 225-mm

5.6.1 The following materials shall be used to fabricate

sandwich specimens of 76-mm (3-in.) width by 381-mm (9-in.) long and have a wall thickness of 1.2-mm (0.049-in.).

5.7.2 Following cutting to length and deburring, aluminum

(15-in.) length by 53-mm (2.10-in.) thickness size:

5.6.1.1 1.3-mm (0.050-in.) thick 5052-H34 or 6061-T6 tubes shall be cleaned and etched in accordance with Practice

E 864.

aluminum skins (Federal Standard QQ-A-250/8d or QQ-A-

250/11d, respectively). 5.7.3 The quantity of adhesive required to fill the tube shear

3 3

5.6.1.2 51-mm (2-in.) thick Type IV honeycomb core meet- assembly annular volume of approximately 65 cm (4 in. ) must

ing Specification E 1091. be determined experimentally for each adhesive. This quantity

5.6.1.3 Structural film adhesive meeting Specification normally falls in the range of 35 to 45 g

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.