ASTM E963-95

(Practice)Standard Practice for Electrolytic Extraction of Phases from Ni and Ni-Fe Base Superalloys Using a Hydrochloric-Methanol Electrolyte

Standard Practice for Electrolytic Extraction of Phases from Ni and Ni-Fe Base Superalloys Using a Hydrochloric-Methanol Electrolyte

SCOPE

1.1 This practice covers a procedure for the isolation of carbides, borides, TCP (topologically close-packed), and GCP (geometrically close-packed) phases (Note 1) in nickel and nickel-iron base gamma prime strengthened alloys. Contamination of the extracted residue by coarse matrix (gamma) or gamma prime particles, or both, reflects the condition of the alloy rather than the techniques mentioned in this procedure.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. (See 3.3.2.1 and 4.1.1.)

Note 1--Ni3 Ti (eta phase) has been found to be soluble in the electrolyte for some alloys.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 963 – 95

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Practice for

Electrolytic Extraction of Phases from Ni and Ni-Fe Base

Superalloys Using a Hydrochloric-Methanol Electrolyte

This standard is issued under the fixed designation E 963; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope quantitatively analyzed by X-ray diffraction or microanalysis.

3.2 Careful control of parameters is necessary for reproduc-

1.1 This practice covers a procedure for the isolation of

ible quantitative results. Within a given laboratory, such results

carbides, borides, TCP (topologically close-packed), and GCP

can be obtained routinely; however, caution must be exercised

(geometrically close-packed) phases (Note 1) in nickel and

when comparing quantitative results from different laborato-

nickel-iron base gamma prime strengthened alloys. Contami-

ries.

nation of the extracted residue by coarse matrix (gamma) or

3.3 Comparable qualitative results can be obtained routinely

gamma prime particles, or both, reflects the condition of the

among different laboratories using this procedure.

alloy rather than the techniques mentioned in this procedure.

1.2 This standard does not purport to address all of the

4. Apparatus

safety concerns, if any, associated with its use. It is the

4.1 Cell or Container for Electrolyte—A glass vessel of

responsibility of the user of this standard to establish appro-

about 400-mL capacity is recommended. For the sample size

priate safety and health practices and determine the applica-

and current density recommended later in this procedure,

bility of regulatory limitations prior to use. (See 3.3.2.1 and

electrolysis can proceed up to about 4 h, and up to about4gof

4.1.1.)

alloy can be dissolved in 250 mL of electrolyte without

NOTE 1—Ni Ti (eta phase) has been found to be soluble in the

exceeding a metallic ion concentration of 16 g/L. Above this

electrolyte for some alloys.

concentration, cathode plating has been observed to be more

likely to occur. A mechanism for cooling the electrolyte is

2. Terminology

recommended. For example, an ice water bath or water-

2.1 Definitions:

jacketed cell may be used to keep the electrolyte between 0°

2.1.1 extraction cell—laboratory apparatus consisting of a

and 30°C.

beaker to contain the electrolyte, a dc power supply, a noble

4.2 Cathode—Material must be inert during electrolysis.

metal sheet or screen cathode and a noble metal wire basket or

Tantalum and platinum sheet or mesh are known to meet this

wire to affix to the sample (anode).

requirement. Use of a single wire is to be avoided, since

2.1.2 geometrically close-packed (GCP) phases—

cathode surface area should be larger than that of sample.

precipitated phases found in nickel-base alloys that have the

Distance between sample and cathode should be as great as

form A B, where B is a smaller atom than A. In superalloys,

possible, within the size of cell chosen. For example, a sample

these are the common FCC Ni (Al, Ti) or occasionally found

with a surface area of 15 cm should have no side closer than

HCP Ni Ti.

1.2 cm to the cathode. If the cell is cylindrical, as for the case

2.1.3 topologically close-packed (TCP) phases—

of a beaker or the upper part of a separatory funnel, the cathode

precipitated phases in nickel-base alloys, characterized as

could be curved to fit the inner cell wall to facilitate correct

composed of close-packed layers of atoms forming in basket

sample-cathode distance. The sample would then be centered

weave nets aligned with the octahedral planes of the FCC g

within the cell at the same height as the cathode. The cathode

matrix. These generally detrimental phases appear as thin

need not make a complete ring around the sample nor be more

plates, often nucleating on grain-boundary carbides. TCP

than 5 cm high.

phases commonly found in nickel alloys are s, μ , and Laves.

4.3 Anode—The sample must be suspended in the electro-

lyte by a material that is inert during electrolysis. Anode

3. Significance and Use

3.1 This practice can be used to extract carbides, borides,

TCP and GCP phases, which can then be qualitatively or

Donachie, M. J. Jr., and Kriege, O. H., “Phase Extraction and Analysis in

Superalloys—Summary of Investigations by ASTM Committee E-4 Task Group I,”

This practice is under the jurisdiction of ASTM Committee E-4 on Metallog-

raphy and is the direct responsibility of Subcommittee E04.11 on X-Ray and Journal of Materials, Vol 7, 1972, pp. 269–278.

Electron Metallography. Donachie, M. J. Jr., “Phase Extraction and Analysis in Superalloys—Second

Current edition approved Jan. 15, 1995. Published March 1995. Originally Summary of Investigations by ASTM Subcommittee E04.91,” Journal of Testing

published as E 963 – 83. Last previous edition E963 – 83 (1989). and Evaluation, Vol 6, No. 3, 1978, pp. 189–195.

E 963

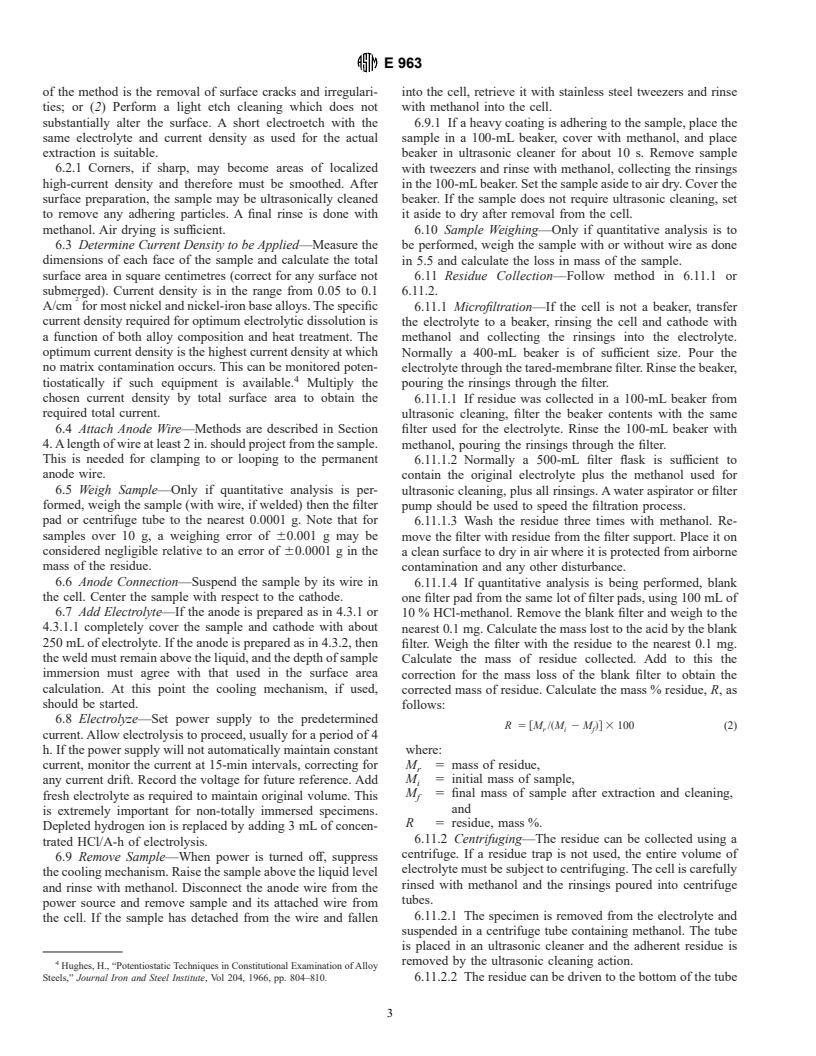

FIG. 1 Schematic Diagram of Extraction Cell

connection material should be cleaned to prevent any contami- which is commonly used for phase analysis of the residue.

nating material from falling into the cell. Good electrical Otherwise, filter diameter is not critical. Filters should be

contact should be maintained between the sample wire and the handled with blunt tweezers.

permanent anode wire from the dc power supply. Two methods 4.6 Centrifuge—Centrifuging for residue collection can be

are found to be successful. Either method is subject to performed as an alternate to microfiltration.

disconnection of the sample due to shrinkage, which puts a 4.7 Balance—If quantitative analysis is desired, a balance

limit on the electrolysis time: sensitive to 0.0001 g is required.

4.3.1 Suspend the sample by platinum or platinum-rhodium

5. Reagents

thermocouple wire (20 gauge) wrapped around it to form a

5.1 Electrolyte—Add and mix 1 part of 12 N hydrochloric

basket. To avoid a shielding problem, the ratio of sample area

acid (sp gr 1.19) to 9 parts of absolute methyl alcohol by

covered by the wire to the exposed sample area should be

volume to make a 10 % HCl-methanol solution. For alloys

small.

containing W, Nb, Ta, or Hf, add one part by weight tartaric or

4.3.1.1 Mechanically attach or spot weld the platinum or

citric acid to 100 parts by volume HCl-methanol to make an

platinum-rhodium thermocouple wire to the sample.

approximately 1 % tartaric or citric acid solution. All reagents

4.3.2 If the weld is not immersed, non-inert wire may be

should be of at least ACS reagent grade quality.

substituted; for example, chromel, nichrome, 300 series stain-

5.1.1 Caution—Add hydrochloric acid to absolute methyl

less steel, etc. Stop-off lacquer should be used below the

alcohol slowly and with constant stirring; otherwise sufficient

meniscus to maintain constant electrolyte level. This also

heat is generated to cause a hazardous condition. Mixing must

eliminates formation of insoluble deposits immediately above

be done in an exhaust hood, because the fumes are toxic.

the meniscus and prevents arcing.

5.2 Sample and Residue Rinse—Absolute methyl alcohol is

4.3.2.1 Caution—Care must be taken to prevent arcing

to be used.

between anode and cathode which could ignite the methanol.

4.4 Power Supply—A variable dc power supply capable of

6. Procedure

providing 0 to 5 V is needed to obtain currents from 0 to 1.2 A

6.1 Sample Size and Geometry—A cube, cylinder, or rect-

depending on total surface area of the sample. For example, a

angular prism is preferred. Ideally, constant density should be

sample with total surface area of 15 cm , electrolyzed at a

maintained during electrolysis. Flattened samples, especially

current density of 0.1 A/cm , requires:

thin sheet, will experience considerable shrinkage due to edge

2 2

15 cm 3 0.1 A/cm 5 1.2 A (1)

effects and current density increase as the electrolysis pro-

4.4.1 Current and voltage fluctuation should be no more ceeds. A cube approximately 1.6 cm on a side will have a total

than 65%. A 65 % current fluctuation represents a current surface area of approximately 15 cm . Smaller samples have

density fluctuation of about 65 % which, for samples under 15 larger increases in current density during constant current

cm total surface area, is less than or equal to one-half the electrolysis due to shrinkage. Larger samples may require more

current density shift due to sample shrinkage over 4 h. than 250 mL of electrolyte and a power supply capable of

Potentiostatic control is not necessary, but may be helpful for delivering more than 1.2 A. Samples requiring higher total

determining optimum current density when setting up proce- current may cause a cathode plating problem due to the higher

dures for a new alloy. voltage required, and may make a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.