ASTM E1496-05(2010)

(Test Method)Standard Test Method for Neutron Radiographic Dimensional Measurements (Withdrawn 2012)

Standard Test Method for Neutron Radiographic Dimensional Measurements (Withdrawn 2012)

SIGNIFICANCE AND USE

Many requirements exist for accurate dimensional information in industrial quality control. Frequently, this information cannot be measured directly, may be very uncertain, or is expensive to obtain. If a radiograph of the object in question displays a sufficient film density variation near the edge of interest, however, dimensional radiography methods may be applied. This test method provides a technique for extracting quantitative dimensional information from the neutron radiograph of an object. Guide E94 and Practices E748 are helpful for understanding the principles involved in obtaining a high-quality neutron radiograph.

Dimensional radiography appears to be particularly relevant in determination of the following: (1) diameters of spent radioactive fuel, (2) gap sizes in contact-circuit mechanisms of shielded components, and (3) prescribed spacings between distinct materials.

While this test method addresses dimensional measurements using neutron radiography, the methods and techniques of dimensional radiography are also equally applicable to various types of radiography, such as x-ray, γ-ray, and neutron.

A fundamental assumption of this test method is that the user will have access to a system that permits the attainment of data describing the density response of the radiograph. Although a system may include any digitization equipment capable of providing the spatial resolutions recommended in 6.1.1, a typical system will include a high-resolution traveling-stage microdensitometer and a neutron radiograph of the object.

An object with accurately known dimensions must be available to calibrate the equipment used to measure the radiographic response, that is, the traveling-stage microdensitometer (or other digitization system capable of spatial resolution comparable to that of the detector).

SCOPE

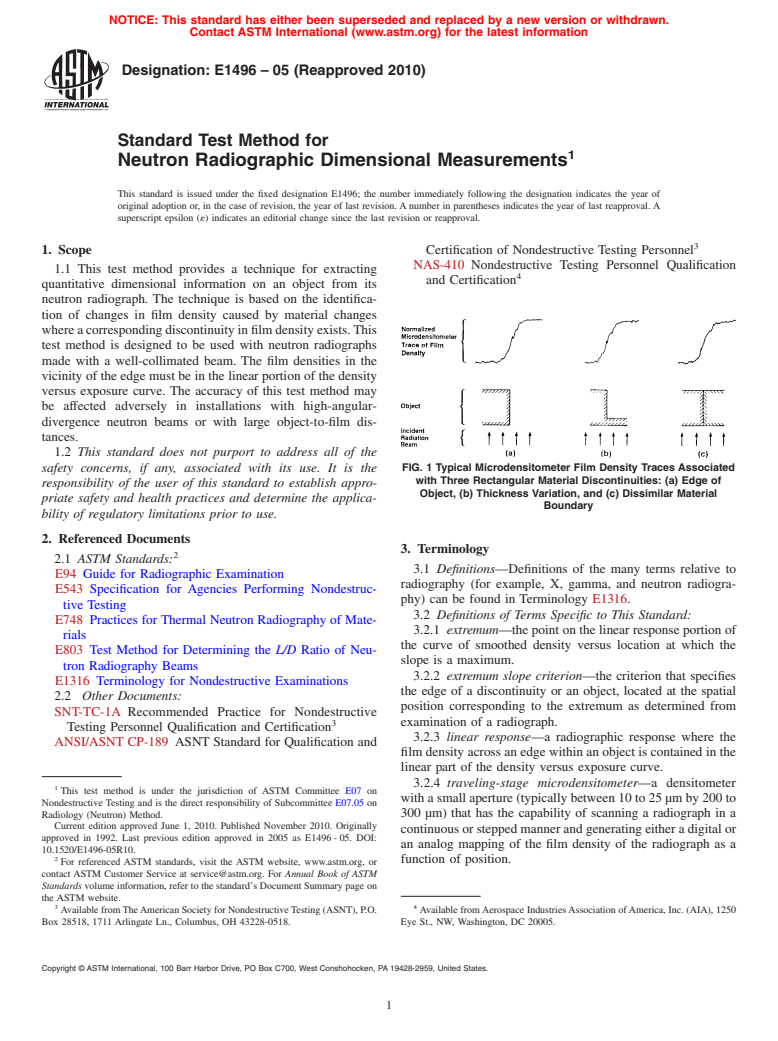

1.1 This test method provides a technique for extracting quantitative dimensional information on an object from its neutron radiograph. The technique is based on the identification of changes in film density caused by material changes where a corresponding discontinuity in film density exists. This test method is designed to be used with neutron radiographs made with a well-collimated beam. The film densities in the vicinity of the edge must be in the linear portion of the density versus exposure curve. The accuracy of this test method may be affected adversely in installations with high-angular-divergence neutron beams or with large object-to-film distances.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method provides a technique for extracting quantitative dimensional information on an object from its neutron radiograph. The technique is based on the identification of changes in film density caused by material changes where a corresponding discontinuity in film density exists. This test method is designed to be used with neutron radiographs made with a well-collimated beam. The film densities in the vicinity of the edge must be in the linear portion of the density versus exposure curve. The accuracy of this test method may be affected adversely in installations with high-angular-divergence neutron beams or with large object-to-film distances.

Formerly under the jurisdiction of Committee E07 on Nondestructive Testing, this test method was withdrawn in June 2012. This standard is being withdrawn without replacement due to its limited use by industry.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E1496 – 05 (Reapproved 2010)

Standard Test Method for

1

Neutron Radiographic Dimensional Measurements

This standard is issued under the fixed designation E1496; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

3

1. Scope Certification of Nondestructive Testing Personnel

NAS-410 Nondestructive Testing Personnel Qualification

1.1 This test method provides a technique for extracting

4

and Certification

quantitative dimensional information on an object from its

neutron radiograph. The technique is based on the identifica-

tion of changes in film density caused by material changes

whereacorrespondingdiscontinuityinfilmdensityexists.This

test method is designed to be used with neutron radiographs

made with a well-collimated beam. The film densities in the

vicinity of the edge must be in the linear portion of the density

versus exposure curve. The accuracy of this test method may

be affected adversely in installations with high-angular-

divergence neutron beams or with large object-to-film dis-

tances.

1.2 This standard does not purport to address all of the

FIG. 1 Typical Microdensitometer Film Density Traces Associated

safety concerns, if any, associated with its use. It is the

with Three Rectangular Material Discontinuities: (a) Edge of

responsibility of the user of this standard to establish appro-

Object, (b) Thickness Variation, and (c) Dissimilar Material

priate safety and health practices and determine the applica-

Boundary

bility of regulatory limitations prior to use.

2. Referenced Documents

3. Terminology

2

2.1 ASTM Standards:

3.1 Definitions—Definitions of the many terms relative to

E94 Guide for Radiographic Examination

radiography (for example, X, gamma, and neutron radiogra-

E543 Specification for Agencies Performing Nondestruc-

phy) can be found in Terminology E1316.

tive Testing

3.2 Definitions of Terms Specific to This Standard:

E748 Practices for Thermal Neutron Radiography of Mate-

3.2.1 extremum—the point on the linear response portion of

rials

the curve of smoothed density versus location at which the

E803 Test Method for Determining the L/D Ratio of Neu-

slope is a maximum.

tron Radiography Beams

3.2.2 extremum slope criterion—the criterion that specifies

E1316 Terminology for Nondestructive Examinations

the edge of a discontinuity or an object, located at the spatial

2.2 Other Documents:

position corresponding to the extremum as determined from

SNT-TC-1A Recommended Practice for Nondestructive

examination of a radiograph.

3

Testing Personnel Qualification and Certification

3.2.3 linear response—a radiographic response where the

ANSI/ASNT CP-189 ASNT Standard for Qualification and

filmdensityacrossanedgewithinanobjectiscontainedinthe

linear part of the density versus exposure curve.

3.2.4 traveling-stage microdensitometer—a densitometer

1

This test method is under the jurisdiction of ASTM Committee E07 on

withasmallaperture(typicallybetween10to25µmby200to

Nondestructive Testing and is the direct responsibility of Subcommittee E07.05 on

Radiology (Neutron) Method. 300 µm) that has the capability of scanning a radiograph in a

Current edition approved June 1, 2010. Published November 2010. Originally

continuousorsteppedmannerandgeneratingeitheradigitalor

approved in 1992. Last previous edition approved in 2005 as E1496-05. DOI:

an analog mapping of the film density of the radiograph as a

10.1520/E1496-05R10.

2

function of position.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3 4

AvailablefromTheAmericanSocietyforNondestructiveTesting(ASNT),P.O. Available fromAerospace IndustriesAssociation ofAmerica, Inc. (AIA), 1250

Box 28518, 1711 Arlingate Ln., Columbus, OH 43228-0518. Eye St., NW, Washington, DC 20005.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

E1496 – 05 (2010)

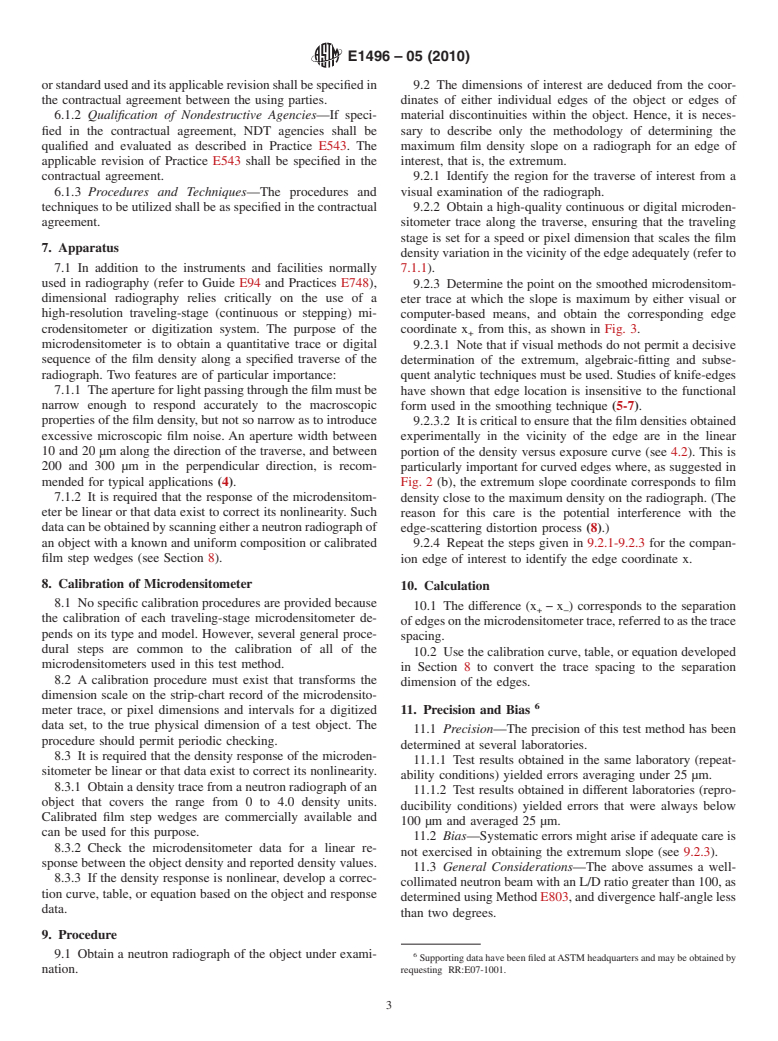

FIG. 2 Typical Microdensitometer Traces of Film Density for (a)

Rectangular Objects and (b) Cylindrical Objects; Note

Placements of Edges x and x on the Traces

+ −

4. Summary of Test Method

4.1 All radiation used in radiography is attenuated in its

FIG. 3 Depiction of Various Slopes on a Smoothed

passage through an object according to its thickness and

Microdensitometer Trace; The Object Edge Coordinate, x ,

+

magnitude of the material attenuation properties appropriate to

Corresponds to the Extremum Slope

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.