ASTM D4419-90(2000)

(Test Method)Standard Test Method for Measurement of Transition Temperatures of Petroleum Waxes by Differential Scanning Calorimetry (DSC)

Standard Test Method for Measurement of Transition Temperatures of Petroleum Waxes by Differential Scanning Calorimetry (DSC)

SCOPE

1.1 This test method measures the transition temperatures of petroleum waxes, including microcrystalline waxes, by differential scanning calorimetry (DSC). These transitions may occur as a solid-solid transition or as a solid-liquid transition.

1.2 The normal operating temperature range extends from 15oC to 150oC (Note 1).

1.3 The values stated in SI units are to be regarded as the standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D4419–90(Reapproved 2000)

Standard Test Method for

Measurement of Transition Temperatures of Petroleum

1

Waxes by Differential Scanning Calorimetry (DSC)

This standard is issued under the fixed designation D 4419; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope ture, while the substance and a reference material are subjected

to a controlled temperature program. The record is the DSC

1.1 Thistestmethodmeasuresthetransitiontemperaturesof

curve. Two modes, power-compensation DSC and heat-flux

petroleum waxes, including microcrystalline waxes, by differ-

DSC, can be distinguished depending on the method of

ential scanning calorimetry (DSC). These transitions may

measurement used. For additional background information

occur as a solid-solid transition or as a solid-liquid transition.

refer to Practice E 472, Terminology E 473, and Test Method

1.2 The normal operating temperature range extends from

E 474.

15°C to 150°C (Note 1).

1.3 The values stated in SI units are to be regarded as the

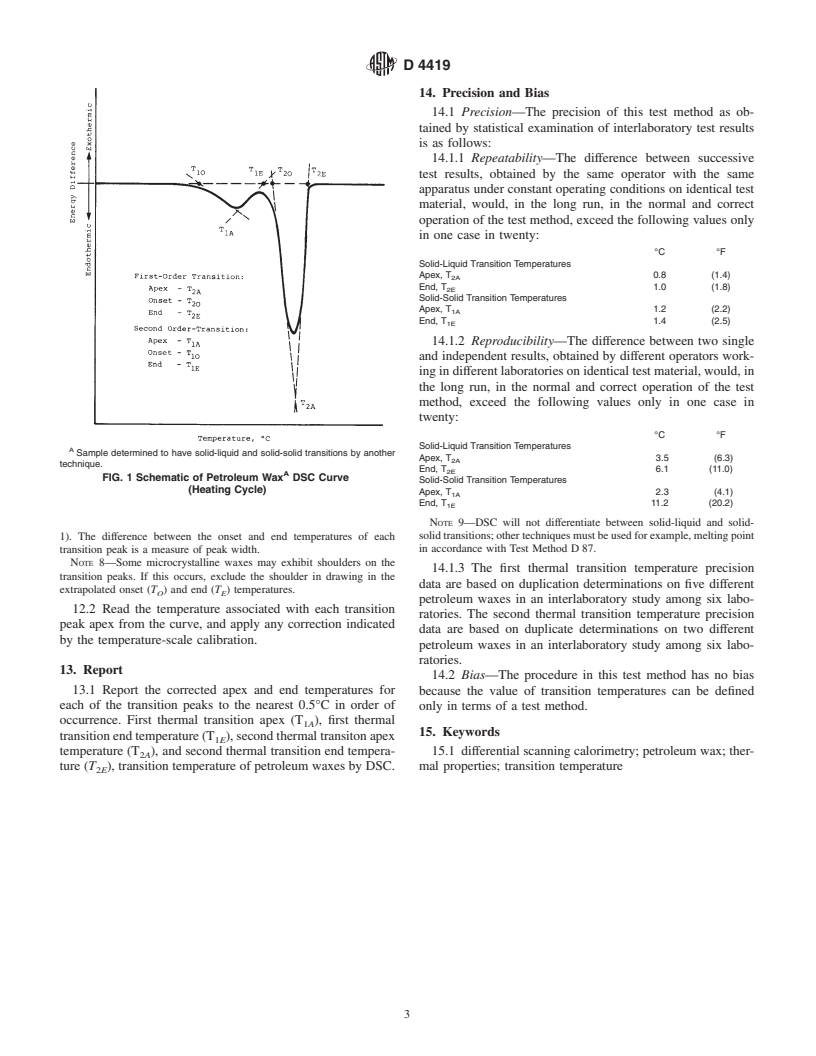

4. Summary of Test Method

standard.

4.1 Separate samples of petroleum wax and a reference

1.4 This standard does not purport to address all of the

material or blank (empty sample container) are heated at a

safety concerns, if any, associated with its use. It is the

controlled rate in an inert atmosphere. A sensor continuously

responsibility of the user of this standard to establish appro-

monitors the difference in heat flow to the two samples. The

priate safety and health practices and determine the applica-

DSC curve is a record of this difference versus temperature.A

bility of regulatory limitations prior to use.

transition in the wax involves the absorption of energy relative

2. Referenced Documents to the reference, resulting in an endothermic peak in the DSC

curve. While the transition occurs over the temperature range

2.1 ASTM Standards:

spanned by the base of the peak, the temperature associated

D 87 Test Method for Melting Point of Petroleum Wax

2

with the peak apex is designated the nominal transition

(Cooling Curve)

temperature (Note 1).

D 1160 Test Method for Distillation of Petroleum Products

2

at Reduced Pressures

NOTE 1—Test Method D 87 also monitors energy transfer between wax

D 3418 Test Method for Transition Temperatures of Poly-

and a standard environment. The highest temperature DSC transition may

3

differ from the melting point because the two methods approach the

mers by Differential Scanning Calorimetry

4

solid/liquid phase transition from different directions.

E 472 Practice for Reporting Thermoanalytical Data

4

E 473 Terminology Relating to Thermal Analysis

5. Significance and Use

E 474 Test Method for Evaluation of Temperature Scale for

5 5.1 DSC in a convenient and rapid method for determining

Differential Thermal Analysis

the temperature limits within which a wax undergoes during

3. Terminology transitions. The highest temperature transition is a solid-liquid

transition associated with complete melting; it can guide the

3.1 Definitions of Terms Specific to This Standard:

choice of wax storage and application temperatures. The

3.1.1 Differential Scanning Calorimetry (DSC)—A tech-

solid-solid temperature transition is related to the properties of

nique in which the difference in energy inputs into a substance

the solid, that is, hardness and blocking temperature.

and a reference material is measured as a function of tempera-

NOTE 2—For a relatively narrow cut petroleum wax, the lowest

transitionwillbeasolid-solidtransition.Anarrowcutwaxisoneobtained

1

This test method is under the jurisdiction of ASTM Committee D02 on

by deoiling a single petroleum distillate with a maximum range of 120°F

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

between its 5 % and 95 % vol in accordance with Test Method D 1160

D02.10.0A on Physical and Chemical Properties.

boiling points (converted to 760 torr). The DSC method cannot differen-

Current edition approved May 25, 1990. Published July 1990. Originally

tiate between solid-liquid and solid-solid transitions. Such information

published as D 4419 – 84. Last previous edition D 4419 – 84.

2

must be predetermined by other techniques. In the case of blends, the

Annual Book of ASTM Standards, Vol 05.01.

3

lower temperature transition may be envelopes of both solid-liquid and

Annual Book of ASTM Standards, Vol 08.02.

4

solid-solid transitions.

Annual Book of ASTM Standards, Vol 14.02.

5

Discontinued; see 1985 Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM International, 100 Bar

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.