ASTM C1244M-05ae1

(Test Method)Standard Test Method for Concrete Sewer Manholes by the Negative Air Pressure (Vacuum) Test Prior to Backfill (Metric)

Standard Test Method for Concrete Sewer Manholes by the Negative Air Pressure (Vacuum) Test Prior to Backfill (Metric)

SCOPE

1.1 This test method covers procedures for testing precast concrete manhole sections when using the vacuum test method to demonstrate the integrity of the installed materials and the construction procedures. This test method is used for testing concrete manhole sections utilizing mortar, mastic, or gasketed joints.

1.2 This test method is intended to be used as a preliminary test to enable the installer to demonstrate the condition of the concrete manholes prior to backfill.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.3 This test method is the companion to inch-pound Test Method C 1244. Note 1

Vacuum test criteria presented in this test method are similar to those in general use. The test and criteria have been widely and successfully used in testing manholes.Note 2

It should be understood that no correlation has been found between vacuum (air) and hydrostatic tests.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: C1244M – 05a

Standard Test Method for

Concrete Sewer Manholes by the Negative Air Pressure

1

(Vacuum) Test Prior to Backfill (Metric)

This standard is issued under the fixed designation C1244M; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

´ NOTE—Table1 was reformatted and Section X1.3 was corrected editorially in February 2006.

1. Scope C969 Practice for Infiltration and Exfiltration Acceptance

Testing of Installed Precast Concrete Pipe Sewer Lines

1.1 This test method covers procedures for testing precast

C1244 Test Method for Concrete Sewer Manholes by the

concretemanholesectionswhenusingthevacuumtestmethod

Negative Air Pressure (Vacuum) Test Prior to Backfill

to demonstrate the integrity of the installed materials and the

construction procedures. This test method is used for testing

3. Terminology

concretemanholesectionsutilizingmortar,mastic,orgasketed

3.1 For definitions of terms relating to manholes, see

joints.

Terminology C822.

1.2 This test method is intended to be used as a preliminary

test to enable the installer to demonstrate the condition of the

4. Summary of Practice

concrete manholes prior to backfill.

4.1 All lift holes and any pipes entering the manhole are to

1.3 This standard does not purport to address all of the

beplugged.Avacuumwillbedrawnandthevacuumdropover

safety problems, if any, associated with its use. It is the

aspecifiedtimeperiodisusedtodeterminetheacceptabilityof

responsibility of the user of this standard to establish appro-

the manhole.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

5. Significance and Use

1.4 This test method is the companion to inch-pound Test

5.1 This is not a routine test. The values recorded are

Method C1244.

applicable only to the manhole being tested and at the time of

NOTE 1—Vacuum test criteria presented in this test method are similar

testing.

to those in general use. The test and criteria have been widely and

successfully used in testing manholes.

6. Preparation of the Manhole

NOTE 2—It should be understood that no correlation has been found

6.1 All lift holes shall be plugged.

between vacuum (air) and hydrostatic tests.

6.2 All pipes entering the manhole shall be temporarily

2. Referenced Documents plugged, taking care to securely brace the pipes and plugs to

2 prevent them from being drawn into the manhole.

2.1 ASTM Standards:

C822 Terminology Relating to Concrete Pipe and Related

7. Procedure

Products

7.1 The test head shall be placed at the top of the manhole

C924 Practice for Testing Concrete Pipe Sewer Lines by

in accordance with the manufacturer’s recommendations.

Low-Pressure Air Test Method

7.2 A vacuum of 33.8 kPa of Hg shall be drawn on the

manhole, the valve on the vacuum line of the test head closed,

1

This test method is under the jurisdiction of ASTM Committee C13 on and the vacuum pump shut off.The time shall be measured for

ConcretePipeandisthedirectresponsibilityofSubcommitteeC13.06onManholes

the vacuum to drop to 30.4 kPa of Hg.

and Specials.

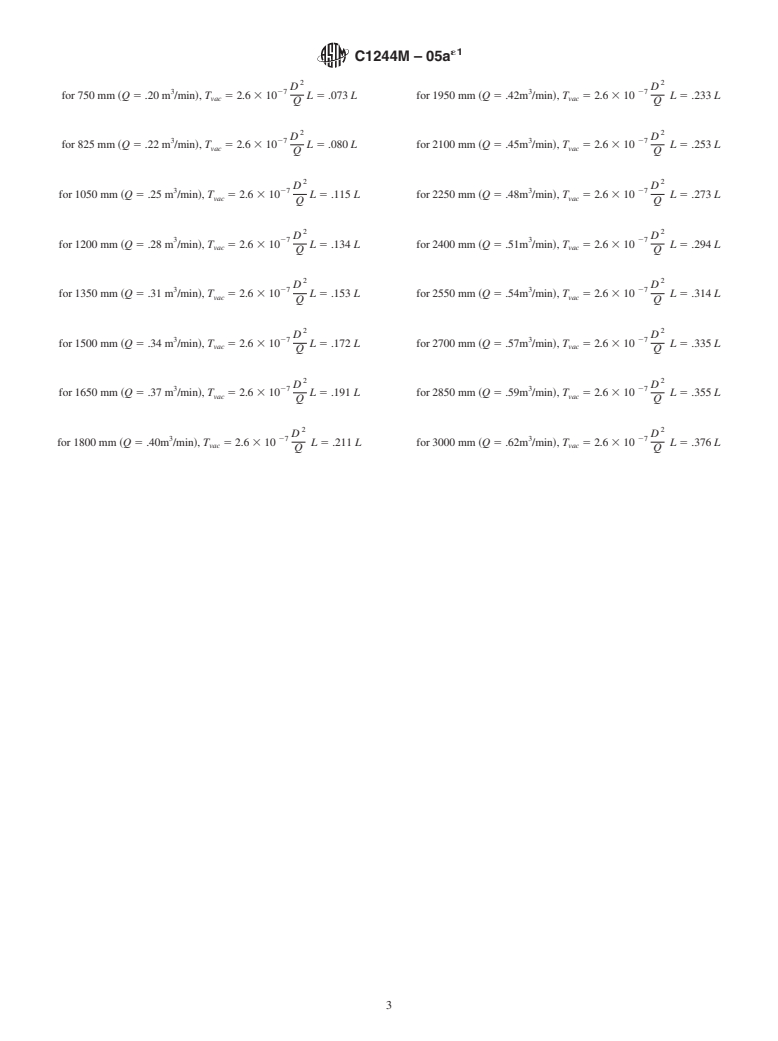

7.3 The manhole shall pass if the time for the vacuum

Current edition approved Oct. 1, 2005. Published January 2006. Originally

reading to drop from 33.8 kPa of Hg to 30.4 kPa of Hg meets

approved in 1993. Last previous edition approved in 2005 as C1244M–05. DOI:

10.1520/C1244M-05AE01.

or exceeds the values indicated in Table 1.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

7.4 If the manhole fails the initial test, necessary repairs

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

shall be made by an approved method.The manhole shall then

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. be retested until a satisfactory test is obtained.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

´1

C1244M – 05a

TABLE 1 Minimum Test Times for Various Manhole Diameters TABLE 1 Minimum Test Times for Various Manhole Diameters

(750–3000 mm) in Seconds (750–3000 mm) in Seconds (continued)

Diameter, mm Diameter, mm

Depth, m Depth, m

750 825 900 1050 1200 1350 1500 1650 1800 1950 2100 2250 2400 2550 2700 2850 3000

Time, in seconds Time, in seconds

<1.2 6 7 7 9 1012 1315 16 <1.2 18 19 21 23 2425 2729

1.8 9 10 11 13 15 18 20 22 25 1.8 26 29 31 34 3638 4143

2.4 11 12 14 17 20 23 26 29 33 2.4 35 38 41 45 4851 5457

3.0 14 15 18 21 25 29 33 36 41 3.0 44 48 52 56 6063 6771

3.7 17 18 21 25 30 35 39 43 49 3.7

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.