ASTM E1043-85(1996)

(Specification)Standard Specification for Pipets, Milk and Cream Examination

Standard Specification for Pipets, Milk and Cream Examination

SCOPE

1.1 This specification covers miscellaneous pipets suitable for use in milk and cream testing procedures.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 1043 – 85 (Reapproved 1996)

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

Pipets, Milk and Cream Examination

This standard is issued under the fixed designation E 1043; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope Products for pipet and slide method. The pipet shall be

calibrated to deliver, when blown out, 0.01 6 0.001 cm of

1.1 This specification covers miscellaneous pipets suitable

milk having a specific gravity of 1.032 at 20°C. Tips shall be

for use in milk and cream testing procedures.

blunt, ground, or polished to discharge milk cleanly.

2. Referenced Documents

NOTE 1—Type I pipets (5.1), before being used in New York, must be

2.1 ASTM Standards:

submitted to the Director of the State Ford Laboratory, Albany, NY, for

examination.

E 542 Practice for Calibration of Volumetric Ware

E 671 Specification for Maximum Permissible Thermal Re-

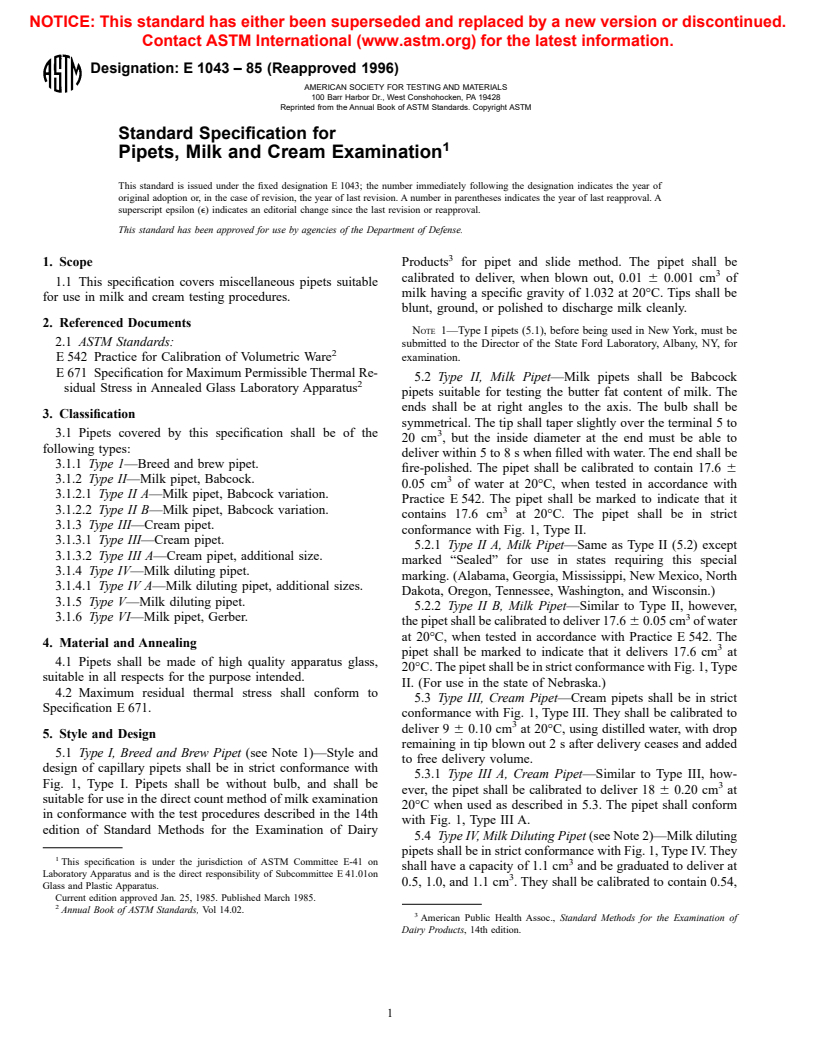

5.2 Type II, Milk Pipet—Milk pipets shall be Babcock

sidual Stress in Annealed Glass Laboratory Apparatus

pipets suitable for testing the butter fat content of milk. The

ends shall be at right angles to the axis. The bulb shall be

3. Classification

symmetrical. The tip shall taper slightly over the terminal 5 to

3.1 Pipets covered by this specification shall be of the 3

20 cm , but the inside diameter at the end must be able to

following types:

deliver within 5 to 8 s when filled with water. The end shall be

3.1.1 Type 1—Breed and brew pipet.

fire-polished. The pipet shall be calibrated to contain 17.6 6

3.1.2 Type II—Milk pipet, Babcock.

0.05 cm of water at 20°C, when tested in accordance with

3.1.2.1 Type II A—Milk pipet, Babcock variation.

Practice E 542. The pipet shall be marked to indicate that it

3.1.2.2 Type II B—Milk pipet, Babcock variation.

contains 17.6 cm at 20°C. The pipet shall be in strict

3.1.3 Type III—Cream pipet.

conformance with Fig. 1, Type II.

3.1.3.1 Type III—Cream pipet.

5.2.1 Type II A, Milk Pipet—Same as Type II (5.2) except

3.1.3.2 Type III A—Cream pipet, additional size.

marked “Sealed” for use in states requiring this special

3.1.4 Type IV—Milk diluting pipet.

marking. (Alabama, Georgia, Mississippi, New Mexico, North

3.1.4.1 Type IV A—Milk diluting pipet, additional sizes.

Dakota, Oregon, Tennessee, Washington, and Wisconsin.)

3.1.5 Type V—Milk diluting pipet.

5.2.2 Type II B, Milk Pipet—Similar to Type II, however,

3.1.6 Type VI—Milk pipet, Gerber.

the pipet shall be calibrated to deliver 17.6 6 0.05 cm of water

at 20°C, when tested in accordance with Practice E 542. The

4. Material and Annealing

pipet shall be marked to indicate that it delivers 17.6 cm at

4.1 Pipets shall be made of high quality apparatus glass,

20°C. The pipet shall be in strict conformance with Fig. 1, Type

suitable in all respects for the purpose intended.

II. (For use in the state of Nebraska.)

4.2 Maximum residual thermal stress shall conform to

5.3 Type III, Cream Pipet—Cream pipets shall be in strict

Specification E 671.

conformance with Fig. 1, Type III. They shall be calibrated to

deliver 9 6 0.10 cm at 20°C, using distilled water, with drop

5. Style and Design

remaining in tip blown out 2 s after delivery ceases and added

5.1 Type I, Breed and Brew Pipet (see Note 1)—Style and

to free delivery volume.

design of capillary pipets shall be in strict conformance with

5.3.1 Type III A, Cream Pipet—Similar to Type III, how-

Fig. 1, Type I. Pipets shall be without bulb, and shall be

ever, the pipet shall be calibrated to deliver 18 6 0.20 cm at

suitable for use in the direct count method of milk examination

20°C when used as described in 5.3. The pipet shall conform

in conformance with the test procedures described in the 14th

with Fig. 1, Type III A.

edition of Standard Methods for the Examination of Dairy

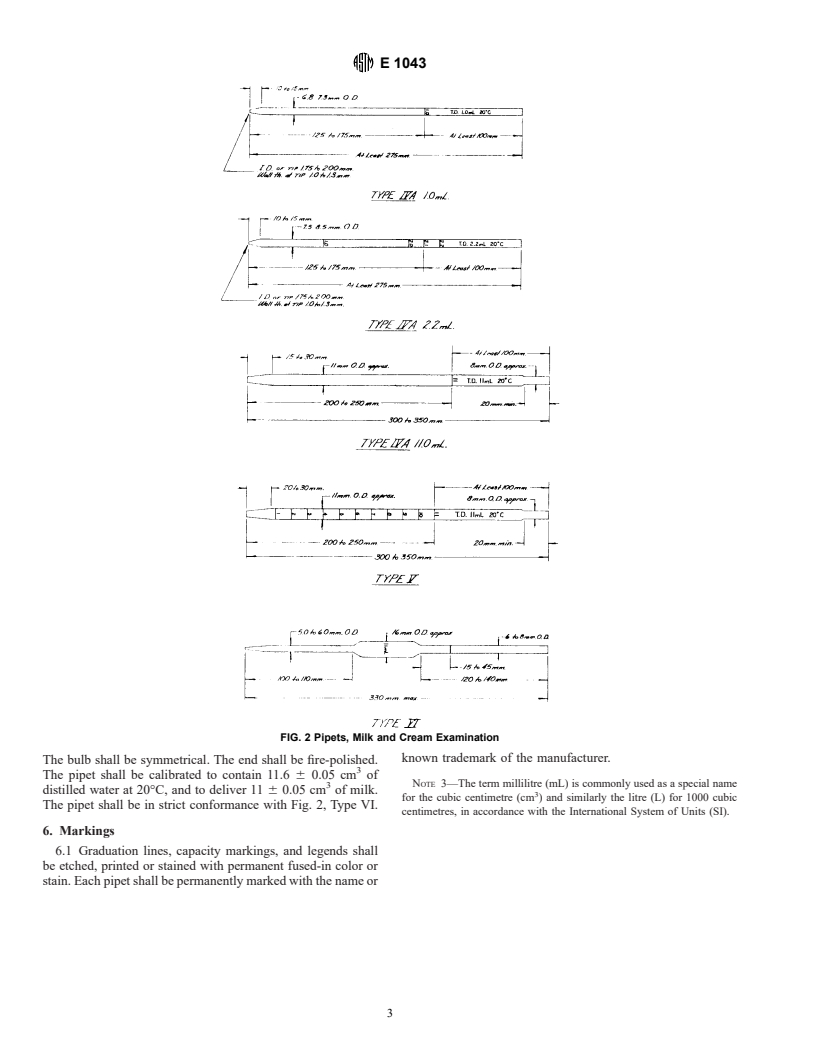

5.4 Type IV, Milk Diluting Pipet (see Note 2)—Milk diluting

pipets shall be in strict conformance with Fig. 1, Type IV. They

This specification is under the jurisdiction of ASTM Committee E-41 on 3

shall have a capacity of 1.1 cm and

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.