ASTM F1276-99(2003)

(Test Method)Standard Test Method for Creep Relaxation of Laminated Composite Gasket Materials

Standard Test Method for Creep Relaxation of Laminated Composite Gasket Materials

SIGNIFICANCE AND USE

This test method is designed to compare related materials under controlled conditions and their ability to maintain a given compressive stress as a function of time. A portion of the torque loss on the bolted flange is a result of creep relaxation. Torque loss can also be caused by elongation of the bolts, distortion of the flanges, and vibration; therefore, the results obtained should be correlated with field results. This test method may be used as a routine test when agreed upon between the user and the producer.

SCOPE

1.1 This test method provides a means of measuring the amount of creep relaxation of a laminated composite gasket material at a predetermined time after a compressive stress has been applied.

1.2 Creep relaxation is measured by means of a calibrated bolt with dial indicator.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:F1276–99 (Reapproved 2003)

Standard Test Method for

Creep Relaxation of Laminated Composite Gasket Materials

This standard is issued under the fixed designation F1276; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 ASTM Adjuncts:

Relaxometer, Method B (Adjunct to Test Method F38)

1.1 This test method provides a means of measuring the

amount of creep relaxation of a laminated composite gasket

3. Summary of Test Method

material at a predetermined time after a compressive stress has

3.1 In this test method, the specimen is subjected to a

been applied.

compressive stress between two platens, with the stress applied

1.2 Creep relaxation is measured by means of a calibrated

by a nut and bolt. Run at room or elevated temperatures, the

bolt with dial indicator.

stress is determined by measuring the change in length of the

1.3 The values stated in SI units are to be regarded as the

calibrated bolt with a dial indicator. The bolt length is

standard. The values given in parentheses are for information

measured at the beginning of the test and at the end of the test.

only.

The percent relaxation is calculated from this.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

4. Significance and Use

responsibility of the user of this standard to establish appro-

4.1 This test method is designed to compare related mate-

priate safety and health practices and determine the applica-

rials under controlled conditions and their ability to maintain a

bility of regulatory limitations prior to use.

given compressive stress as a function of time.Aportion of the

2. Referenced Documents torque loss on the bolted flange is a result of creep relaxation.

2 Torque loss can also be caused by elongation of the bolts,

2.1 ASTM Standards:

distortion of the flanges, and vibration; therefore, the results

A193/A193M Specification for Alloy-Steel and Stainless

obtained should be correlated with field results. This test

Steel Bolting Materials for High Temperature or High

method may be used as a routine test when agreed upon

Pressure Service and Other Special Purpose Applications

between the user and the producer.

B637 Specification for Precipitation-Hardening Nickel Al-

loy Bars, Forgings, and Forging Stock for High-

5. Apparatus

Temperature Service

5.1 Relaxometer, composed of two platens, special drilled

E691 Practice for Conducting an Interlaboratory Study to

and calibrated bolt, washer and nut composed of Specification

Determine the Precision of a Test Method

A193/A193M Grade B7 or Grade UNS N07718, or other

F38 Test Methods for Creep Relaxation of a Gasket Mate-

alloys of construction that would satisfy the calibration Proce-

rial

dure (see Annex) for the test temperature specified and a dial

F104 Classification System for Nonmetallic Gasket Mate-

indicator assembly as shown in Fig. 1.

rials

5.2 Box End Wrench.

F868 Classification for Laminated Composite Gasket Ma-

5.3 Steel Blanking Die.

terials

6. Test Specimens

This test method is under the jurisdiction ofASTM Committee F03 on Gaskets

6.1 Specimen size shall be 10.16 6 0.381 mm (0.400 6

and is the direct responsibility of Subcommittee F03.20 on Mechanical Test

0.015in.)wideby31.75 60.381mm(1.250 60.015in.)long.

Methods.

6.2 Four specimens are required per test.

Current edition approved Oct. 1, 2003. Published October 2003. Originally

approved in 1990. Last previous edition approved in 1999 as F1276 – 99. DOI:

6.3 A minimum of three tests shall be conducted.

10.1520/F1276-99R03.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Dario P. Bernasconi, 40 Farrington St., Stoughton, MA 02072, and Donald G.

Standards volume information, refer to the standard’s Document Summary page on Johnson, Metal Samples, P.O. Box 8, Munford, AL 36268, are suppliers of the

the ASTM website. relaxometer.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F1276–99 (2003)

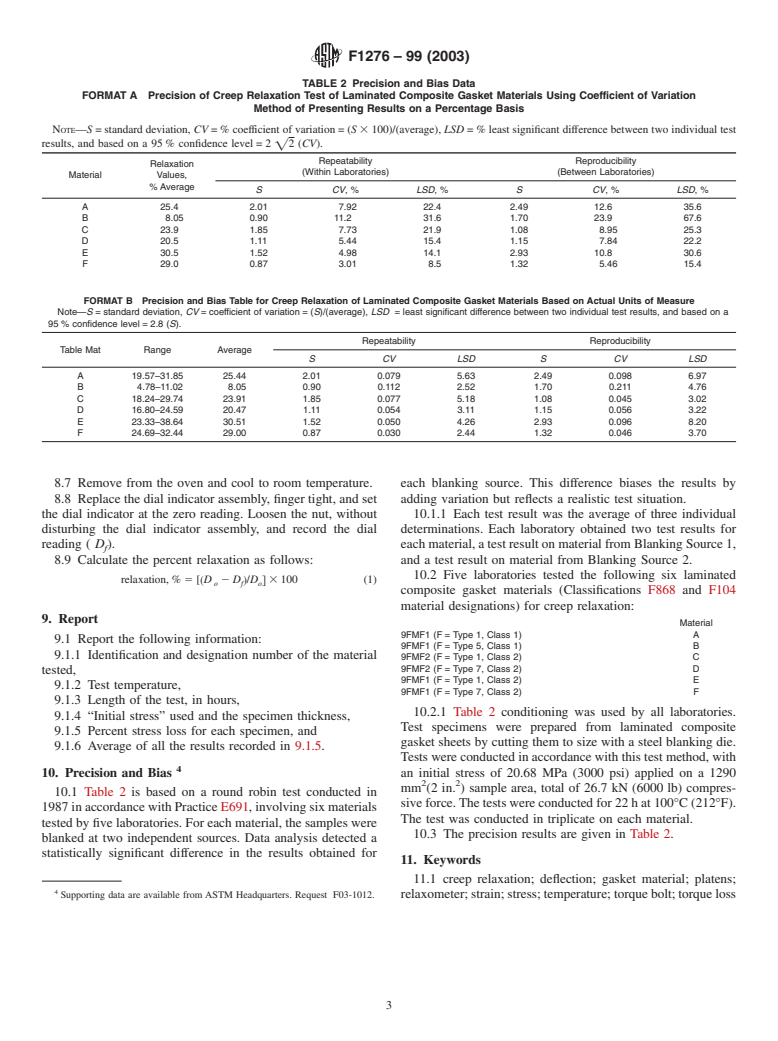

TABLE 1 Test Method for Creep Relaxation of Laminated

Composite Materials Conditioning for Laminated Composite

Gasket Materials

Classification

F104

Type of Gasket Identification

Conditioning

Material in the First Two

Procedure

Nonmetallic Layers Numerals

of Six-Digit

Number

Compressed asbestos sheet; F11, F12, 1hat100 6 2°C (212 6 3.6°F)

asbestos beater sheet; F51, F52 Cool in desiccator over

flexible graphite anhydrous calcium chloride

21 to 30°C (70 to 85°F)

Asbestos paper and millboard F13 4 h at 100 6 2°C (212 6 3.6°F)

Cool as in Procedure A of

Classification F104

Cork composition F21, F23 At least 46 h at 21 to 30°C

Cork and cellular rubber (70 to 85°F) and 50 to 55 %

relative humidity

Cork and rubber F22 At least 46 h at 21 to 30°C

(70 to 85°F) and 50 to 55 %

relative humidity

Treated and untreated papers F31, F32, 4 h at 21 to 30°C (70 to 85°F)

from cellulose or other F33, F34 over anhydrous calcium

organic fibers chloride followed immediately

by at least 20 h at 21 to 30°C

(70 to 85°F) and 50 to 55 %

relative humidity

Compressed nonasbestos F71, F72 1 h at 100 6 2°C (212 6 3.6°F)

sheet; nonasbestos beater Cool in desiccator over

sheet anhydrous calcium chloride

21 to 30°C (70 to 85°F)

Nonasbestos paper and F73 4 h at 100 6 2°C (212 6 3.6°F)

millboard Cool as in Procedure A of

Classification F104

8. Procedure

8.1 Clean all surfaces and lightly lubricate the washer and

bolt threads; graphite and molybdenum disulfide have been

found to be acceptable lubricants.

8.2 Place the specimens between the platens in accordance

with Fig. 1 making sure they are no closer than 2 mm (0.078

in) to the other pieces and the edge of the platens.

8.3 Place the washer in position and screw on the nut, finger

tight.

8.4 Screw on the dial indicator assembly, finger tight, and

FIG. 1 Relaxometer and Dial Indicator Assembly

set the dial indicator at the zero reading.

8.5 Apply stress to the specimens by tightening the nut with

a wrench until the desired dial indicator reading is reached;

6.4 Nominal thickness of specimens shall be that of the

record the reading (D ). Apply the stress in one continuous

o

laminated composite gasket.

motion with a maximum loading time of 3 s.Abolt elongation

of 0.1222 to 0.1270 mm (0.00481 to 0.00500 in.) is typical for

7. Conditioning

a compressive force of 26.7 kN (6000 lbf). Remove the dial

7.1 When all nonmetallic layers of the laminated composite

indicator assembly. (The calibration procedure is outlined in

are the same type, condition in accordance with that type as

Annex A1.)

shown in Table 1.

7.2 When the nonmetallic layers of the laminated composite NOTE 1—When testing materials thicker than 0.8 mm (0.03 in.), the

time to tighten the nut may be extended to 5 s maximum to allow for the

are of different types, the specimen shall be conditioned for 22

longer arc required to apply the test load.

h in a controlled-humidity room or in a closed chamber of air

at 21 to 30°C (70 to 85°F) and 50 to 55 % relative humidity. In 8.6 Place the specimen unit in a hot air-circulating oven for

all cases where testing is conducted outside the area of 22hat100 6 2°C (212 6 3.6°F), unless otherwise specified.

specified humidity, specimens shall be removed from the The maximum test temperature for SpecificationA193/A193M

chamber one at a time as needed. Grade B7 shall not exceed 204°C (400°F). The maximum test

7.3 Other conditioning may be as agreed upon between the temperature for Grade UNS N07718 shall not exceed 482°C

producer and the user. (900°F).

F1276–99 (2003)

TABLE 2 Precision and Bias Data

FORMAT A Precision of Creep Relaxation Test of Laminated Composite Gasket Materials Using Coefficient of Variation

Method of Presenting Results on a Percentage Basis

NOTE—S = standard deviation, CV = % coefficient of variation = (S 3 100)/(average), LSD = % least significant difference between two individual test

results, and b

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.