ASTM F811-02

(Practice)Standard Practice for Accelerometer Use in Vehicles for Tire Testing

Standard Practice for Accelerometer Use in Vehicles for Tire Testing

SIGNIFICANCE AND USE

The measured accelerometer output can be used to calculate traction properties of combined tire-vehicle systems for passenger cars, light trucks, and heavy trucks through use of applicable methods of testing.

This practice is intended to achieve uniformity in test vehicle accelerometer use and in accelerometer signal processing. Through such usage, a basis for meaningful comparisons of test results from different sources will be obtained.

This practice is not applicable to accelerometers used in destructive testing, such as vehicle crash tests or vehicle vibration measurements.

SCOPE

1.1 This practice covers guidelines for using accelerometers in test vehicles to evaluate dynamic accelerations resulting from various maneuvers such as braking, accelerating, or cornering.

1.2 This practice is applicable to accelerometers that are rigidly attached to the body of the test vehicle or stabilized to the earth-fixed axis system by means of a gyroscope.

1.3 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautions are given in Section 6.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:F811–02

Standard Practice for

1

Accelerometer Use in Vehicles for Tire Testing

ThisstandardisissuedunderthefixeddesignationF811;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.4 gyro-stabilized accelerometer, n—a precision vertical

gyroscope fitted with one to three accelerometers to provide

1.1 Thispracticecoversguidelinesforusingaccelerometers

orthogonal measurements referenced to the earth-fixed axis

in test vehicles to evaluate dynamic accelerations resulting

system. F538

from various maneuvers such as braking, accelerating, or

3.1.5 servo accelerometer, n—an accelerometer containing

cornering.

servo mechanisms, electronics, and a seismic element to sense

1.2 This practice is applicable to accelerometers that are

inertial reaction. F538

rigidly attached to the body of the test vehicle or stabilized to

3.1.6 strain gage accelerometer, n—an accelerometer using

the earth-fixed axis system by means of a gyroscope.

strain gages to sense the motion of the seismic element.

1.3 The values stated in SI units are to be regarded as the

F538

standard. The values given in parentheses are for information

3.2 Definitions of Terms Specific to This Standard:

only.

3.2.1 performance accelerometer, n—a packaged accelera-

1.4 This standard does not purport to address all of the

tionmeasuringsystemwithintegraldataprocessingcapability.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4. Significance and Use

priate safety and health practices and determine the applica-

4.1 The measured accelerometer output can be used to

bility of regulatory limitations prior to use. Specific precau-

calculate traction properties of combined tire-vehicle systems

tions are given in Section 6.

for passenger cars, light trucks, and heavy trucks through use

2. Referenced Documents of applicable methods of testing.

2

4.2 This practice is intended to achieve uniformity in test

2.1 ASTM Standards:

vehicleaccelerometeruseandinaccelerometersignalprocess-

F538 Terminology Relating to the Characteristics and Per-

ing. Through such usage, a basis for meaningful comparisons

formance of Tires

of test results from different sources will be obtained.

3. Terminology 4.3 This practice is not applicable to accelerometers used in

destructive testing, such as vehicle crash tests or vehicle

3.1 Definitions:

vibration measurements.

3.1.1 accelerometer, n—an instrument that senses inertial

reaction to measure linear or angular acceleration. F538

5. Apparatus

3.1.2 bandwidth, [1/T], n—the range of frequencies within

5.1 Body-Mounted Accelerometer—An accelerometer shall

whichcertainperformancecharacteristicsoccur;specificlimits

be used to measure vehicle accelerations in any of the three

normally apply. F538

primary vehicle axes (use x, y, z as illustrated in Fig. 1) and

3.1.3 g, n—a unit of acceleration where 1 g is equal to the

2 2

shall have the following specifications:

acceleration of gravity, 9.8 m/s (32.2 ft/s ). F538

5.1.1 Range—The full-scale range of the accelerometer

shallbeatleast 61.0gandnotmorethan 65.0gforunitsused

inthexandyaxes,andatleast 62.0gandnotmorethan 65.0

1

ThispracticeisunderthejurisdictionofASTMCommitteeF09onTiresandis

g for units used in the z axis.

the direct responsibility of Subcommittee F09.10 on Equipment, Facilities, and

5.1.2 Accuracy—Amplitude accuracy shall be equal or

Calibration.

better than 61% of full scale including all error sources.

Current edition approved October 10, 2002. Published October 2002. Originally

published as F811–83. Last previous edition F811–01. DOI: 10.1520/F0811-02.

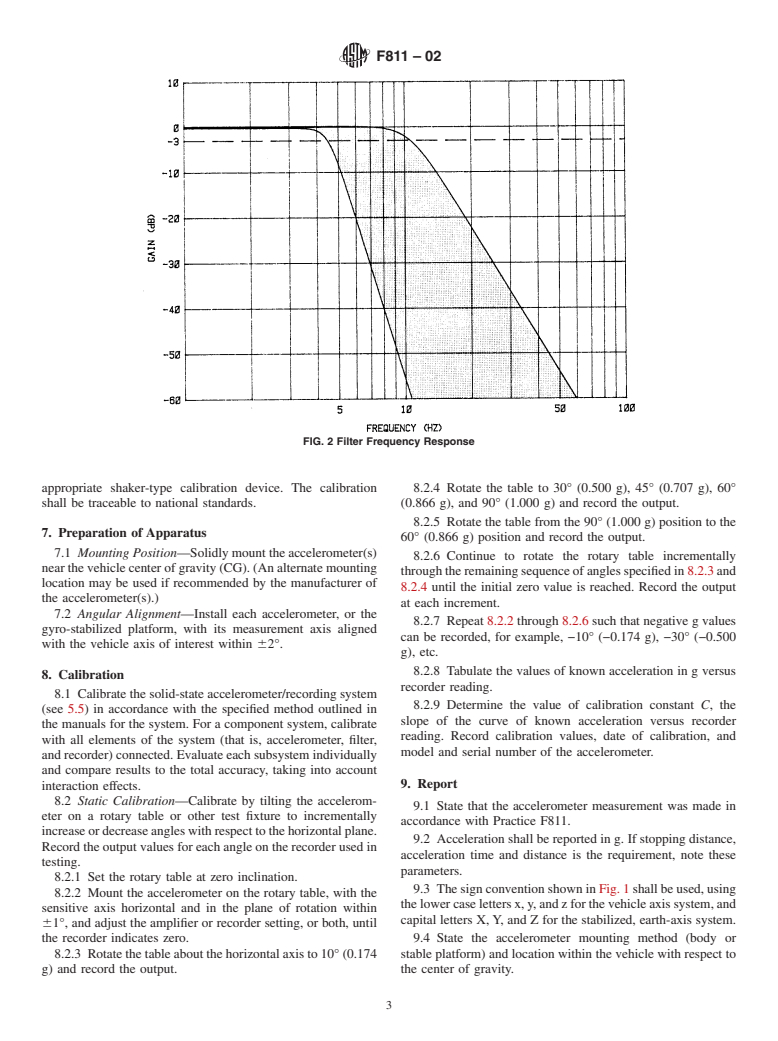

5.1.3 Bandwidth—The frequency response of the complete

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

system shall be from DC to a minimum of 20 Hz. The output

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

shall not vary more than 62% of the static output over this

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. frequency range.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F811–02

FIG. 1 Sign Convention

5.1.4 Temperature—The operating temperature range shall vehicle calibration procedures suitable for test stability. The

be, as a minimum, between −23 and 66°C (−10 and 150°F) software for these units considers the roll rates for several

withatemperaturesensitivityoflessthan0.054%/°C(0.03%/

different vehicle suspension combinations and will adjust t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.